Patents

Literature

79results about How to "Compensation for measurement errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Movable Body Drive Method and Movable Body Drive System, Pattern Formation Method and Pattern Formation Apparatus, and Device Manufacturing Method

InactiveUS20090033900A1High accuracyStable drivingPhotomechanical apparatusUsing optical meansMoving averageServo control

First positional information of a stage is measured using an interferometer system, for example, an X interferometer and a Y interferometer. At the same time, second positional information of the stage is measured using an encoder system, for example, one X head and one Y head. A coordinate offset is set by performing a moving average of the difference between the first positional information and the second positional information for over a predetermined measurement time, and the reliability of output signals of the encoder system is verified using the coordinate offset. In the case the output signals are determined to be normal, the stage is servocontrolled using the sum of the first positional information and the coordinate offset. Such servocontrol by a hybrid method makes it possible to perform drive control of the stage having stability of the interferometer and accuracy of the encoder together.

Owner:NIKON CORP

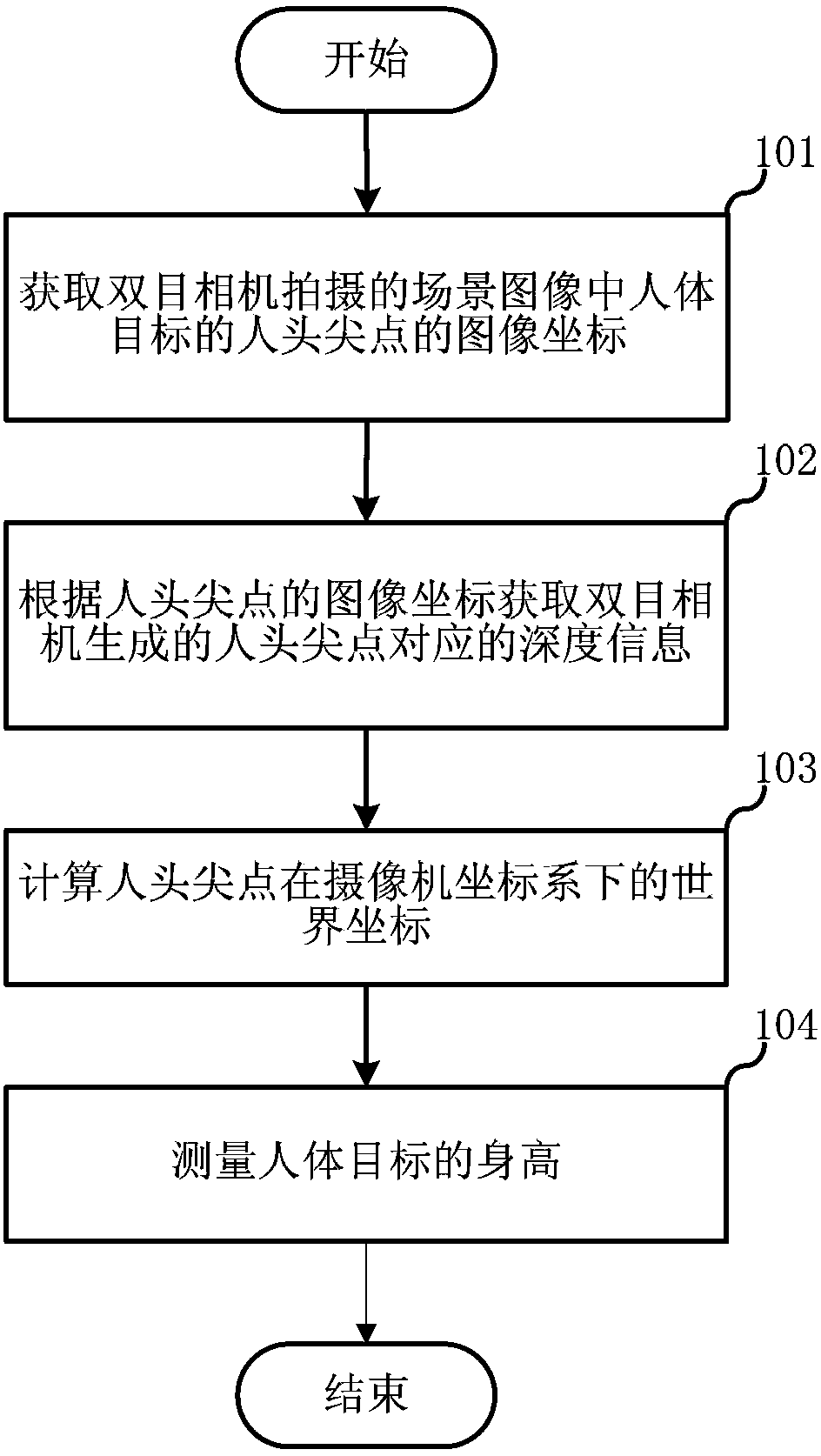

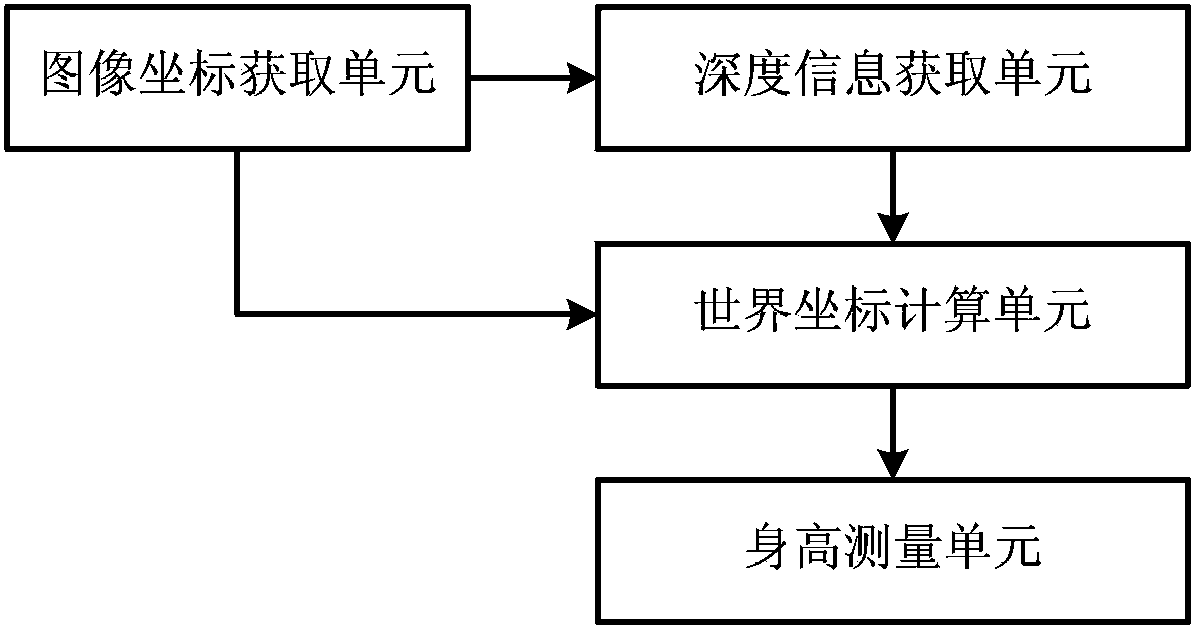

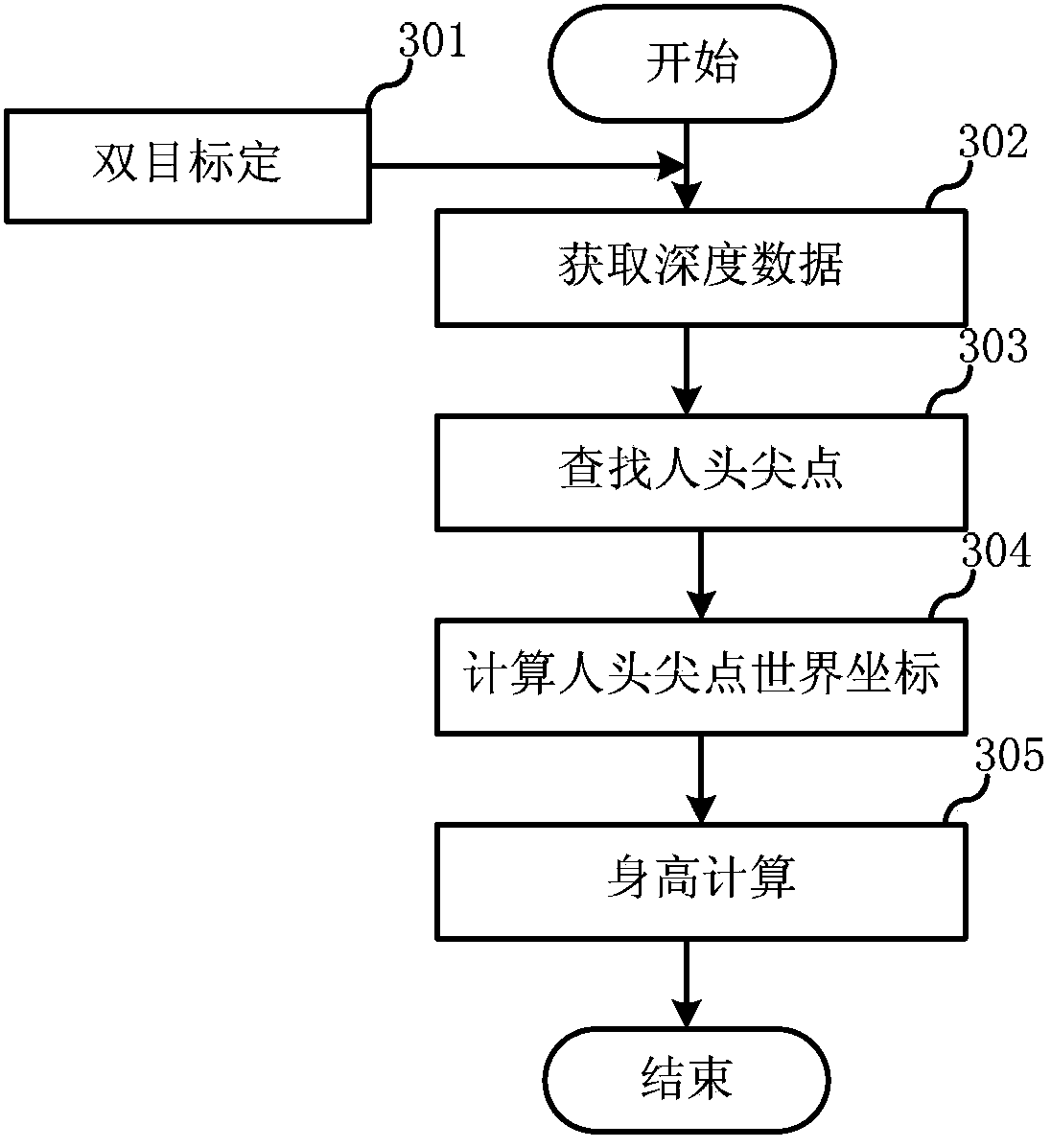

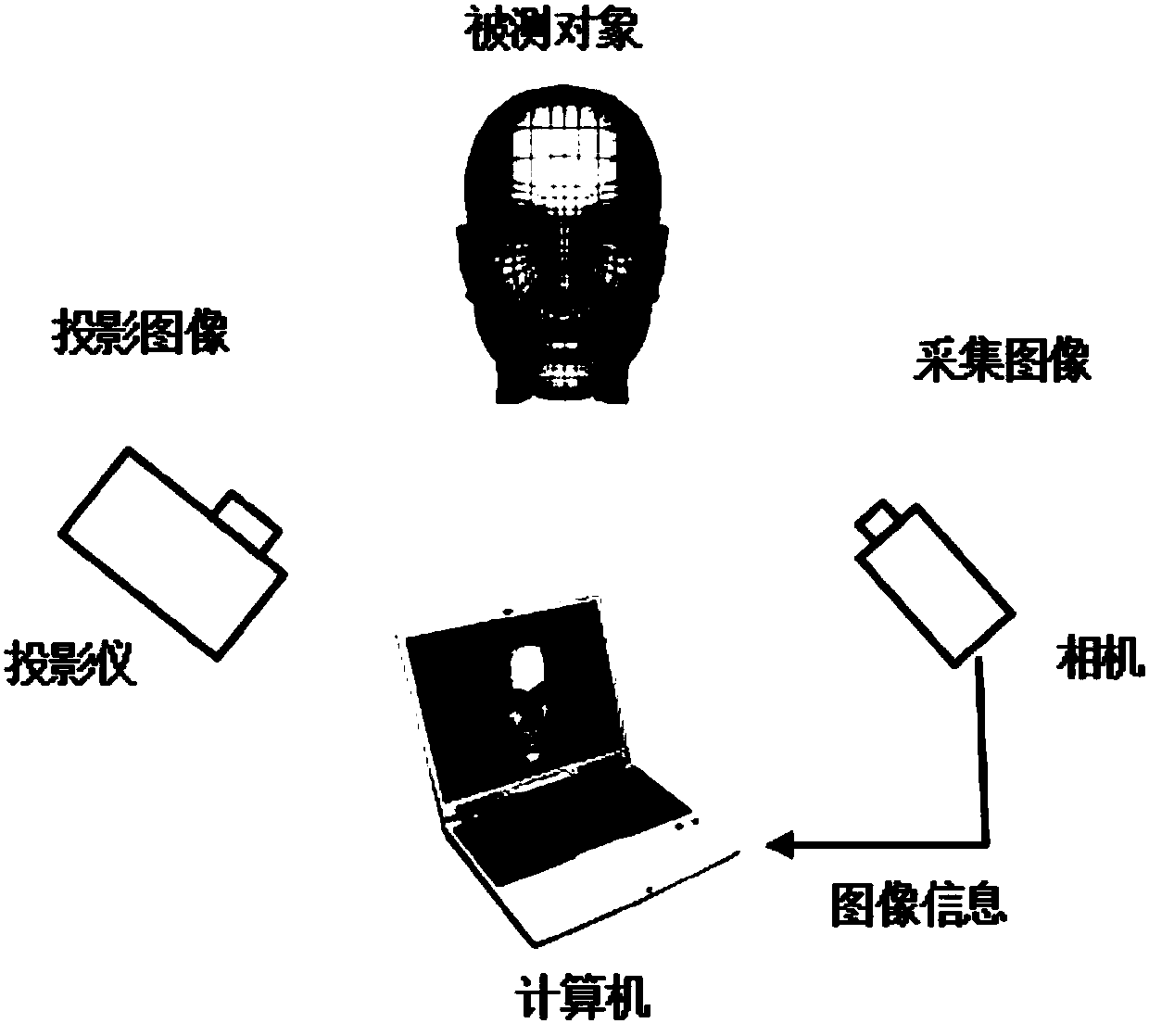

Measuring method and measuring device for height of human body based on binocular vision technique

ActiveCN104173054AHigh precisionCompensation for measurement errorsCharacter and pattern recognitionDiagnostic recording/measuringHuman bodyVisual technology

The invention relates to the technical field of computer vision and discloses a measuring method and a measuring device for the height of a human body based on a binocular vision technique. According to the measuring method and the measuring device disclosed by the invention, the height of a human body target is measured by acquiring image coordinates of a human head sharp point of the human body target in a scene image shot by a binocular camera and depth information corresponding to the image coordinates and calculating world coordinates of the human head sharp point under a coordinate system of the camera. According to the measuring method and the measuring device, the requirement on the compatibility of a measured person is low, and the height measurement can be finished by a mode that the person stands within the measurable range for shooting by the camera; the body heights of multiple persons in the scene can be simultaneously measured; in addition, the measurement precision is higher.

Owner:HANGZHOU HIKVISION DIGITAL TECH

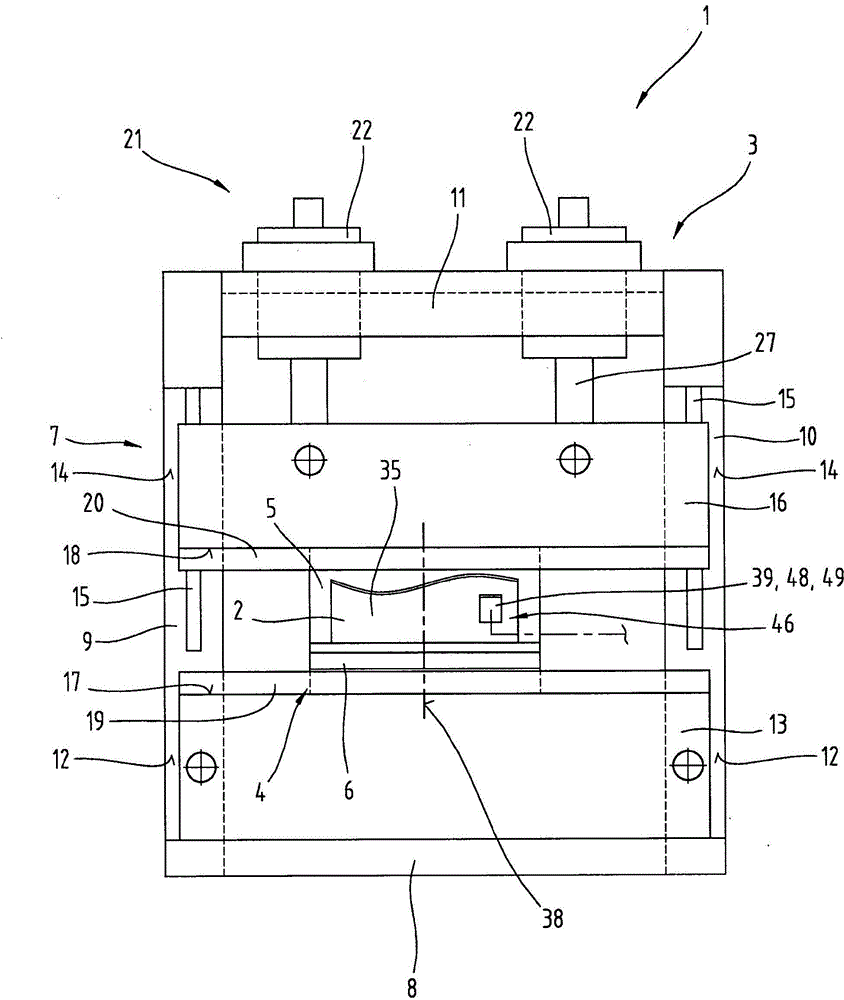

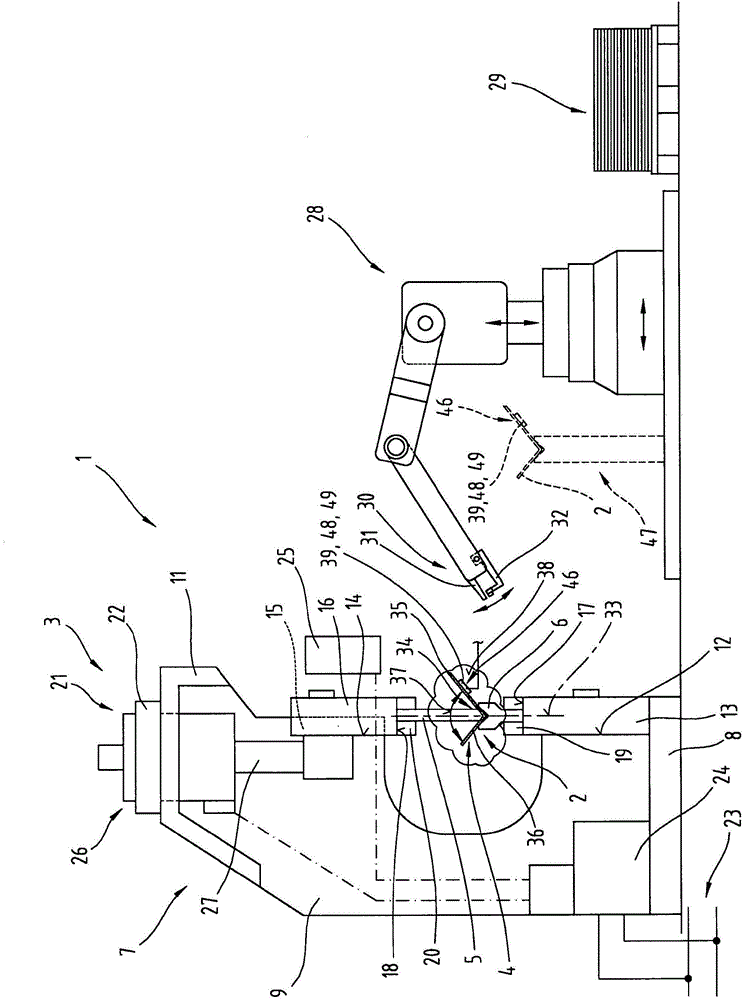

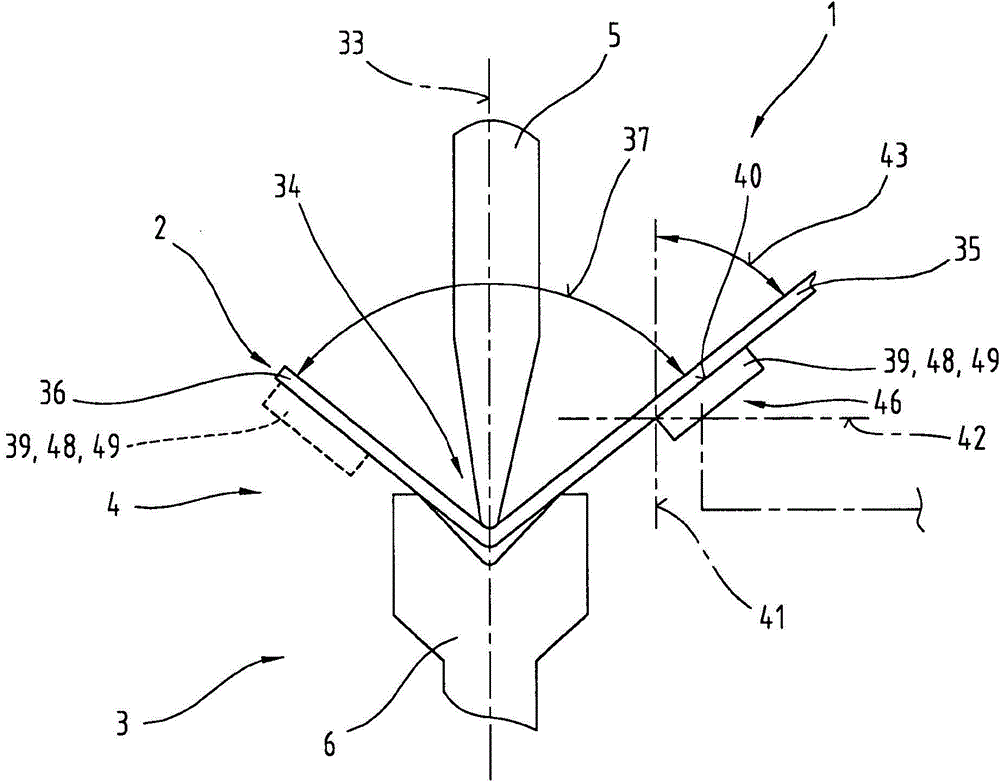

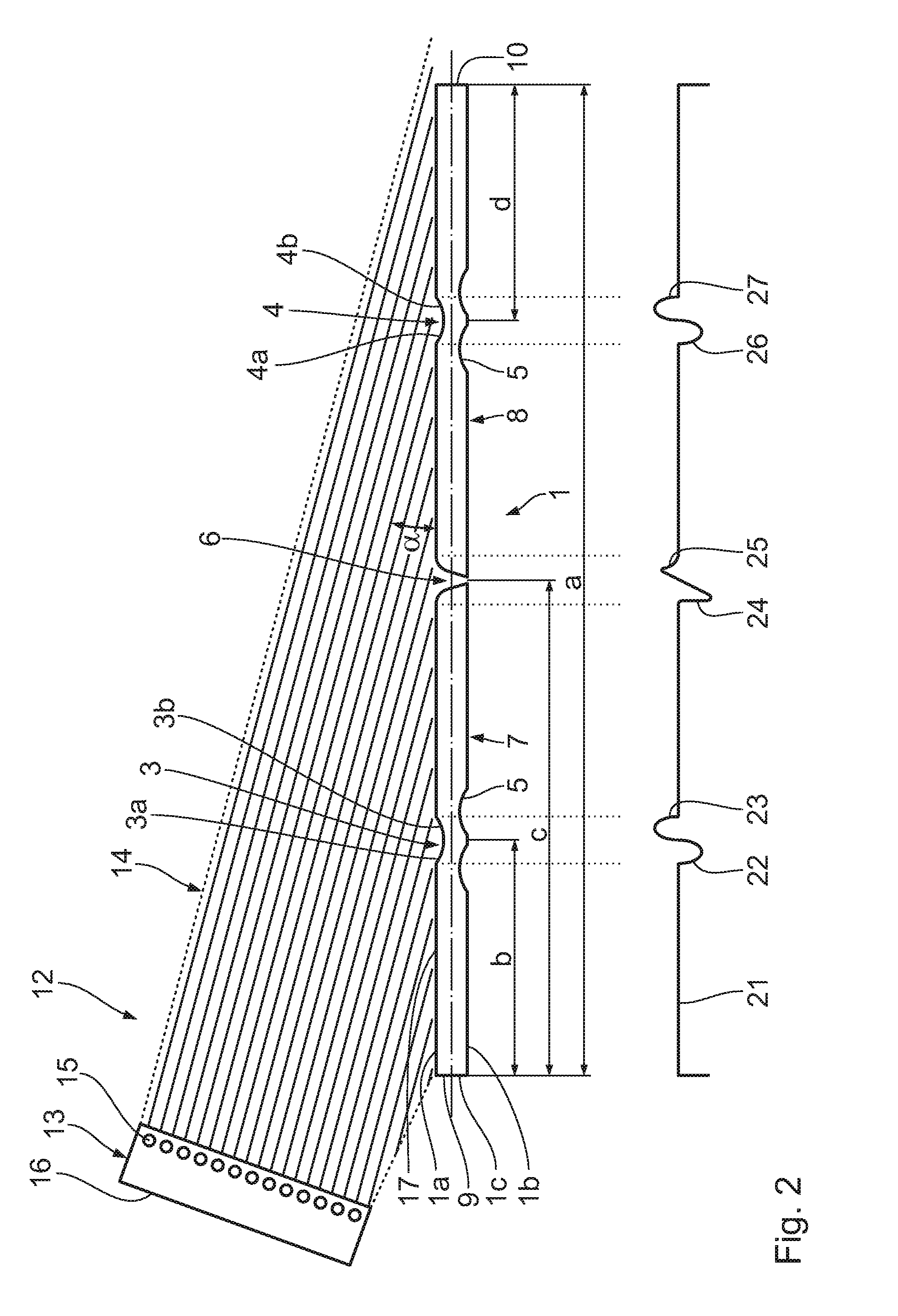

Bending press having an angle-measuring device and method for determining the bending angle

ActiveCN104582867AReduce the risk of injuryEliminate manual positioningAngles/taper measurementsIncline measurementEngineeringMechanical engineering

The invention relates to a production plant (1), in particular for folding workpieces (2) to be produced from sheet metal, comprising a bending press (3), in particular a press brake, having pressing beams (13, 16), at least one bending tool (4), such as a bending punch (5) and a bending die (6), which is connected to the pressing beams (13, 16), and at least one angle-measuring device (46) for determining an angular position of at least one limb (35, 36), formed by a bending operation, of the workpiece (2) with respect to a reference plane (41, 42). In this case, the angle-measuring device (46) comprises at least one inclination sensor (39) which has a reference surface (40) and the inclination sensor (39) having the reference surface (40) is supported by the angle-measuring device (46) so as to be placeable against a surface section of at least one of the limbs (35, 36) of the workpiece (2).

Owner:TRUMPF MASCHEN AUSTRIA

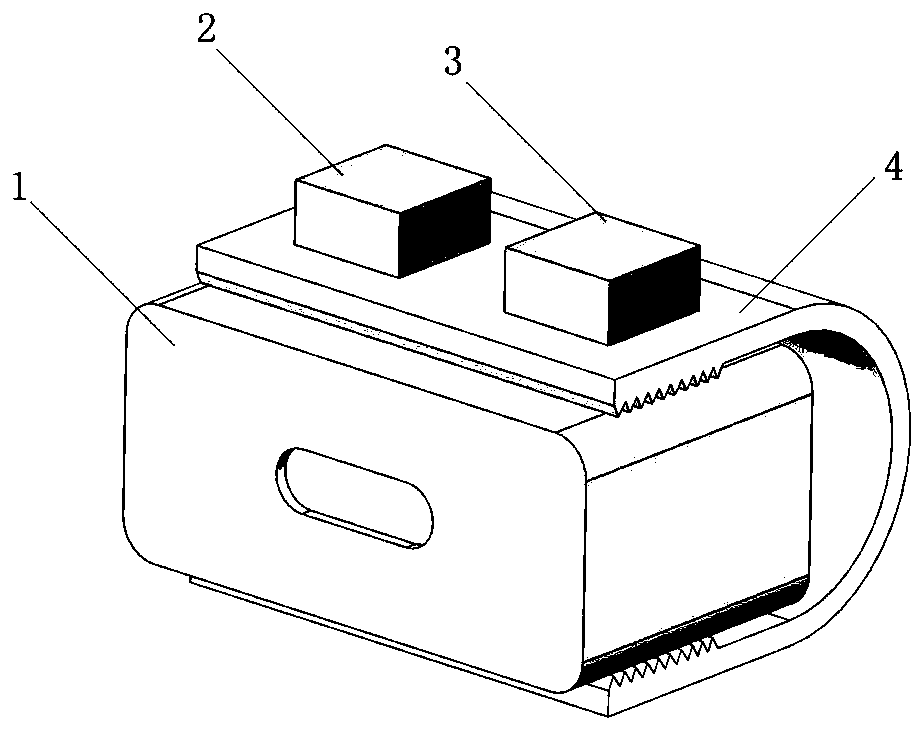

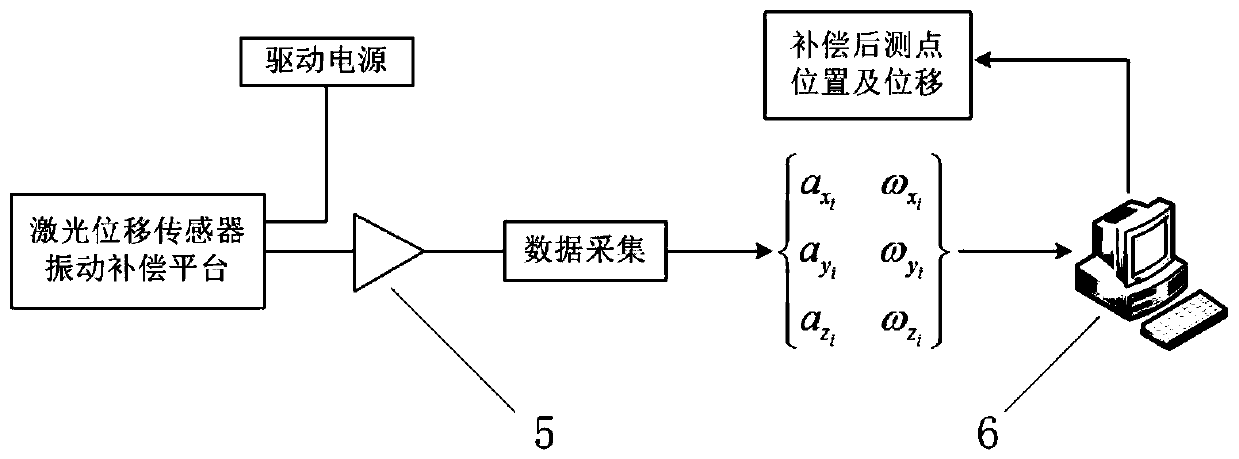

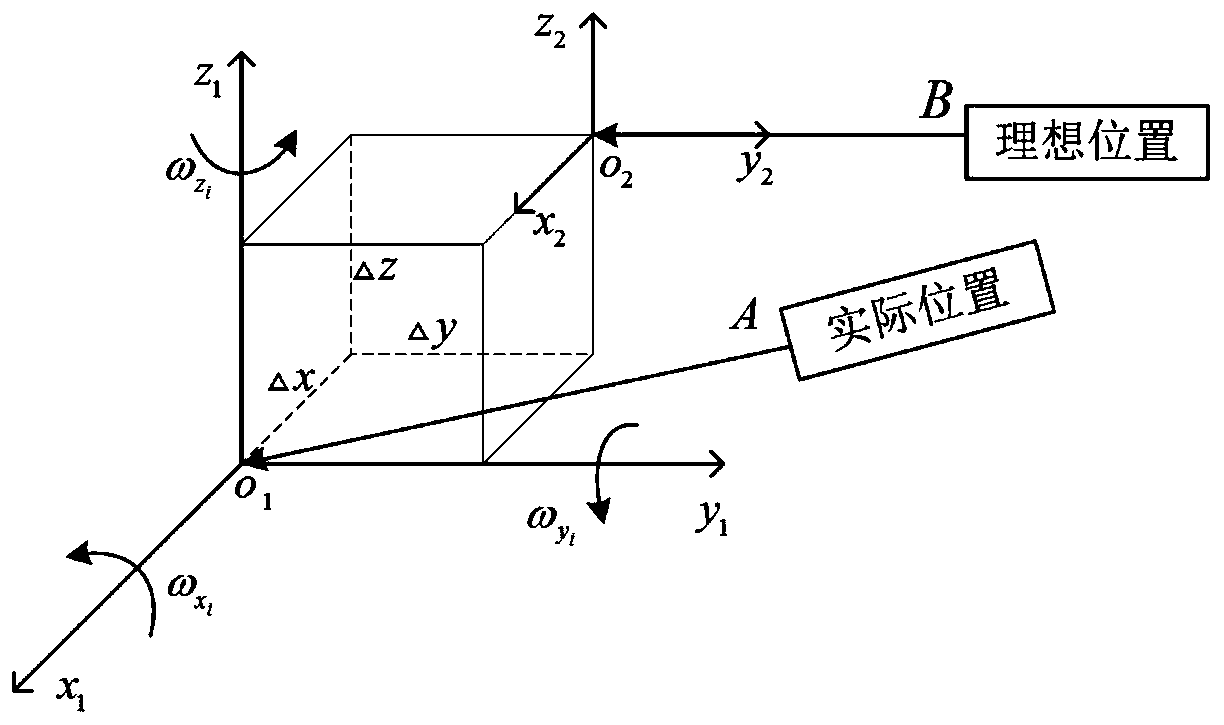

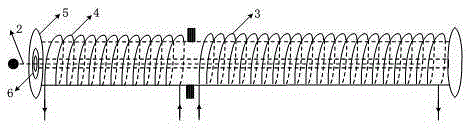

Vibration compensation platform of laser displacement sensor

ActiveCN110672017ACompensation for measurement errorsSimple structureUsing optical meansData acquisitionSignal amplifier

The invention provides a vibration compensation platform of a laser displacement sensor. The vibration compensation platform comprises a laser measurement device, a signal processor and a compensationcalculation device; the laser measurement device comprises a laser displacement sensor, an acceleration sensor, an angular velocity sensor and a fixture; the signal processor comprises a data collection card and a signal amplifier; the data collection card is used for collecting output voltages of the laser displacement sensor, the acceleration sensor and the angular velocity sensor; and the compensation calculation device respectively calculates a displacement, a vibration displacement error and a vibration angle error according to the output voltages of the laser displacement sensor, the acceleration sensor and the angular velocity sensor collected by the data collection card, and substitutes the displacement, the vibration displacement error and the vibration angle error into a shape and position correction matrix to obtain a compensated measurement point position and displacement of the laser displacement sensor. The vibration compensation platform provided by the invention solves the problem that the existing laser displacement sensor is vulnerable to vibration to affect the measurement accuracy of a measured component.

