Restrictor and production process of a fluid leakage restrictor for aerostatic bearings

A production process, technology of restrictors, applied to components, shafts and bearings, air cushion bearings, etc. of pumping devices for elastic fluids, capable of solving problems such as undiscovered restrictor solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

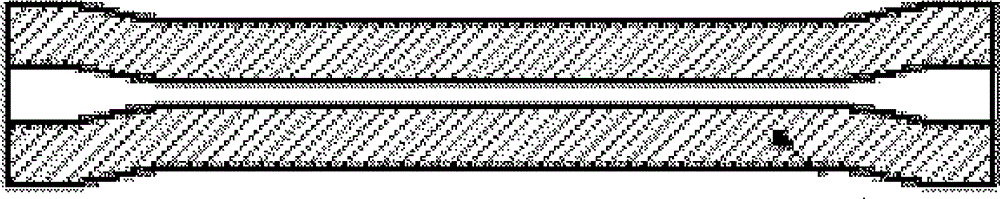

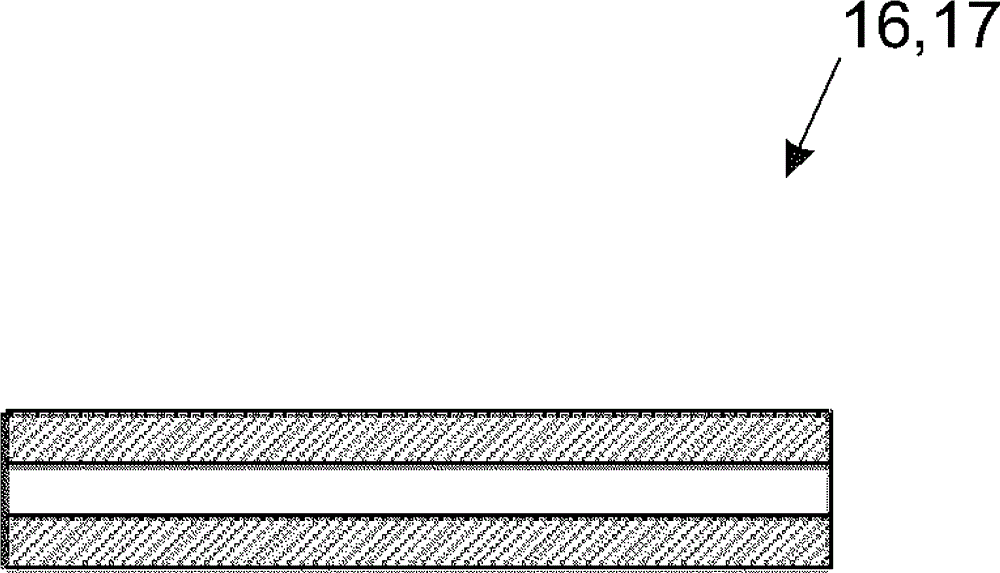

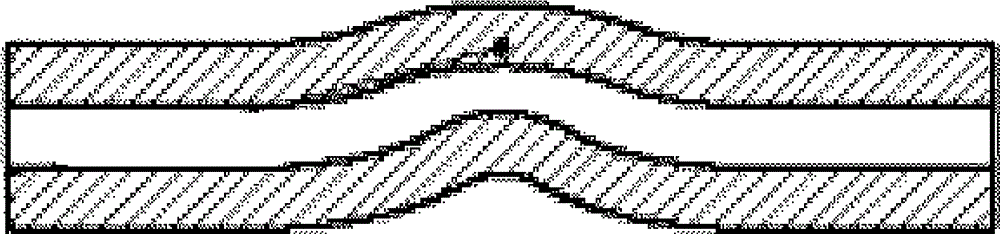

[0040] The present invention presents technological advances at the level of restrictors (better known by those skilled in the art as restrictor tubes / microtubes) and the production process that yields restrictors with desired fluid flow characteristics.

[0041] According to the working principle of the cooling circuit and as in figure 1 As shown in , the gas compression mechanism preferably takes place by the axial and oscillatory movement of the piston 1 inside the cylinder 2 . At the top of the cylinder 2 is a cylinder head 3 which, in conjunction with the piston 1 and cylinder 2 , forms a compression chamber 4 . A discharge valve 5 and a suction valve 6 , which regulate the inflow and outflow of gas in the cylinder 2 , are positioned in the cylinder head 3 . It should also be noted that the piston 1 is driven by an actuator 7 coupled to the linear motor of the compressor. Further explanation of such motors is not provided herein.

[0042] The piston 1 of the compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com