Apparatus for detection of the accuracy of format of a web of corrugated cardboard

a technology of corrugated cardboard and accuracy, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of large construction effort for crosswise displacement of sensors, and the time required for the respective measuring process in relation to the high speed of corrugated cardboard webs in corrugated-cardboard machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

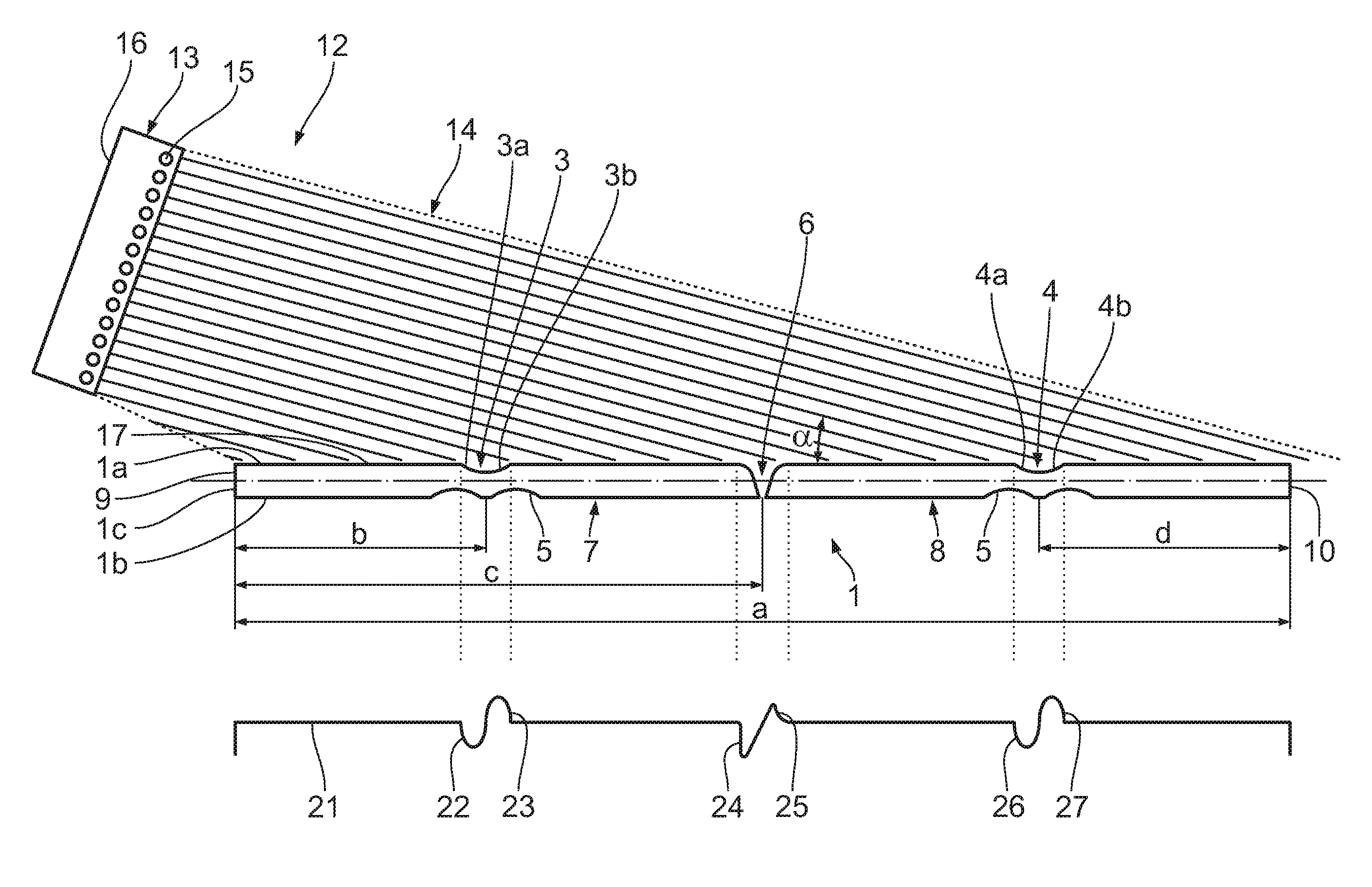

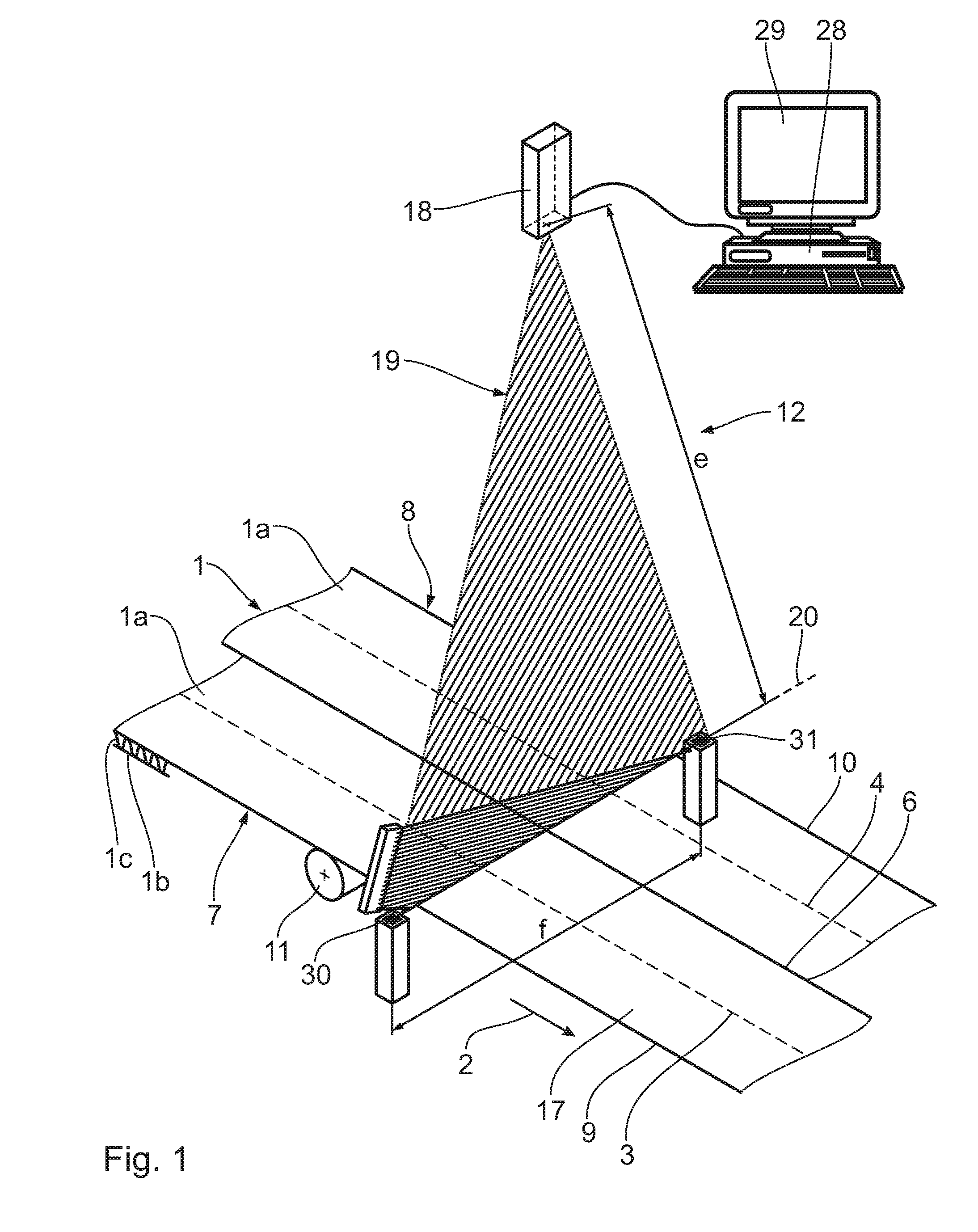

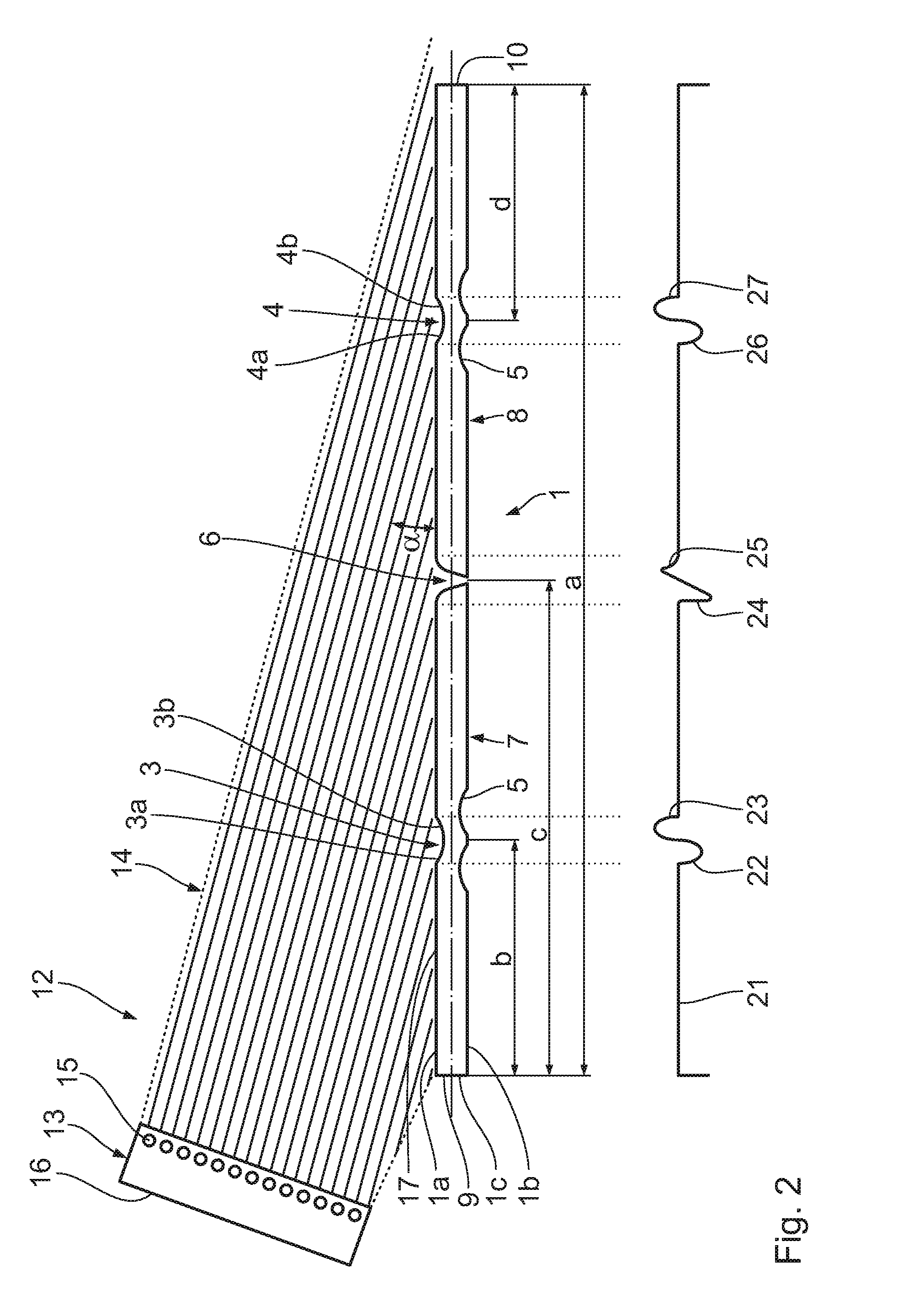

[0016]FIGS. 1 and 2 show a schematic view of a web of corrugated cardboard 1 which may however also be a conventional web of cardboard. The web of corrugated cardboard 1 conventionally comprises at least an upper smooth liner 1a and a lower, likewise smooth liner 1b between which is disposed a corrugated paper web 1c which is glued to the liners 1a and 1b. In the course of its production, the web of corrugated cardboard 1 is located on an apparatus for producing corrugated cardboard, strictly speaking downstream of a grooving and longitudinal cutting arrangement (not shown) when seen in the conveying direction 2, as it is for example shown and described in EP 0 692 369 B1 (corresponding to U.S. Pat. No. 5,857,395) which is explicitly referred to. In this arrangement, the web of corrugated cardboard 1 has been provided with upper grooves 3, 4 running in the conveying direction 2 and lower counter grooves 5 allocated thereto. In this arrangement, the web of corrugated cardboard 1 has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| distances | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com