Owner:DALIAN MARITIME UNIVERSITY

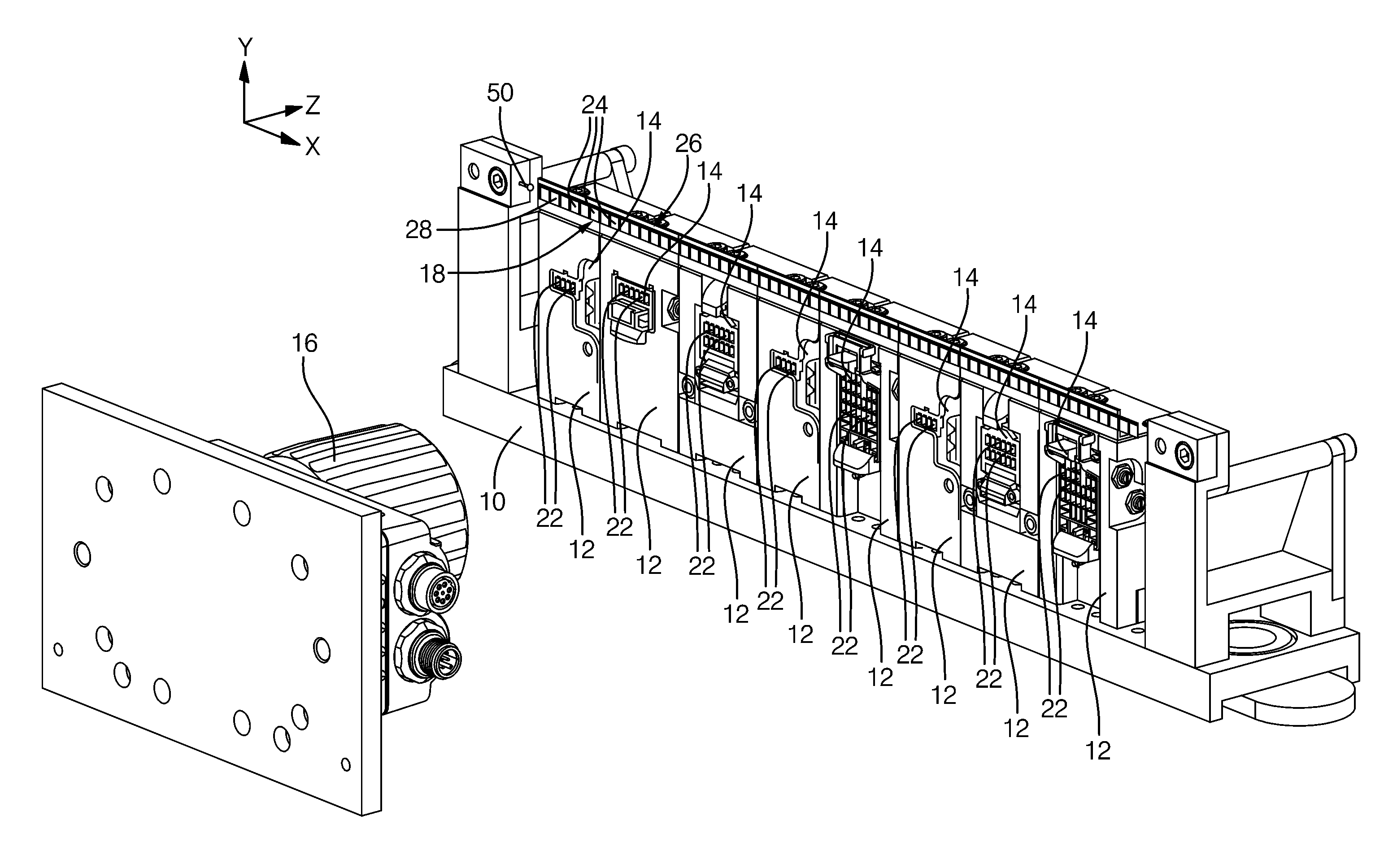

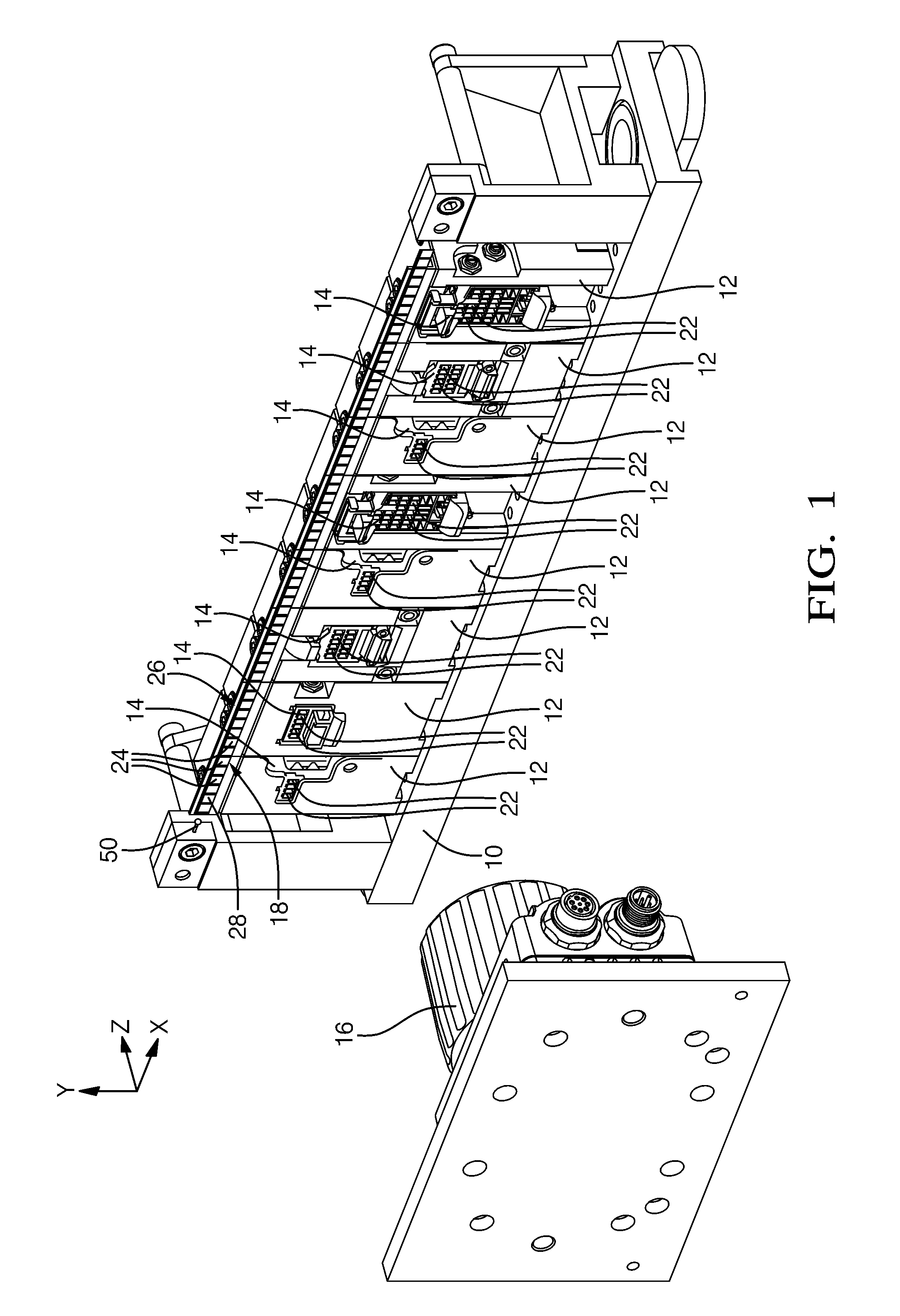

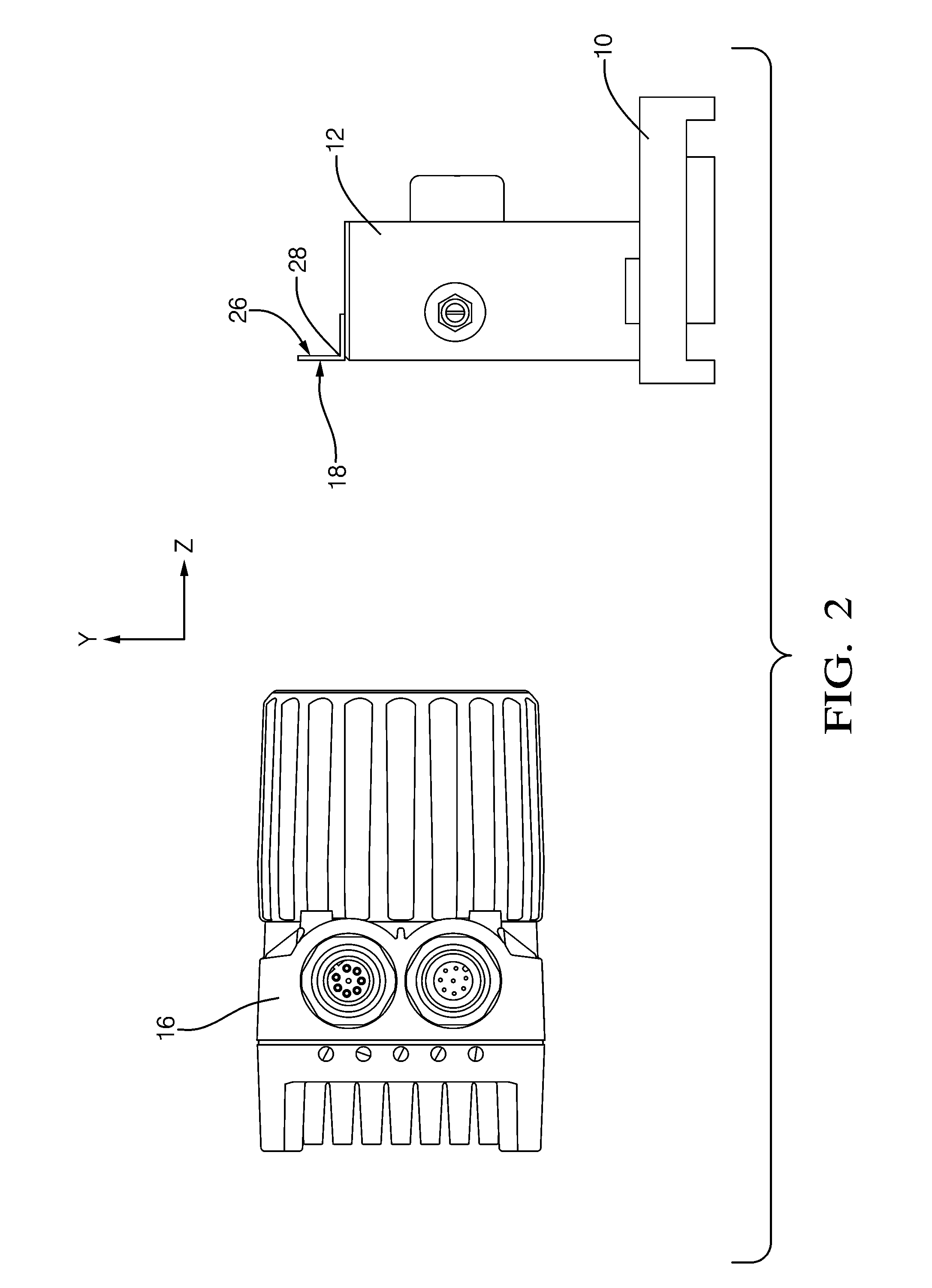

Method and apparatus for fitting of a plug housing

ActiveUS20120304439A1Compensation for measurement errorsEasy to processProgramme-controlled manipulatorContact member assembly/disassemblySpatially resolvedEngineering

A method to fit a contact portion in a plug housing by a robot is presented. Steps in the method include attaching a plug housing to a holder and gripping the contact portion by a gripping device of the robot. Other steps in the method include taking at least one spatially resolved picture by at least one optical detection device such that the plug housing and the contact portion are contained in the picture, determining a respective position of the plug housing and the contact portion in the picture by a control unit of the moveable robot, calculating a robot movement by the control unit that is a function of the determined positions, and performing the calculated movement by the robot to fit the contact portion in the plug housing. An apparatus to perform the method and another method to calibrate the control unit of the robot are also presented.

Owner:APTIV TECH LTD

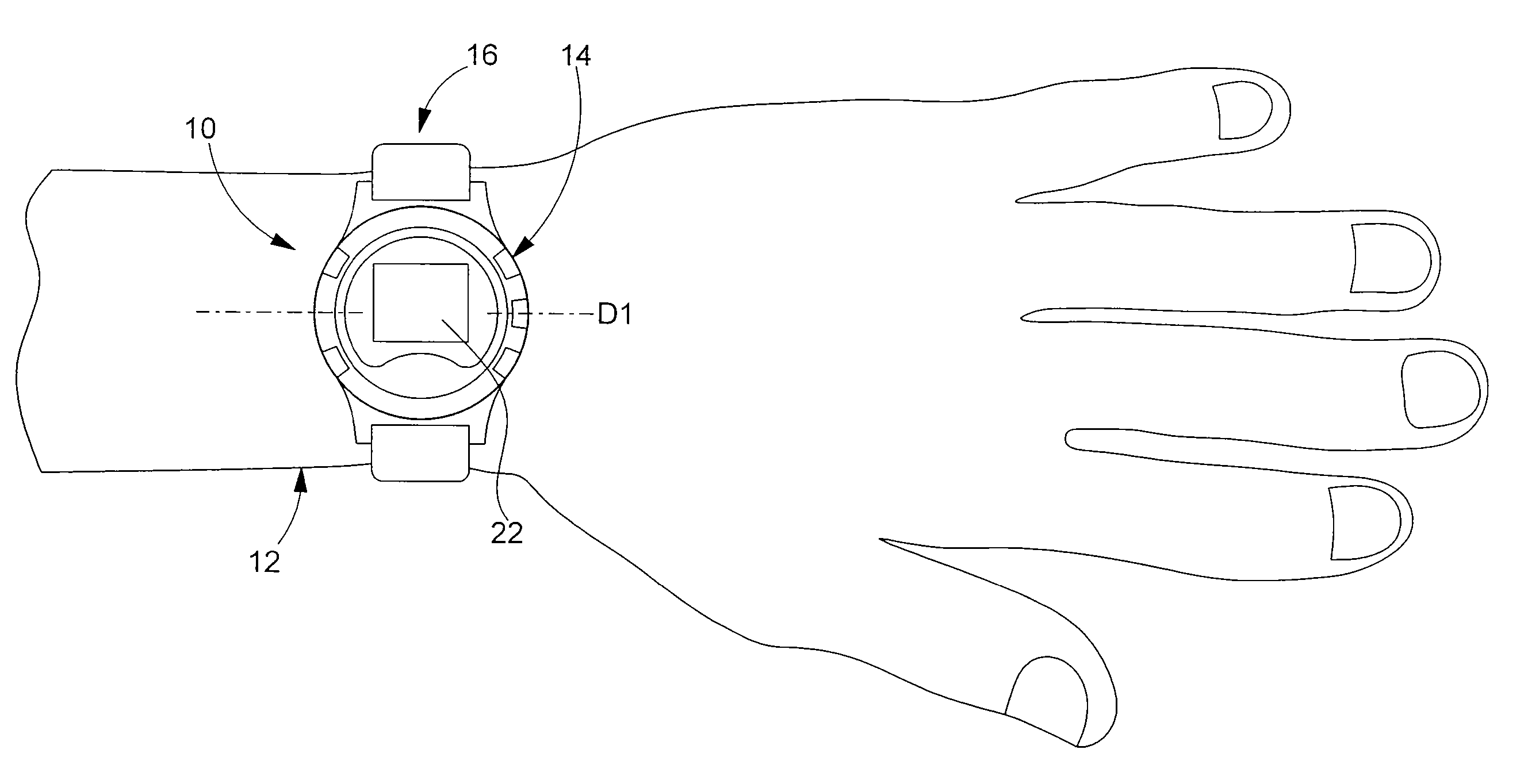

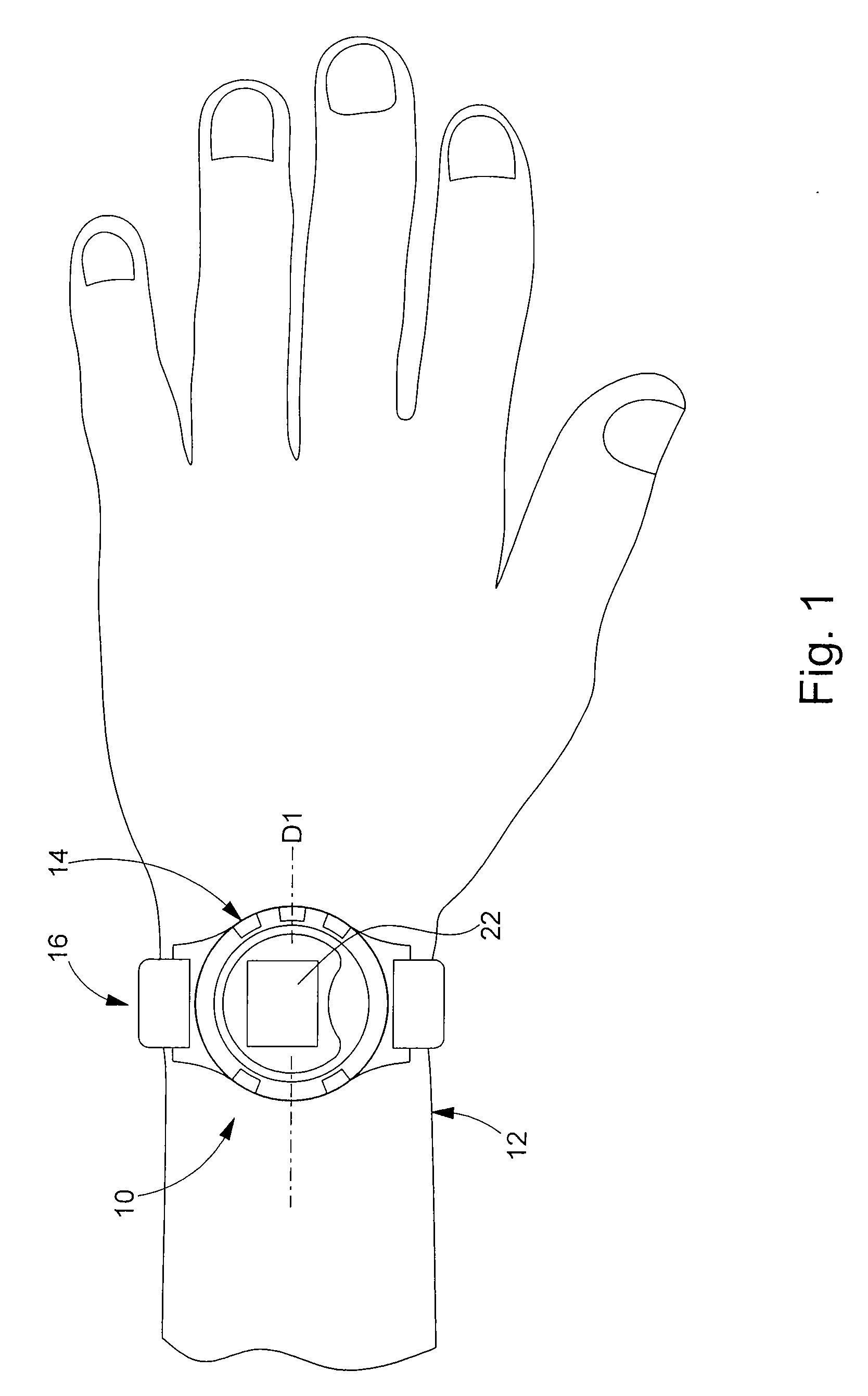

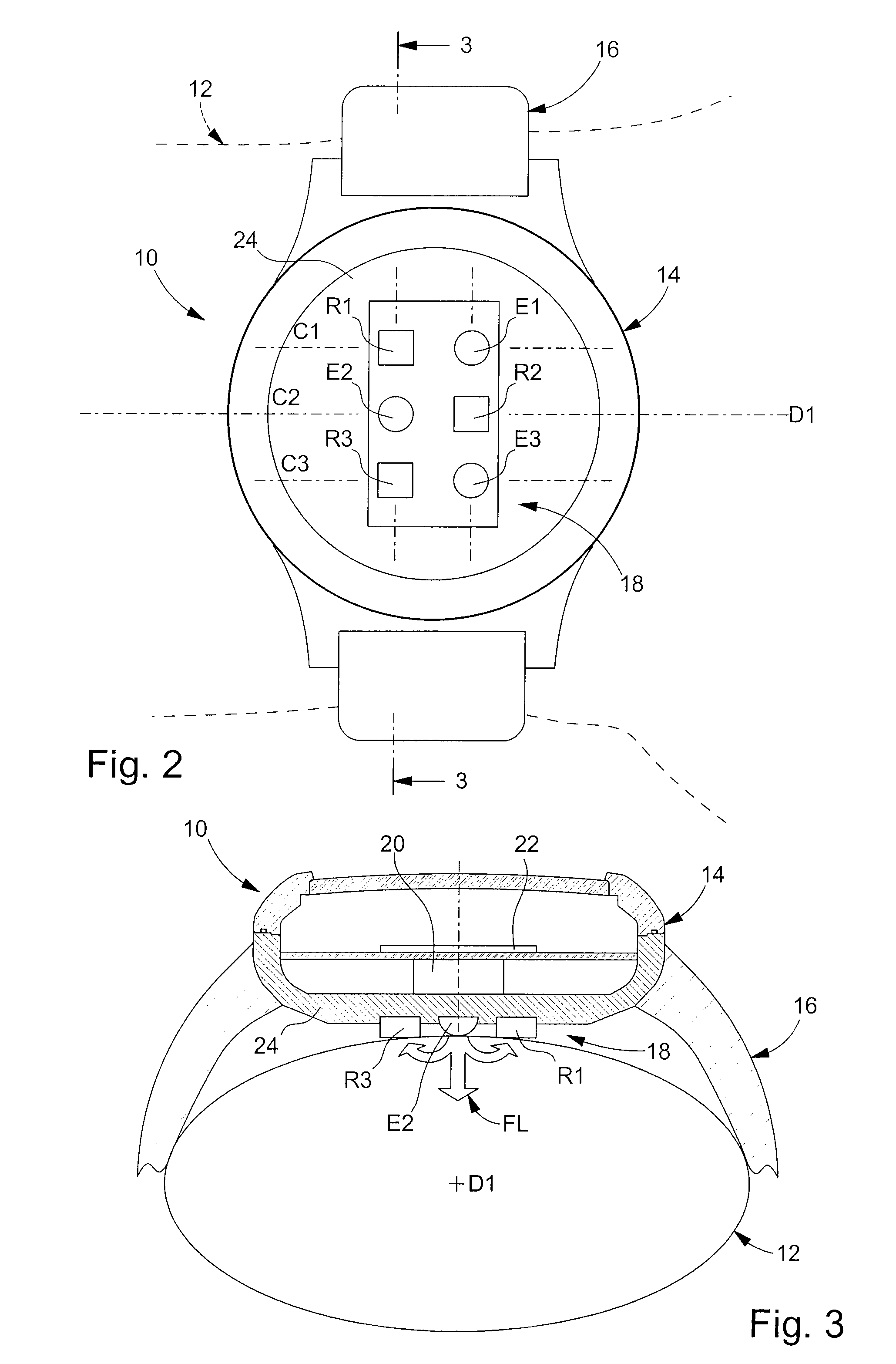

Pulsometer worn on wrist and associated control method

ActiveUS20080019218A1Economical and simple to implementQuality improvementElectric indicationMechanical clocksEngineeringWrist

The invention proposes a pulsometer (10) comprising a case (14) which contains an electronic optical pulse measuring device (18) and an electronic circuit, a tightening wristband (16) which holds the back cover of the case (14) pressed against the wrist (12), characterized in that the electronic optical measuring device (18) includes at least two light sources (E1, E2, E3) and at least two receivers (R1, R2, R3), in that the light sources (E1, E2, E3) and the receivers (R1, R2, R3) are arranged in the form of a matrix comprising two lines (L1, L2) each oriented along an orthogonal direction to the direction (D1) of the wrist (12), and at least two columns (C1, C2, C3), oriented parallel to the direction (D1) of the wrist (12), in that each line (L1, L2) of the matrix alternately contains a light source (E1, E2, E3) and a receiver (R1, R2, R3), and each column (C1, C2, C3) of the matrix contains a light source (E1, E2, E3) and a receiver (R1, R2, R3). The invention also proposes a control method for this pulsometer (10).

