A pulsed power device based on an annular ceramic solid-state wire

A technology of pulse power and solid line, applied in pulse shaping and other directions, can solve the problems of ceramic material body breakdown along the surface, complex structure design, and poor waveform quality, so as to reduce the occurrence probability of surface flashover and uniform electric field distribution , The effect of improving the waveform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

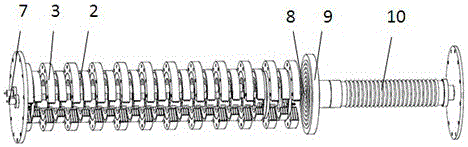

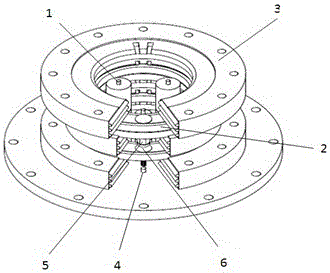

[0026] Such as figure 1 As shown, the pulse power device based on the annular ceramic solid wire of the present invention is composed of a pulse generation section and a load section arranged in a cylinder, and the pulse generation section and the load section are sealed and separated by an insulating partition. The pulse generation segment is charged with SF 6 gas (or SF 6 with N 2 Mixed gas) insulation, transformer oil insulation in the load section, and a plexiglass insulation board between the two insulation media. The outer cylinder of the entire device is not shown in the figure. The pulse generating section is the main body of the device, including ring pulse forming lines, gas switches, ring insulating plates, charging inductors and other components.

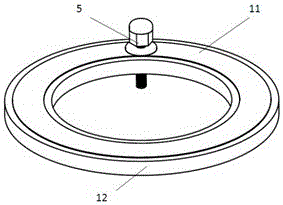

[0027] Such as figure 2 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com