Experiment table and method for testing transmission errors of high-speed-ratio high-precision speed reducer

A technology of transmission error and test experiment, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of increasing measurement links, unstable measurement results, and difficulty in measurement accuracy meeting the test accuracy requirements of high-precision reducers, so as to improve the measurement accuracy. Accuracy, low cost, and the effect of relaxing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

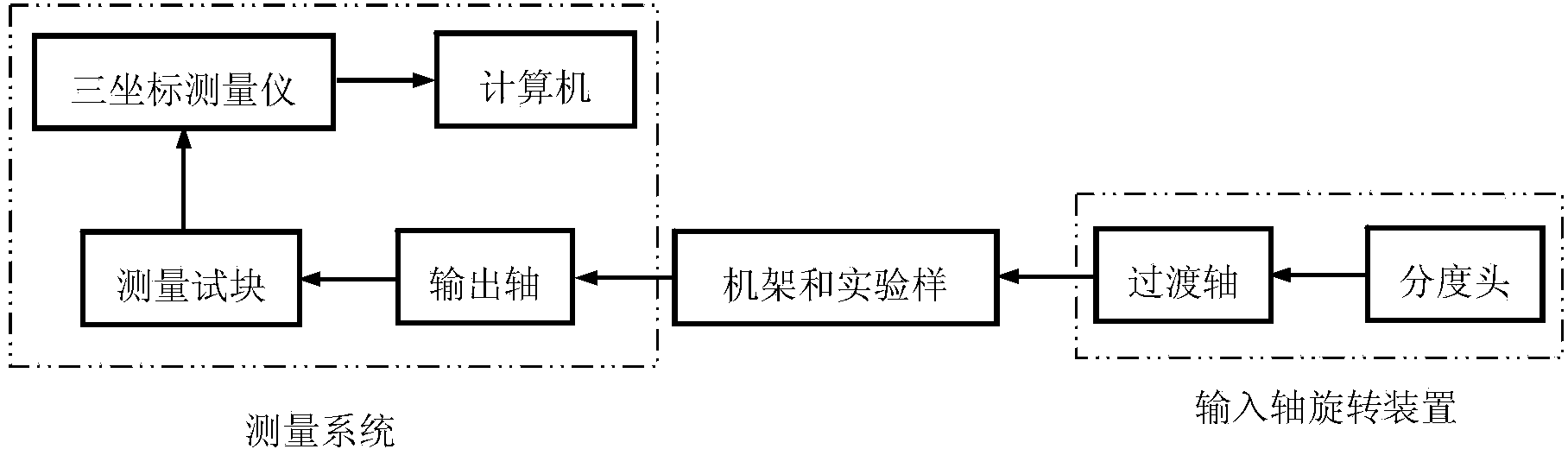

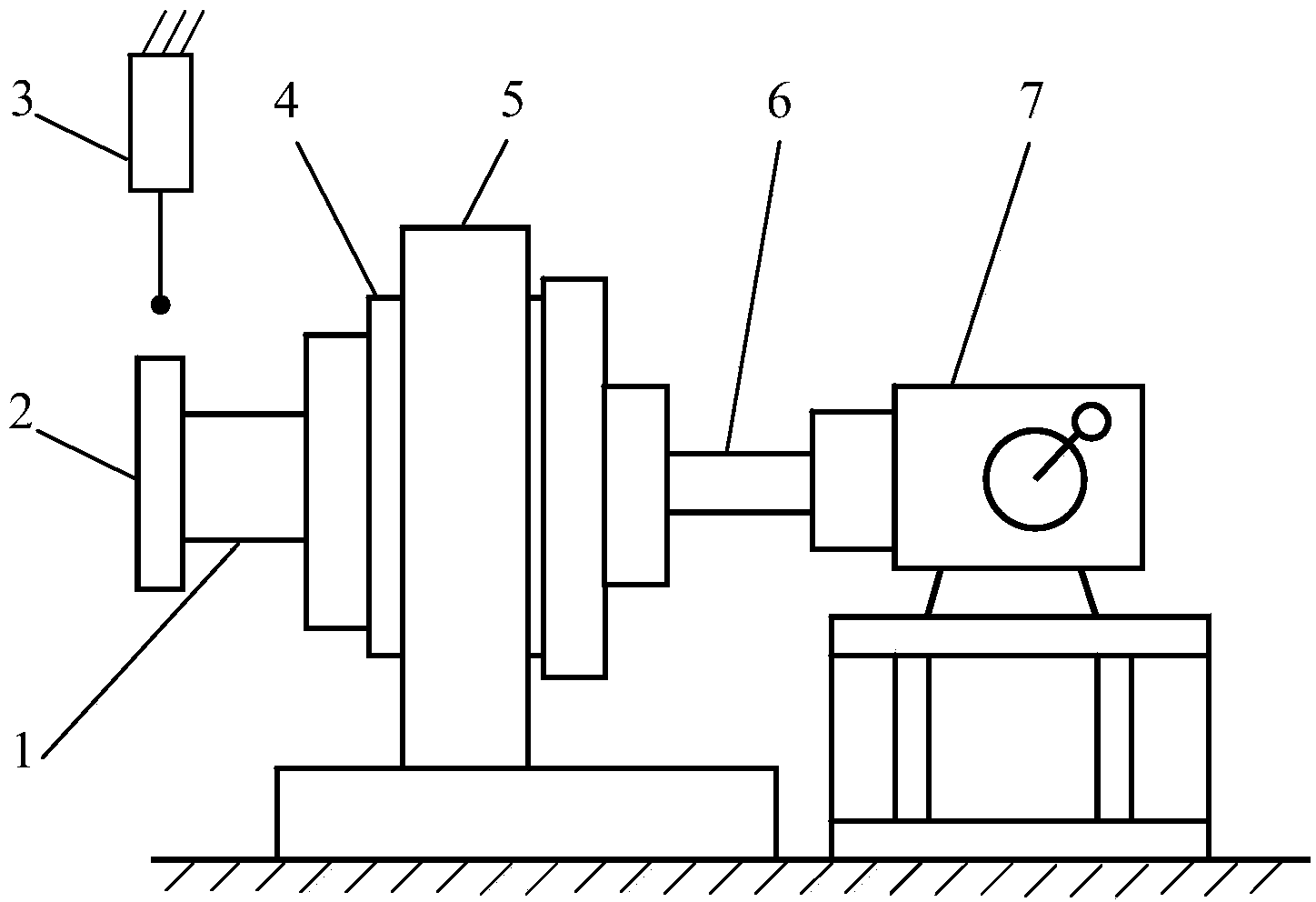

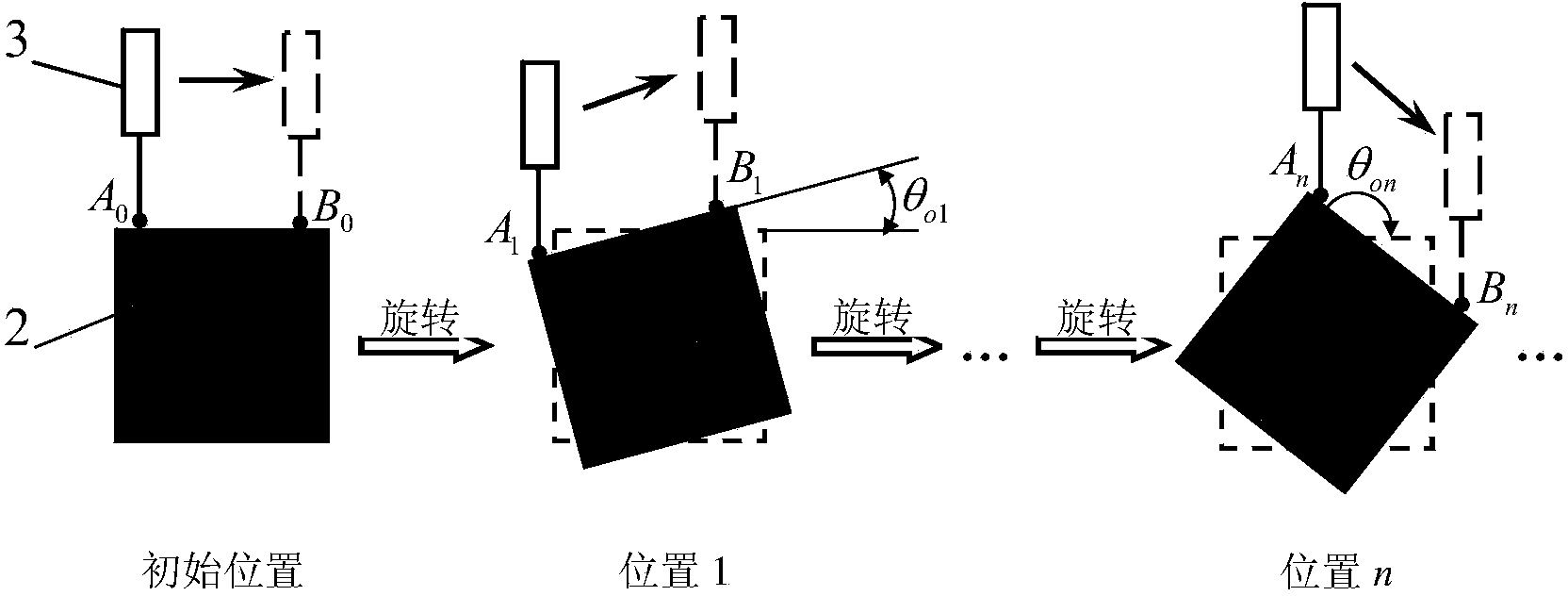

[0026] like figure 1 and figure 2 As shown, the present invention is a large speed ratio high-precision reducer transmission error test bench, which is composed of an input shaft rotating device, a frame 5 and a measuring system.

[0027] The input shaft rotation device is composed of a dividing head 7 and a transition shaft 6; one end of the transition shaft 6 is keyed to the input shaft of the tested reducer 4; the other end of the transition shaft 6 is a ball head, and clamped Tight on the three-jaw chuck of the dividing head 7.

[0028] Described measuring system is made up of output shaft 1, measuring test block 2 and three-coordinate measuring instrument 3, and described frame 5 and described dividing head 7 are all fixed on the workbench of three-coordinate measuring instrument 3; 5 is provided with a connecting flange; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com