Owner:ETA SA MFG HORLOGERE SUISSE

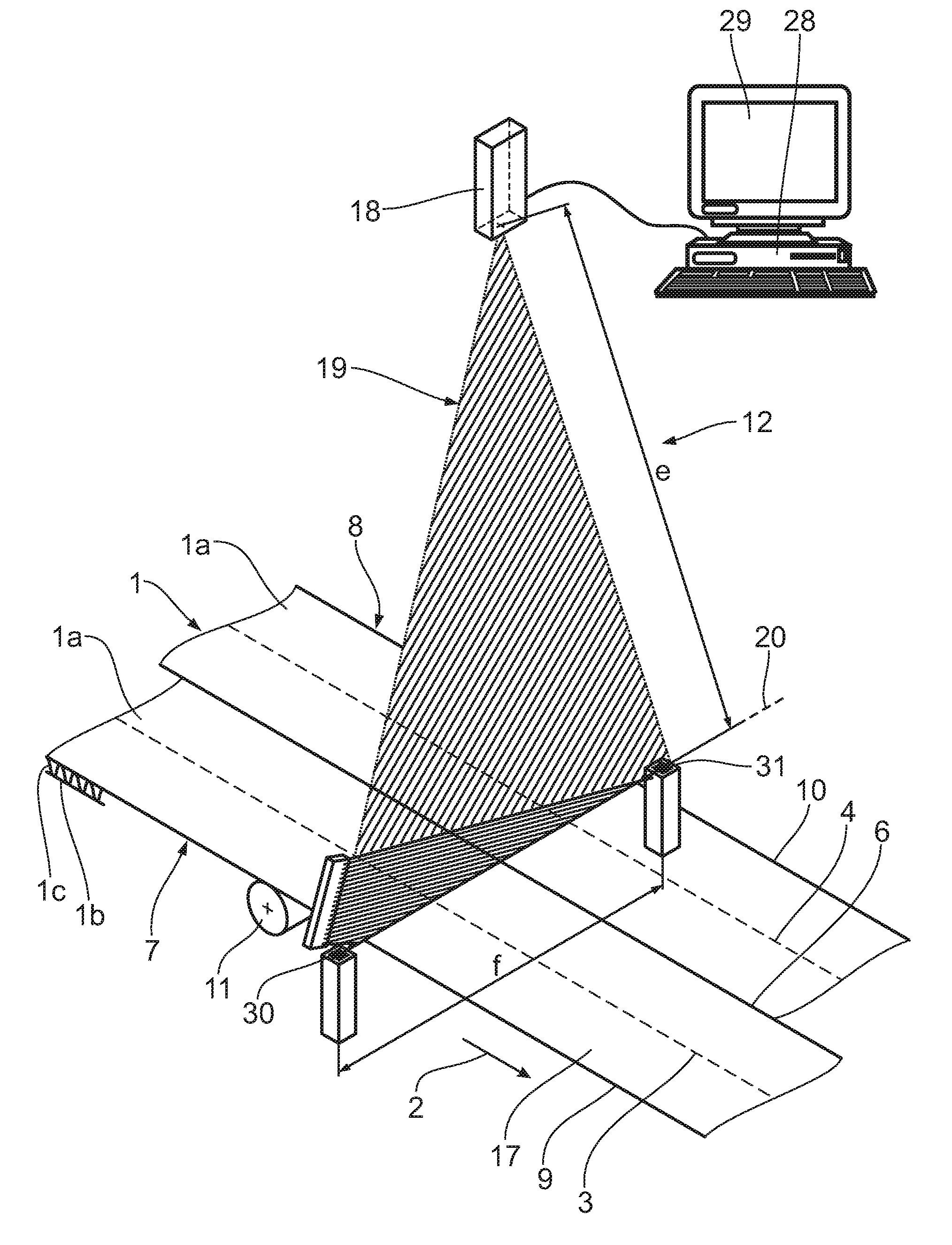

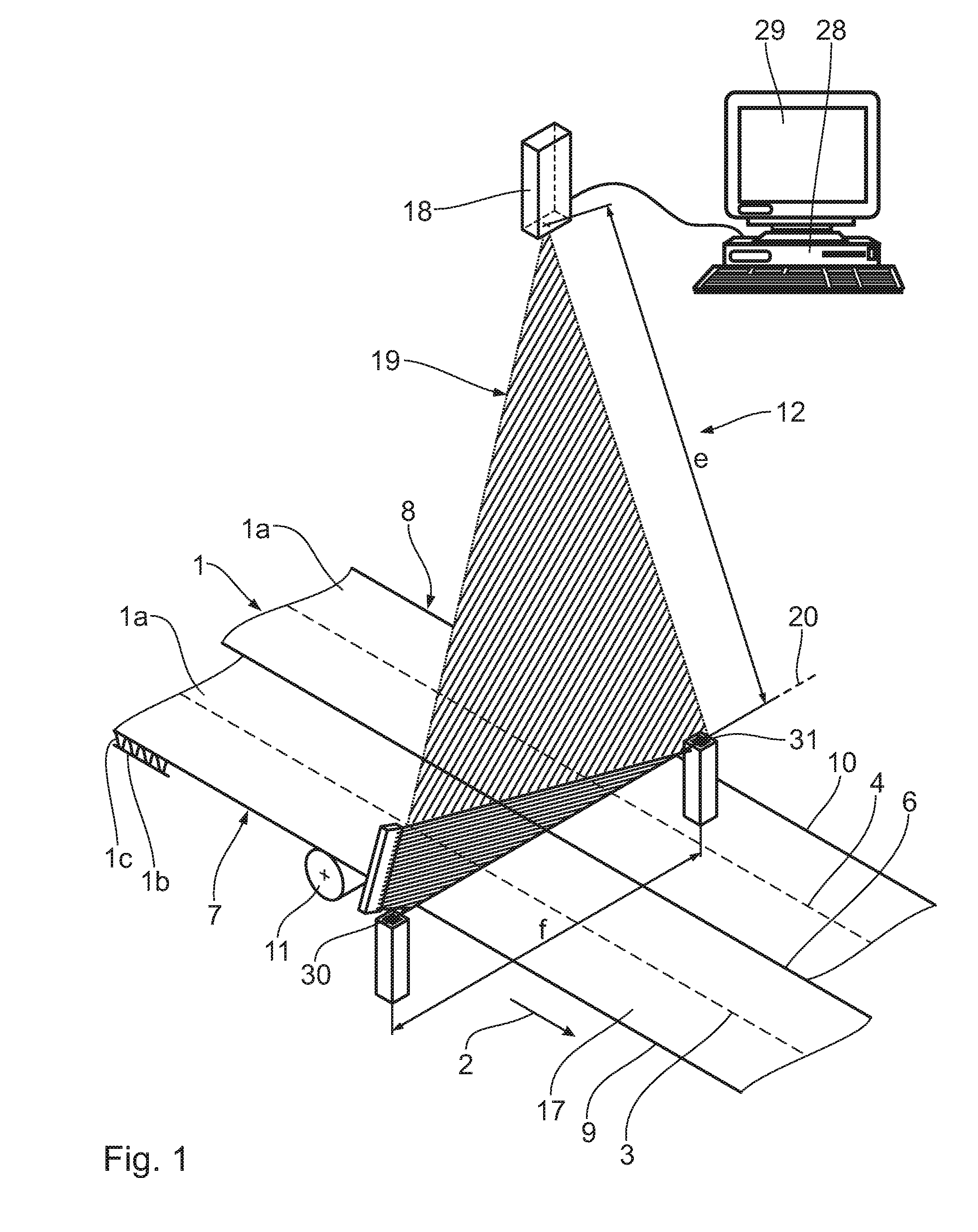

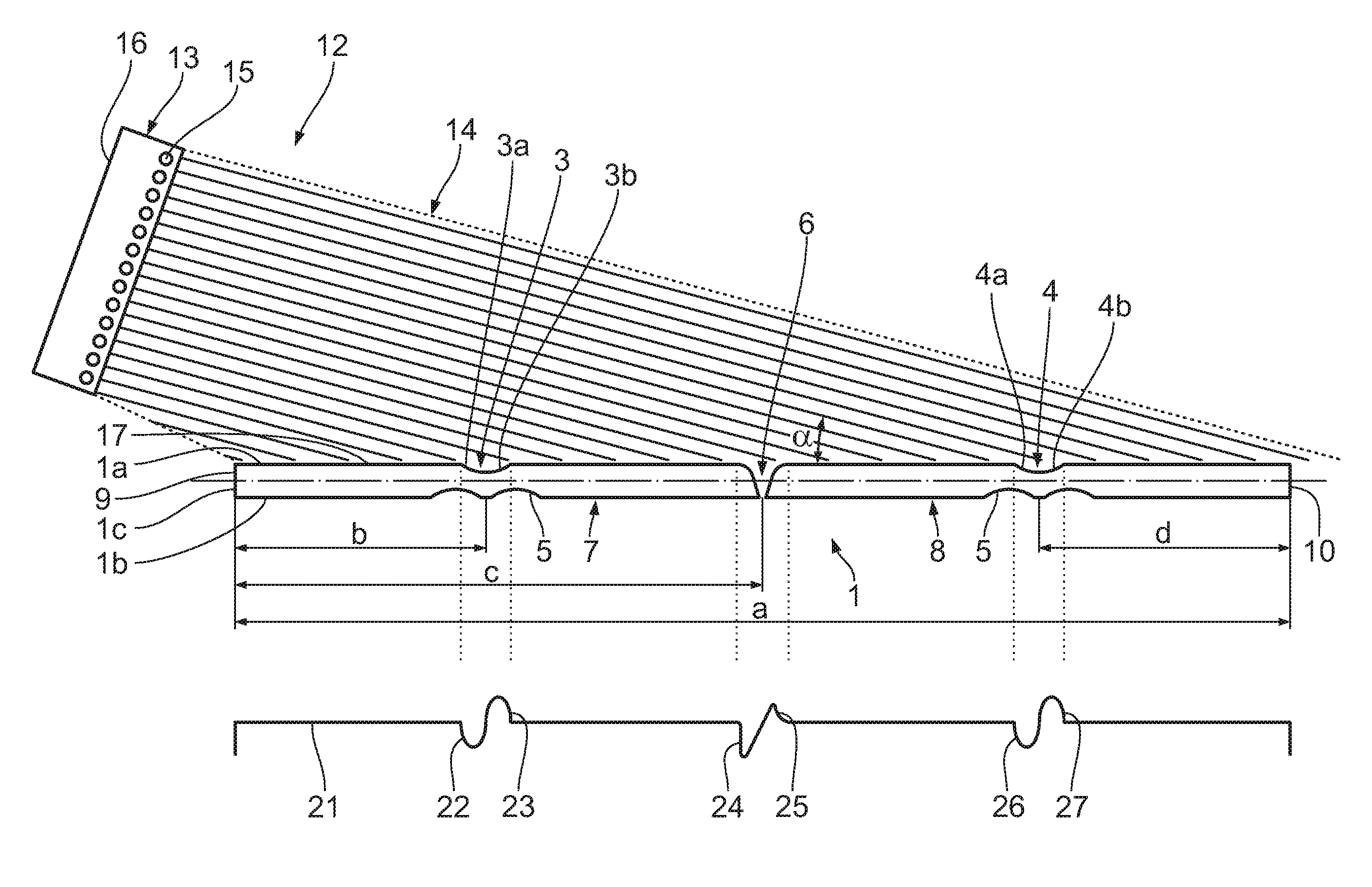

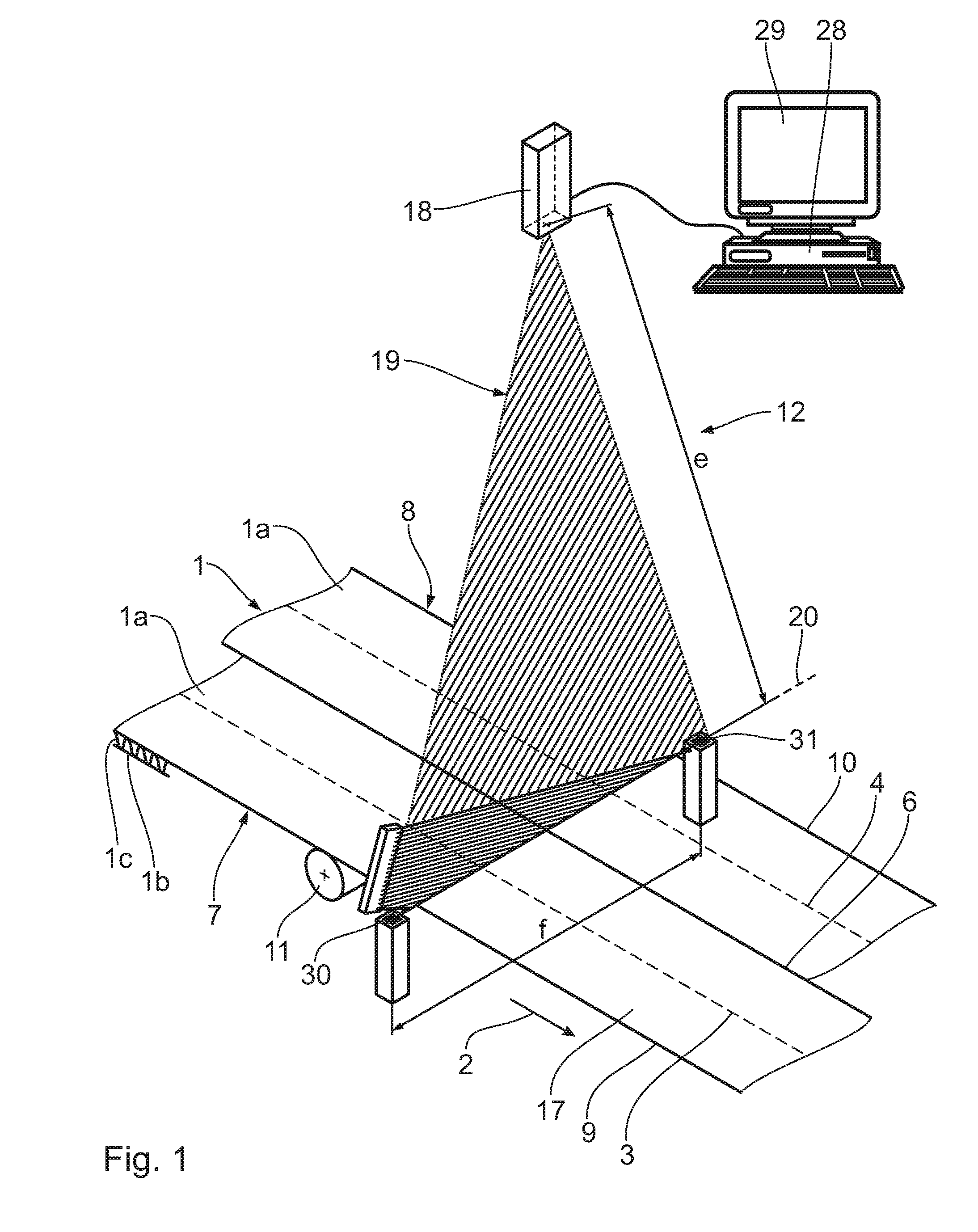

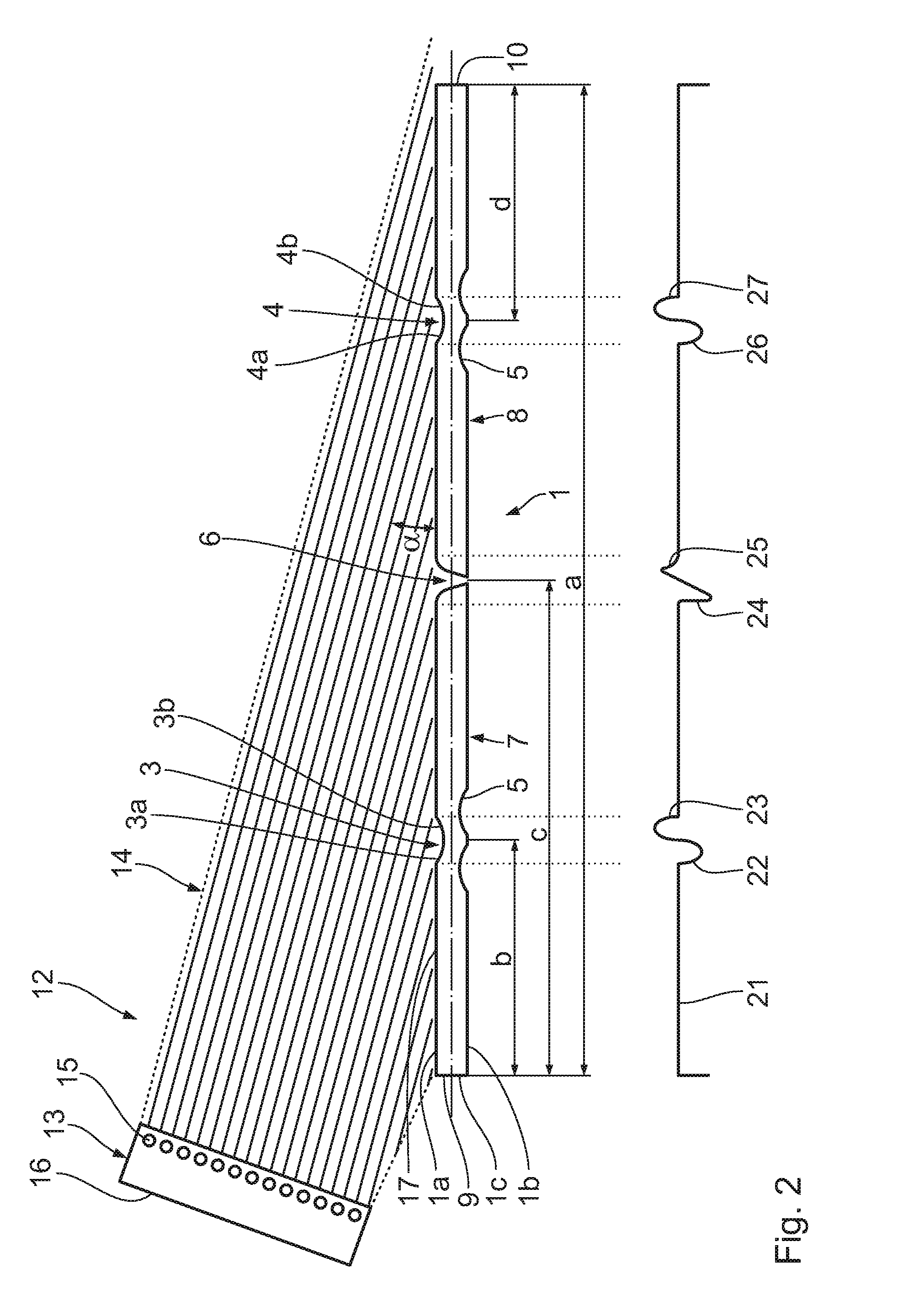

Apparatus for detection of the accuracy of format of a web of corrugated cardboard

InactiveUS20090091761A1Compensation for measurement errorsMechanical working/deformationOptically investigating flaws/contaminationCardboardEngineering

An apparatus for detection of the accuracy of format of a web of corrugated cardboard moved in a conveying direction comprises a light source which emits a light band to the surface of the web of corrugated cardboard in a direction crosswise of the conveying direction and at an angle to the web of corrugated cardboard. A measuring camera detects the different light intensities of the light reflected by the plane portions and the profiled patterns of the web of corrugated cardboard. This electronic image in the camera is evaluated by an evaluation device for determining the distance of the profiled patterns from each other.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

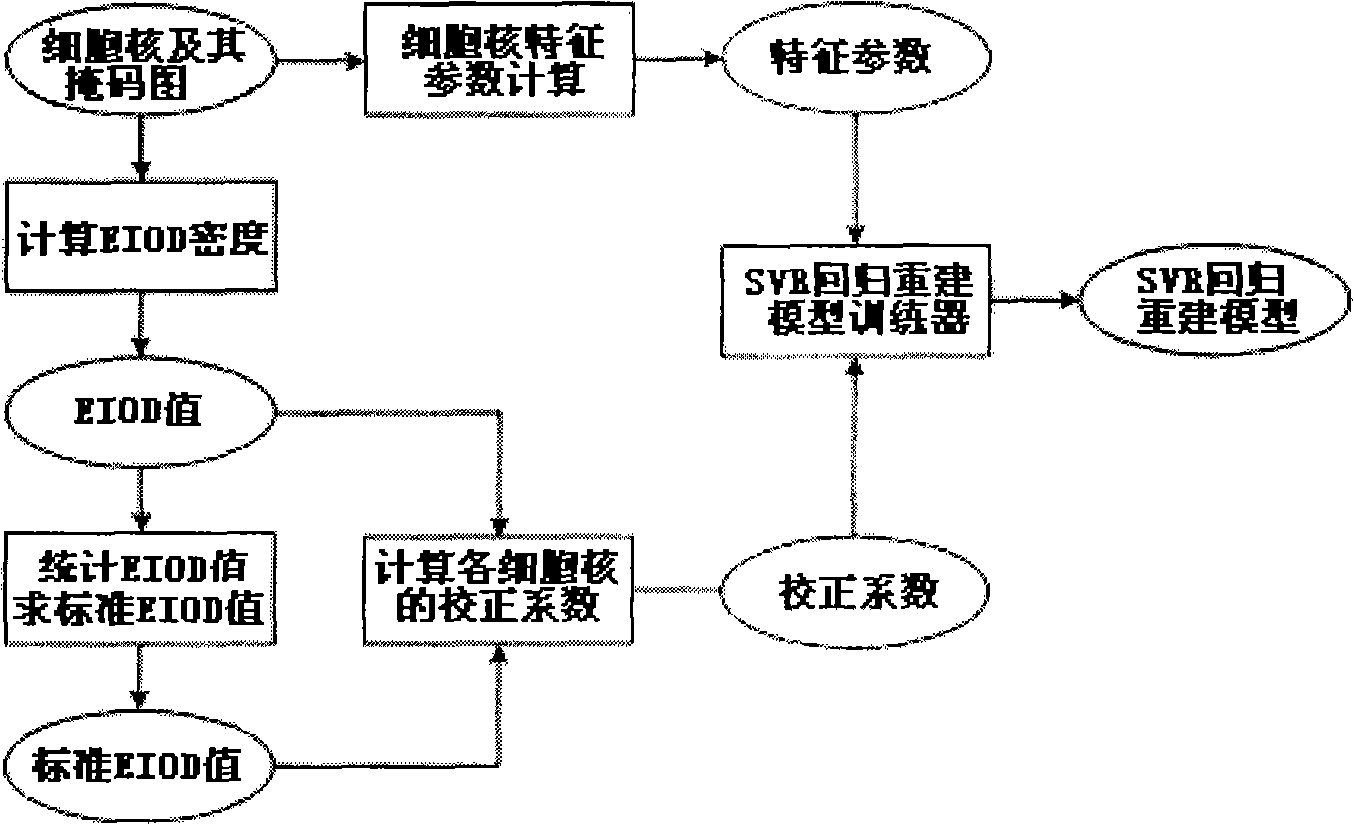

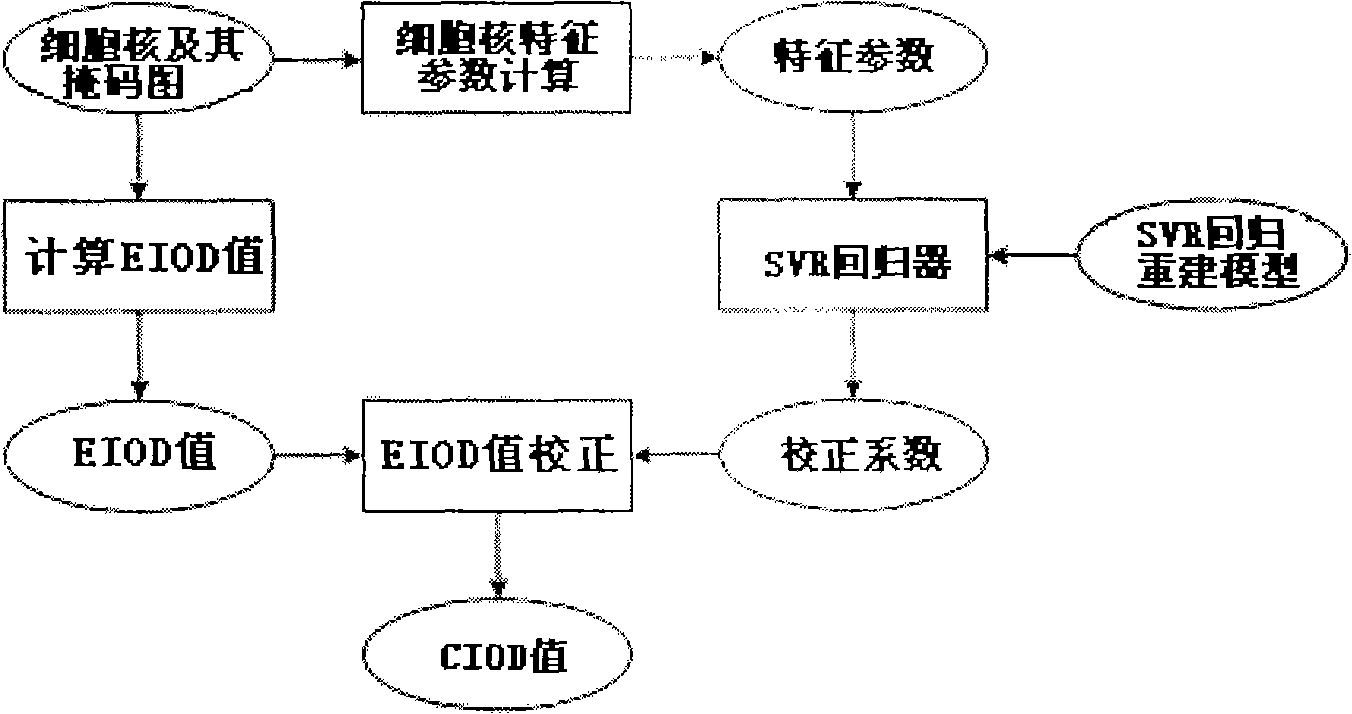

Correct measurement method for nucleus DNA matter content in cell quantitative investigation

InactiveCN101492740AImprove accuracyImprove anti-interference abilityImage analysisMicrobiological testing/measurementFeature parameterMathematical morphology

The invention provides a method for accurately measuring the content of karyon DNA substances in quantitative analysis of cells, including the following steps: expansion algorithm mathematical morphology is used for obtaining EIOD value; statistical method is used for obtaining EIOD standard value so that the IOD correction coefficient of a single karyon is calculated; the characteristic parameters and correction coefficient of karyon are used for training the regression model of the correction coefficient by SVR algorithm, and the model and the SVR algorithm are used for returning and reconstructing CIOD value of cells; the CIOD value of reference karyon is used for converting the content of DNA substances of each karyon. The method improves the accuracy and anti-interference of measuring the content of DNA substances; the conversion method of the content of DNA substances in the invention can obtain the content of DNA substances which can be easily understood and utilized, is the same as medical expression, and is conveniently applied to diagnosis or research.

Owner:WUHAN LANDING INTELLIGENCE MEDICAL CO LTD

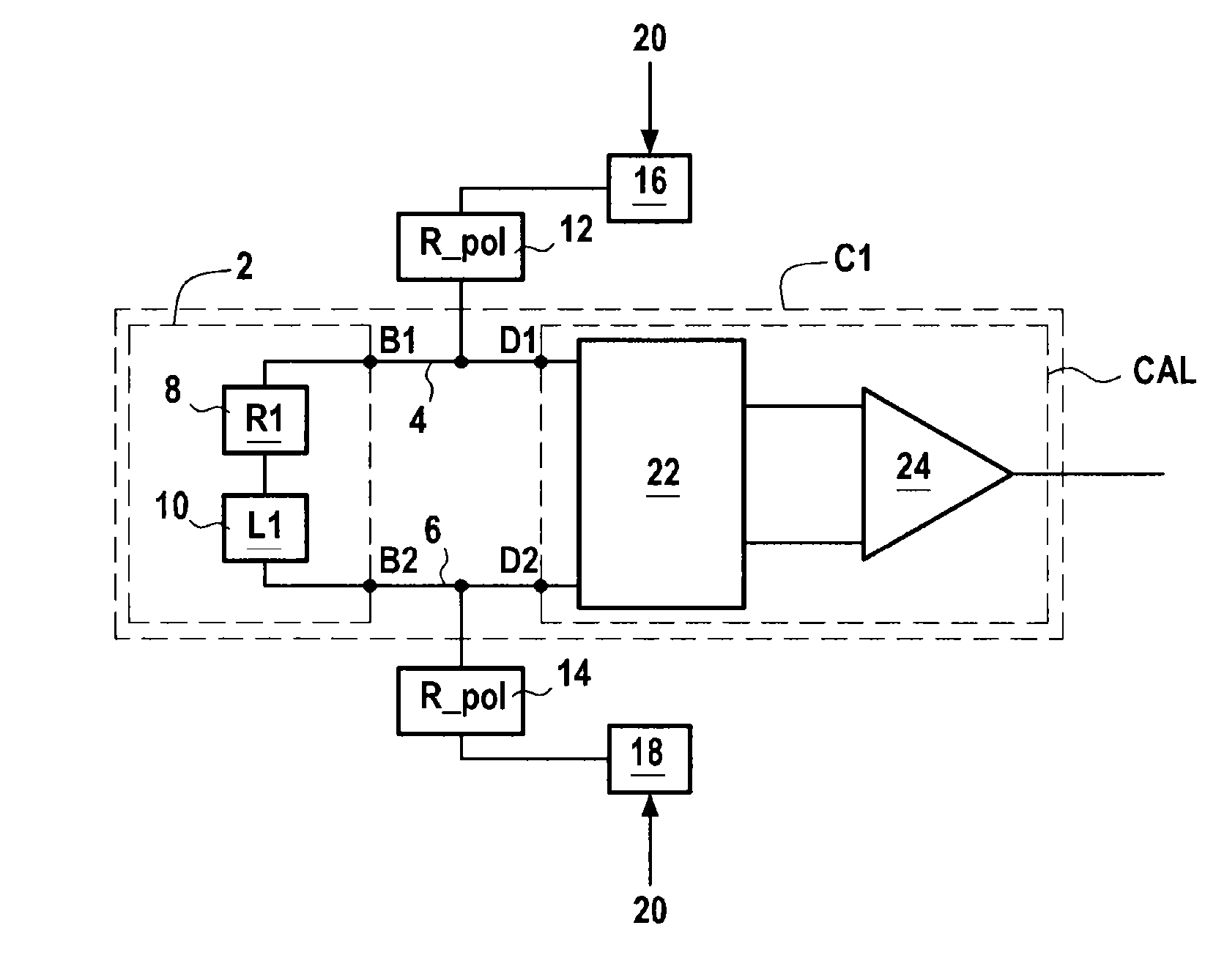

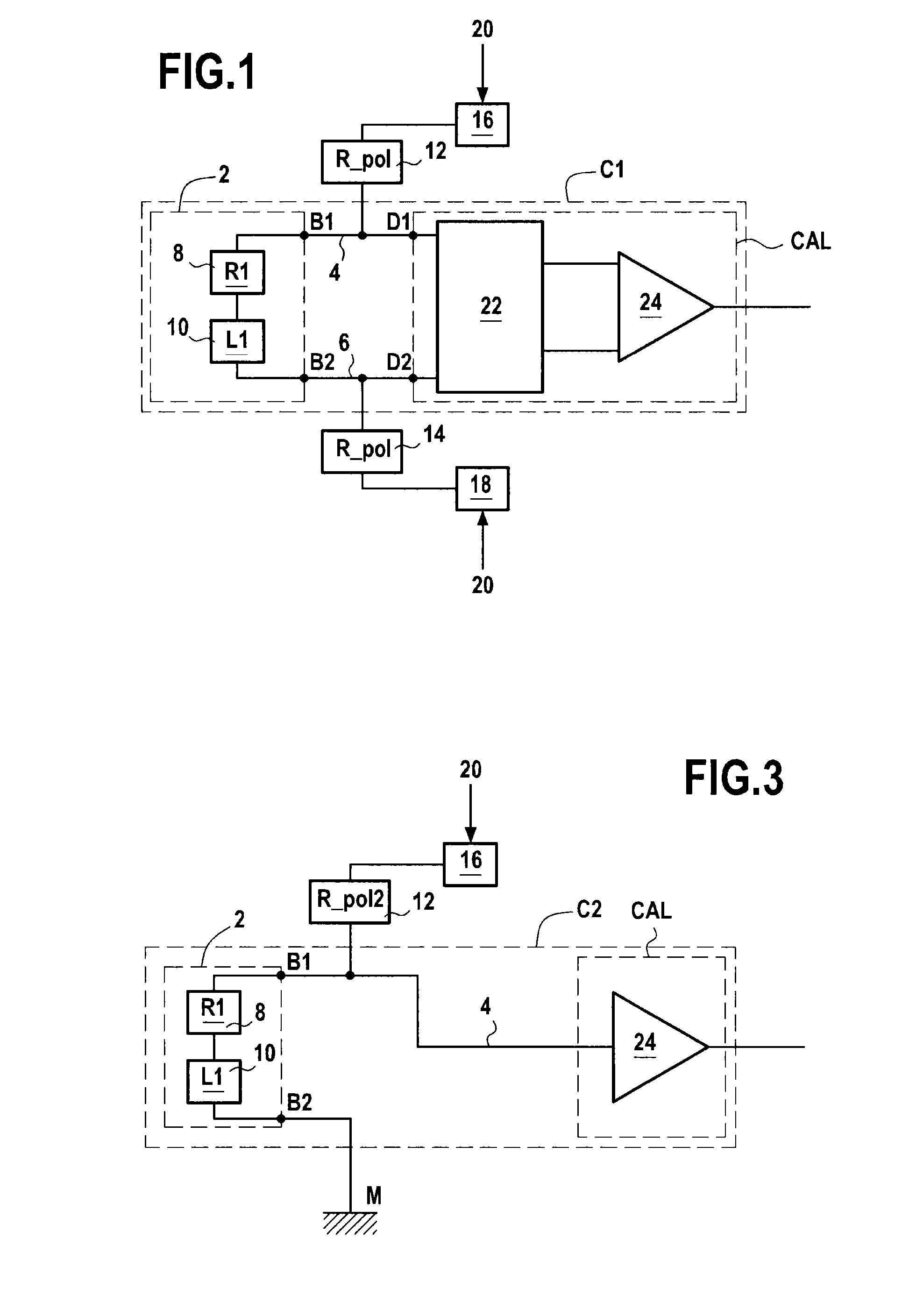

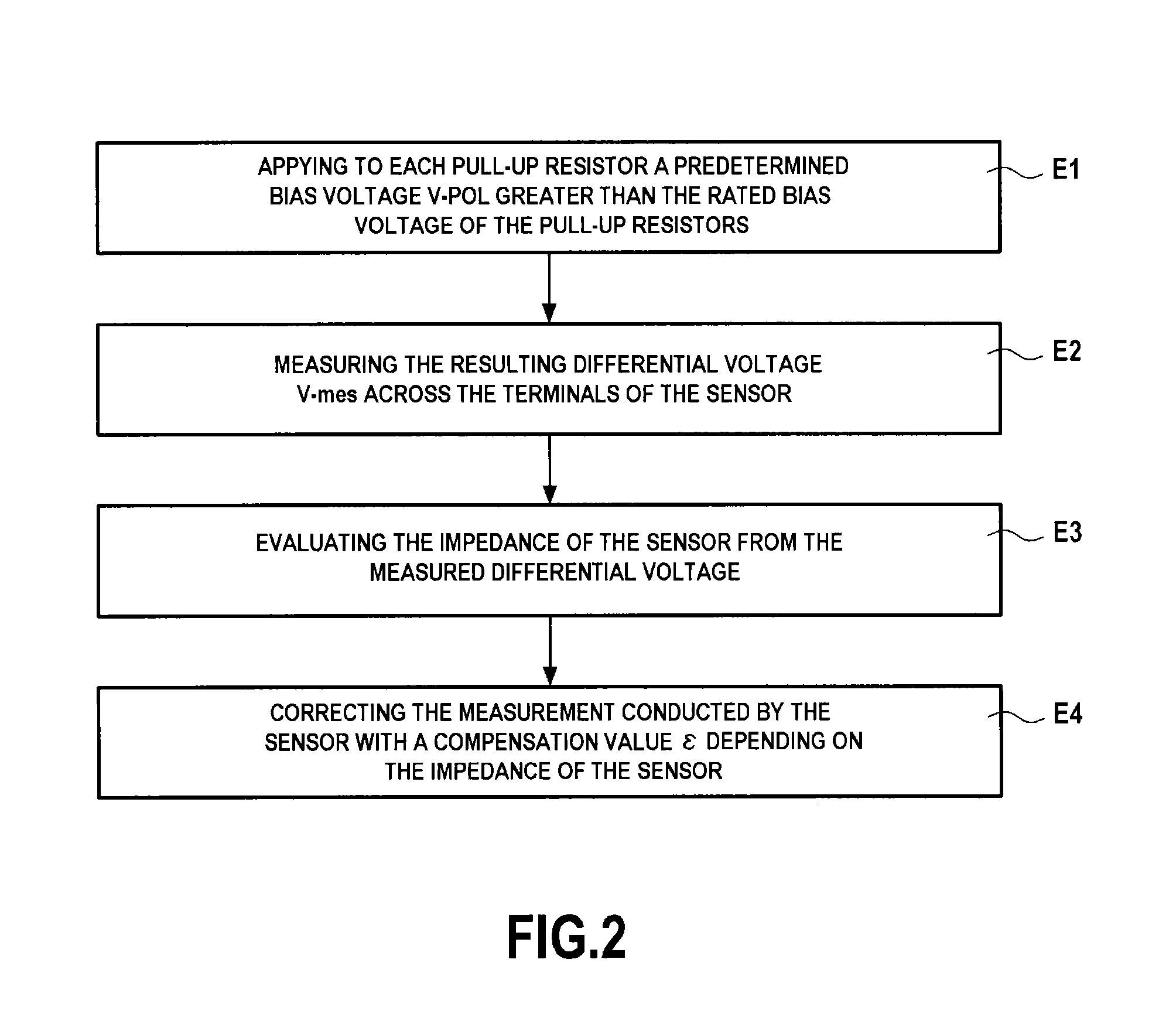

Method for correcting the voltage measured across the terminals of a sensor

ActiveUS20140145737A1Compensation for measurement errorsResistance/reactance/impedenceForce measurementMeasuring outputEngineering

A method for correcting measurement of a voltage across output terminals of a sensor, the sensor configured to be assimilated with an assembly including a generator and a series resistance, each of the output terminals being respectively connected to a pull up / down resistor. The method includes: evaluating the series resistance of the sensor, including measuring first and second voltages across the output terminals when first and second bias voltages are applied on each pull up / down resistor; evaluating the series resistance from the first and second voltages; and correcting, from the series resistance, a voltage measured across the output terminals of the sensor to infer therefrom a corresponding voltage generated by the generator.

