Method for producing a spindle drive for an adjusting element of a motor vehicle

A screw drive and component technology, which is applied to wing fan components, construction, transmission devices, etc., can solve the problems of time-consuming, high cost, and unsatisfactory sealing effect in the assembly process, and achieve cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

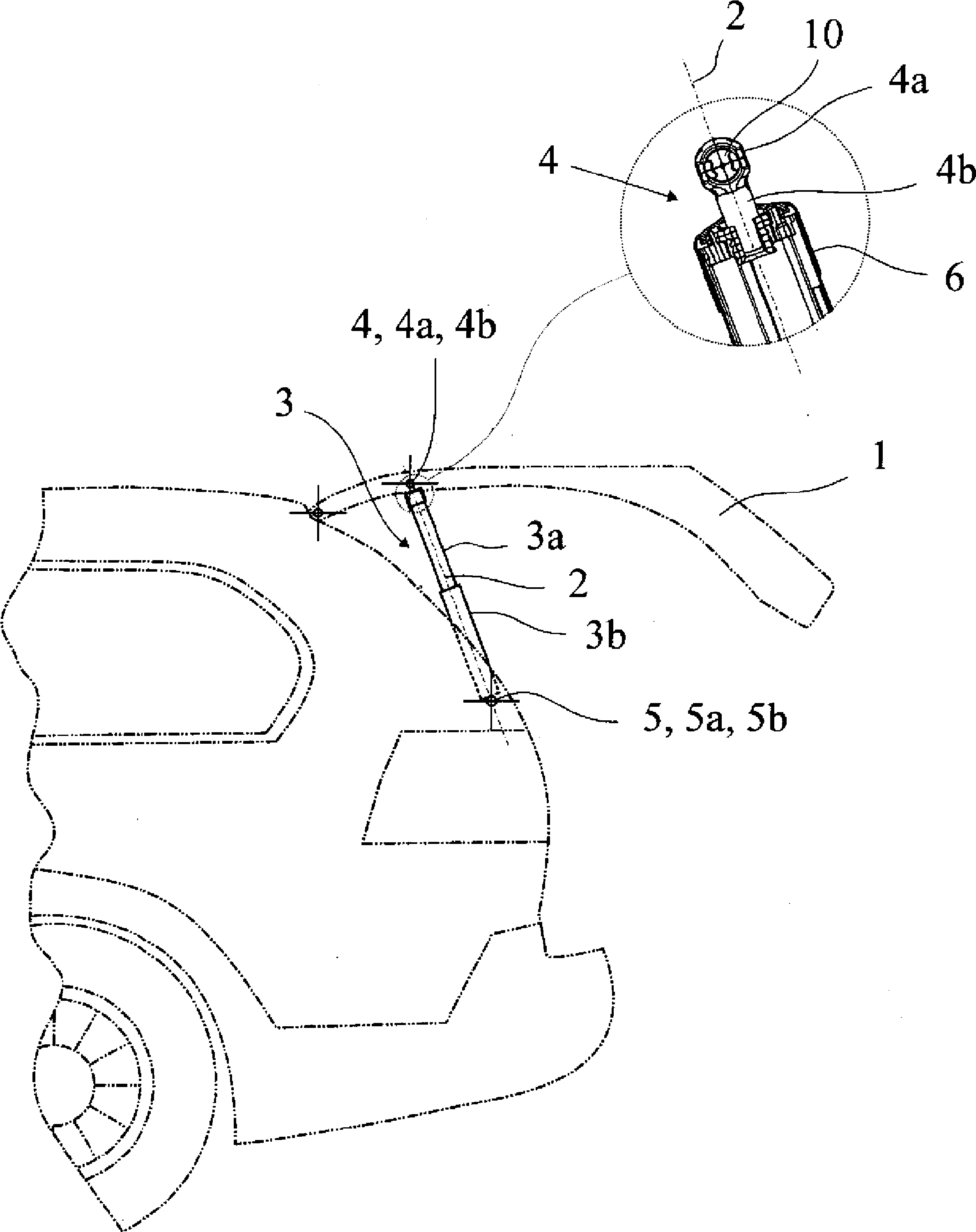

[0021] The screw drive shown in the drawing is used to electrically adjust the vehicle adjustment component 1 formed by the rear cover. But the proposed screw drive can be used for all possible automotive tuning components 1 . For example, rear lids, bonnets, side doors, charging compartment covers, roof windows or the like of motor vehicles may be mentioned here.

