Snowplow and snowplow roller brush lifting control device and method

A lift control and snow sweeper technology, which is applied in the use of feedback control, snow surface cleaning, cleaning methods, etc., can solve the problems of the unstable height of the roller brush from the ground, the inability to achieve the cleaning effect, and the frostbite of the driver's body. Good snow sweeping effect, solving the trouble of mechanical devices, reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

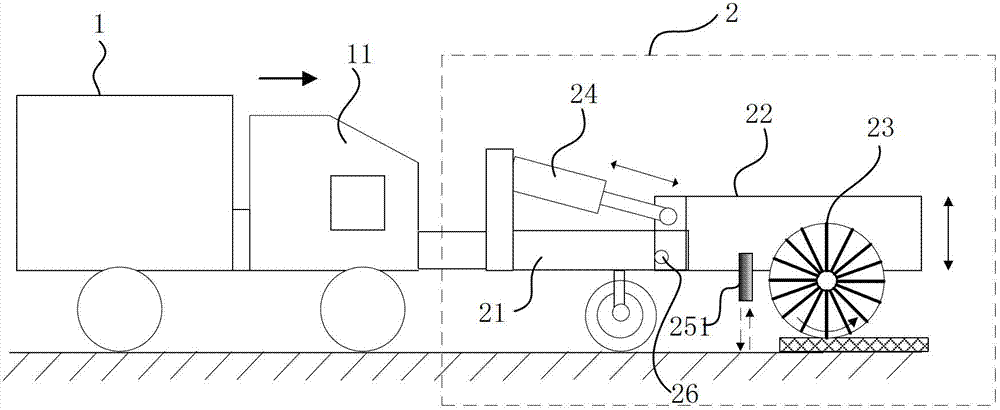

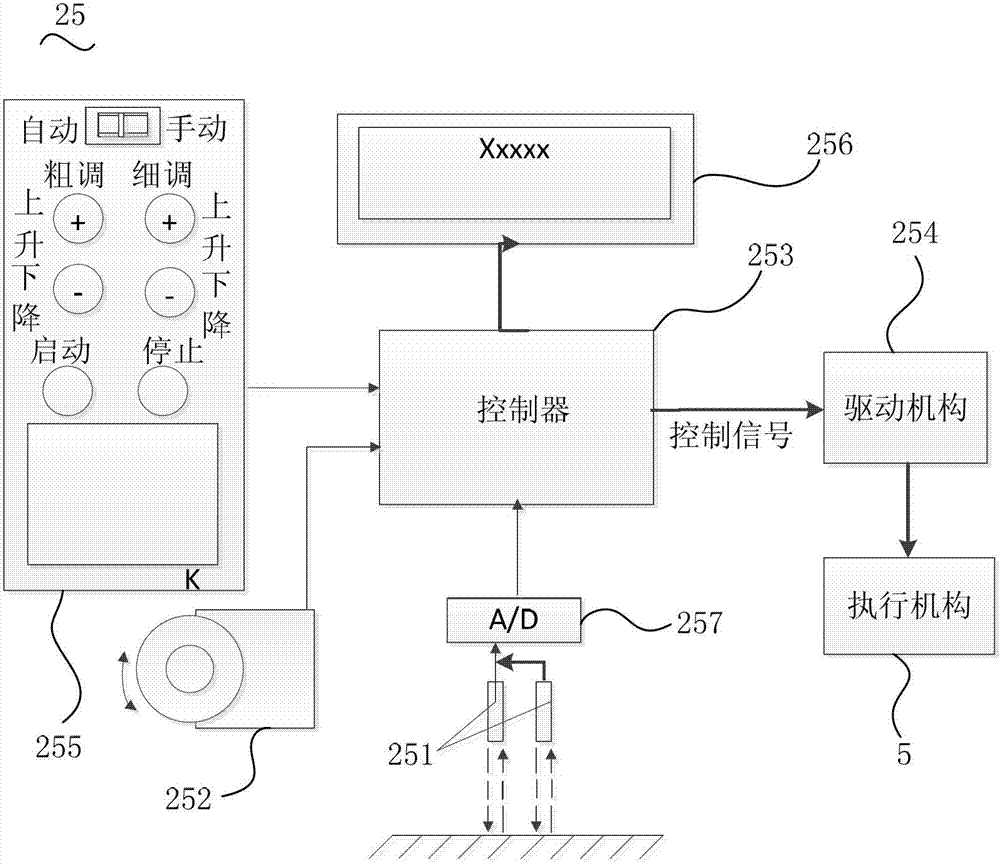

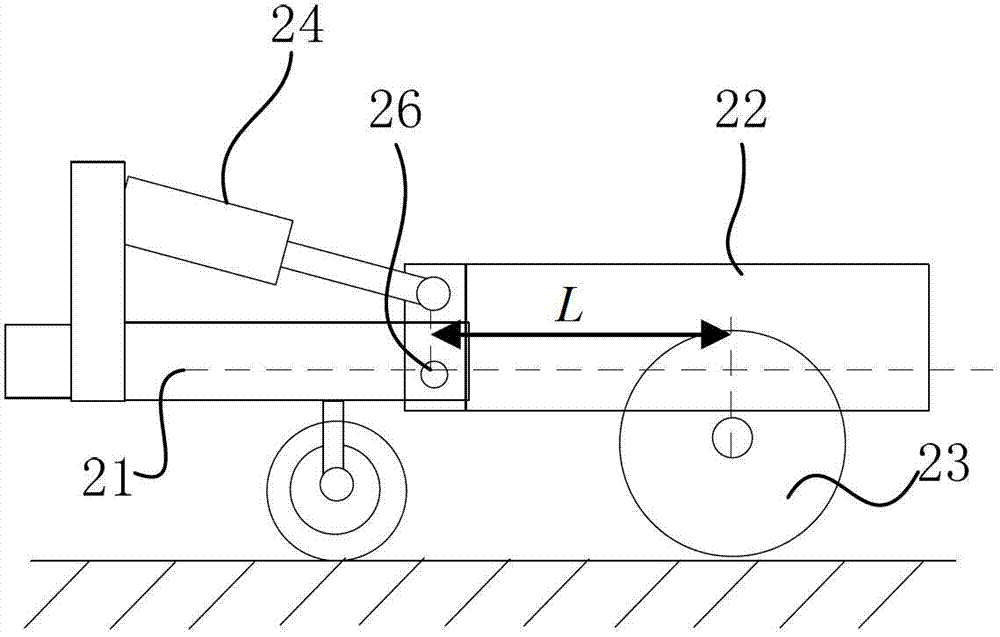

[0025] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0026] The present invention firstly provides a rolling brush lifting control method of a snowplow, which includes the following steps:

[0027] Step 1: Detect the rotation angle of the roller brush rack through the first sensor and indirectly calculate the reference height of the roller brush from the ground, record the reference height from the ground as the first height, and directly detect the ground clearance of the roller brush through the second sensor height, recorded as the second height;

[0028] Step 2: subtracting the first height from the second height to obtain a deviation value,

[0029] If the deviation value is greater than the error setting value and remains for a period of time, it is determined that the sensor corresponding to one set of unre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com