Owner:SAFRAN ELECTRONICS & DEFENSE

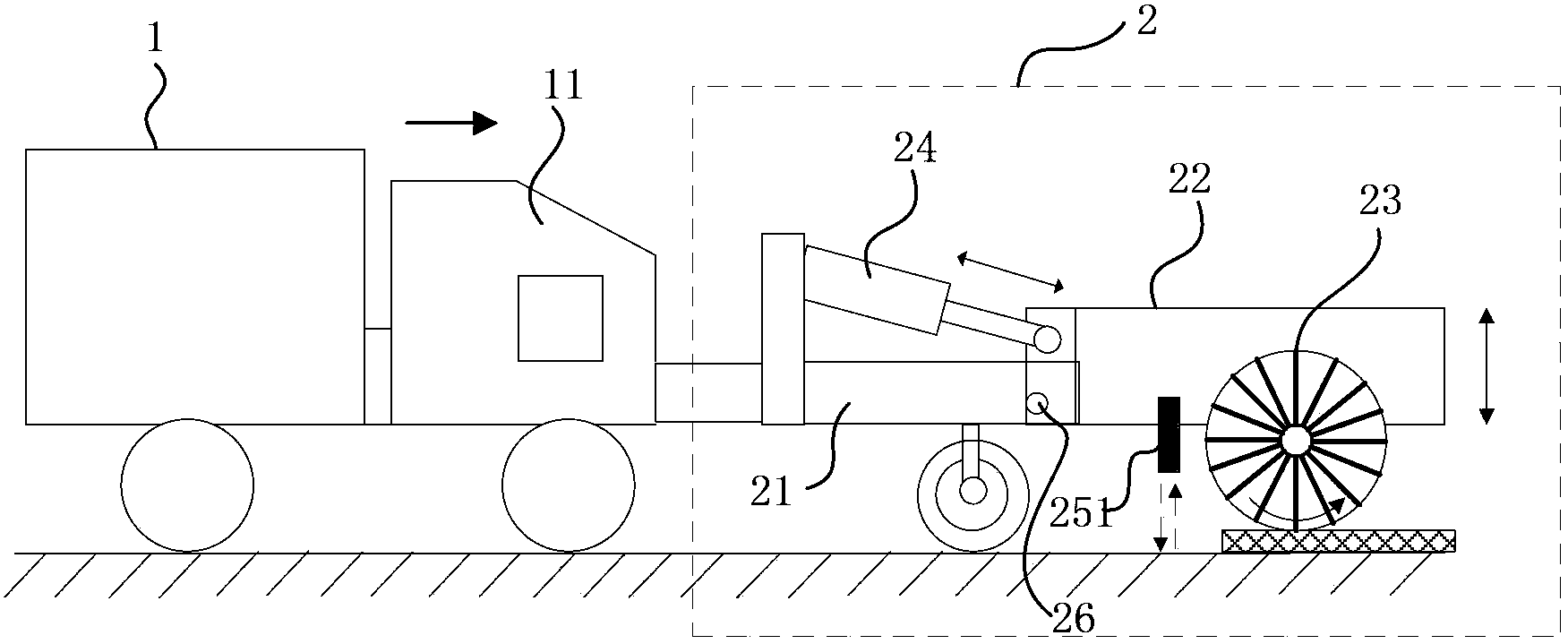

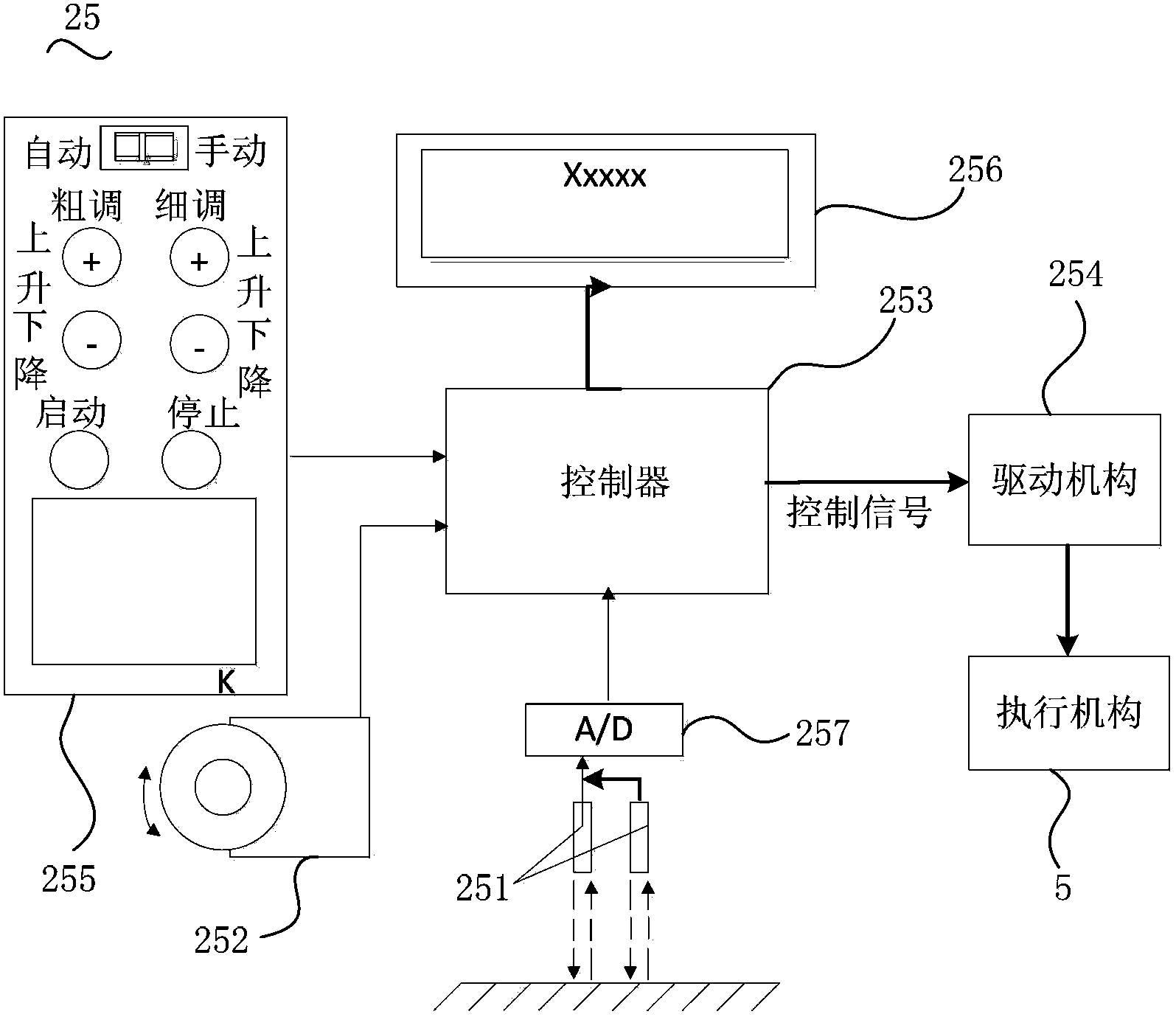

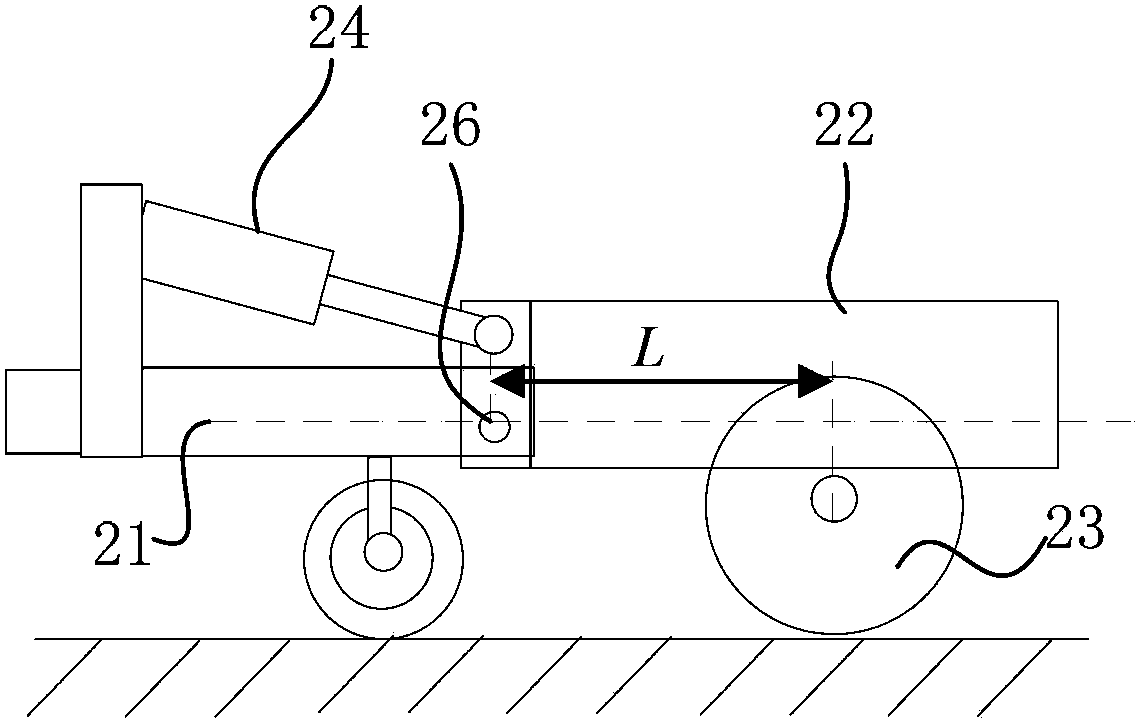

Snow removal truck, snow removal truck rolling brush elevating control device, and snow removal truck rolling brush elevating control method

ActiveCN104111660AStable ground clearanceSuitable for tight pressureControl using feedbackSnow cleaningSnow removalTerrain

The present invention relates to a snow removal truck, a snow removal truck rolling brush elevating control device, and a snow removal truck rolling brush elevating control method. The snow removal truck comprises a truck body and a snow removing device arranged at the front end of the truck body, and the snow removing device comprises a main rack, a rolling brush rack in hinge joint with the main rack, a rolling brush, an execution mechanism for driving the rolling brush to rotate, and a rolling brush elevating control device. The rolling brush elevating control device comprises a first sensor used for detecting the rotation angle of the rolling brush rack, a second sensor used for detecting the terrain clearance of the rolling brush directly and a controller. The controller calculates an actual height value according to the data detected by the first and second sensors, compares the actual height value with a preset height set value, operates a PID control algorithm, and controls the rolling brush to elevate to a set height according to the calculation result. According to the snow removal truck rolling brush elevating control device and the snow removal truck rolling brush elevating control method, the terrain clearance of the snow removal truck can be stable, and the operation personnel do not need to operate manually outside a cab in the cold weather, thereby improving the working comfort level of the workers.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

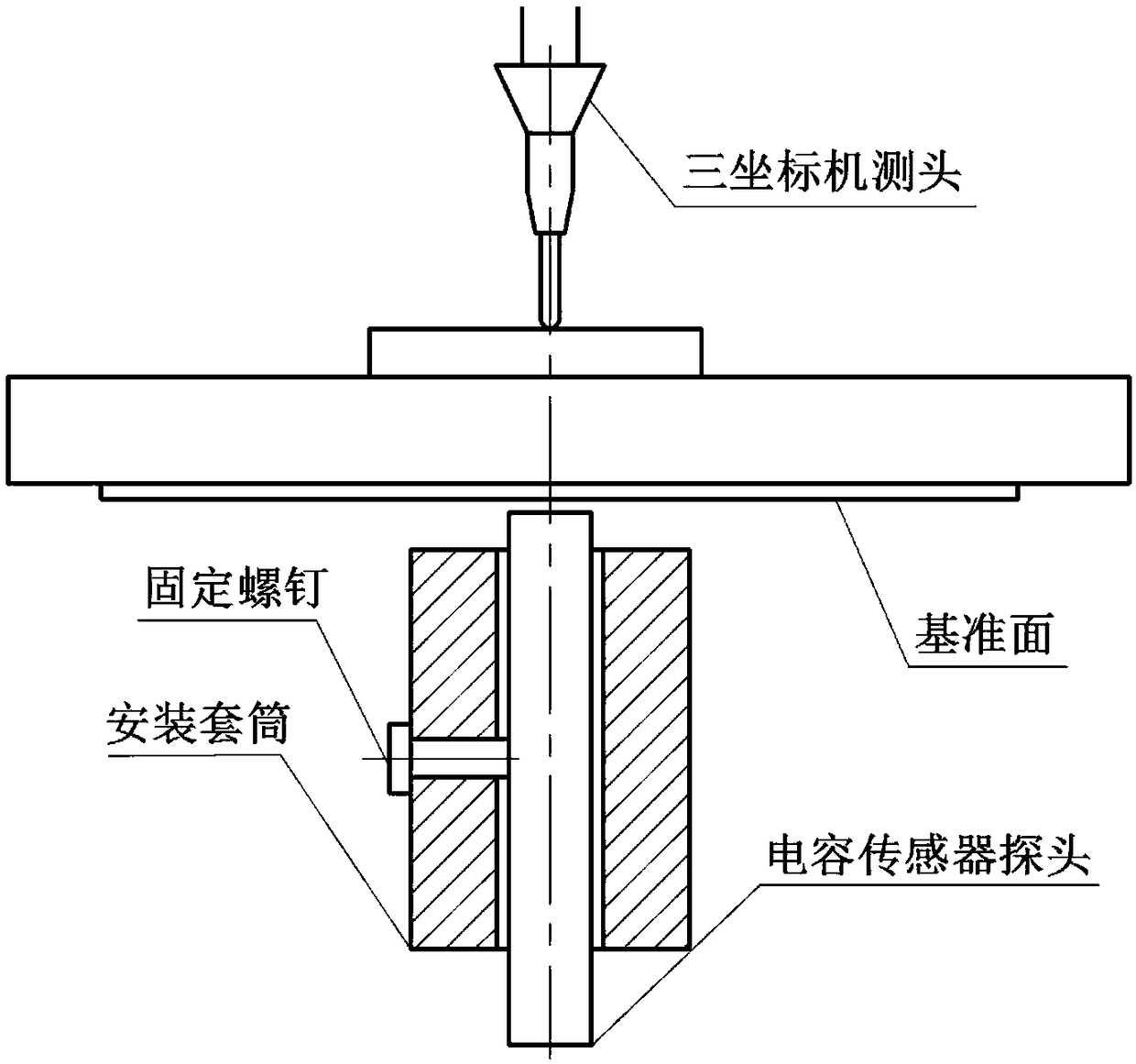

High-precision two-dimensional worktable Z-axis error compensating method and system thereof

ActiveCN109443203AHigh positioning accuracyCompensation for surface errorUsing optical meansWork benchesThermal deformationEngineering

The invention discloses a high-precision two-dimensional worktable Z-axis error compensating method and a system thereof, wherein the Z-axis error compensating device comprises a capacitor displacement sensor (602) and a reference surface (604). The compensating device is used in cooperation with a two-dimensional worktable, wherein the reference surface (604) is used for being set in a target area of the two-dimensional worktable. The capacitor displacement sensor (602) is used for obtaining the displacement of the reference surface (604) in a Z-axis direction through detecting the distance between the capacitor displacement sensor (602) and the reference surface (604). The displacement is the Z-axis error at the target area caused by the two-dimensional worktable, thereby compensating the Z-axis error of the two-dimensional worktable based on the displacement. According to the method and the system, through improving the principle of the Z-axis error compensating method and a means for measuring the Z-axis error, the reference error in the Z-axis direction can be effectively overcome, thereby realizing measurement and compensation of the Z-axis direction error caused by thermal deformation, guide rail precision, mounting error, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

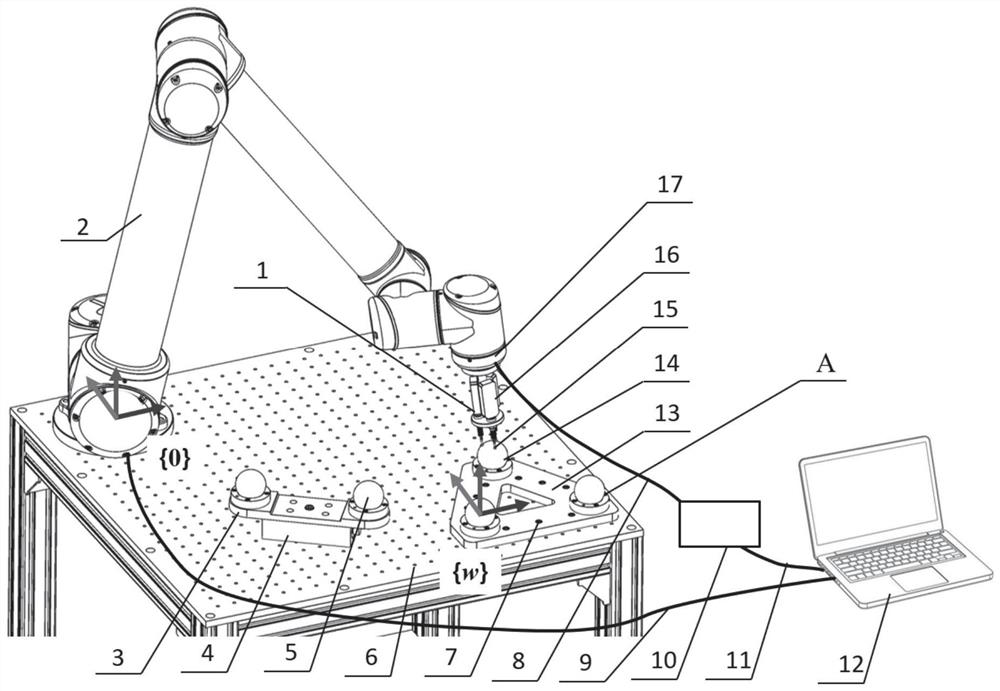

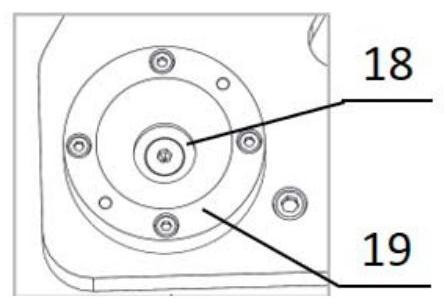

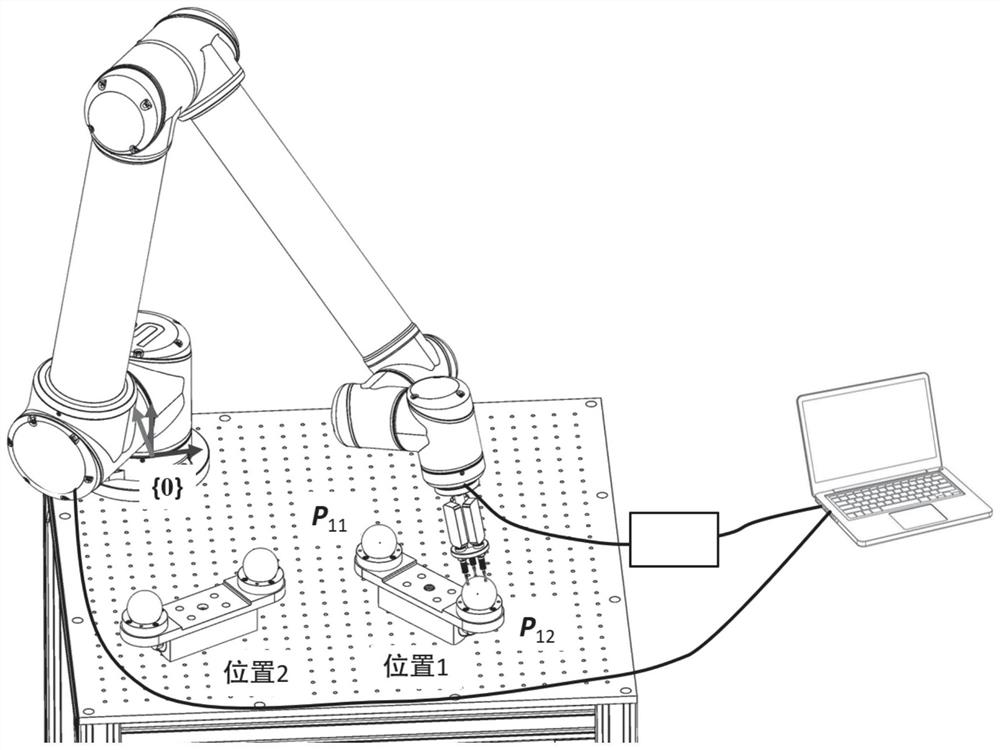

Industrial robot step-by-step calibration system and method

PendingCN112847341ALow costLarge measuring rangeProgramme-controlled manipulatorTotal factory controlSimulationKinematic calibration

The invention discloses an industrial robot step-by-step calibration system and method. The calibration system comprises a tail end measuring device arranged on a robot flange, as well as a movable double-ball device, a fixed three-ball-seat device, a counter, a computer and the like which are matched with a robot. The calibration method comprises first-step calibration: calibrating kinematics parameters of the robot by using a wide-area distance error; and second-step calibration: based on the result of the first-step calibration, calibrating the pose of a robot-based coordinate system by using a position error. Furthermore, the calibration method can also comprise the following steps: firstly, calibrating the measurement error of the tail end measurement device; and then carrying out the first-step calibration and the second-step calibration. The calibration system has the advantages of being portable, low in cost and the like; meanwhile, the calibration method improves the precision and reliability of kinematics calibration, calibration of the robot-based coordinate system is achieved, then the absolute positioning precision of the robot is improved, and the application range of the robot in precision manufacturing is widened.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