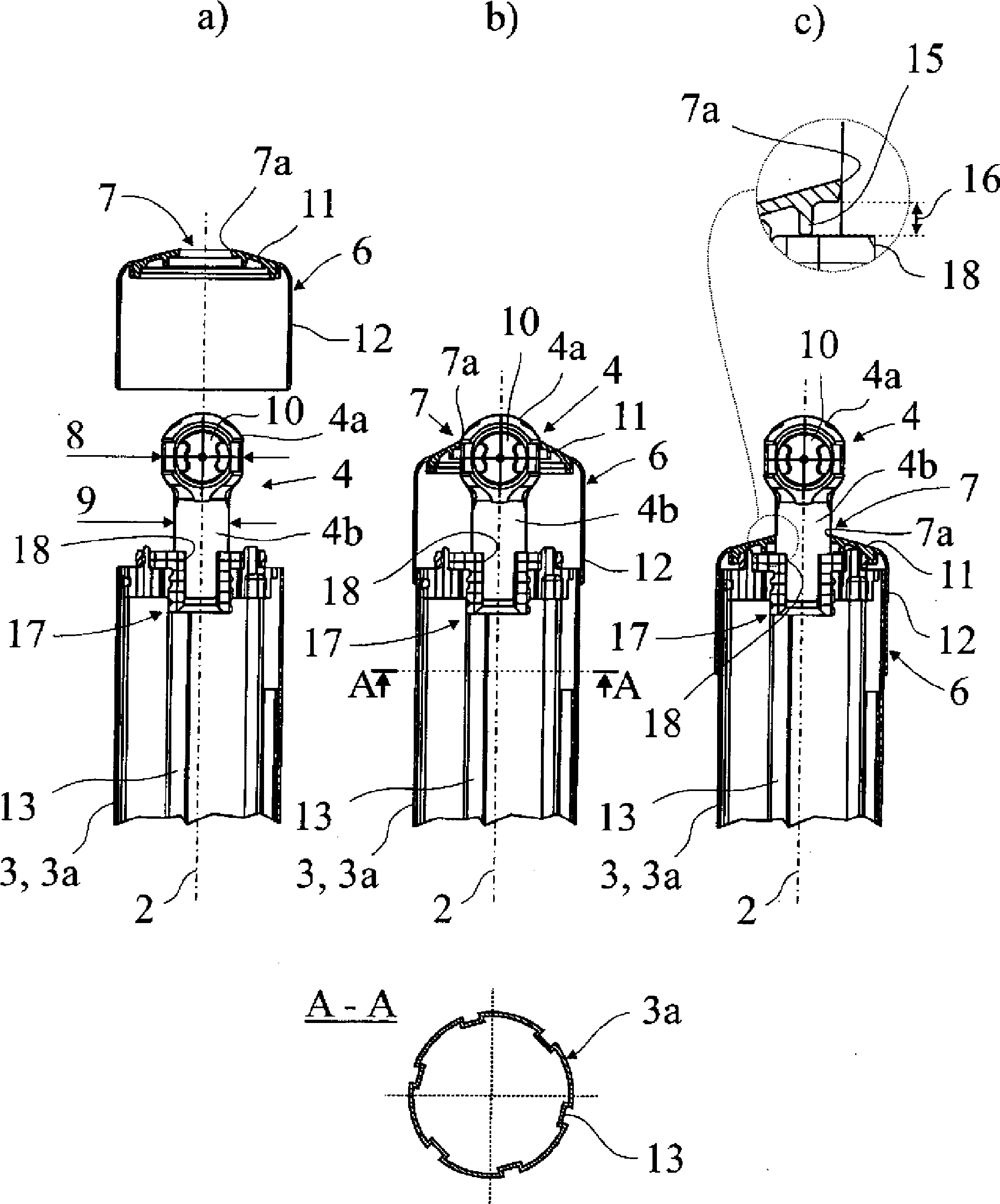

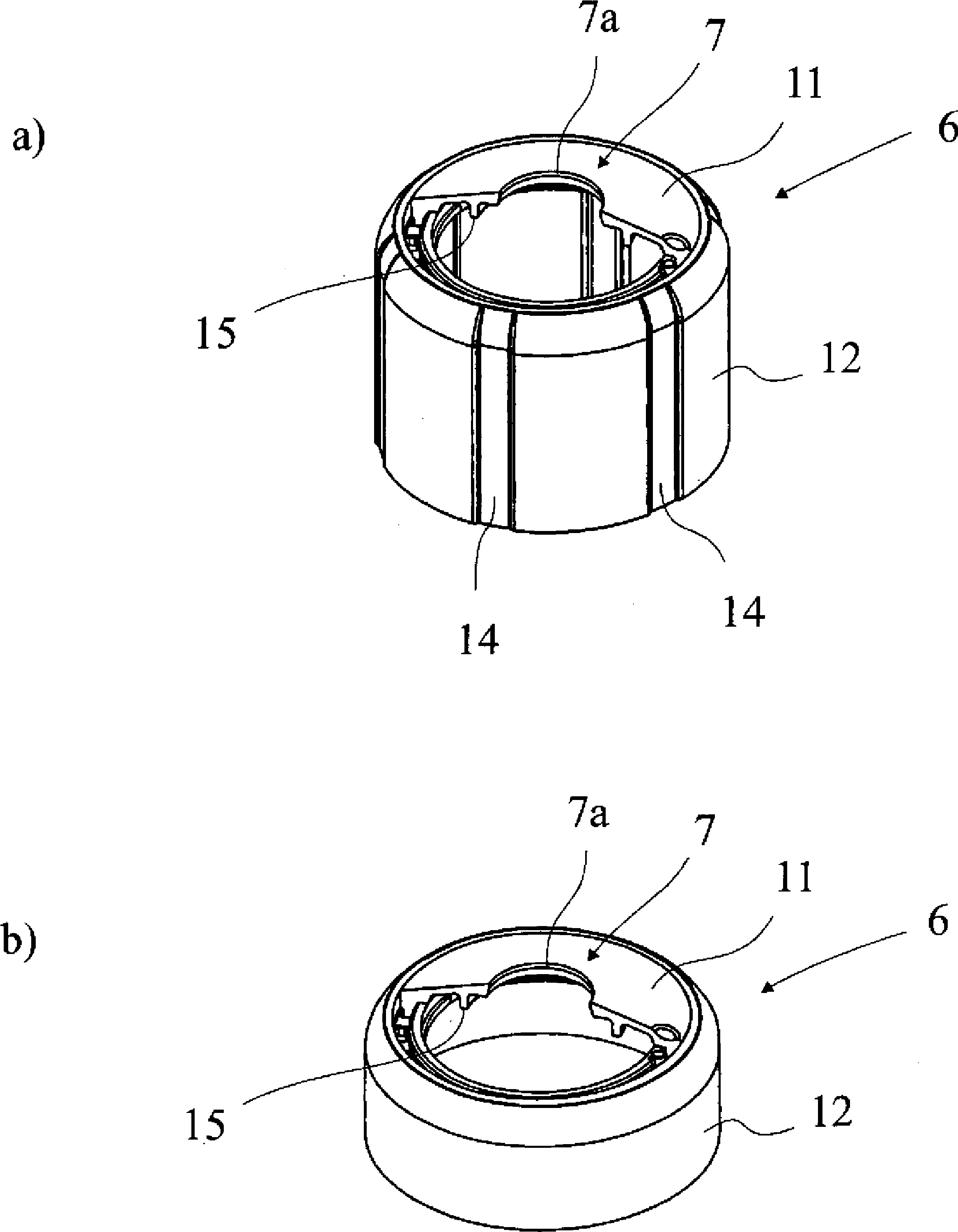

[0022] Along a geometric screw drive axis 2 , the screw drive has a substantially tubular screw drive housing 3 and two connections 4 , 5 for deriving the linear drive movement.

[0023] The screw drive housing 3 is here preferably constructed in two parts and consists of an upper housing part 3a and a lower housing part 3b. The two housing parts 3 a , 3 b are formed tubularly with an essentially circular cross section. The two housing parts 3 a , 3 b are moved telescopically relative to each other during screw drive adjustment in a known manner.

[0024] Here the two screw-driven joints 4, 5 are preferably each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com