An automatic detection method for the quality of pen core

An automatic detection and quality technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as low efficiency and blank quality detection of automatic refills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] The essence of the invention is to realize the automatic and rapid detection of the quality of the pen core on the production line of the pen core processing. A method for automatic pen core quality detection proposed by the invention has been implemented and applied on a principle prototype at present.

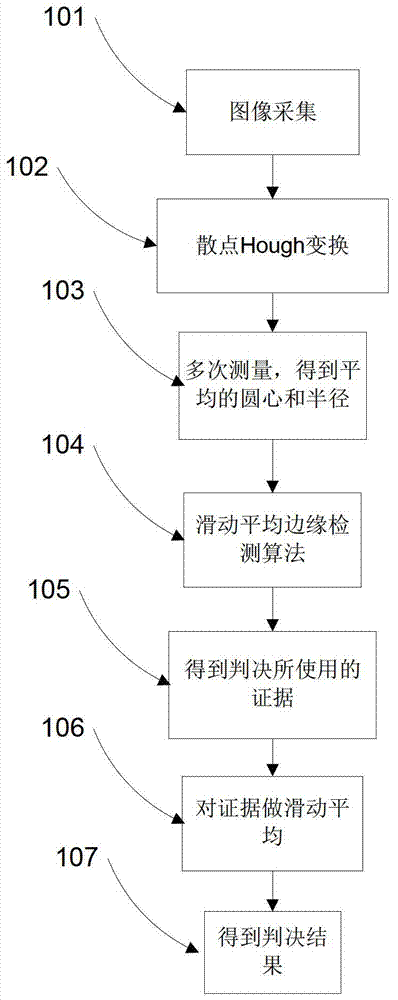

[0031] like figure 1 As shown, the method includes the following steps:

[0032] Step 101), using a high-definition industrial camera to collect digital images of stitch circles on the assembly line;

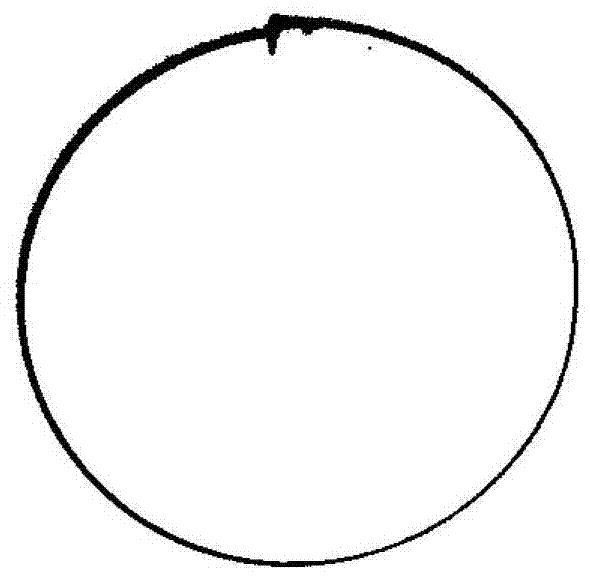

[0033] Step 102), performing a scatter-point Hough transform on the collected image, this step includes:

[0034] (1) First randomly select a point on the entire image, and use this point as a reference point to draw two horizontal and vertical lines;

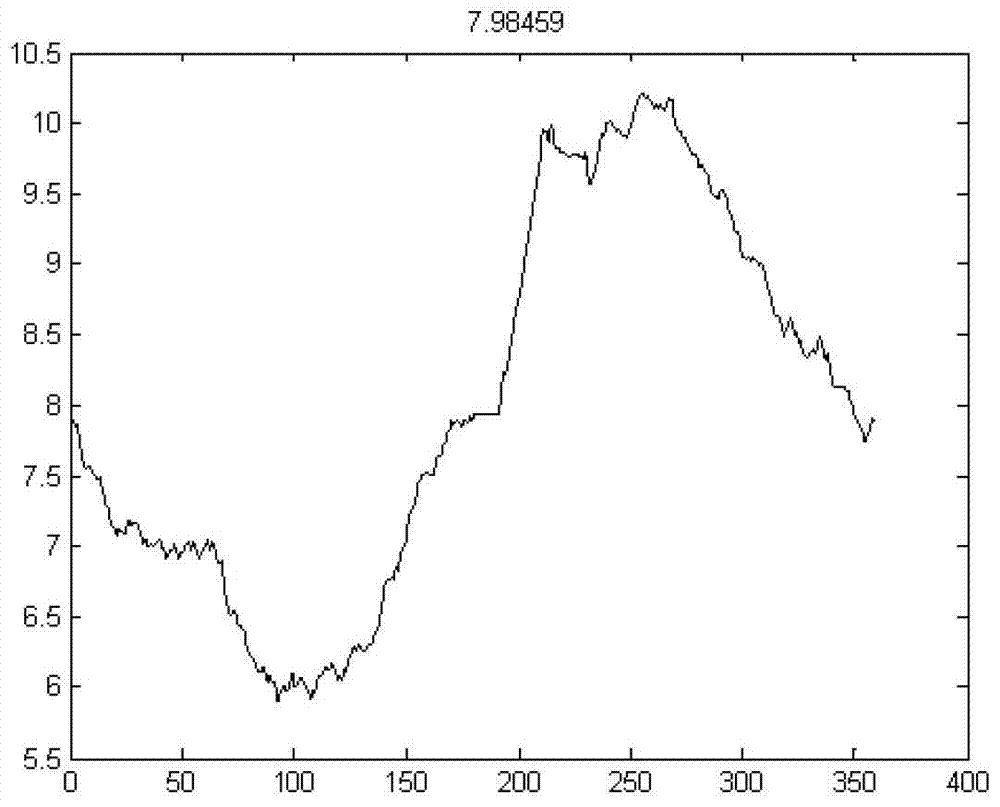

[0035] (2) Perform Hough transform on these two lines to transform from the two-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com