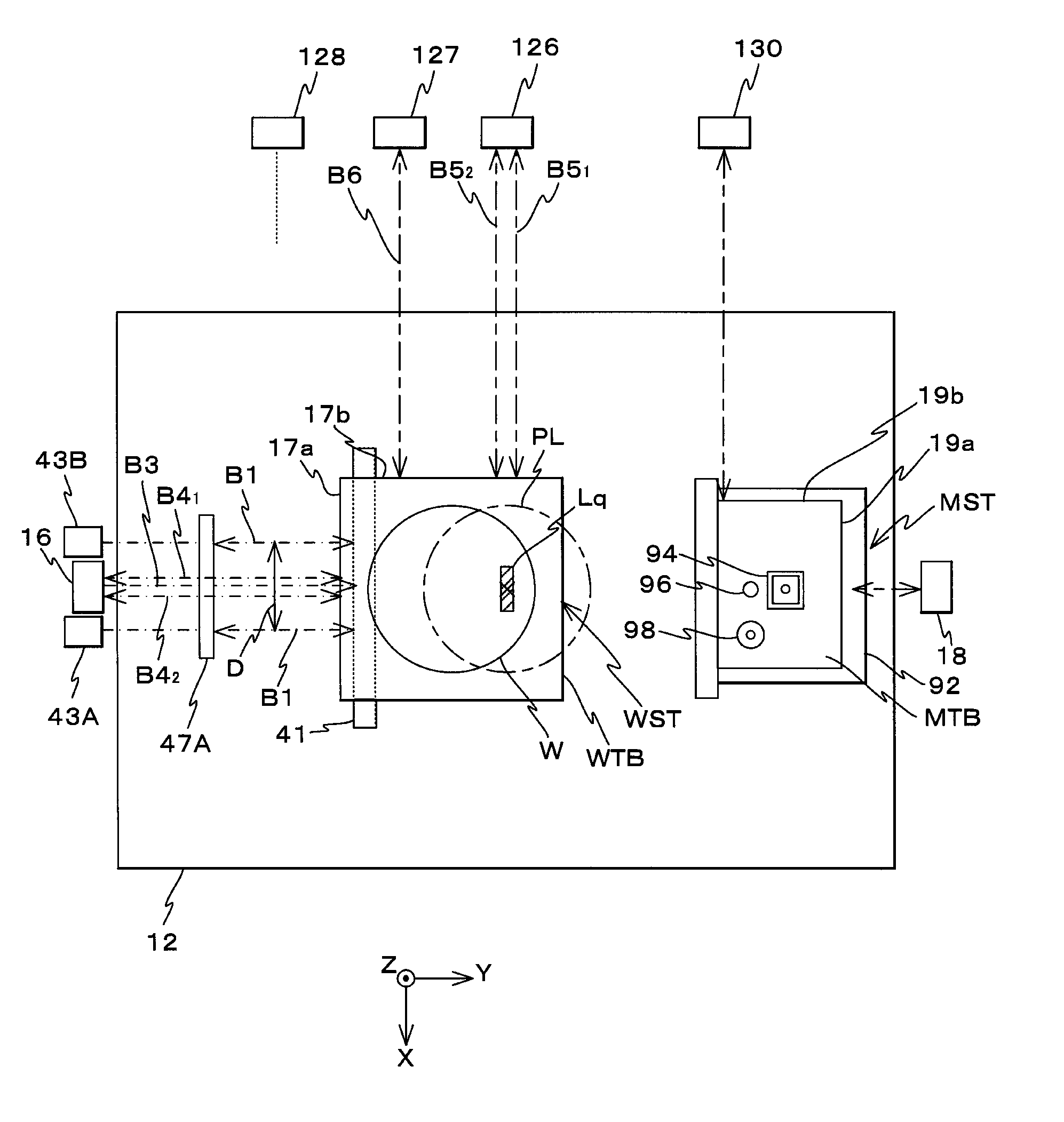

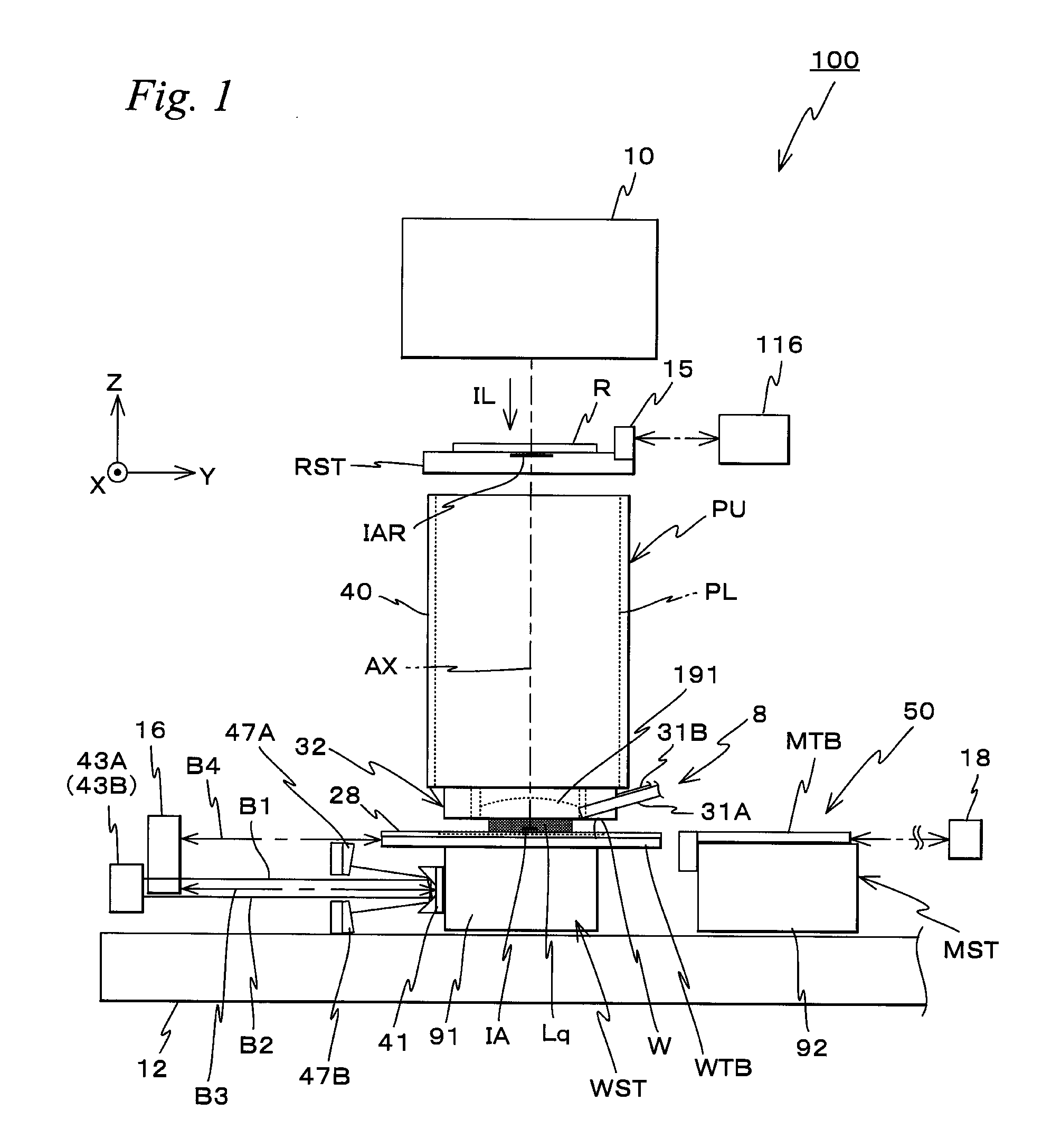

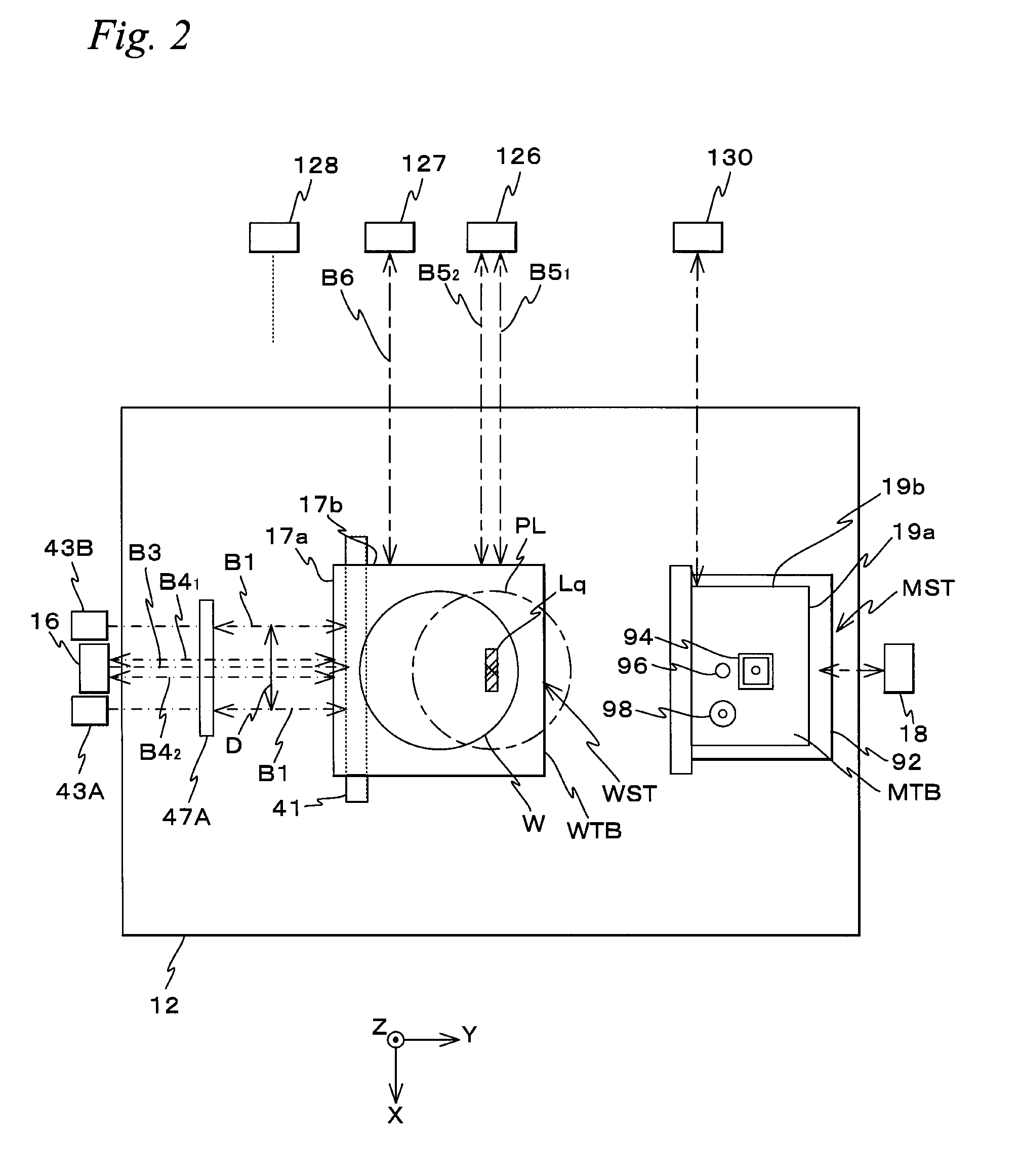

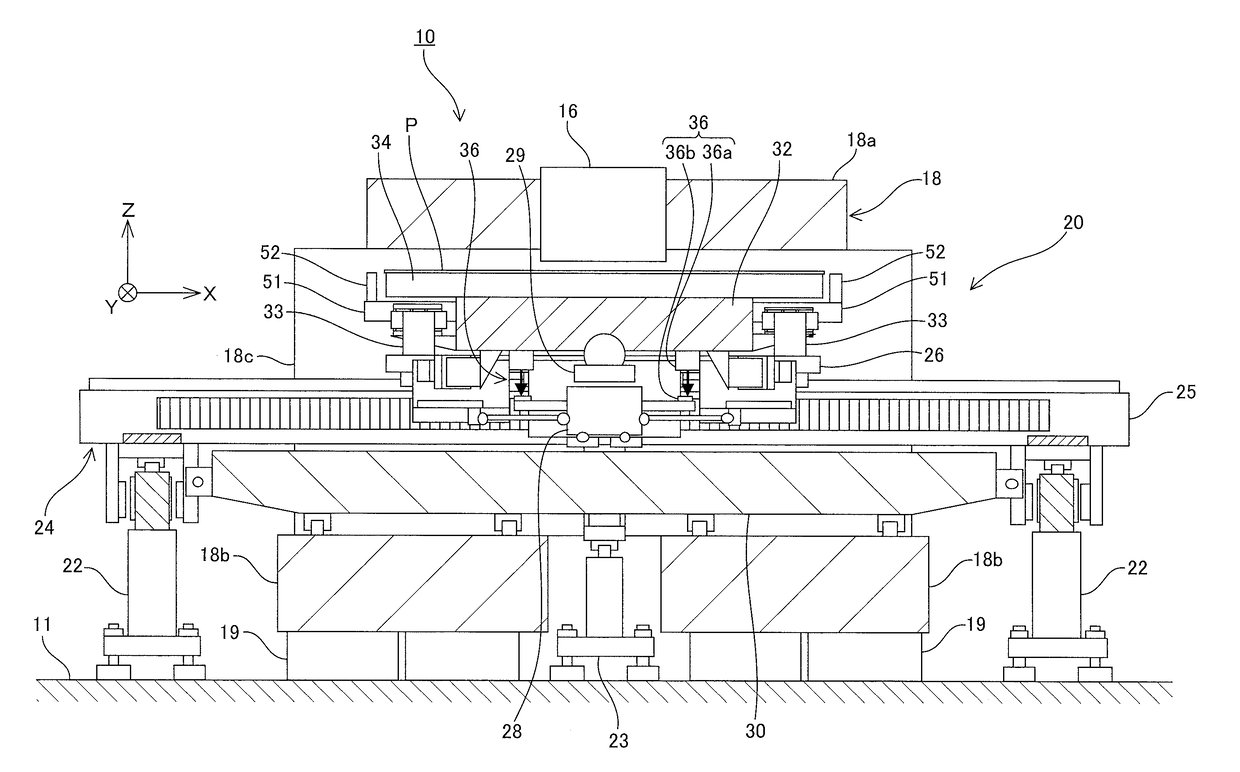

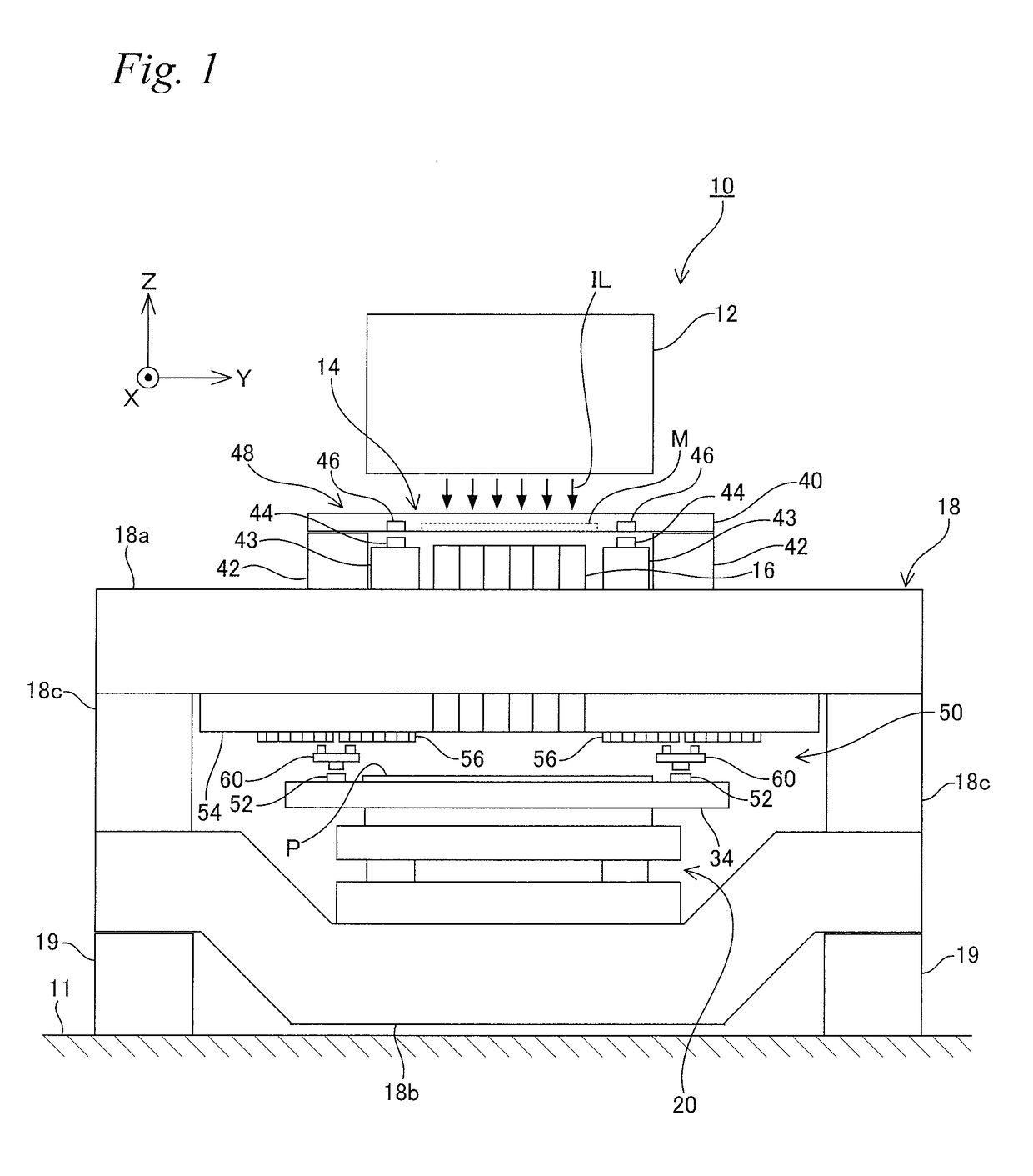

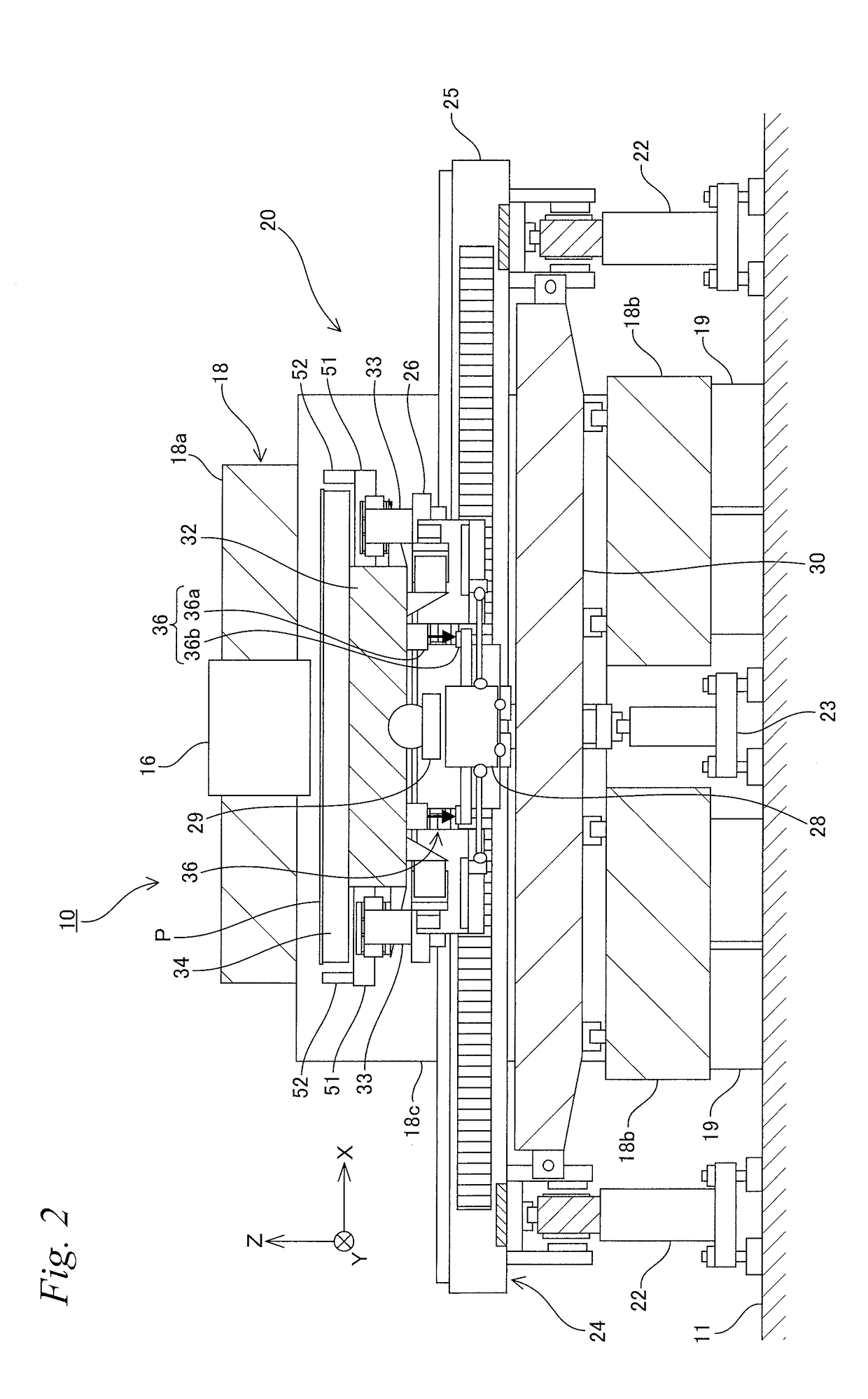

Exposure apparatus and exposure method, and flat panel display manufacturing method

ActiveUS20180284619A1Compensation for measurement errorsPhotomechanical exposure apparatusMicrolithography exposure apparatusObservational errorInformation control

A control system controls a drive system of a substrate holder, based on correction information to compensate for measurement error of a measurement system including an encoder system that occurs due to movement of at least one of a plurality of grating areas (scale), a plurality of heads and a substrate holder, and position information measured by the measurement system, and a measurement beam from a head of each of the plurality of heads moves off from one of the plurality of grating areas and switches to another adjacent grating area, during the movement of the substrate holder in the X-axis direction.

