Cloth bonding device

A cloth bonding and cloth guiding technology, which is applied to the seams of textile materials, textiles and papermaking, tools for sewing clothes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

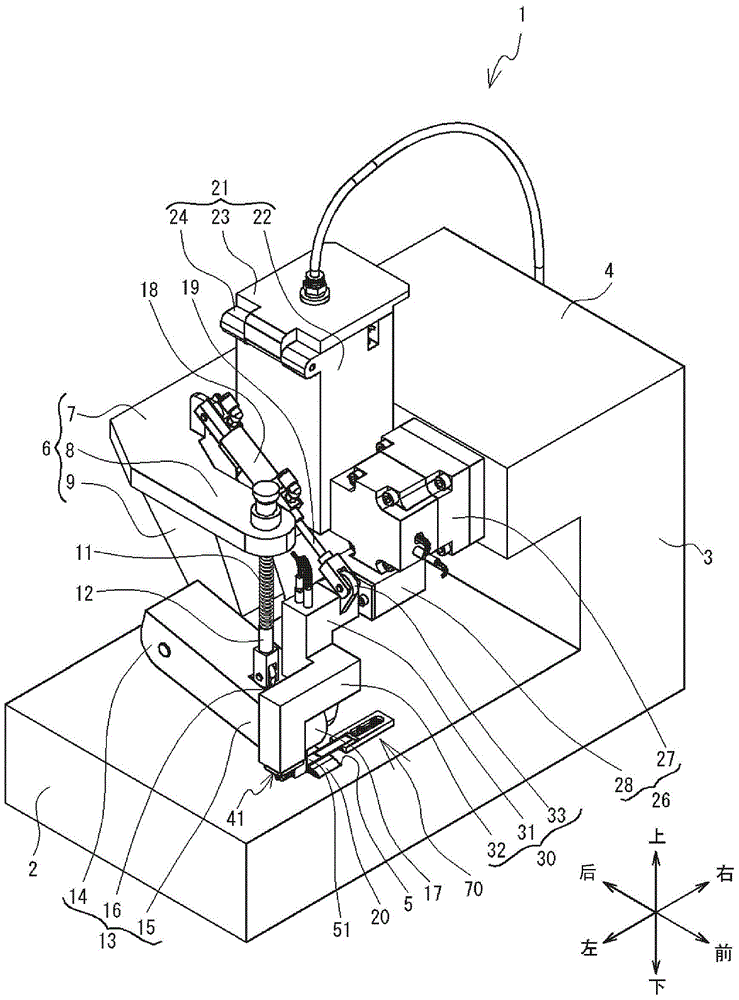

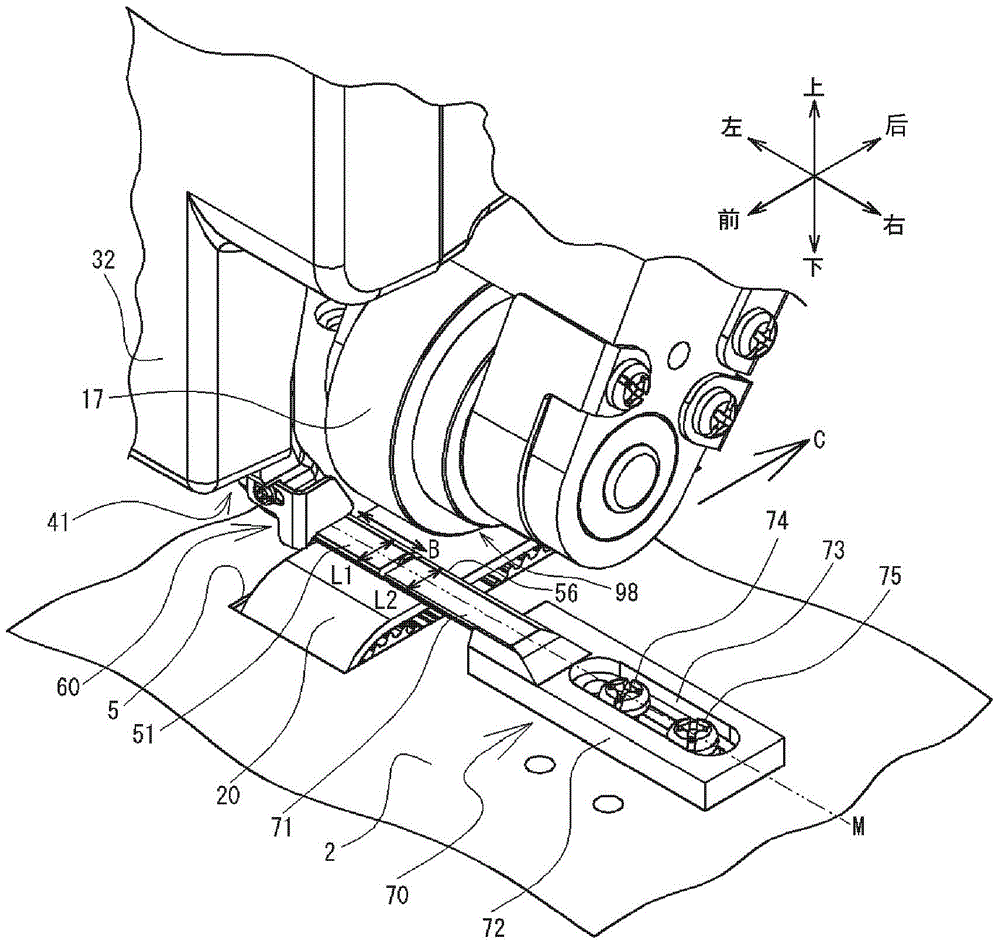

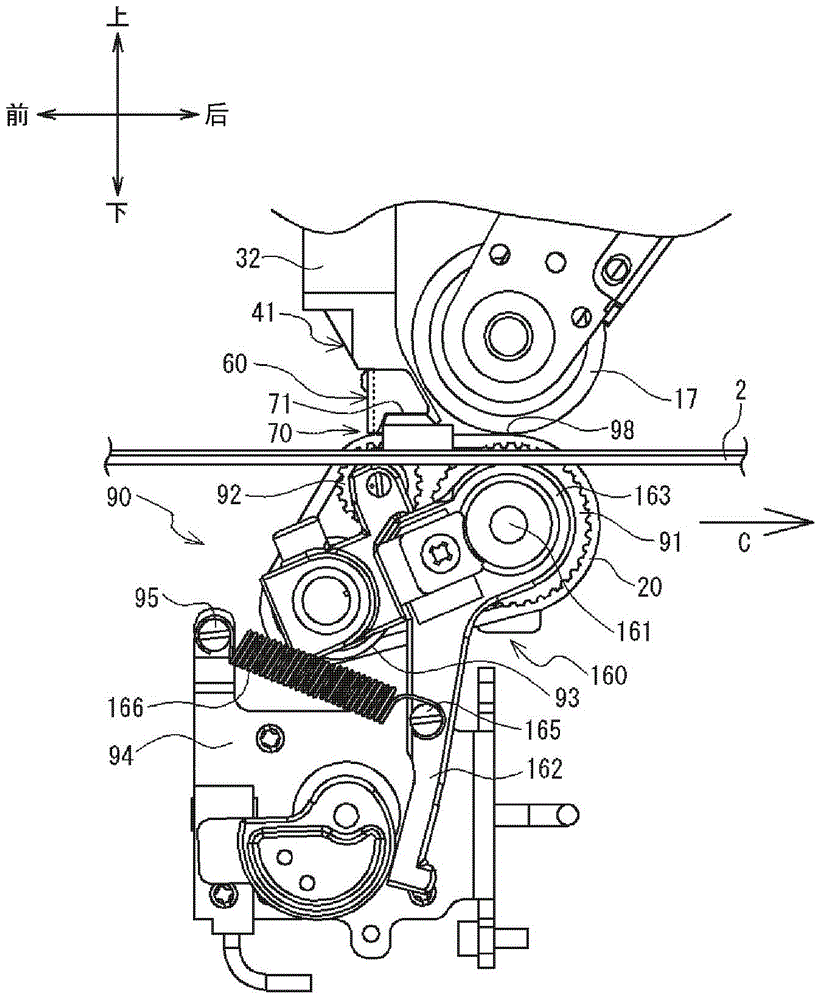

[0030] A cloth bonding apparatus 1 according to a first embodiment of the present invention will be described with reference to the drawings. In the following description, up and down, left and right, and front and rear indicated by arrows in the drawing are used. The cloth bonding apparatus 1 can bond the upper cloth and the lower cloth while conveying them in the conveying direction C. The conveyance direction C is a direction from the front side of the cloth bonding apparatus 1 toward the rear side. The front side of the cloth bonding apparatus 1 is the upstream side in the conveyance direction C, and the rear side of the cloth bonding apparatus 1 is the downstream side in the conveyance direction C.

[0031] Such as Figure 1 ~ Figure 3 As shown, the cloth bonding apparatus 1 includes a base part 2 , a column part 3 , and an arm part 4 . The base portion 2 has a substantially rectangular parallelepiped shape. The base portion 2 is fixed to a table (not shown). The col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com