Edge trimmer

An edge trimming machine and edge trimming technology, applied in polishing equipment and grinding fields, can solve the problems of low labor consumption, difficult quality assurance, and scrapping, etc., and achieve the effect of fast trimming speed, reduced investment and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

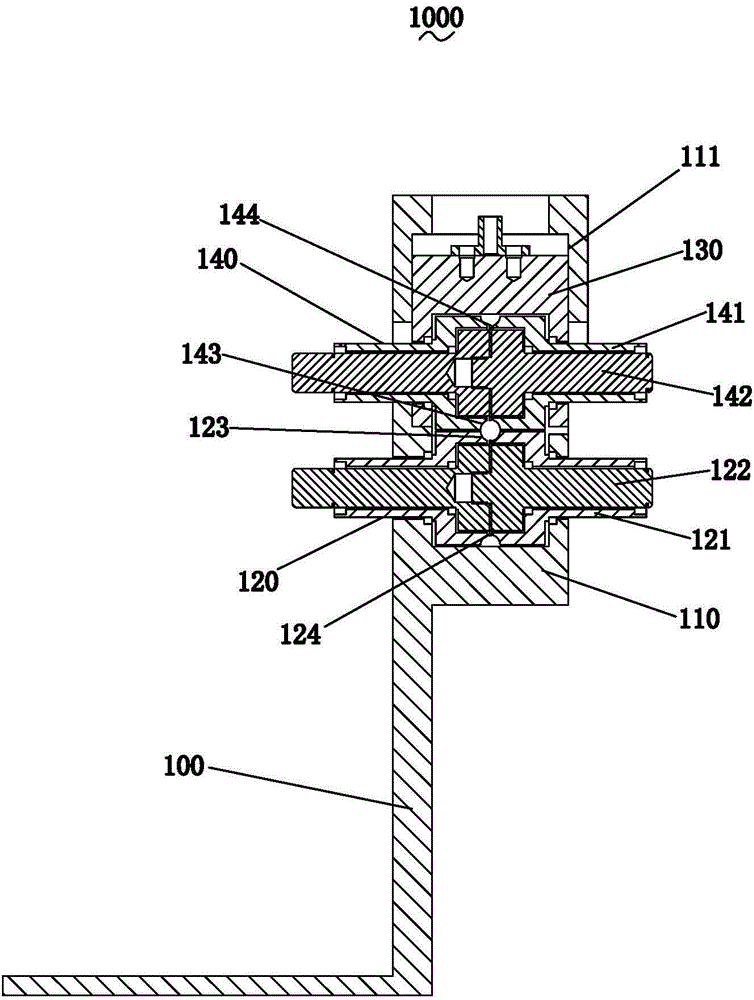

[0043] Such as figure 1 As shown, the edge trimmer 1000 of Embodiment 1 of the present invention is used for edge trimming of seals, and includes a body 100, a first bracket 110 is connected to the top of the body 100, and a rotatable first roller 120 is fixed on the first bracket 110. . The top of the first support 110 is fixed with a second support 130 that can slide up and down. The inside of the first support 110 is provided with a chamber 111 that can slide up and down for the second support 130 . tracks (not shown). A rotatable second roller 140 is fixed on the second bracket 130 .

[0044] The first roller 120 includes a first outer wheel 121 and a first inner wheel 122 located inside the first outer wheel 121 and coaxial with the first outer wheel 121 . The second roller 140 includes a second outer wheel 141 and a second inner wheel 142 located inside the second outer wheel and coaxial with the second outer wheel 141 . The middle outer surface of the first outer wh...