Owner:NIKON CORP

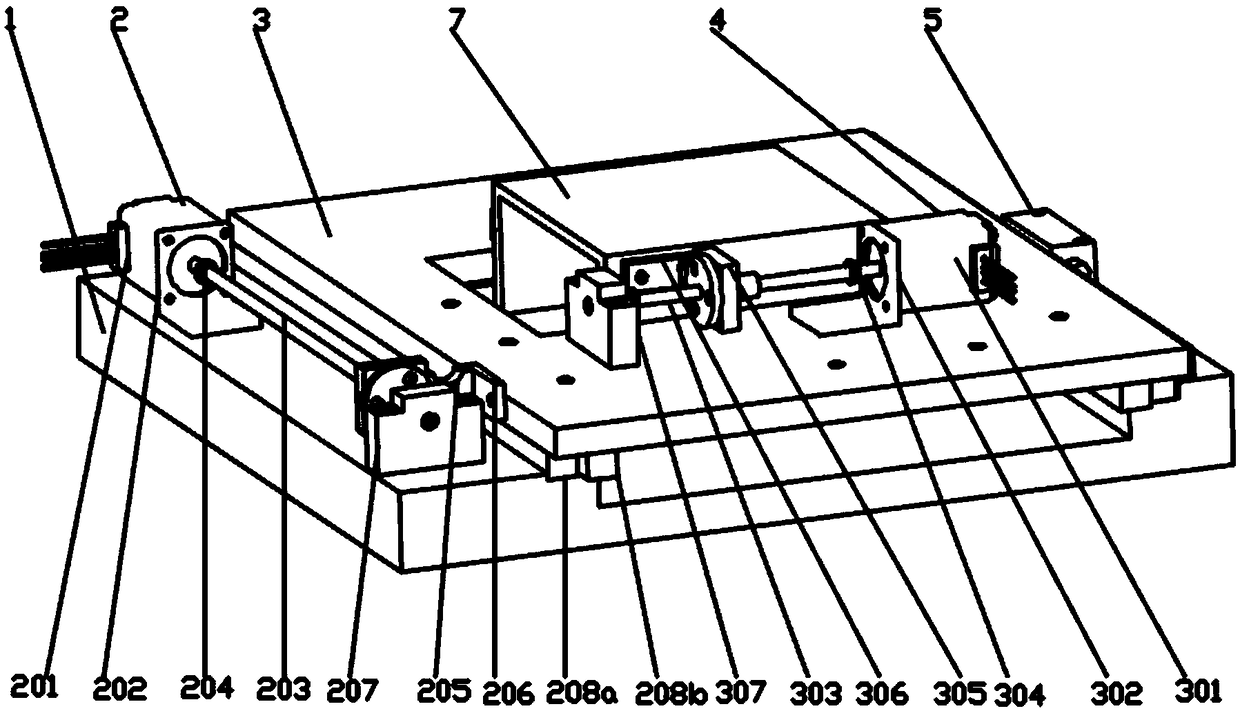

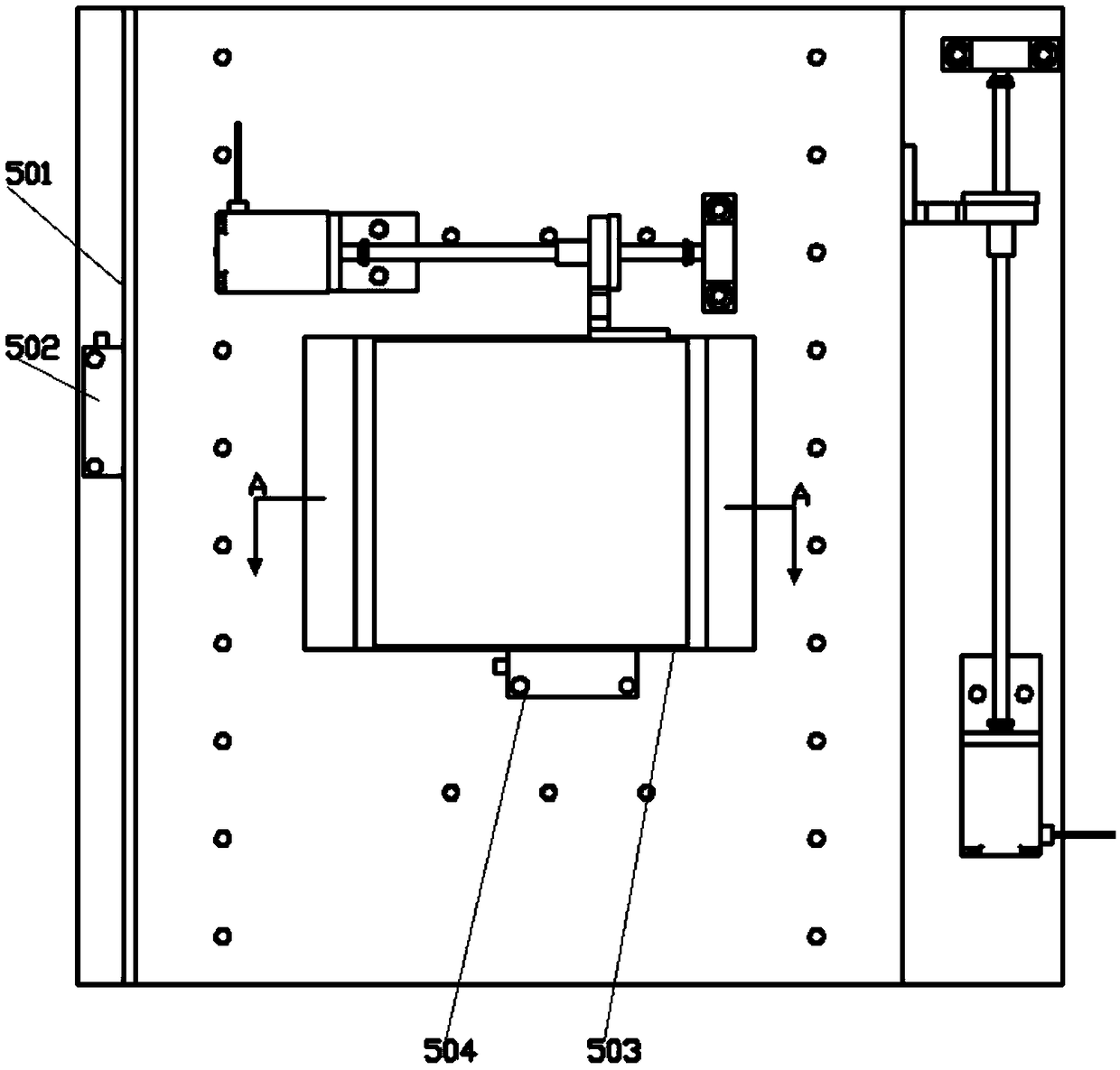

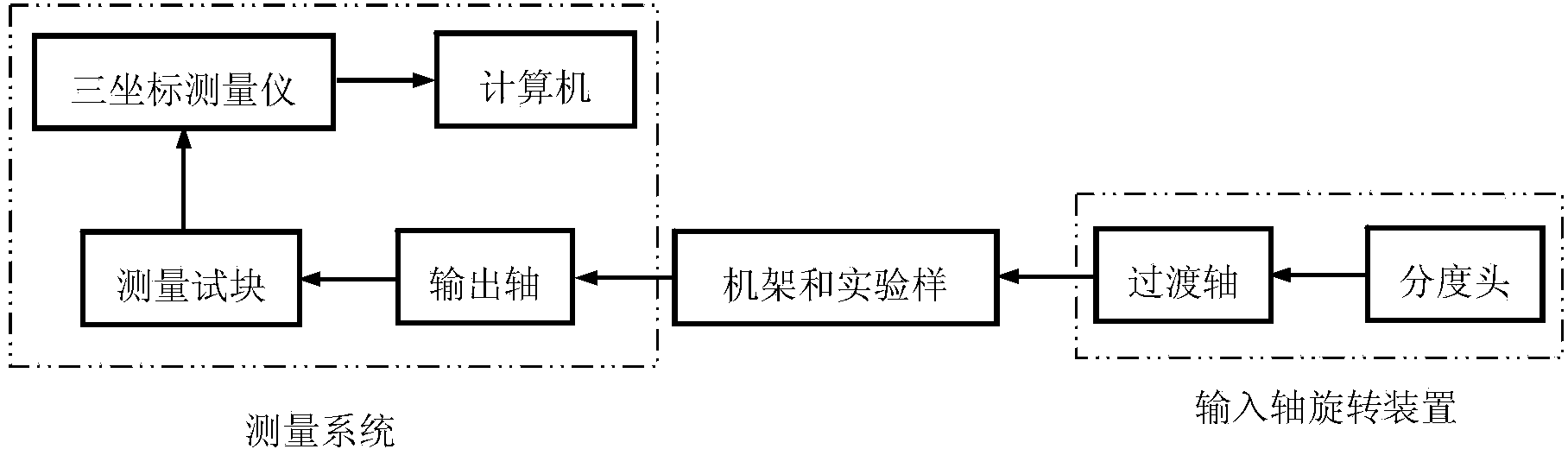

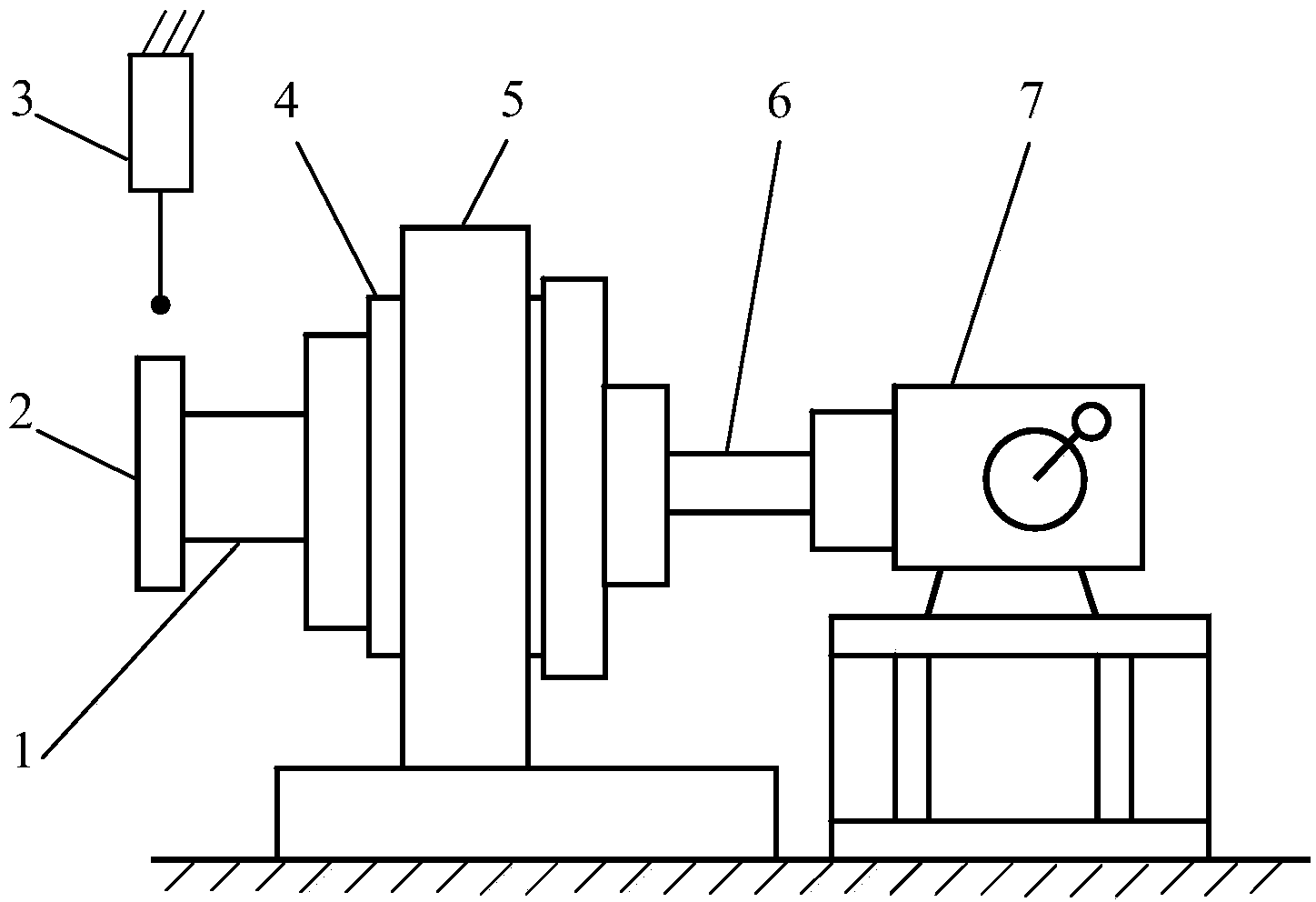

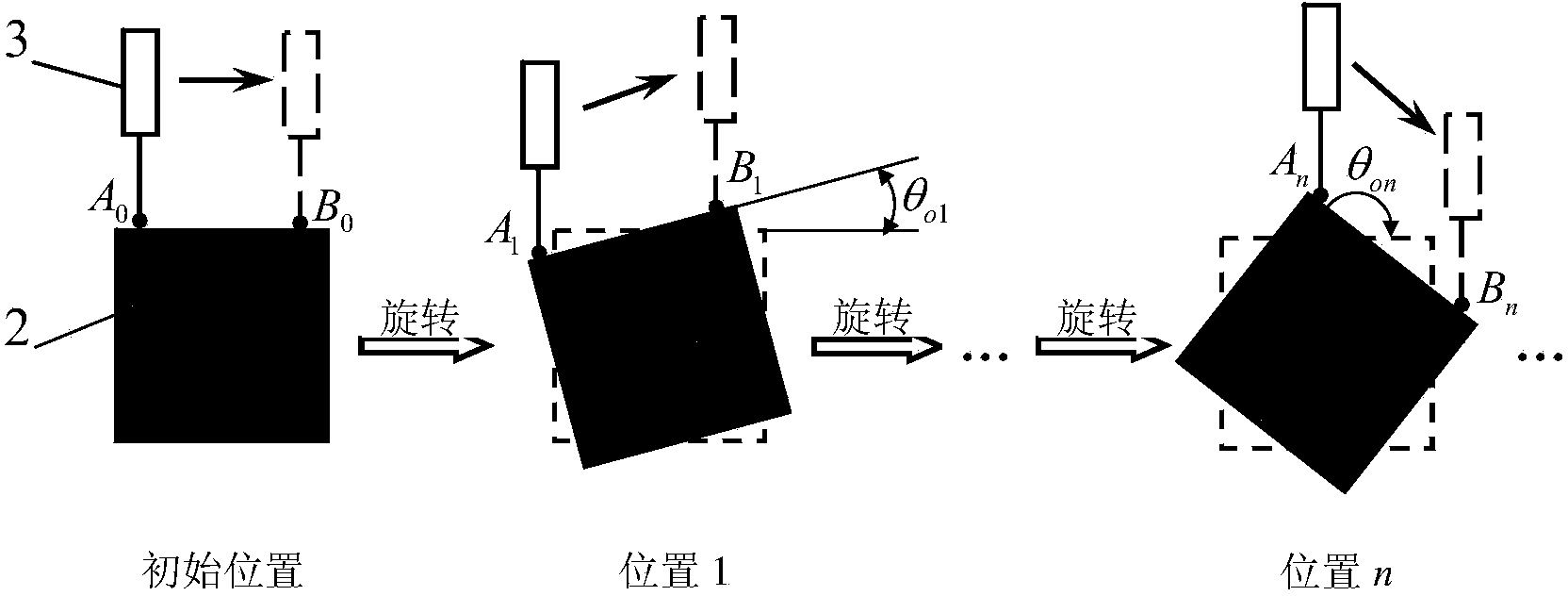

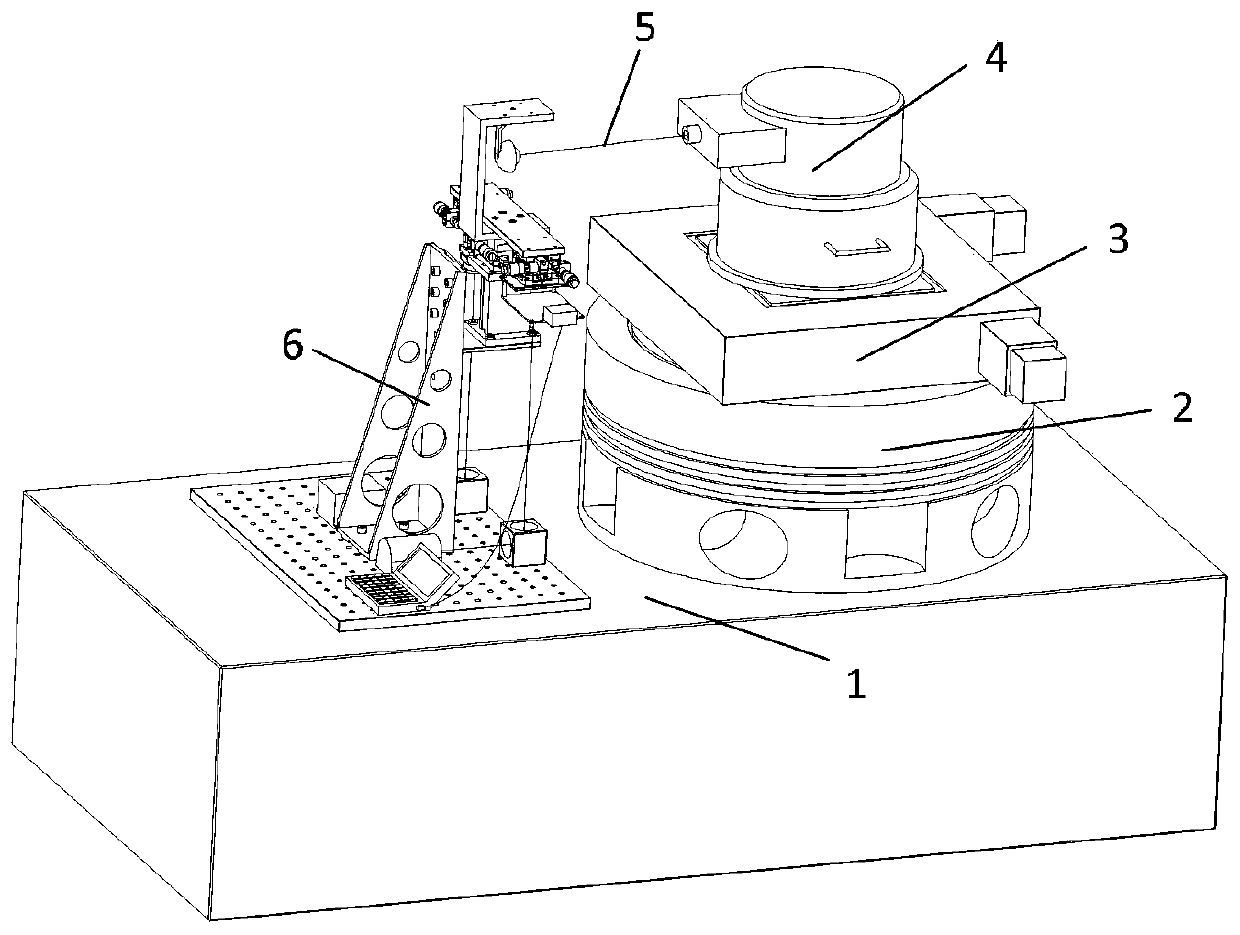

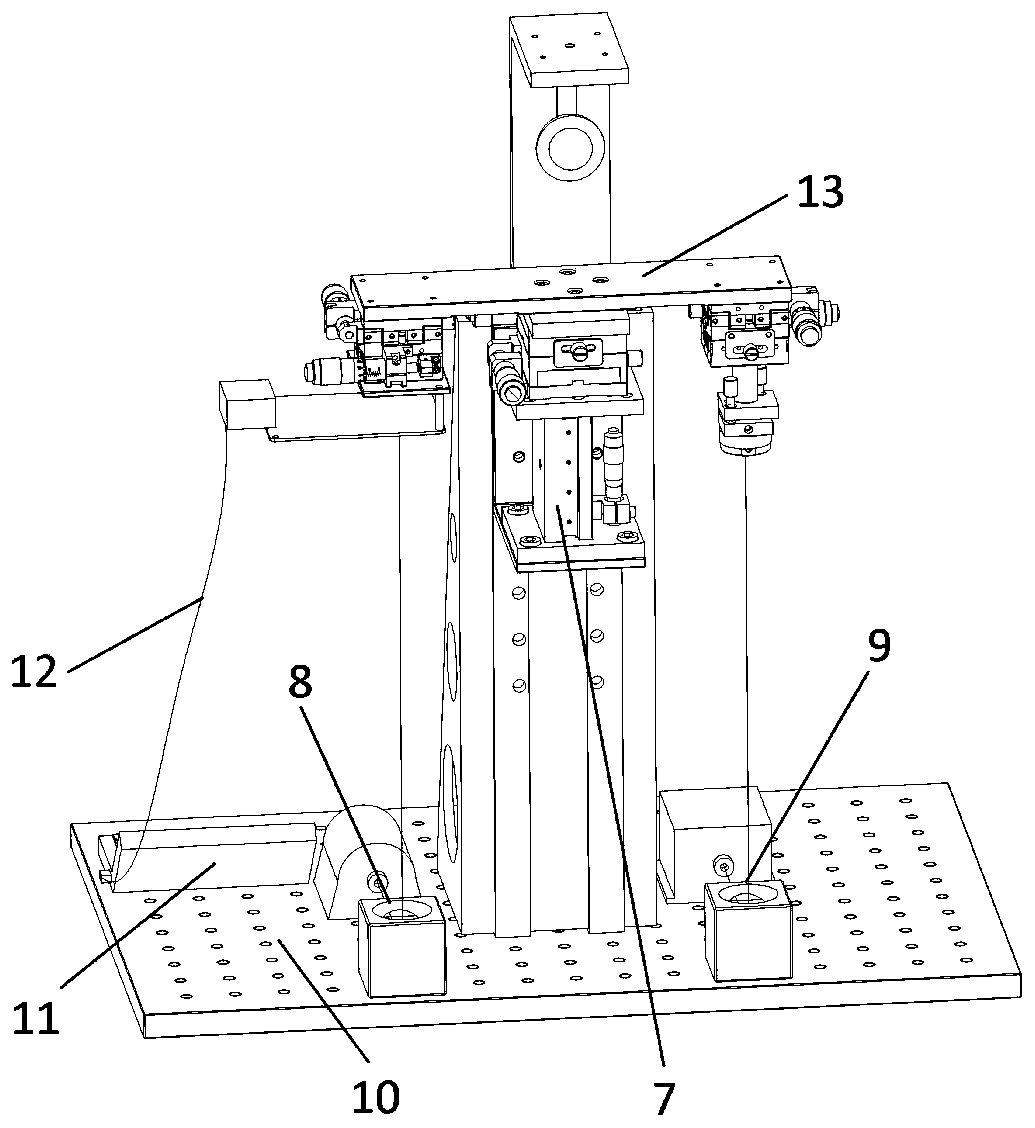

Experiment table and method for testing transmission errors of high-speed-ratio high-precision speed reducer

InactiveCN103759939AHigh measurement accuracyImprove general performanceMachine gearing/transmission testingObservational errorMeasuring instrument

The invention discloses an experiment table for testing transmission errors of a high-speed-ratio high-precision speed reducer. The experiment table is composed of an input shaft rotating device, a rack and a measuring system. The input shaft rotating device comprises a transition shaft and a dividing head. The measuring system is composed of an output shaft, a measuring test block and a three-dimensional measuring instrument. Both the rack and the dividing head are fixed to a worktable of the three-dimensional measuring instrument. The speed reducer to be measured is fixed to the rack. The output end of the speed reducer to be measured and the measuring test block are connected together through the output shaft. The measuring test block is in the shape of a regular polygon prism. The measuring test block is rotated by a first angle, the coordinates of two measuring points on the same measuring plane of the test bock are respectively measured through a probe of the three-dimensional measuring instrument, and the included angle between the projection of the connecting line of the two measuring points in the plane xoz of a rectangular coordinate system and the projection of the measuring test block at an initial position is the first angle. The experiment table has the advantages of being high in measuring accuracy, low in cost, simple in structure, easy to operate, capable of compensating for the measuring errors caused by assembling errors of the experiment table and the like.

Owner:TIANJIN UNIV

Measuring device for an optical measuring system

ActiveUS20180094914A1Compensation for measurement errorsAccurate measurementImage enhancementImage analysisMeasurement deviceOptical measurements

A measuring device for an optical measuring system, comprising a rigid body which comprises a probe body or a tool and on which a first optical marker is arranged. The measuring device further comprises a holding part for holding the measuring device by hand or for clamping the measuring device in a machine. At least a second optical marker is arranged on the holding part. Still further, the measuring device comprises a spring element which connects the rigid body to the holding part.

Owner:CARL ZEISS IND MESSTECHN GMBH

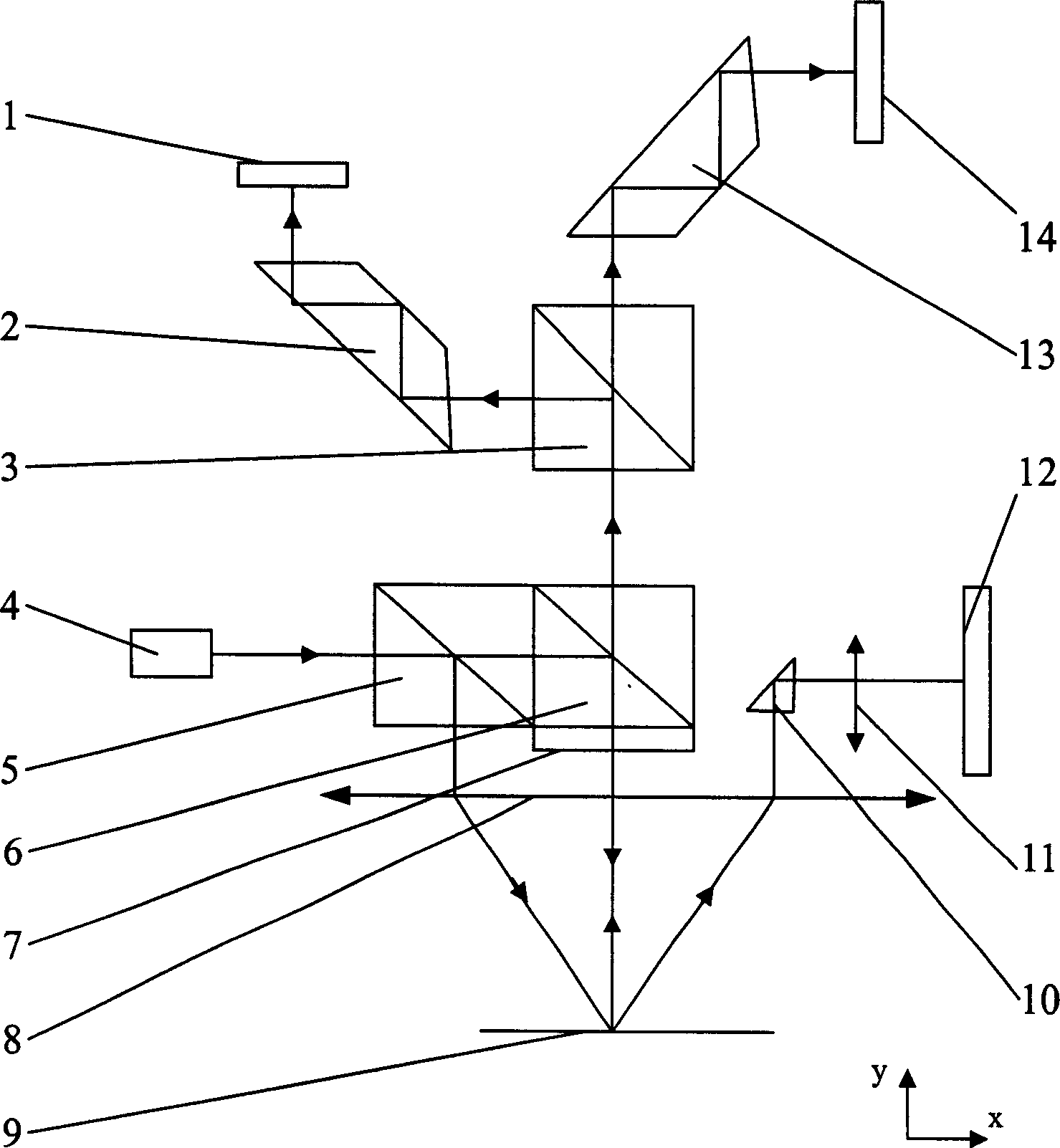

Triangle method range error compensation device based on angular measurement

InactiveCN1632463AHigh precisionCompensation for measurement errorsOptical rangefindersUsing optical meansObservational errorMeasurement device

This invention discloses a triangulation distance measurement compensation device based on angle measurement, which belongs to error compensation technique of triangulation distance measurement. The device comprises calibration light source, convex of the vertical incidence distance measurement device, reflection lens of the object surface to be measured or object surface and the reflection lens behind the convex and photoelectricity receiver. It is characterized by comprising optics angel measurement device. The said angel measurement device comprises a quarter wavelet, deflection light splitting lens, light splitting lens, two threshold angle prisms and two photoelectricity diodes.

Owner:TIANJIN UNIV

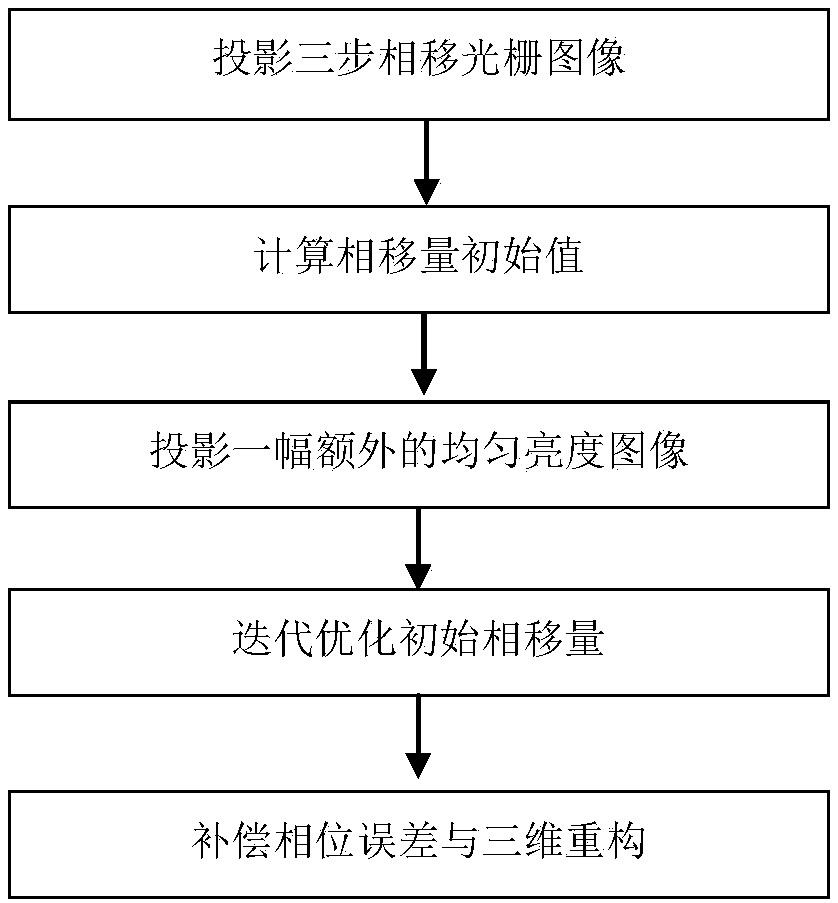

Facial shake compensation method for three-dimensional face measurement

ActiveCN108596008AAccurate measurementWith motion error compensation functionCharacter and pattern recognitionPattern recognitionObservational error

The invention discloses a facial shake compensation method for three-dimensional face measurement. The method includes the following steps that: a three-step phase shift method is used to project a three-step phase-shifted grating image to a measured object, the projected three-step phase-shifted grating image is shot through a camera, the initial value of a phase shift amount caused by shake canbe solved on the basis of a relationship between the three-step phase-shifted grating images; an additional uniform brightness image is projected to the measured object and is shot so as to be adoptedas reference background light intensity; and the initial phase shift amount is optimized, the ideal phase shift amount can accurately reflect ripple error caused by face shake, and the ideal phase shift amount is substituted into the phase solution formula of the three-step phase shift method, so that compensated face phase information can be obtained, and an accurate three-dimensional face reconstruction result can be obtained through phase and depth conversion. The method of the invention has a motion error compensation function and can compensate measurement error caused by the face shakein a three-dimensional face recognition process, and can accurately measure the three-dimensional contour of a shake object under a condition of using a low-cost measurement system.

Owner:NANJING UNIV OF SCI & TECH

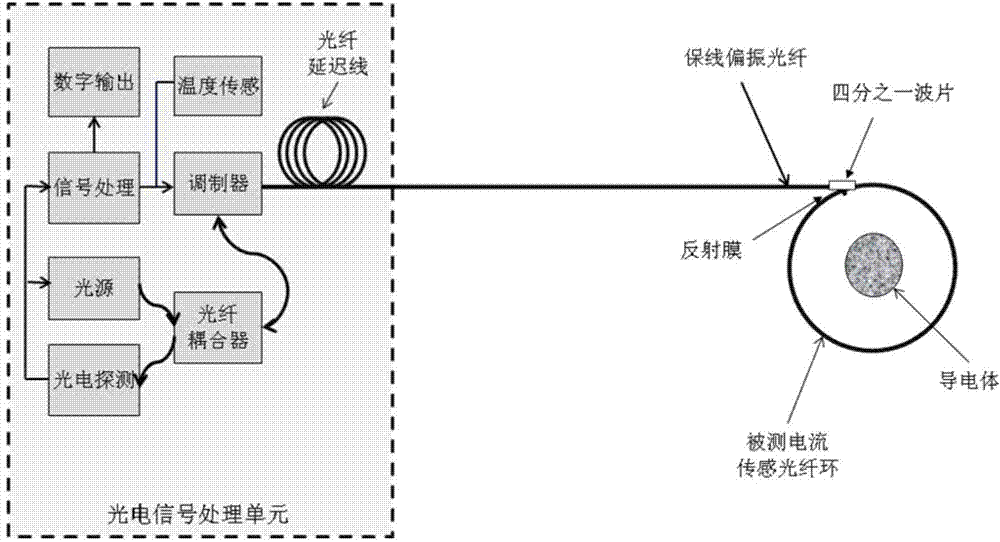

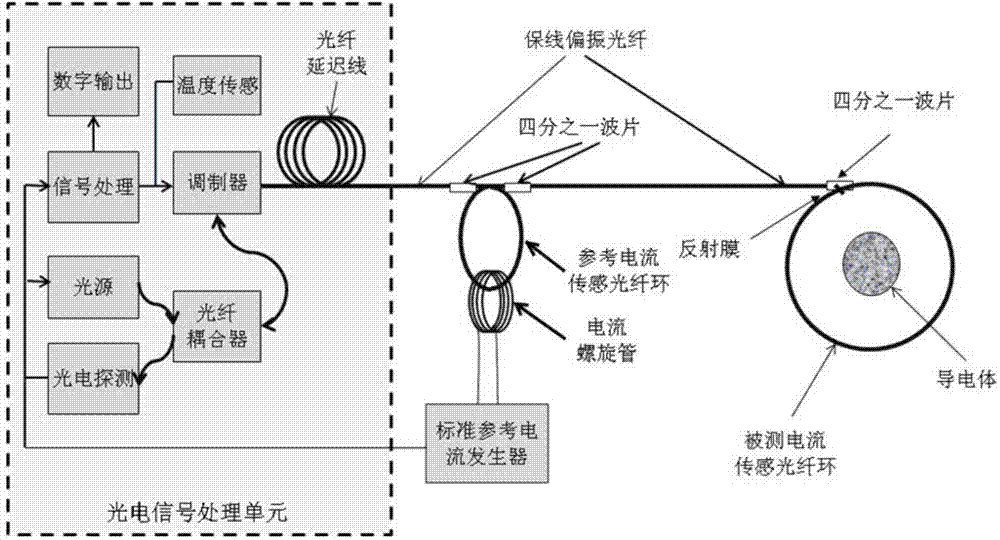

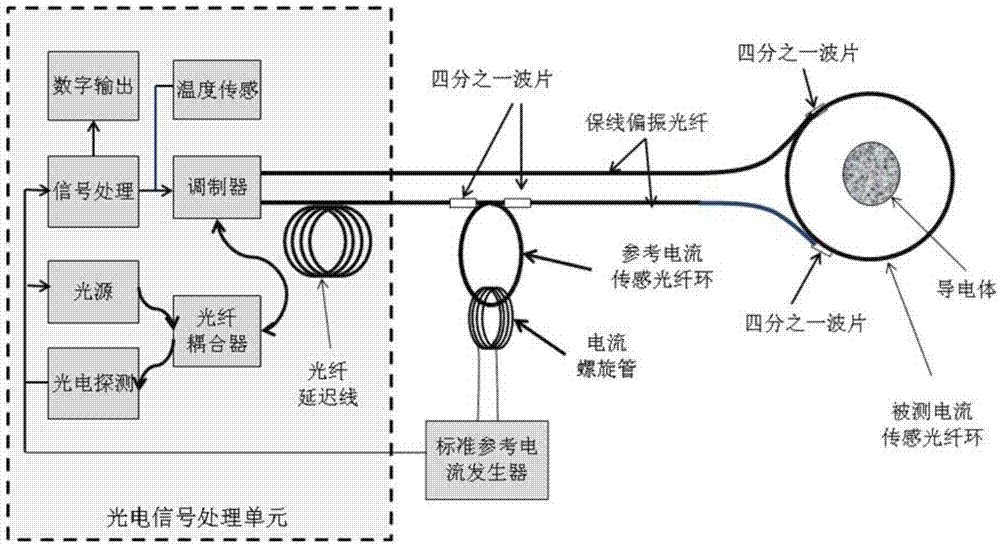

Full fiber optic current sensor and current closed loop feedback correction method

ActiveCN102929323AImprove anti-interference abilityCompensation for measurement errorsElectric variable regulationObservational errorReference current

The invention discloses a full fiber optic current sensor and a current closed loop feedback correction method. The full fiber optic current sensor comprises an optoelectronic signal processing unit and two sensor fiber rings which are connected with the optoelectronic signal processing unit in series and located at the back of an optical fiber delay line, one of the sensor fiber ring is a reference current sensor fiber ring, the other sensor fiber ring is a measured current sensor fiber ring, the reference current sensor fiber ring is connected between the optical fiber delay line and the measured current sensor fiber ring in series, a current wire is wound on the reference current sensor fiber ring, two ends of the current wire are connected onto a standard reference current generator, and the standard reference current generator is in communication connection with the optoelectronic signal processing unit. The full fiber optic current sensor and the current closed loop feedback correction method can compensate measuring errors of the system caused by long-term ageing and high temperature changes.

Owner:上海康阔光智能技术有限公司

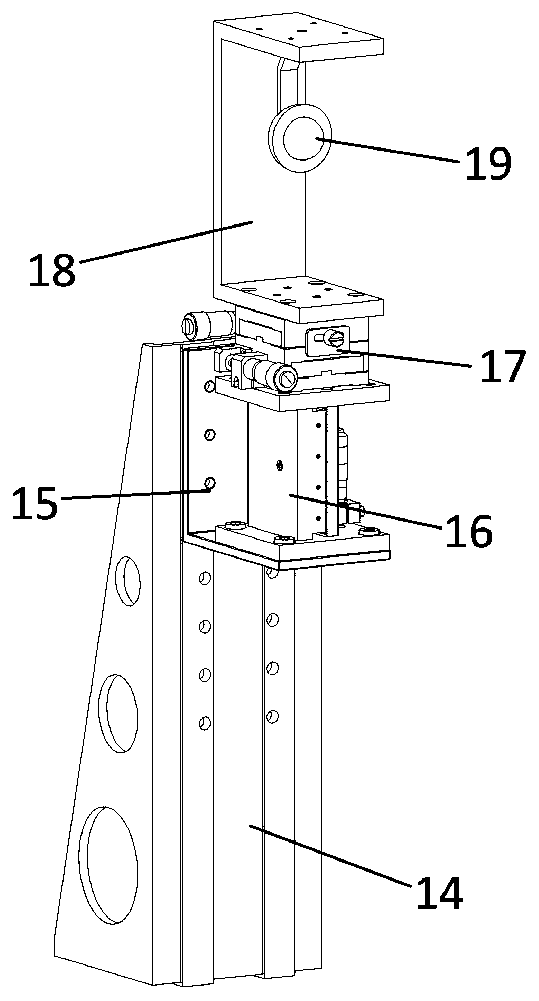

Another laser tracker geometric error compensation device

ActiveCN109974586AHigh measurement accuracyGuaranteed reliabilityUsing optical meansGeometric errorEngineering

The invention discloses another laser tracker geometric error compensation device. The compensation device is divided into two parts, namely a cat-eye vertical movement structure and a laser tracker rotation structure. The cat-eye vertical movement structure is divided into three parts, namely a column guide rail structure, a laser collimation structure and a positioning error compensation structure. The laser tracker rotation structure is composed of a laser tracker, an electric two-dimensional platform and a precise rotary table. Through the compensation device, a system measurement error caused by a geometric error can be subject to effective compensation, the measurement precision of the laser tracker is improved, and meanwhile the reliability of a laser tracking measurement system based on a polygonal method is guaranteed.

Owner:BEIJING UNIV OF TECH

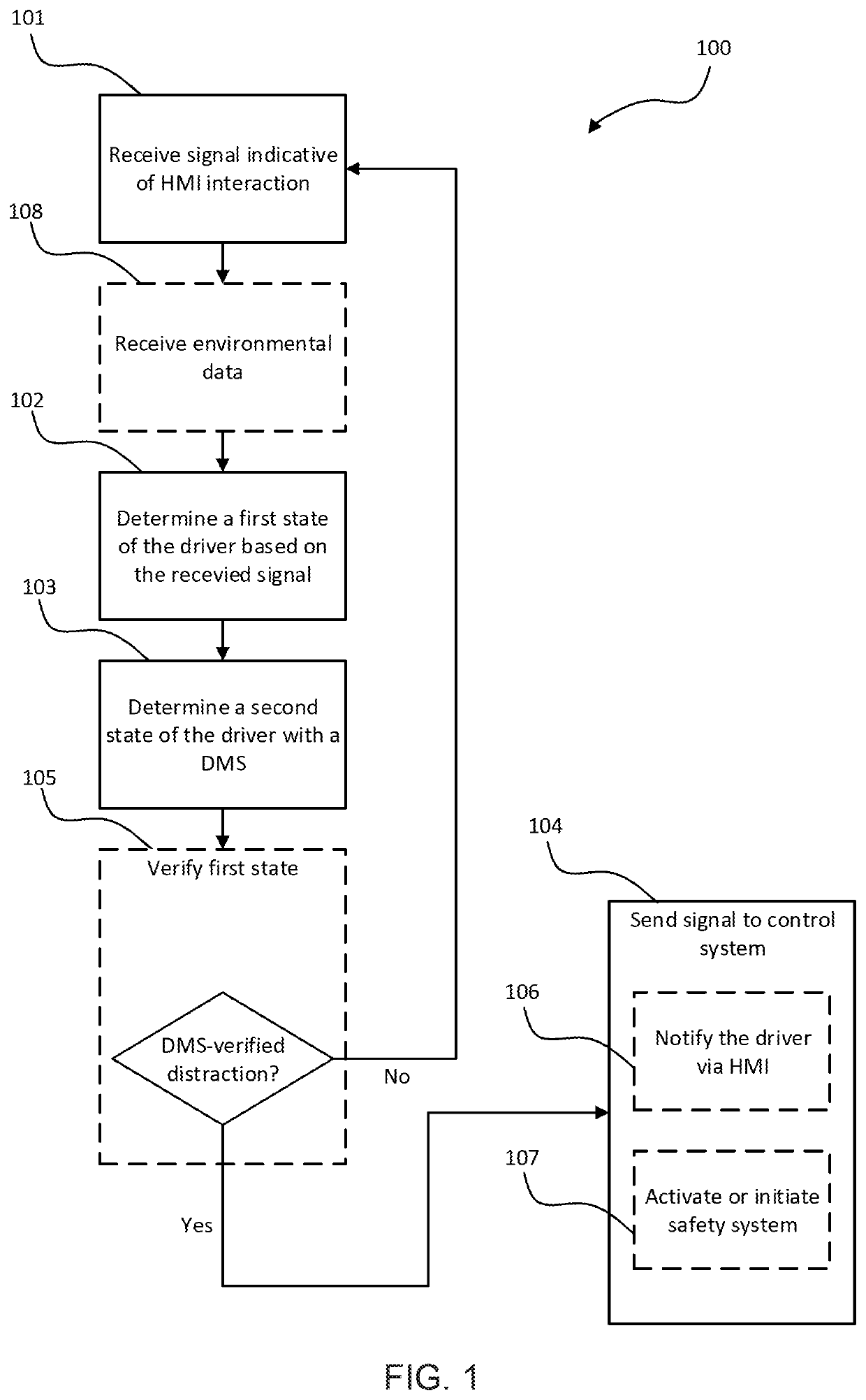

Driver distraction determination

InactiveUS20200339133A1Mitigate such drawbackRobust and cost-effectiveCharacter and pattern recognitionDriver input parametersIn vehicleDriver/operator

A method for determining driver distraction in a vehicle is disclosed. The method comprises receiving a signal comprising information about user-interaction with an in-vehicle human machine interface (HMI), and determining a first state of the driver based on the received information. The first state comprises at least one distraction parameter. Further, the method comprises determining a second state of a driver of the vehicle by means of a driver monitoring system (DMS), where the second state of the driver comprises at least one attention parameter, and sending a signal to a control system of the vehicle based on the determined first state of the driver and the determined second state of the driver. A corresponding computer-readable storage media, a control device, and a vehicle are also disclosed.

Owner:ZENUITY AB

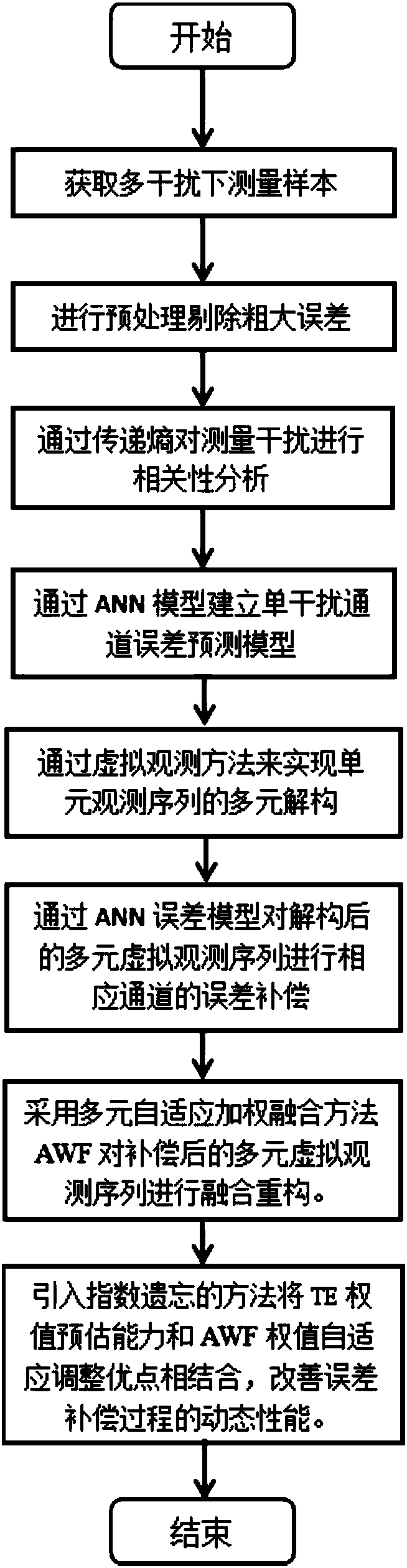

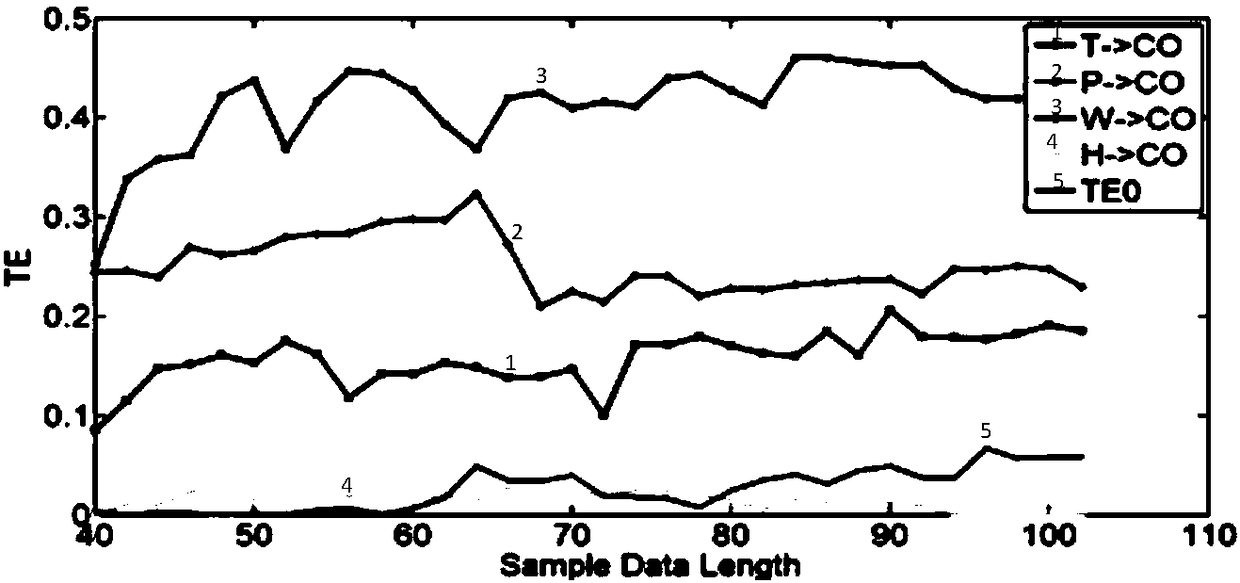

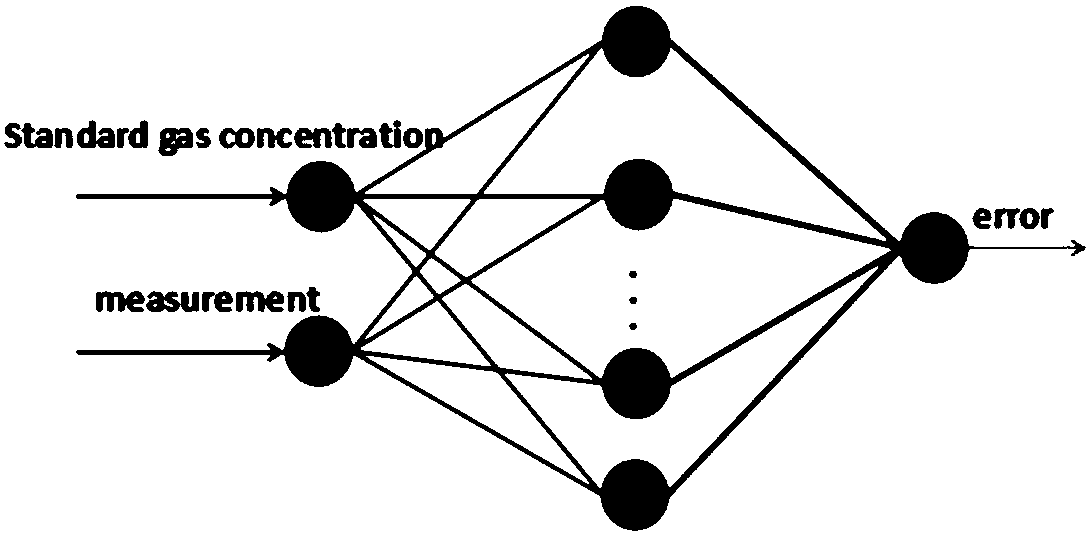

Mobile pollution source remote-measurement error compensation method based on TE-ANN-AWF

ActiveCN108593557AImprove applicabilityImprove anti-interference abilityMaterial analysis by optical meansNeural learning methodsObservational errorCorrelation analysis

The invention discloses a mobile pollution source remote-measurement error compensation method based on TE-ANN-AWF. The TE transfer entropy is used to perform a causal correlation analysis on interference and measure results, an error source is determined and a multi-interference imbalance degree is measured, and the directivity of the TE transfer entropy is used for leading out a quantification standard and a determination method having a non-substantial causal correlation. A virtual observation method is provided for realizing multiple deconstruction of a unit observation sequence, an ANN error prediction model is used to realize compensation of a single interference channel virtual observation sequence, and a multiple adaptive weight fusion method is employed for fusion reconstruction on a multiple virtual observation sequence. By aiming at a weight convergence problem in a fusion algorithm, an index forgetting method is introduced in a model to combine the good weight pre-estimatedcapability of TE and the weight adaptive adjustment of AWF, and the dynamic performance of a error compensation process is improved.

