Hand-shaking type concrete self-constriction measuring device

A measuring device and concrete technology, which is applied to electromagnetic measuring devices, electric/magnetic solid deformation measurement, material inspection products, etc., can solve problems such as errors and untrue data of measured shrinkage values, and achieve accurate self-shrinkage values and simple structure. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

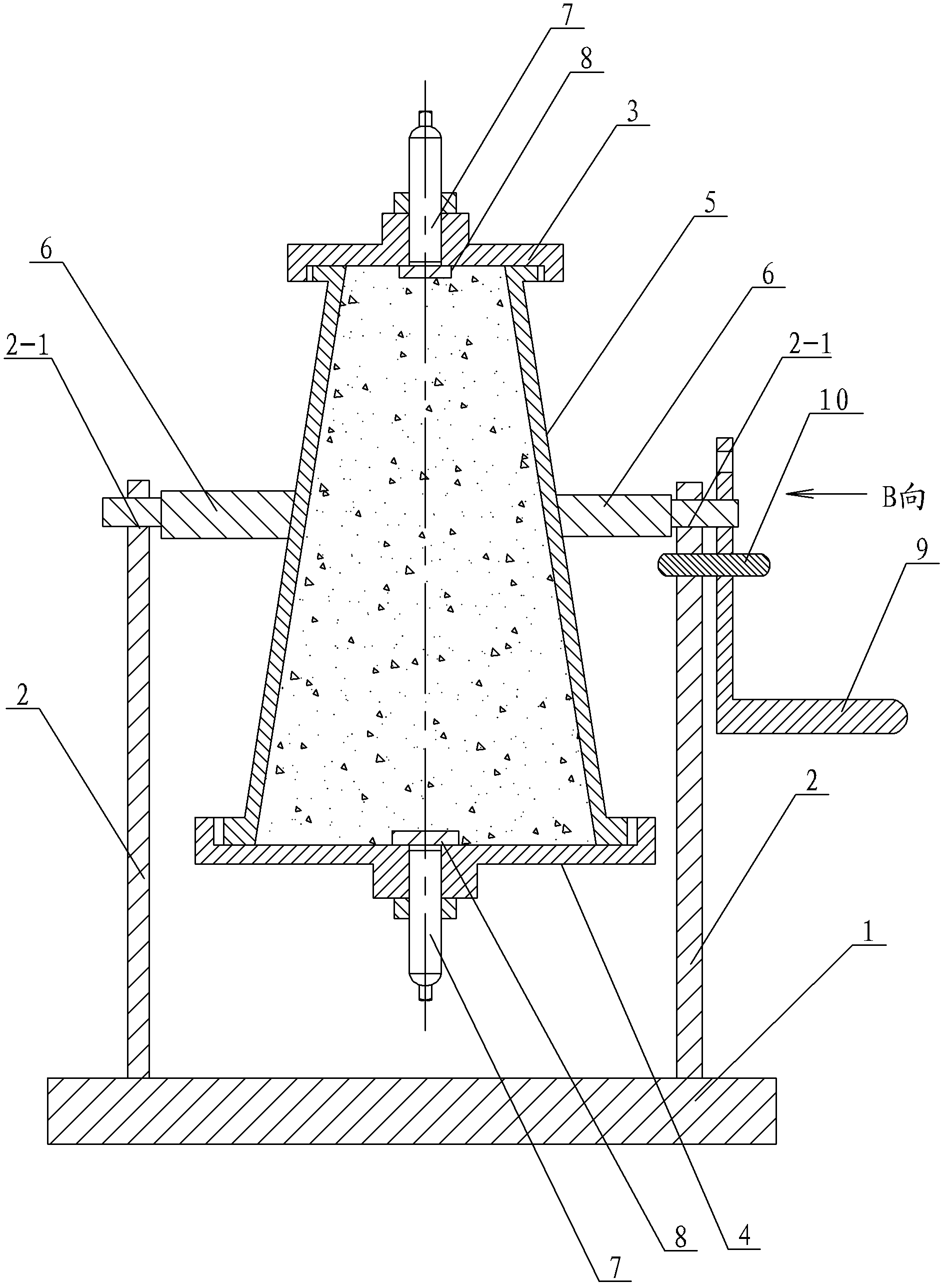

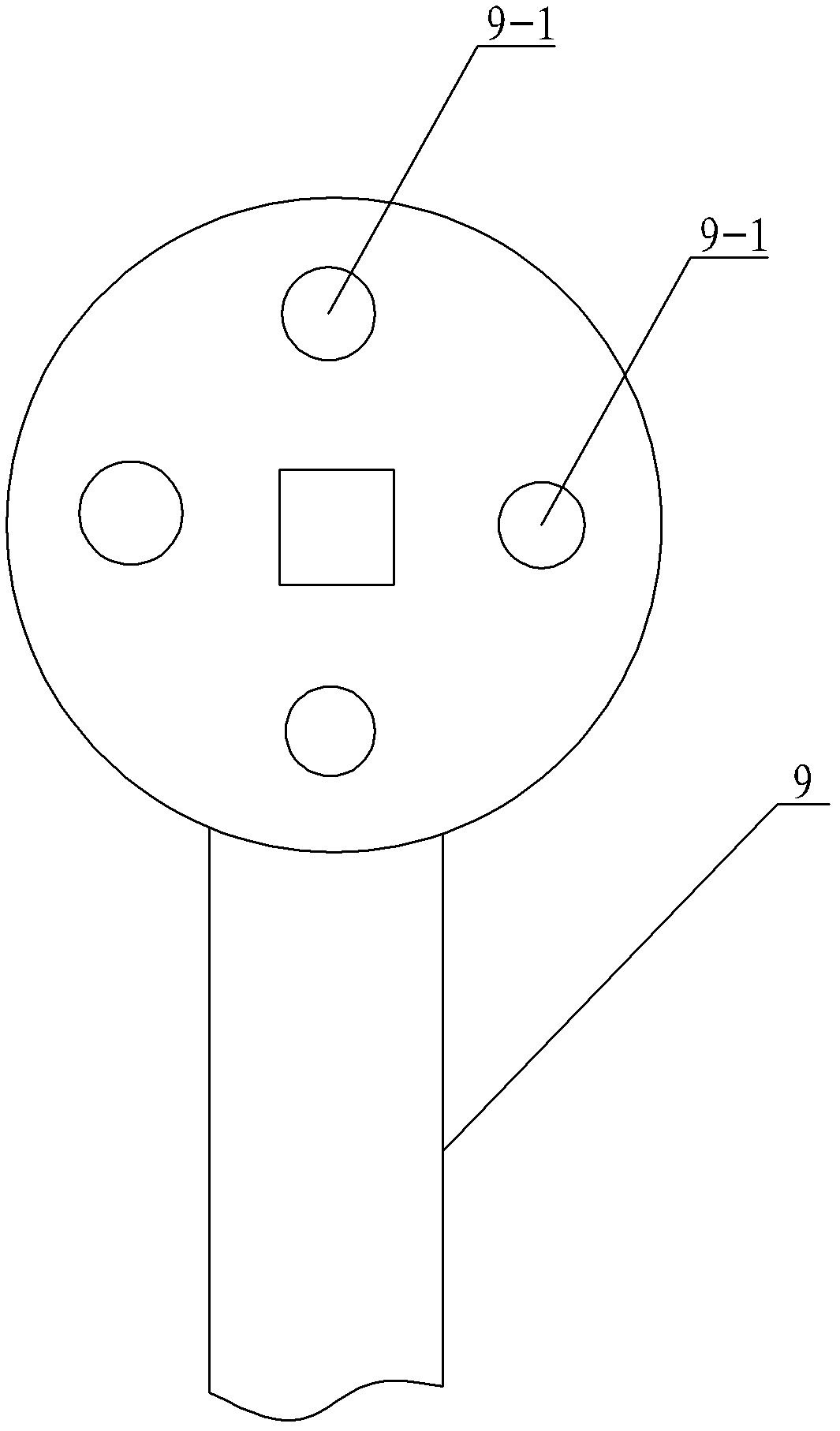

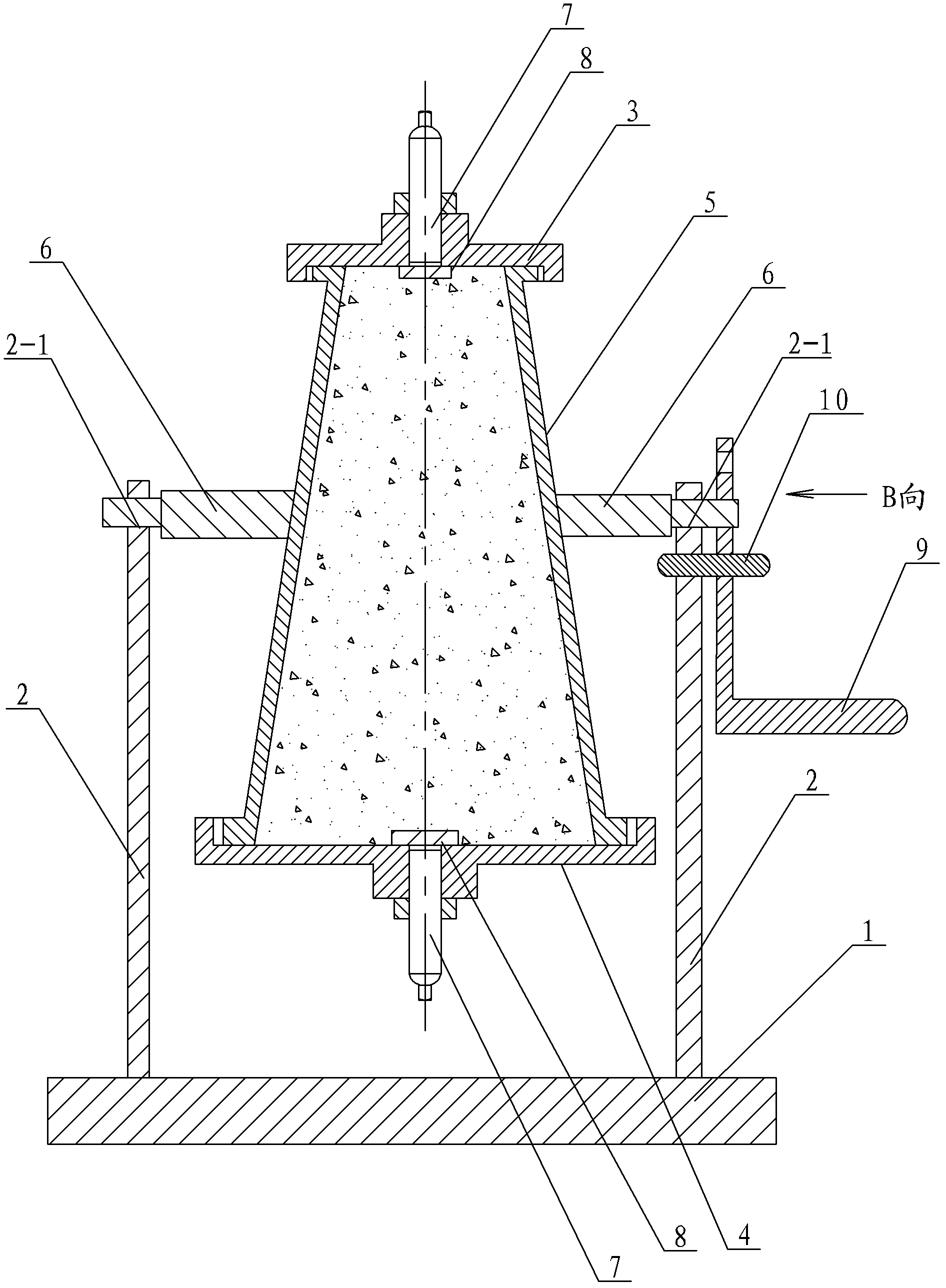

[0008] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, the hand-operated concrete self-shrinkage measuring device of this embodiment includes a base 1 and two pillars 2, the upper end of each pillar 2 is provided with a groove 2-1, and the two pillars 2 are fixed