Embodiment 2

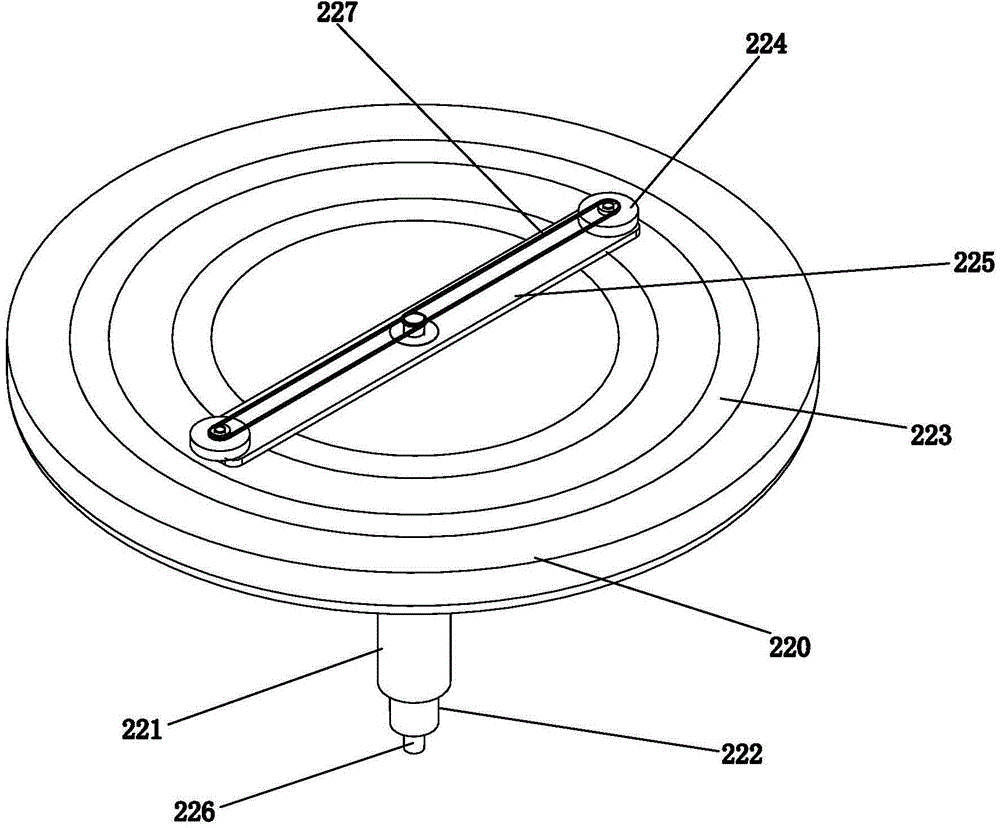

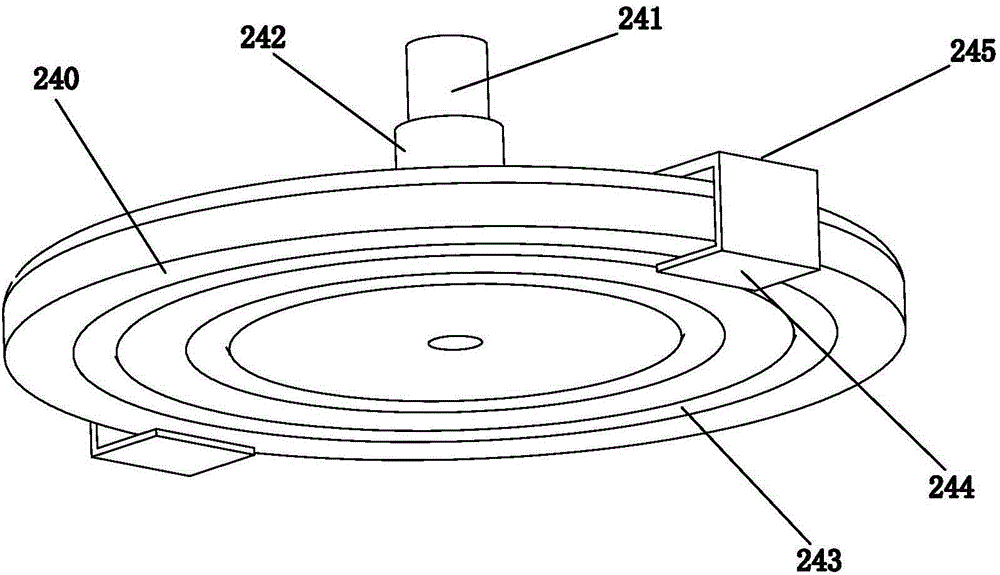

[0049] Such as figure 2 , image 3 As shown, the trimming machine according to Embodiment 2 of the present invention is used for trimming ring seals, and includes a body (not shown), which is connected with a rotatable circular first chuck 220 and a rotatable The circular second chuck 240, the first chuck 220 and the second chuck 240 are set up and down correspondingly. Between the first chuck 220 and the second chuck 240 on the first chuck 220, a first trimming sheet 224 that can rotate along the axis of the first chuck 220 is provided, and on the second chuck 240, an extension Insert between the first chuck 220 and the second chuck 240 the second trimming sheet 244 that can rotate along the axis of the second chuck 240 .

[0050] A first outer shaft 221 is fixed on the lower end of the first chuck 220 , and the first outer shaft 221 drives the first chuck 220 to rotate along the axis. The first outer shaft 221 is a hollow structure, and a first central shaft 222 coaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com