Owner:HANGZHOU DIANZI UNIV

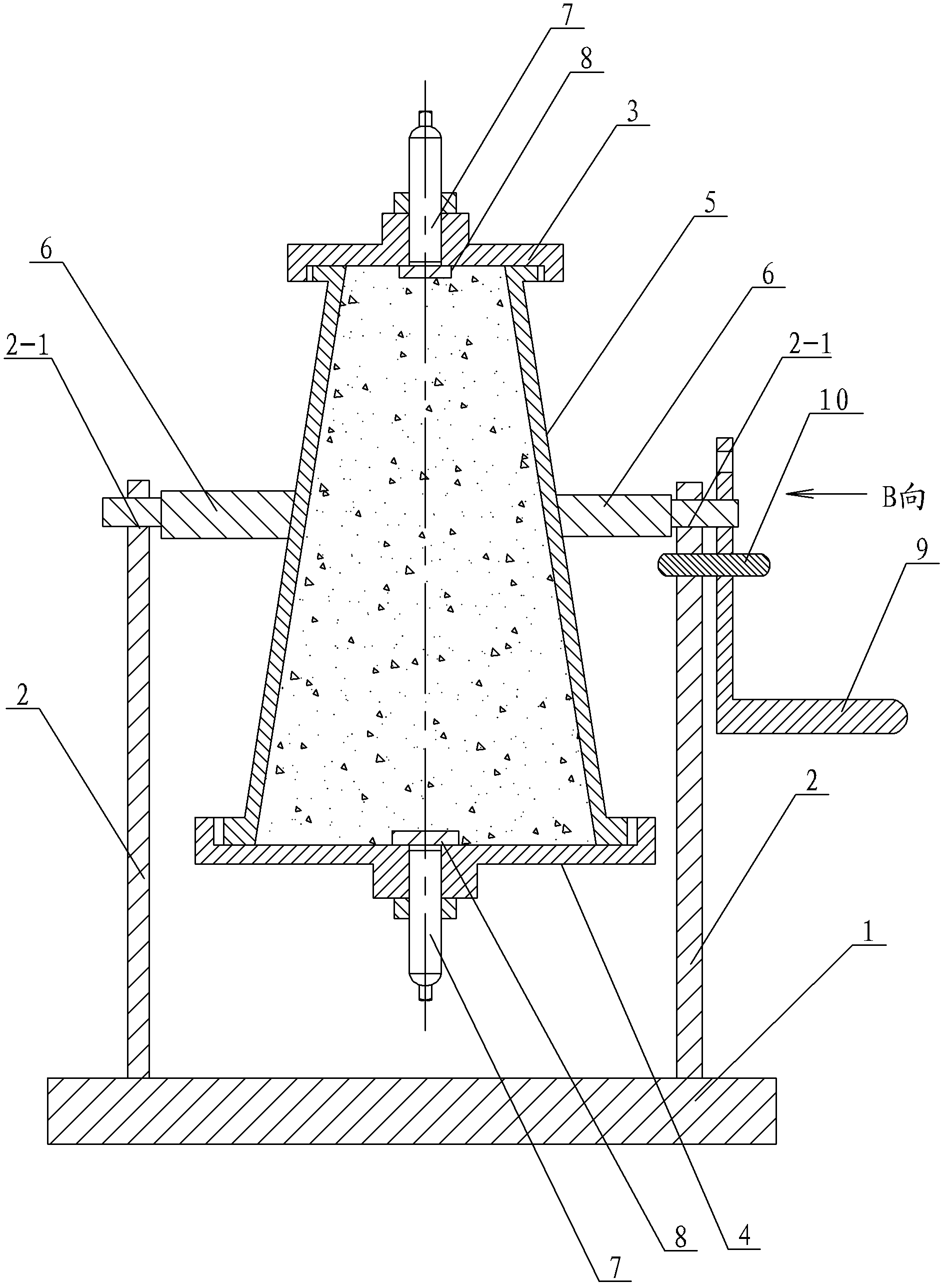

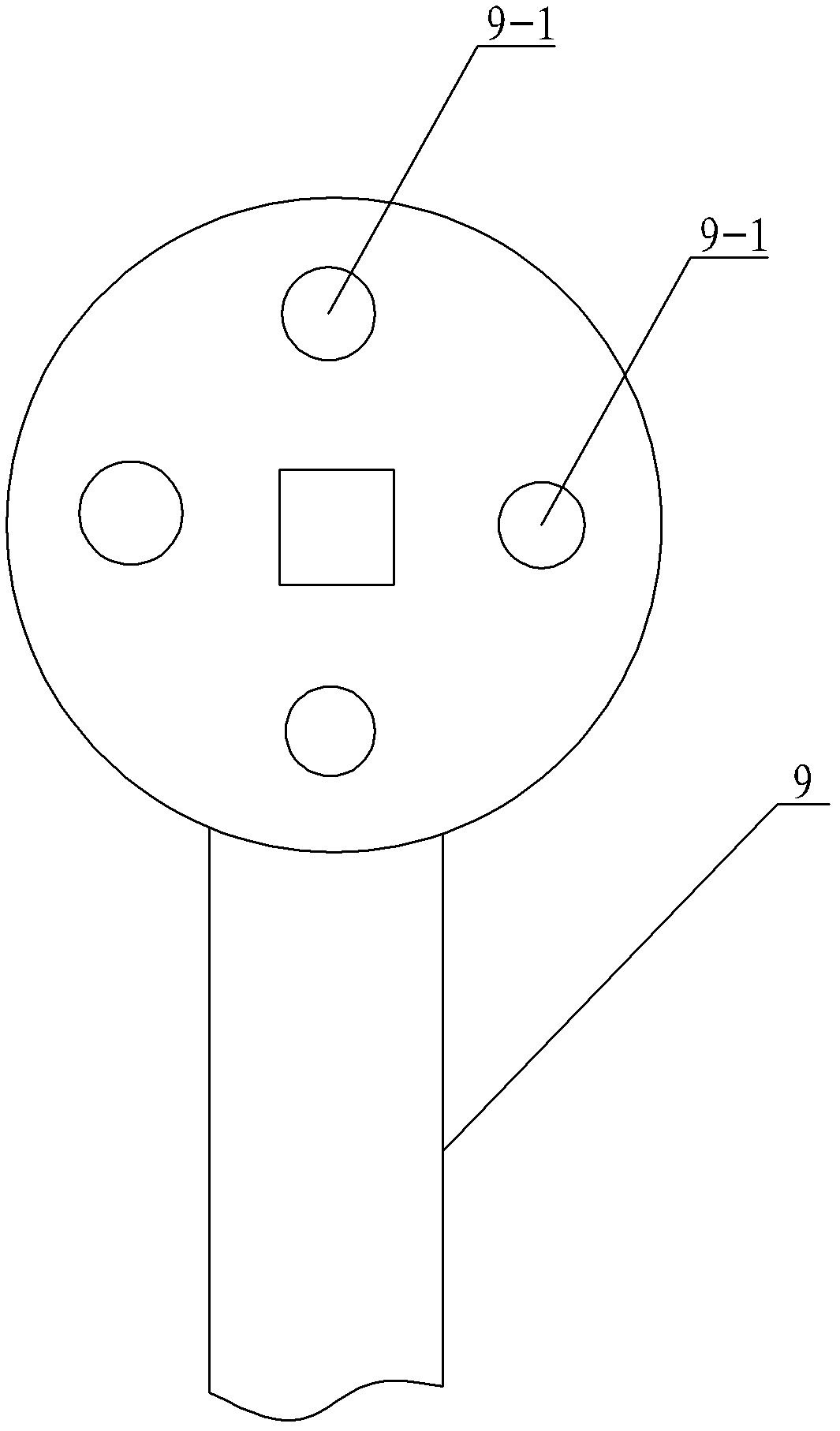

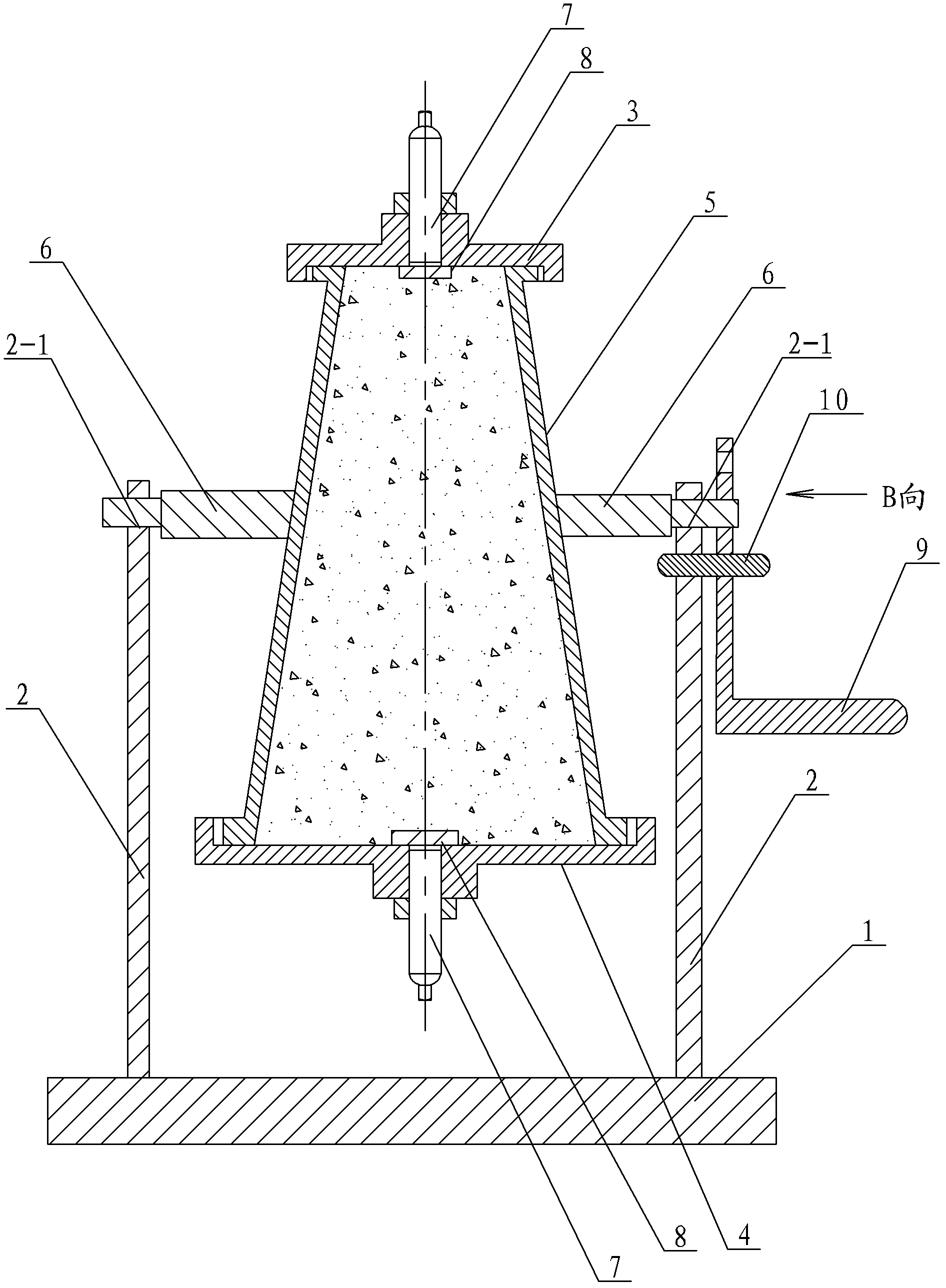

Hand-shaking type concrete self-constriction measuring device

ActiveCN102608298AAvoid measurement errorsCompensation for measurement errorsElectrical/magnetic solid deformation measurementMaterial testing goodsMeasurement deviceEngineering

The invention provides a hand-shaking type concrete self-constriction measuring device, relating to a concrete measuring device and solving the problems that the concrete is easily influenced by a template restraining function in a process of measuring the concrete self-constriction by the existing laboratory, the data of a measured constriction value are not real, and an error is generated and the like. One ends of two cylinders are respectively and rotatably mounted in a groove at the upper end of a support; the other ends of the two cylinders are respectively and fixedly connected with two side walls of a frustum-shaped container; the centers of an upper cover and a lower cover are provided with central holes; upper and lower ends of newly-mixed concrete are respectively pre-buried with steel sheets; two sensors are respectively fixedly arranged on the upper cover and the lower cover in a penetrating mode; a sensor is a vortex displacement sensor; the upper part of a hand-shaking handle is uniformly provided with four through holes along a peripheral direction; the hand-shaking handle is fixedly arranged at one ends of the cylinders; and a fixing rod respectively passes through a through hole of the hand-shaking handle and the support. The hand-shaking type concrete self-constriction measuring device disclosed by the invention is suitable for measuring the concrete self-constriction in the laboratory.

Owner:HARBIN INST OF TECH

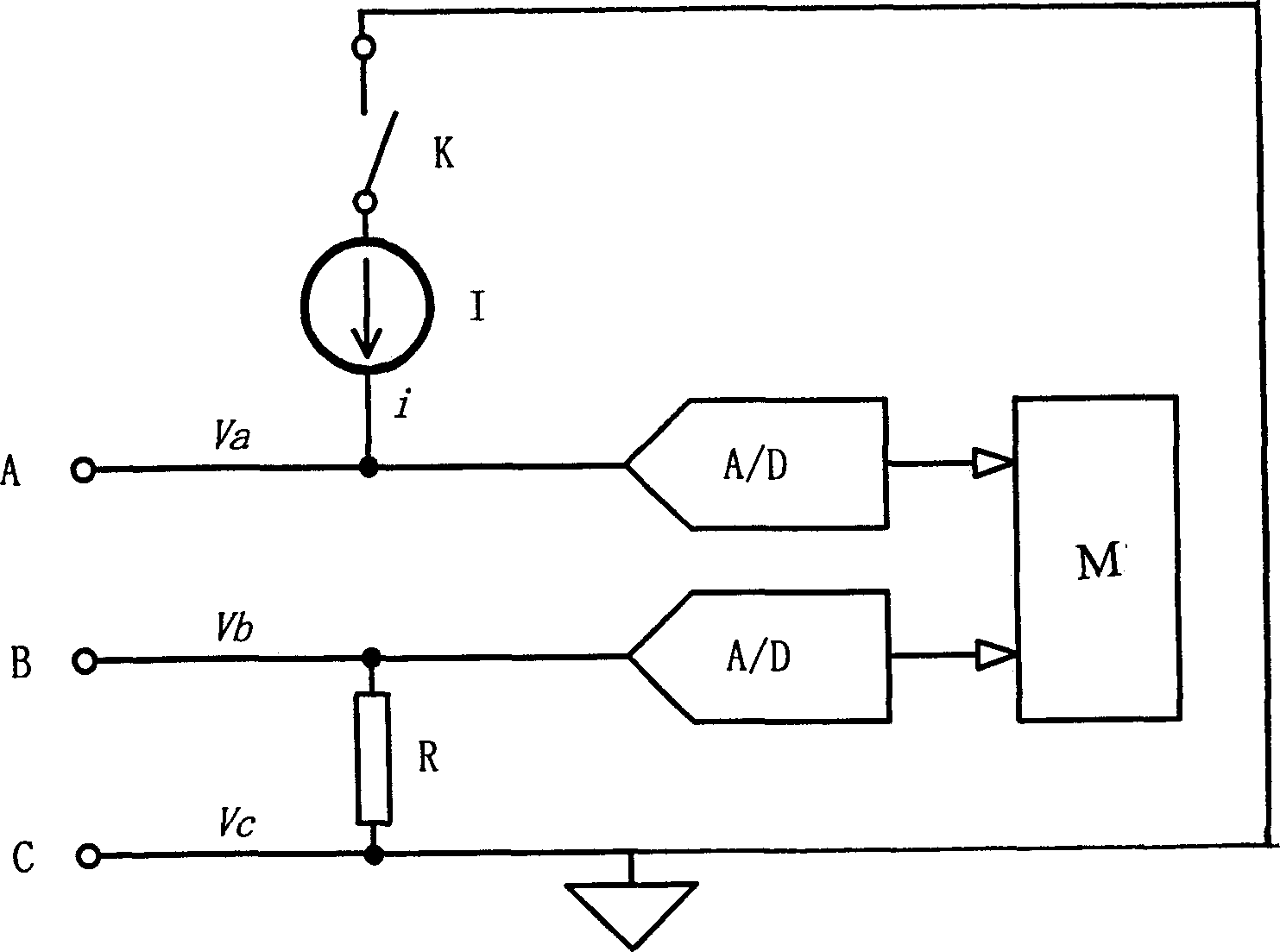

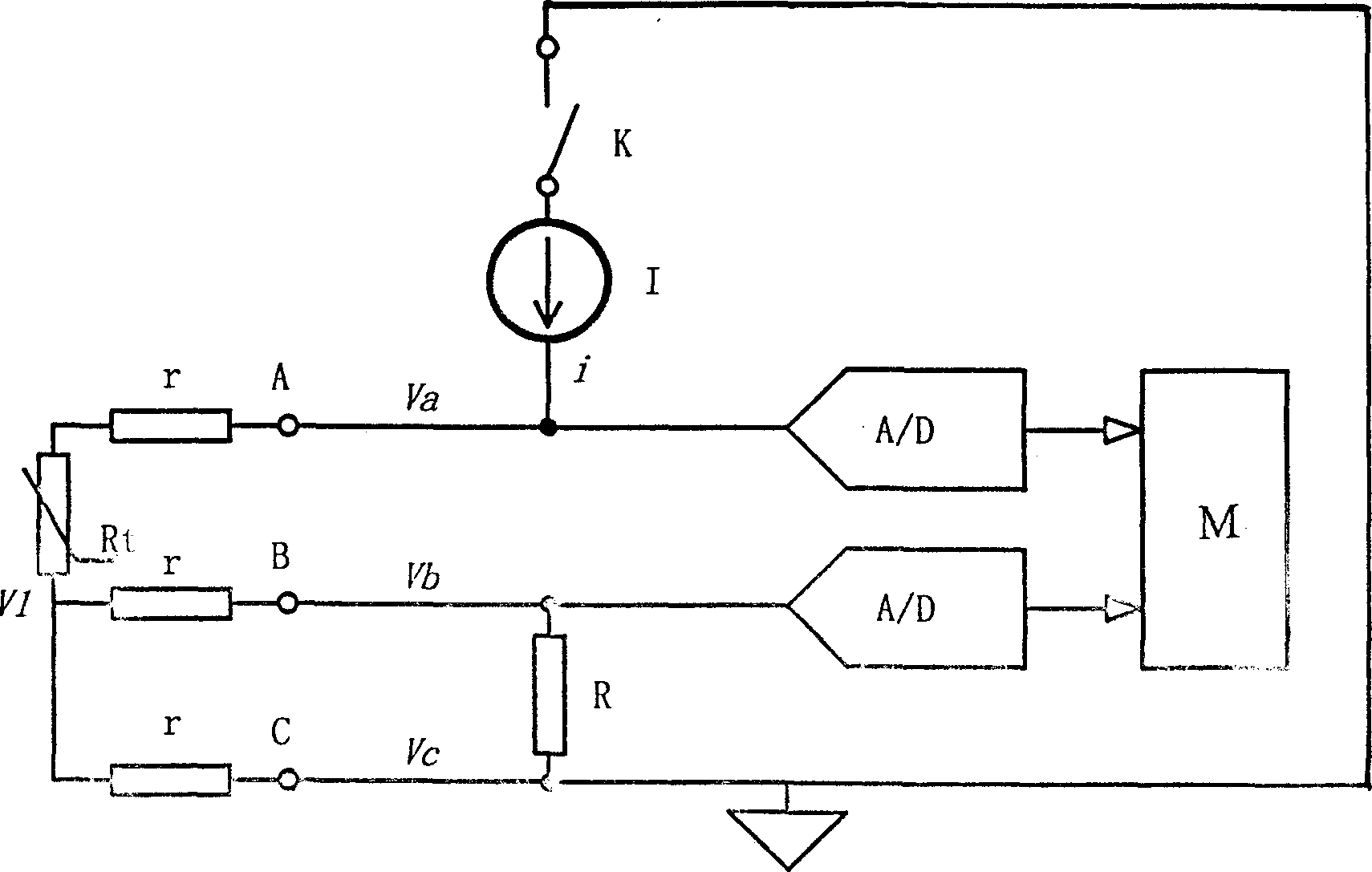

Error compensation method of thermal resistance measurement by using multifunctional analogue signal circuit

InactiveCN1395110ACompensation for measurement errorsHigh measurement accuracyResistance/reactance/impedenceElectrical resistance and conductanceAnalog signal

The configuration of the multiple functional analog signal circuit adopted in the invention includes following parts: the voltage input end A, the current input end B, Then signal reference ground C, microproceesor M, the precision resistor R, the switch K, the constant current source I and A / D converter. When the thermal resistance Rt being measured, the one end of Rt is connected to A, the other end is connected to B and C. The error compensation is carries out according to the following relational expression by using the microproceesor so as to obtain the actual value. The invented method provides the features of easy of operatino, full compensation for the thermal resistance measured.

Owner:ZHEJIANG SUPCON INSTR

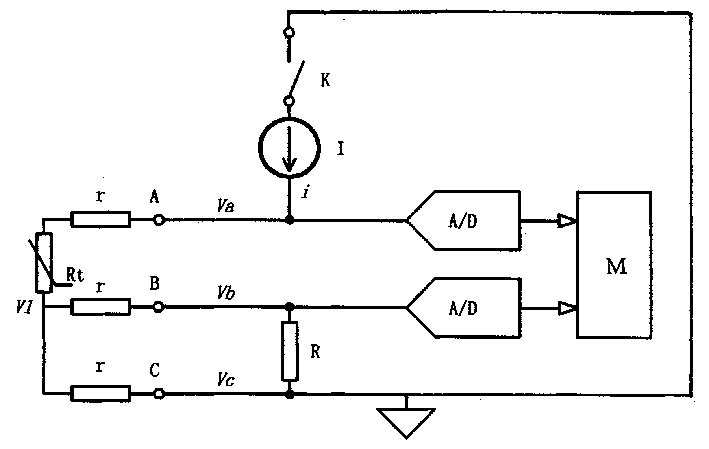

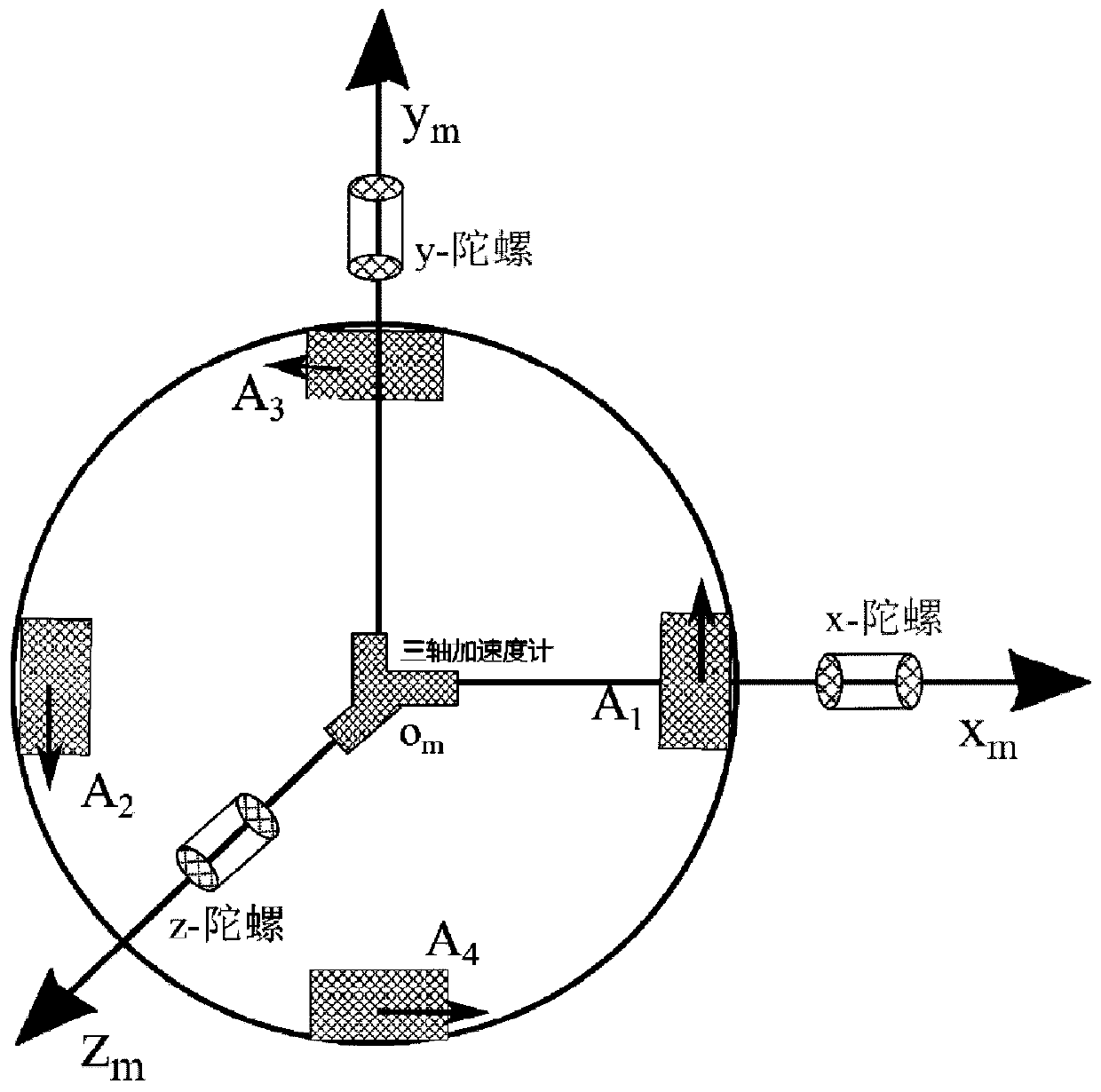

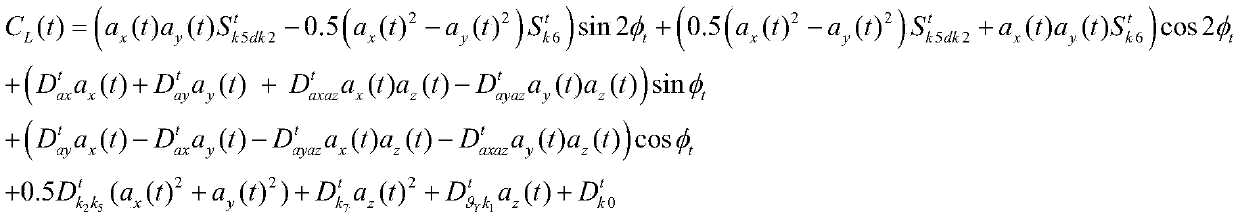

A linear motion error compensation device and method for a rotational accelerometer gravity gradiometer

ActiveCN109212619BCompensation for measurement errorsHigh measurement accuracyGravitational wave measurementOvervoltageLinear motion

