Plastic film towing method and apparatus

A technology of traction device and adhesive film, which is applied in the field of automatic cutting and pasting of adhesive film, which can solve the problems of complexity and bulky occupation, and achieve the effect of simplifying automatic moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

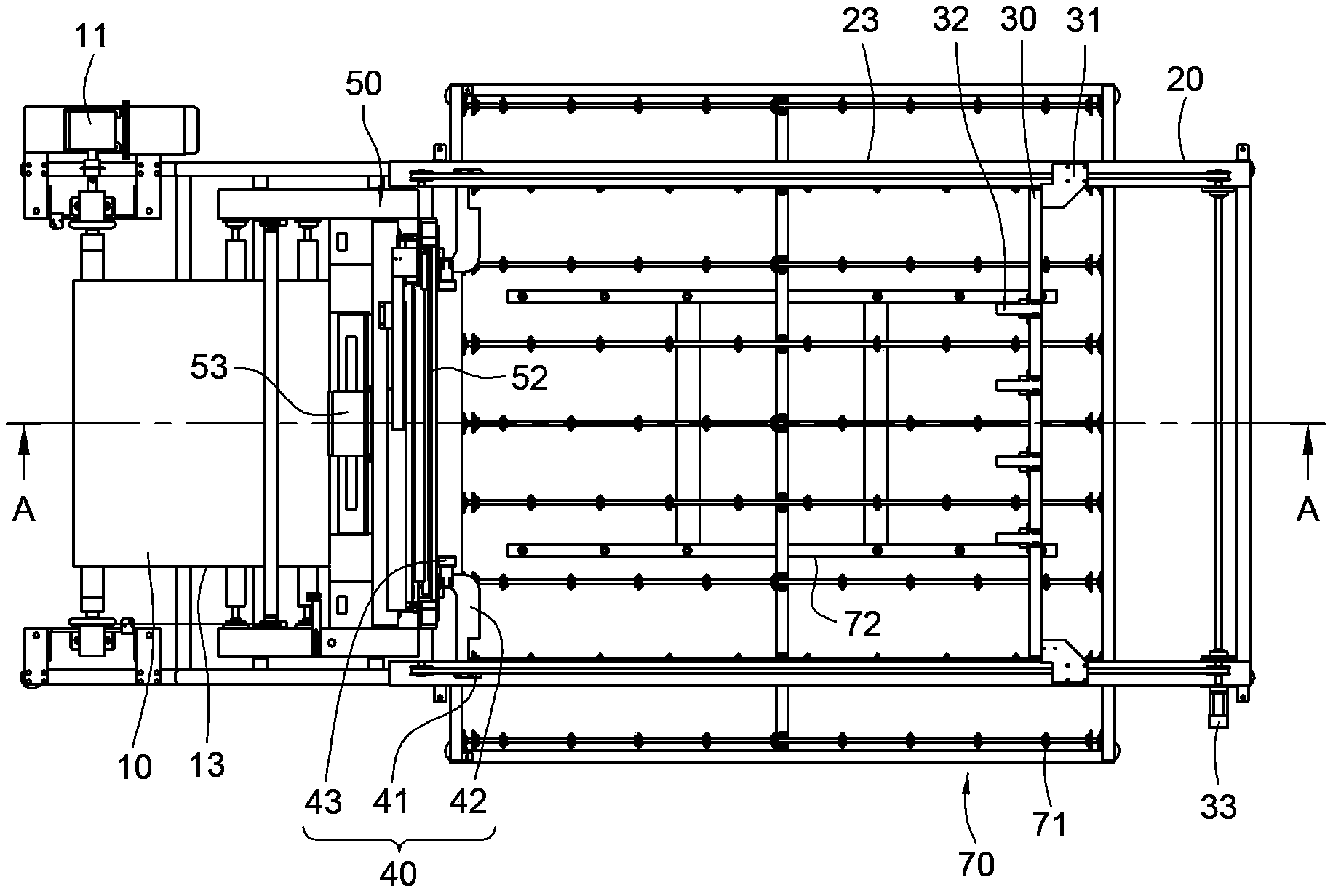

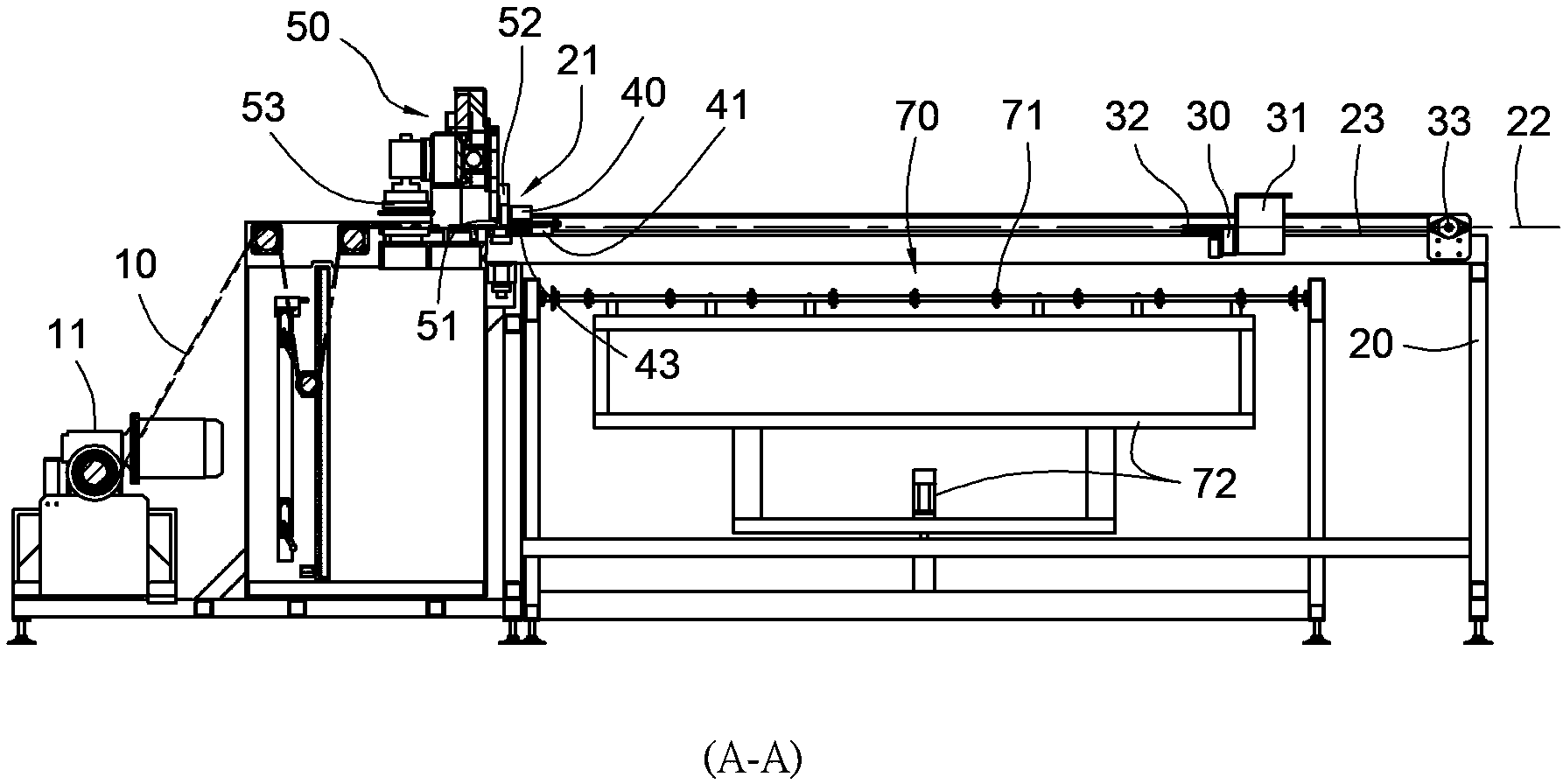

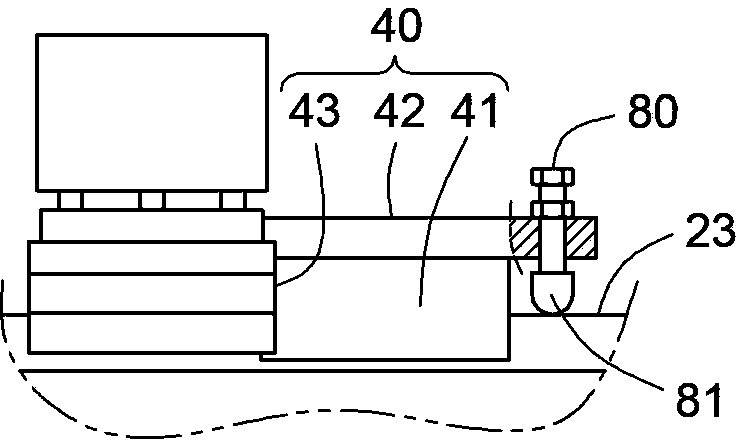

[0020] Please refer to figure 1 and figure 2 ,in figure 1 Disclose the top view configuration diagram of the present invention, figure 2 reveal figure 1 The sectional view of the A-A section in the middle, as shown in the figure, illustrates that the present invention provides a preferred embodiment of a film pulling device, including a frame 20, a pulling rod 30, and a pulling claw 40. in:

[0021] The frame 20 can be composed of, for example, extruded metal rods, so that the middle of the frame 20 is roughly empty and the surroundings have a platform shape that can be used as a fixed end. According to this, the feeder 11 of the adhesive film raw material 10 can be arranged at one end of the frame 20 , and the feeder 11 can continuously supply the adhesive film raw material 10 bundled into a cylindrical form to the direction of the frame 20 . Accordingly, the present invention defines that the end of the frame 20 that can be loaded with the film material 10 is a feed e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com