A rotary pump hydraulic oil tank

A rotor pump and oil tank technology, applied in the field of hydraulic oil tanks, can solve problems such as the inability to observe the quality change of lubricating oil, and achieve the effect of increasing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

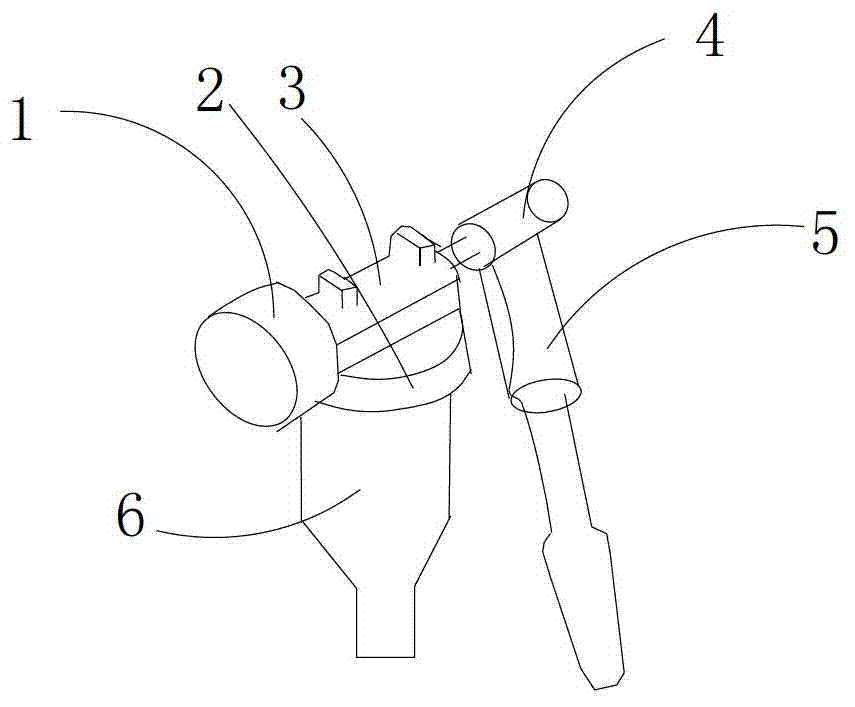

[0012] like figure 1 As shown, a rotor pump hydraulic oil tank, which is located in the mechanical seal isolation chamber of the rotor pump, includes a cylindrical oil tank main body 6, and the top of the oil tank main body is provided with an opening, and the oil tank main body A connecting piece 2 is sheathed on the outside, through which the main body of the oil tank is detachably connected to a fixed seat 3, and the fixed seat is also provided with a pressure gauge 1, and one side of the fixed seat is connected to There is a manual pressure regulating handle 4, and the vertical direction of the manual pressure regulating handle is connected with a booster handle 5, and the manual pressure regulating handle is conveniently adjusted through the booster handle, because the principle of the lever is labor-saving and easy to adjust.

[0013] A cavity is provided inside the main body of the oil tank.

[0014] The openings of the main body of the oil tank respectively extend aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com