Owner:SOUTHEAST UNIV

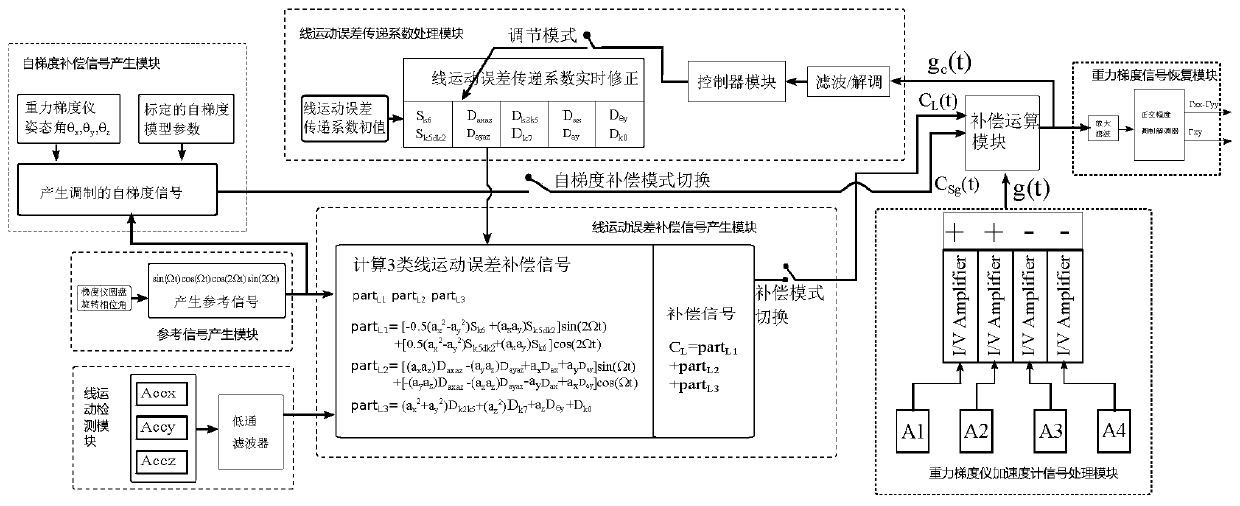

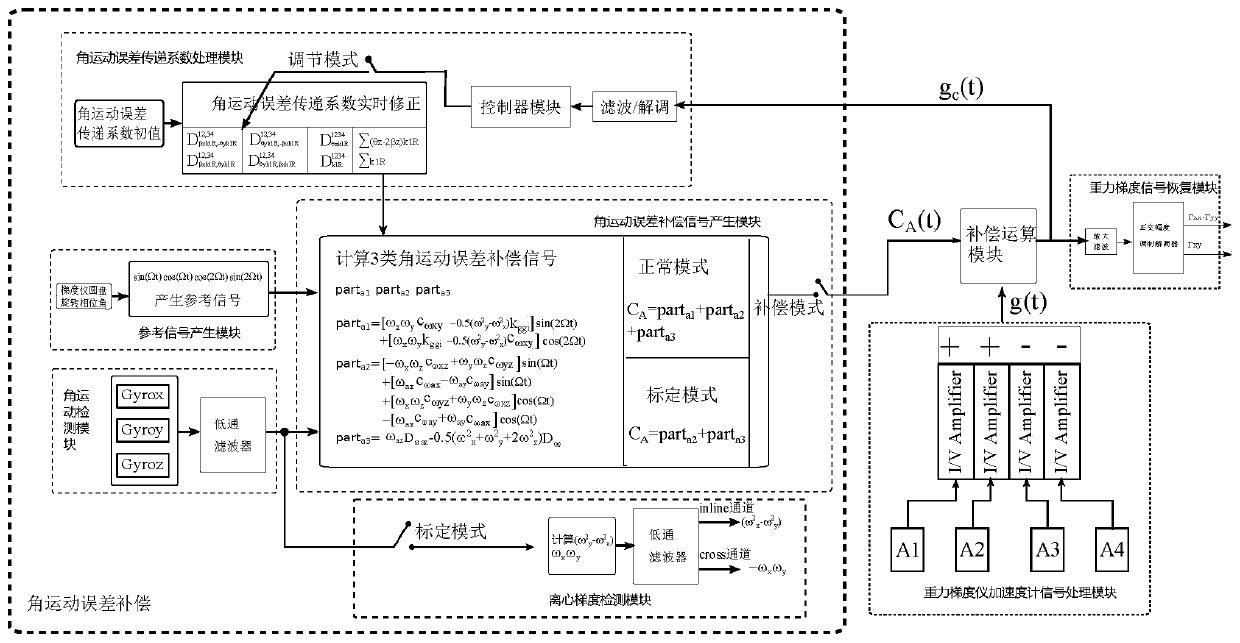

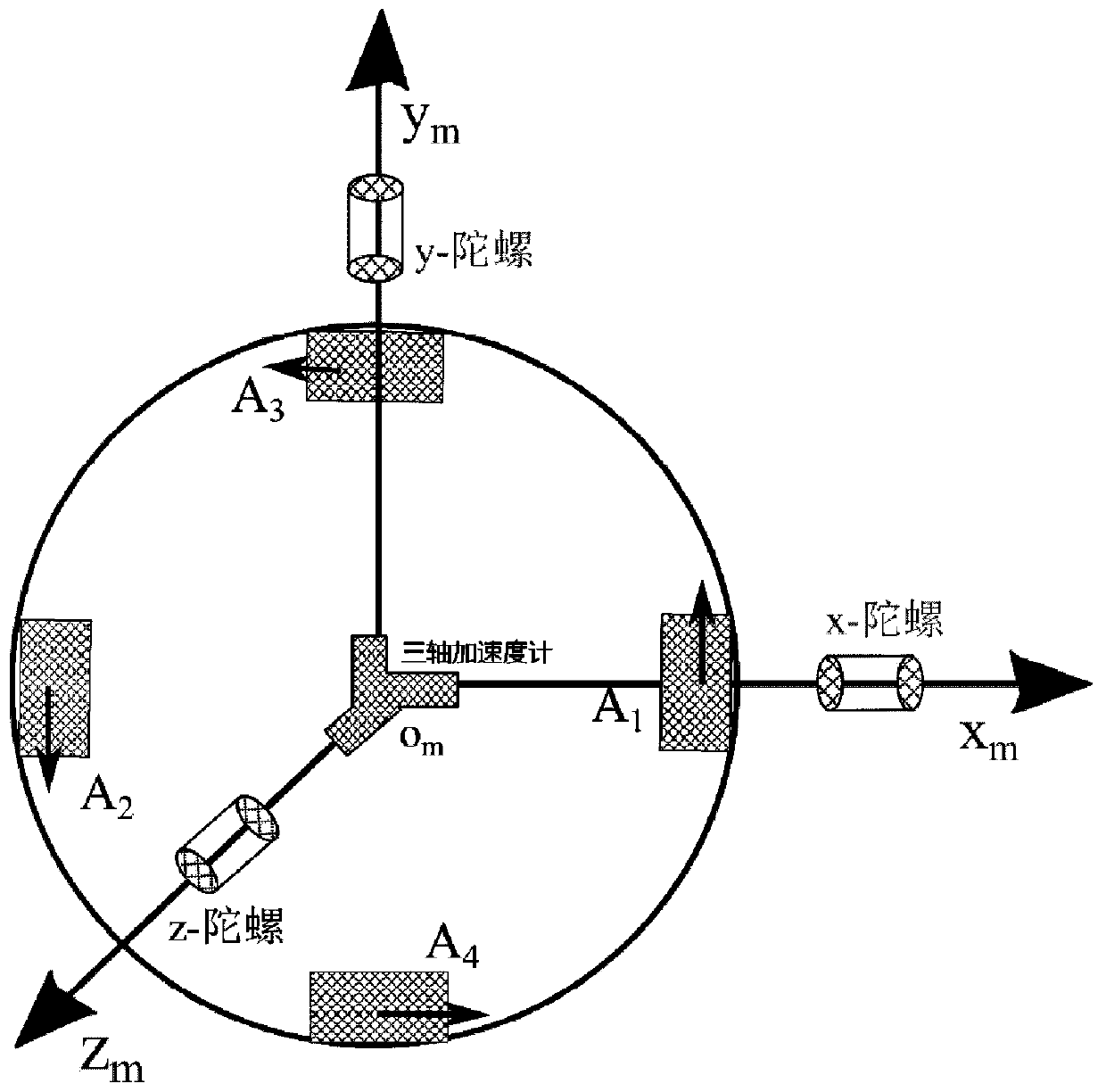

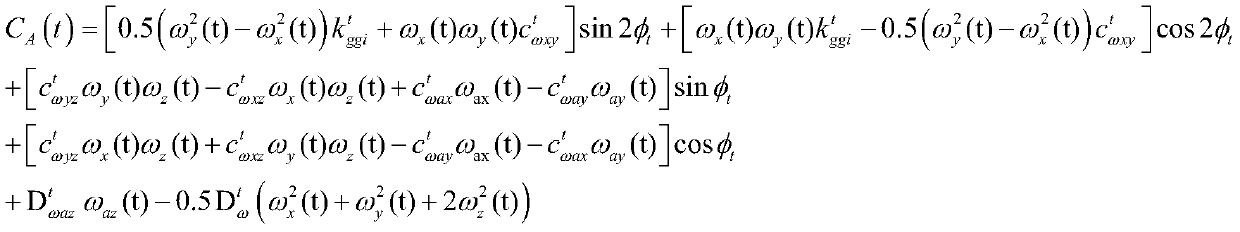

Rotational accelerometer gravity gradiometer angular motion error compensation device and method

ActiveCN109212629BCompensation for measurement errorsHigh measurement accuracyGravitational wave measurementAccelerometerCarrier signal

The invention discloses a device and a method for compensating the angular motion error of a rotary accelerometer gravity gradiometer. The device mainly comprises: an angular motion detecting module,detecting the angular motion of the gravity gradiometer in real time; a reference signal generating module, generating a quadrature amplitude modulation carrier in real time; an angular motion error transmission coefficient processing module, according to the compensated gravity gradiometer signal fed back, finely adjusting the angular motion error transmission coefficient in real time; an angularmotion error compensation signal generating module, generating an angular motion error compensation signal according to the input gravity gradiometer angular motion signal, the quadrature amplitude modulation carrier, and the angular motion error transmission coefficient; a compensation arithmetic module, compensating the gravity gradiometer signal containing the angular motion error; and a centrifugal gradient detection module, capable of detecting the centrifugal gradient experienced by the gravity gradiometer, and when the device is operating in the calibration mode, the output of the centrifugal gradient detection module is used to calibrate the gravity gradiometer scale factor.

Owner:SOUTHEAST UNIV

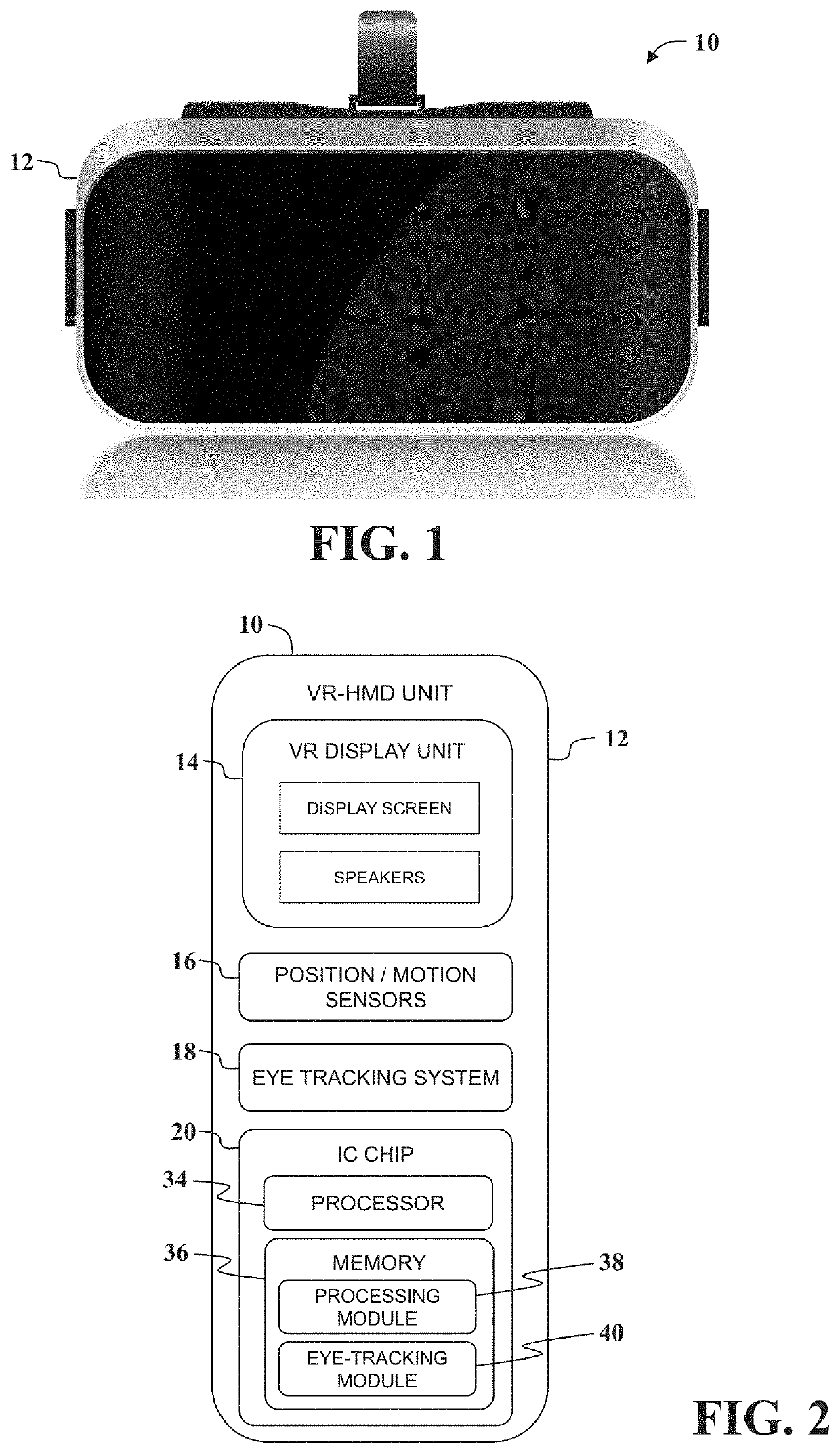

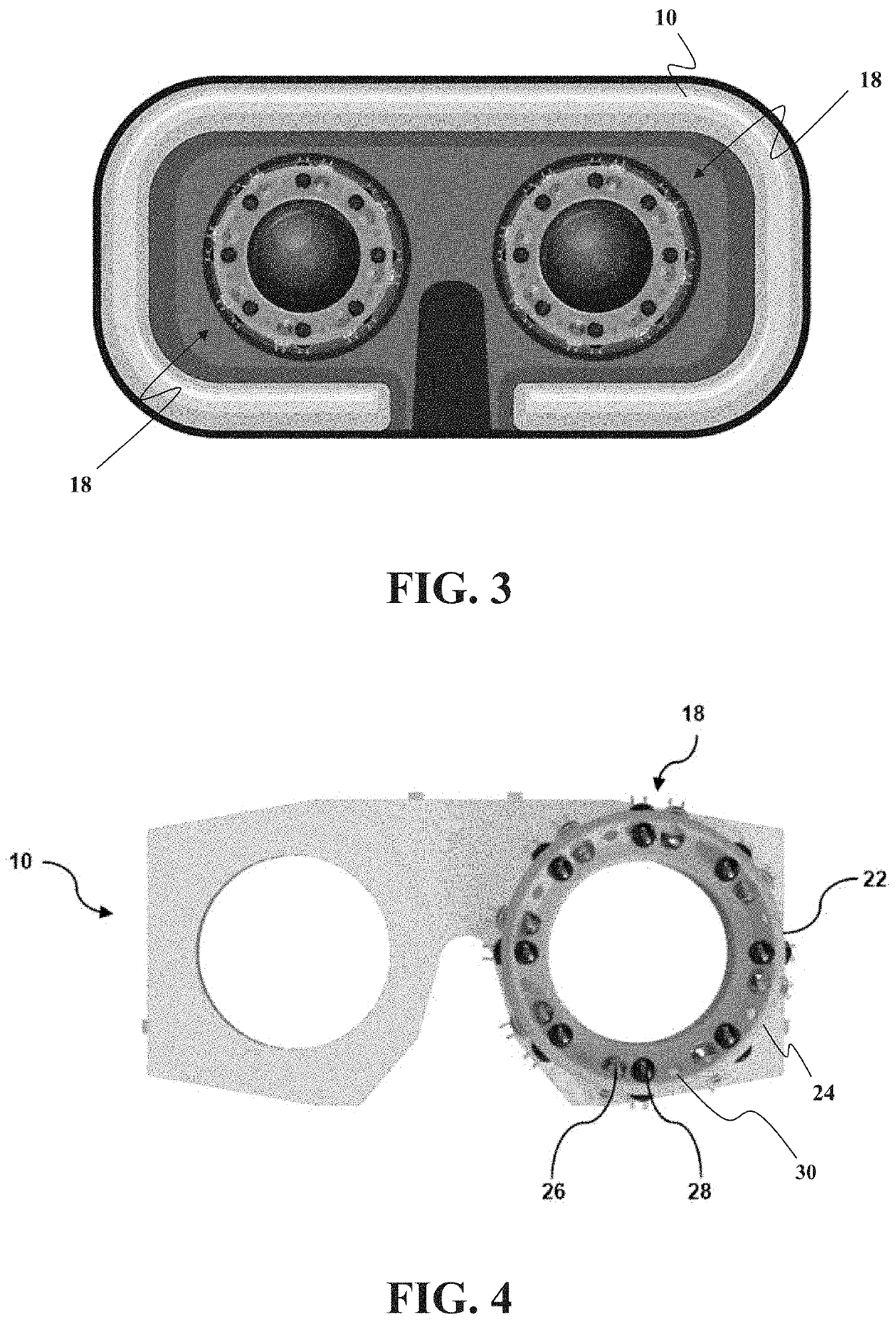

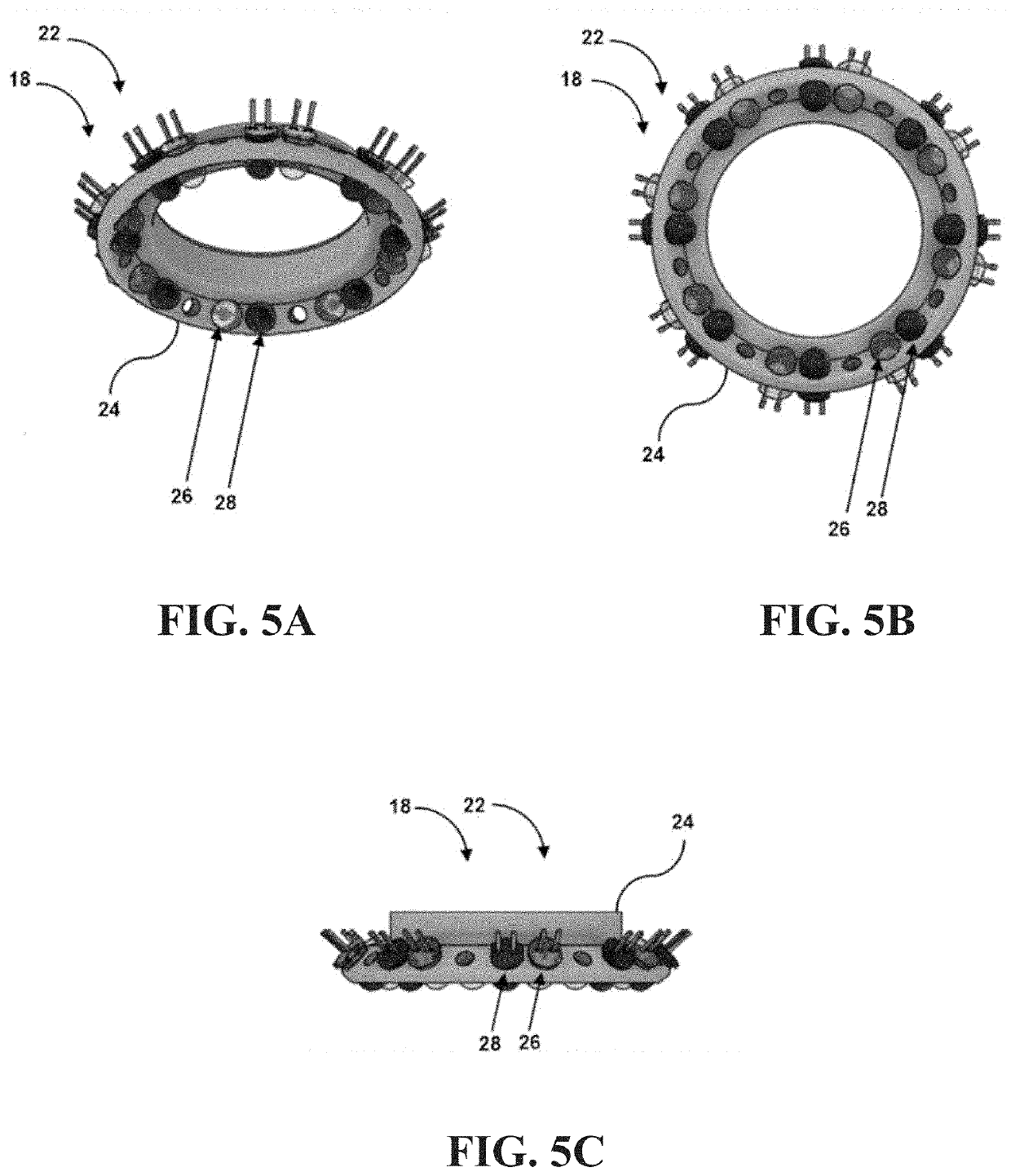

Eye tracking system for use in head-mounted display units

ActiveUS20220050522A1Compensation for measurement errorsInput/output for user-computer interactionUsing optical meansDisplay deviceEye tracking system

An eye tracking system for use with a head-mounted display (HMD) unit is described. The eye tracking system includes a support frame mounted to the HMD unit, a light source mounted to the support frame and configured to illuminate an area of a patient eye, a plurality of photosensors mounted to the support frame and configured to receive reflected light from different portions of the illuminated patient eye, a temperature sensor mounted to the support frame and configured to measure a temperature of the photosensors, and a processor. The processor is programmed to execute an algorithm including a processing module that compensates photosensor measurement error due to variable operating temperature in the HMID unit, and an eye-tracking module that determines a gaze position of the patient eye using a mapping between intensities of photosensors and a gaze position estimated during a calibration procedure.

Owner:INSEYE INC

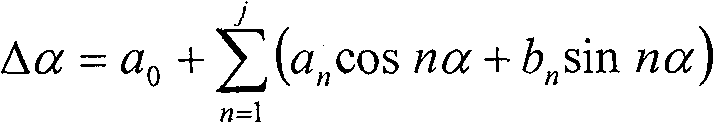

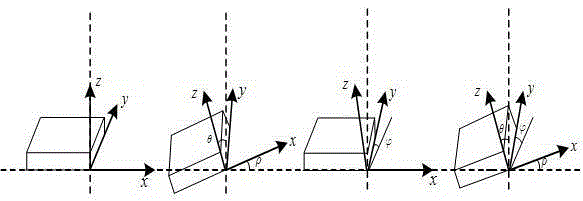

Magneto- electronic compass error compensation method

InactiveCN101241009BRealize high-precision measurementCompensation for measurement errorsCompassesObservational errorUltimate tensile strength

The invention provides an electronic magnetic compass error compensation method which bases on deformation round distribution and cyclical assumptions. The measurement error caused by around ferromagnetic materials and other factors must be compensated to enhance electronic magnetic compass measurement accuracy. At present, domestic and foreign popular methods of compensation are based on assumptions which relate to the effect of the environmental interference magnetic field causing the magnetic field strength level projection component distribution from round into oval. But because of more and complicated influence factors, in fact the magnetic field strength level projection component distribution can not be guarantee as perfect oval. In view of this situation, the invention provides error compensation algorithmic method which bases on deformation round distribution and cyclical assumptions, the objective is to compensate the measurement error caused by around ferromagnetic materialsand other factors, and achieve magnetic azimuth high-precision measurement.

Owner:UNIV OF SCI & TECH BEIJING

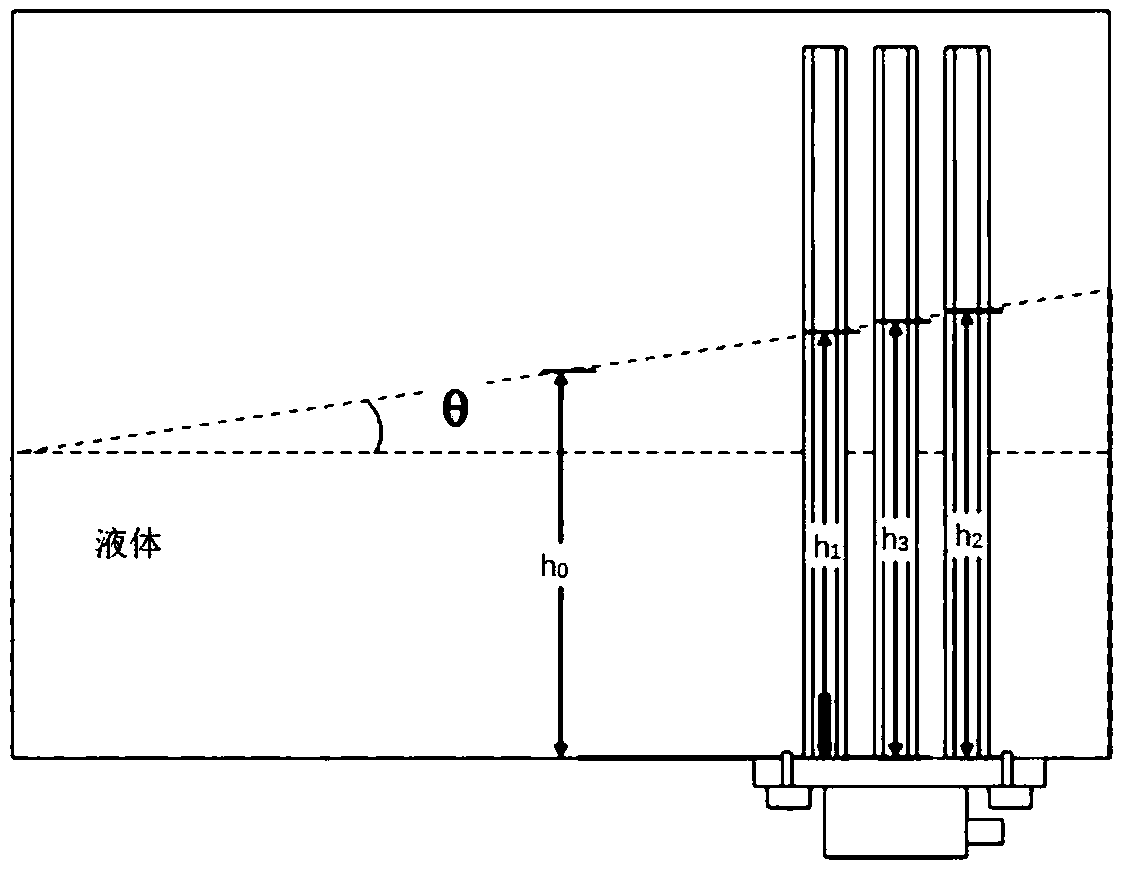

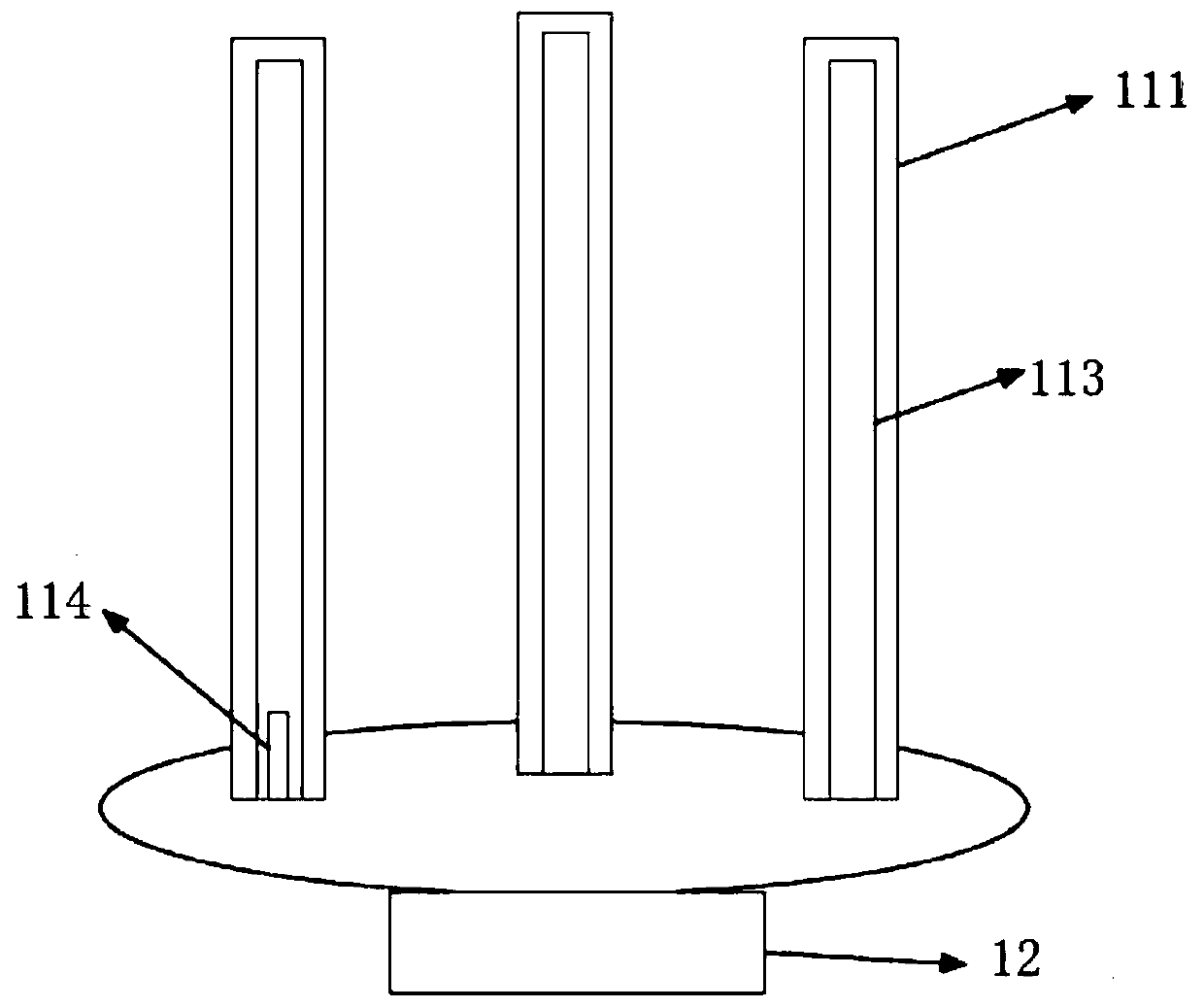

Liquid level sensor, container, aircraft and liquid level detection method

ActiveCN110793594AEasy to installProvide accuratelyLevel indicators by physical variable measurementFlight vehicleEngineering

The invention provides a liquid level sensor, a container, an aircraft and a liquid level detection method, and relates to the technical field of test. The liquid level sensor comprises a liquid leveldetection device and an operation processing device, wherein the liquid level detection device comprises three detection probe mechanisms, the three detection probe mechanisms are arranged in an equilateral triangle, information of three liquid level heights in the container are acquired by the three detection probe mechanisms, and the operation processing device is used for determining a dip angle of an installation surface of the three detection probe mechanisms in the container relative to a horizontal surface and liquid level height information of the container according to the information of the three liquid level heights and installation positions of the three detection probe mechanisms. According to the liquid level sensor, the container, the aircraft and the liquid level detectionmethod, provided by the invention, a measurement error of the container at different positions can be compensated, dip angle information of the container can be accurately improved, the liquid levelsensor is simple in structure, high in reliability and high in installation freedom, accurately-measured and high-accuracy liquid level information can be acquired.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Apparatus for detection of the accuracy of format of a web of corrugated cardboard

InactiveUS7952714B2Compensation for measurement errorsMechanical working/deformationMaterial analysis by optical meansCardboardEngineering

An apparatus for detection of the accuracy of format of a web of corrugated cardboard moved in a conveying direction comprises a light source which emits a light band to the surface of the web of corrugated cardboard in a direction crosswise of the conveying direction and at an angle to the web of corrugated cardboard. A measuring camera detects the different light intensities of the light reflected by the plane portions and the profiled patterns of the web of corrugated cardboard. This electronic image in the camera is evaluated by an evaluation device for determining the distance of the profiled patterns from each other.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

A light-touch intraocular pressure horizontal or vertical measuring device and method

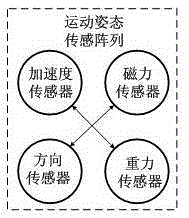

ActiveCN104274153BCompensation for measurement errorsAccurate measurementTonometersMeasurement deviceExcitation current

The invention discloses a soft touch type horizontal or vertical intraocular pressure measuring device and method. The device comprises a small magnetic needle pressure measuring probe, a detection front-end device, a signal drive conditioning circuit, an intraocular pressure instrument moving posture sensing array, a DSP core processing unit, an LCD and a wireless printing module. The method comprises the following steps: detecting a posture of the intraocular pressure instrument in real time, acquiring triaxial acceleration, driving a small magnetic needle to softly touch the eyeball at a constant speed and to apply a certain pressure to the eyeball so as to allow the central cornea to deform by generating exciting current in an electrified solenoid drive coil, recording a current signal fed back in the small magnetic needle reciprocating process by virtue of an induction coil, and calculating the forced acceleration of the intraocular pressure according to the current signal fed back by the induction coil, the measurement time and the triaxial acceleration converted quantity; and calculating the actual measured intraocular pressure value by combining a linear regression equation according to the forced acceleration of the intraocular pressure and the central cornea thickness CCT. The method disclosed by the invention is an accurate horizontal or vertical intraocular pressure measuring method, and great convenience is provided for patients suffering from eye diseases and diagnosis and treatment physicians.

Owner:苏州晶致医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com