on the base in parallel 1, the hand-operated concrete self-shrinkage measuring device also includes an upper cover 3, a lower cover 4, a frustum-shaped container 5, two cylinders 6, two sensors 7, two steel sheets 8, a hand crank 9 and Fixed bar 10, frustum-conical container 5 is the stainless steel frustum-conical container with smooth inner wall, and one end of two cylinders 6 is respectively rotated and installed in the groove 2-1 of a pillar 2 upper end, and the other end of two cylinders 6 is connected with respectively The two side walls of the frustum-shaped container 5 are fixed, and the frustum-shaped container 5 is filled with fresh concrete. There is a center hol...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment, the two sensors 7 of this embodiment are respectively fixed on the upper cover 3 and the lower cover 4 through a nut. Such arrangement facilitates replacement and maintenance. Other compositions and connections are the same as in the first embodiment.

[0010] Working process of the present invention is:

[0011] Fill the fresh concrete in the frustum-shaped container, first adjust the vertical position of the frustum-shaped container, the bottom of the large-diameter container is below, and the top of the small-diameter container is above. Adjust the gap between the eddy current displacement sensor and the steel sheet, and input the voltage signal output by the eddy current displacement sensor into the instrument or computer. When the concrete is in the plastic stage, the frustum-shaped container is kept vertically still. At this time, the change of the gap between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com