Molding die and molding method

A molding method and mold technology, applied in the direction of coating, can solve problems such as difficulty in ensuring product rigidity, and achieve the effect of improving appearance and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

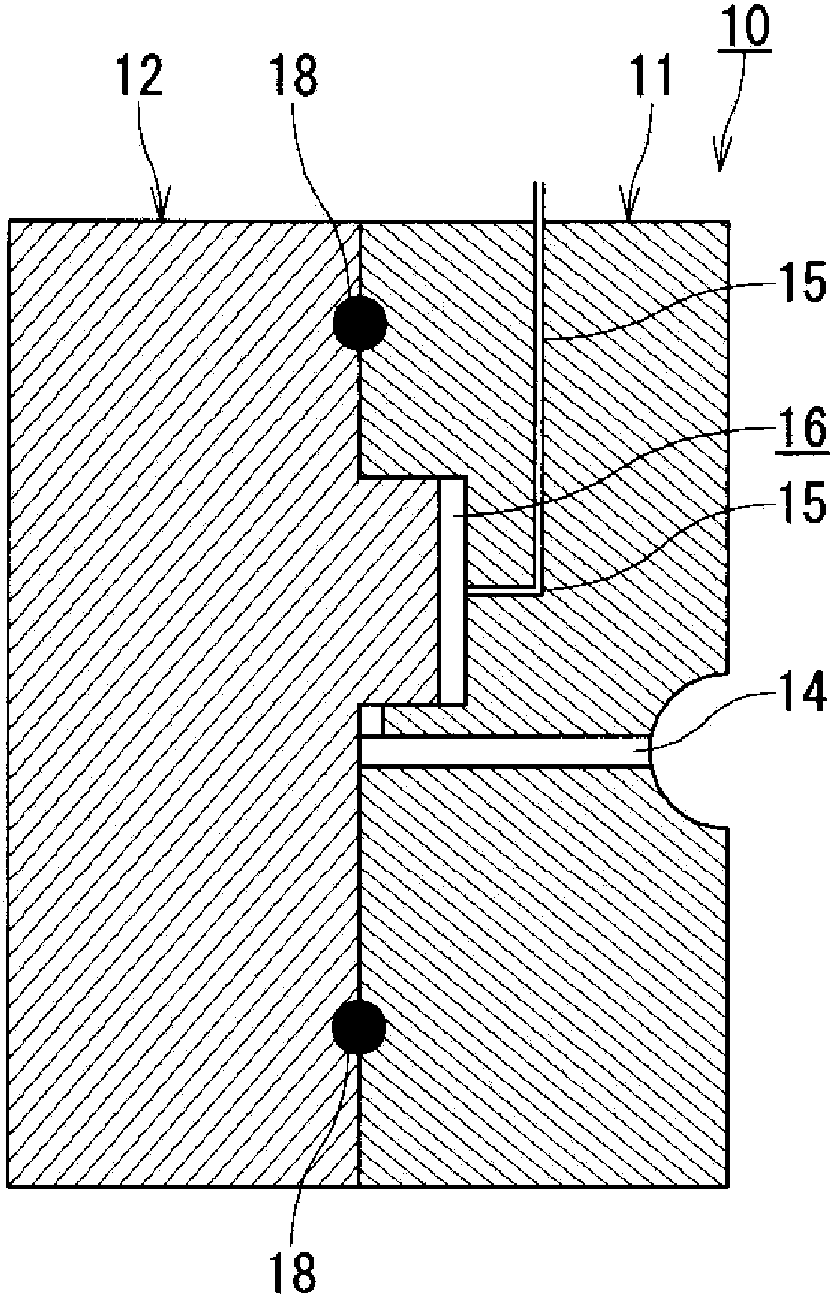

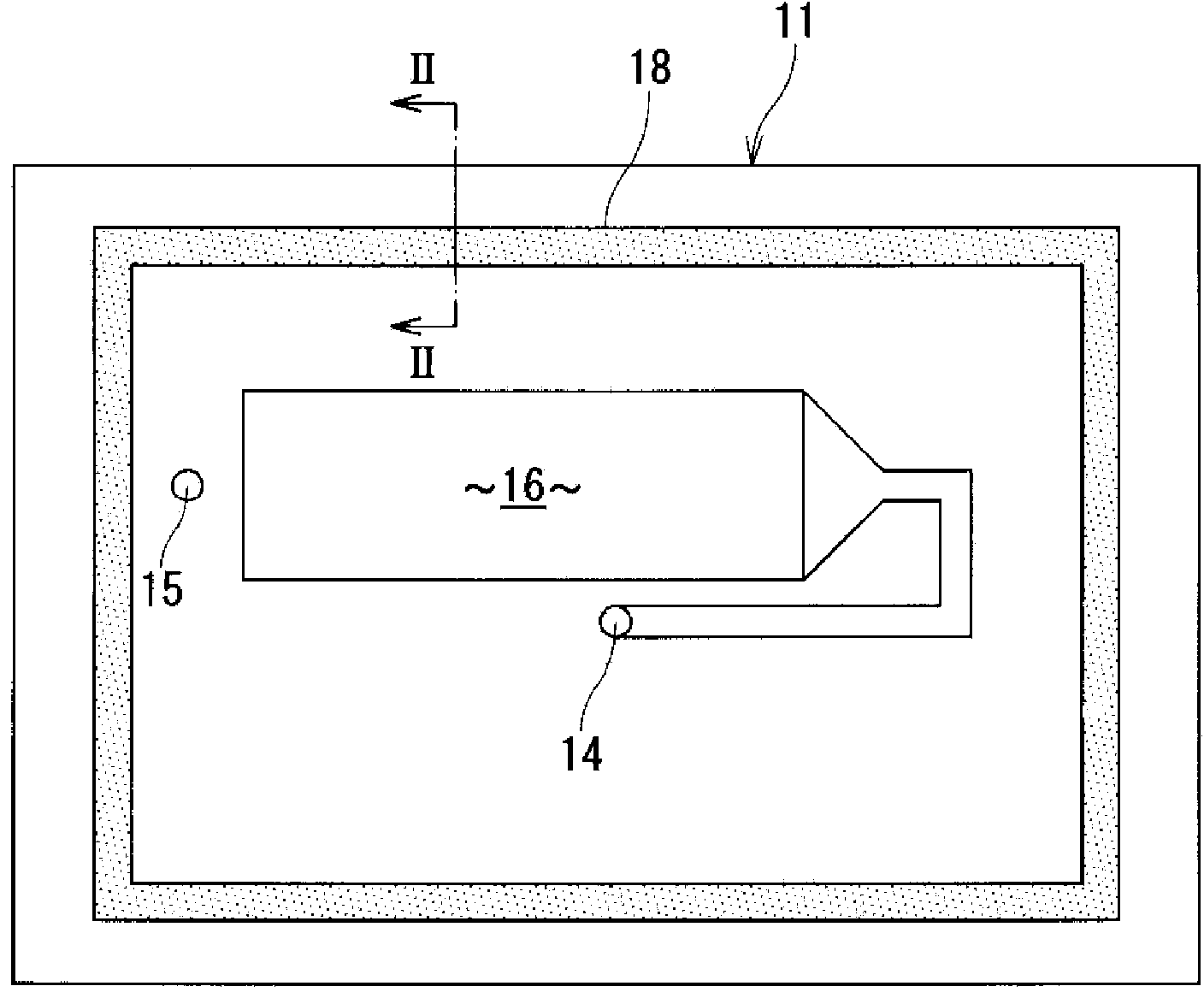

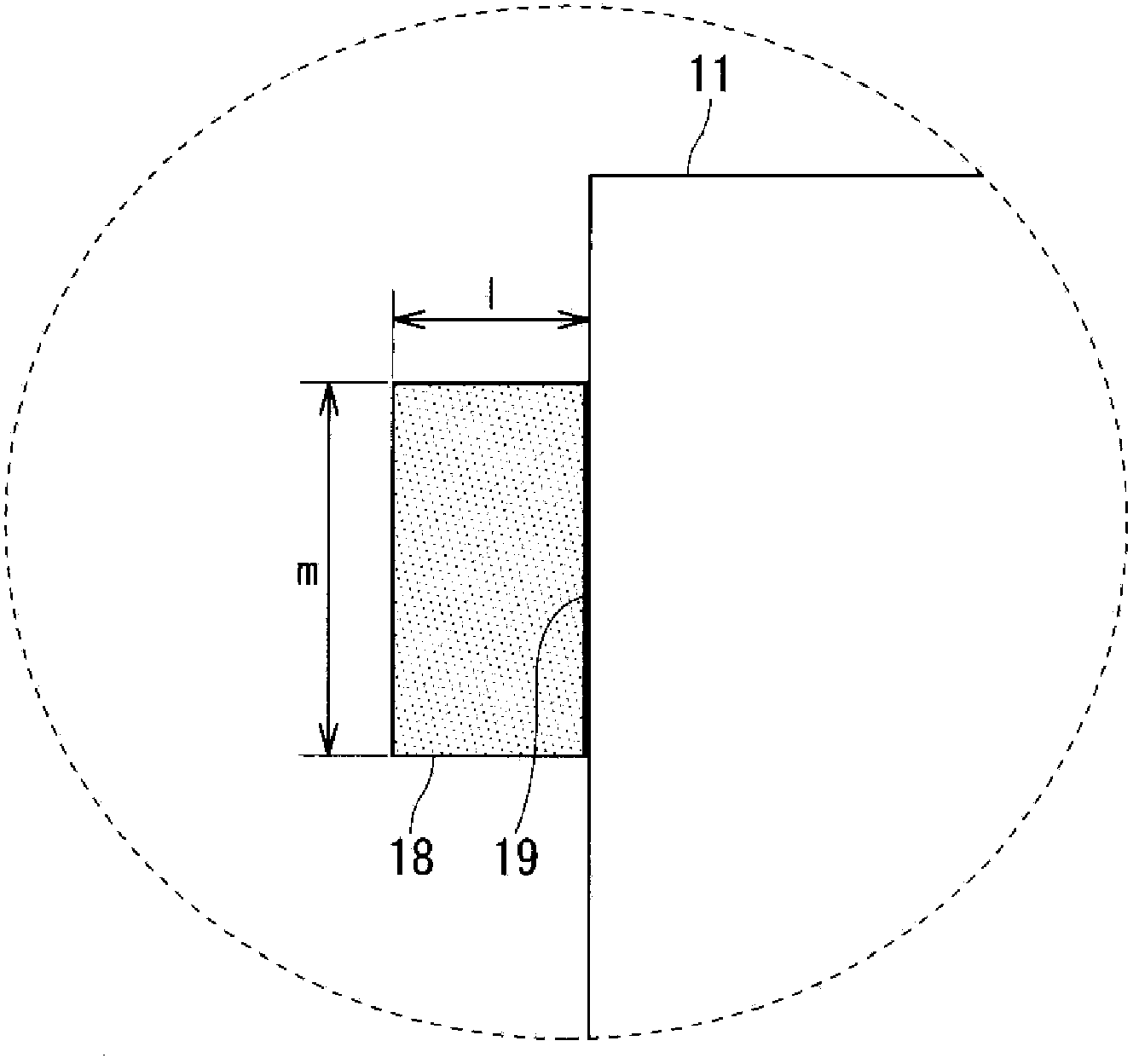

[0069] Injection foam molding can be performed by attaching the molding die 10 to an injection molding machine (not shown). Such as Figure 8 As shown, when the forming mold 10 is closed, the fixed mold 11 and the movable mold 12 are clamped, as Figure 9 As shown, the continuous air cells of the closed-loop seal 18 are collapsed to obtain a sealed configuration. When the air is supplied from the white air supply and discharge holes 15 , even if the molten resin is injected into the mold cavity 16 , it is possible to apply a pressure to prevent the molten resin from breaking.

[0070] In addition, if Figure 10 As shown, when the forming mold 10 is opened by using the reverse action of the core, the sealing member (elastic foam) 18 with open cells and rubber elasticity can release the residual air due to the property of the open cells with elastic recovery force. It is discharged from the inside of the mold 10 to the outside.

[0071] As a result, the remaining air in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com