Dam seepage pressure measuring device

A pressure measuring device and seepage technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of inconvenient pressure measuring tubes, high requirements for sealing technology, and increasing pressure measuring tubes, so as to reduce sealing Possibility of failure, simplified adjustment workload, effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

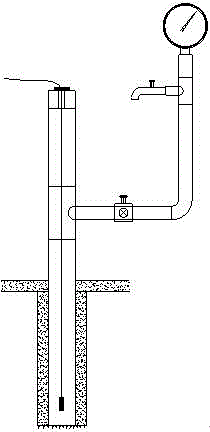

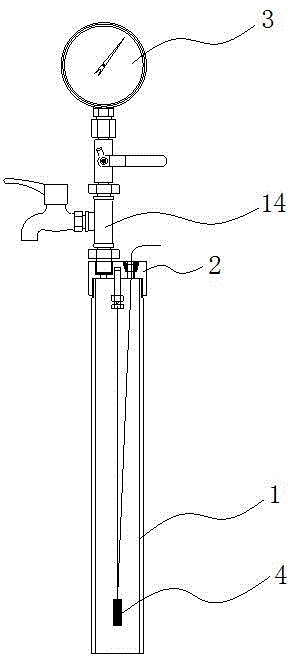

[0021] according to figure 2 with image 3 As shown, the embankment seepage pressure measuring device in the present invention includes a piezometric tube 1 , a top end cover 2 , a pressure gauge 3 and a piezometer 4 .

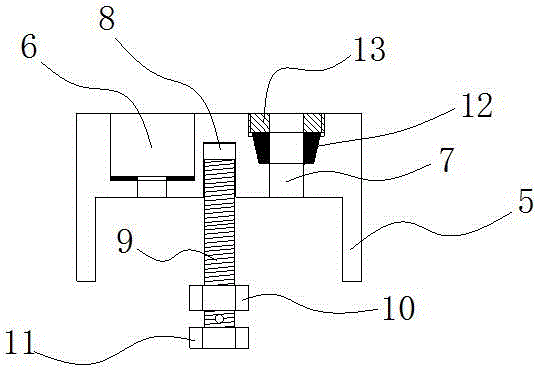

[0022] Wherein, the top end cover 2 is used to cover the top opening of the pressure measuring tube 1, and the edge of the top end cover 2 is provided with an outer skirt 5 extending toward the direction of the pressure measuring tube 1 and used to cover the surface of the pressure measuring tube 1. 5 and the pressure measuring tube 1 are connected by thread. The end cover 2 is provided with a first through hole 7 and a second through hole 6 .

[0023] Wherein, the pressure gauge 3 is located outside the pressure measuring tube 1 and connected to the second through hole 6 through a pipe joint. The pipe joint is composed of a three-way pipe 14, a pipe coupler, a control valve and a drain tap. One end of the main pipe on the three-way pipe 14 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com