A local annealing positioning device for fasteners

A technology of local annealing and positioning device, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of uncontrollable width of annealing, unsatisfactory product performance, poor coaxiality and concentricity, etc. Consistency, improve processing pass rate, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

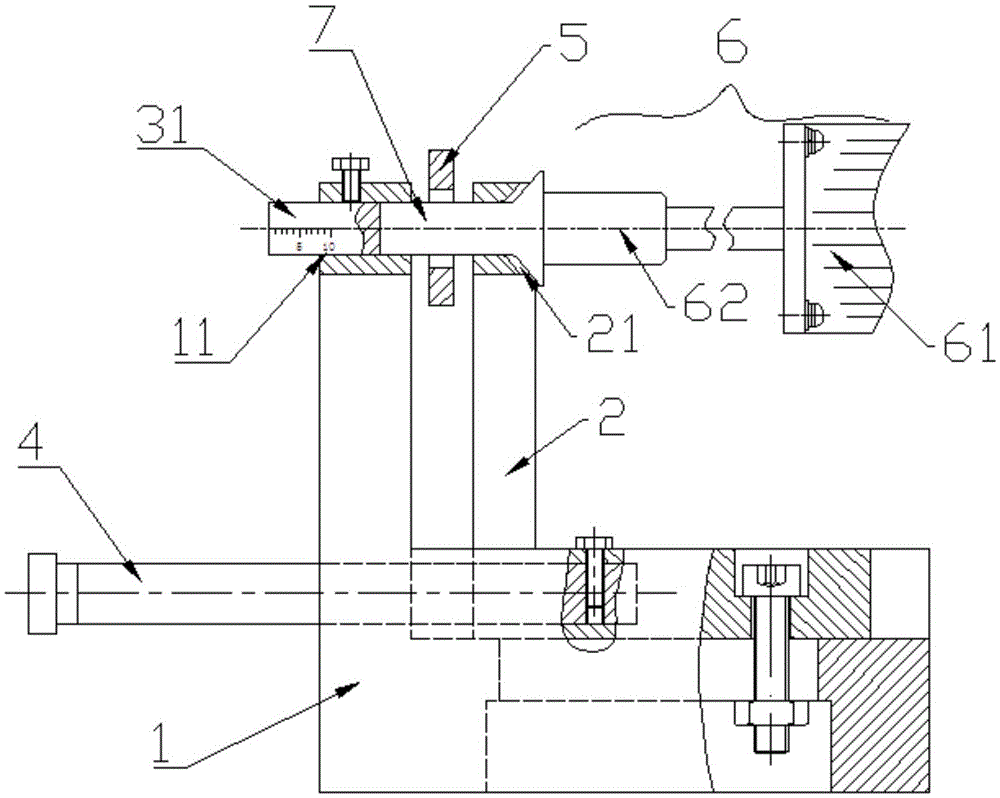

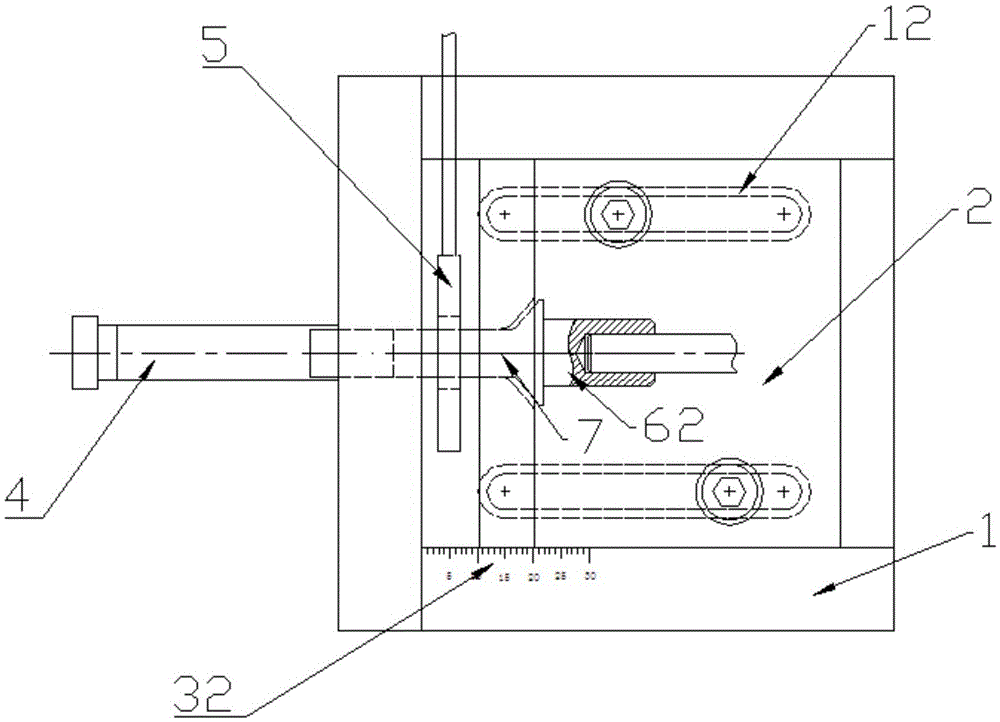

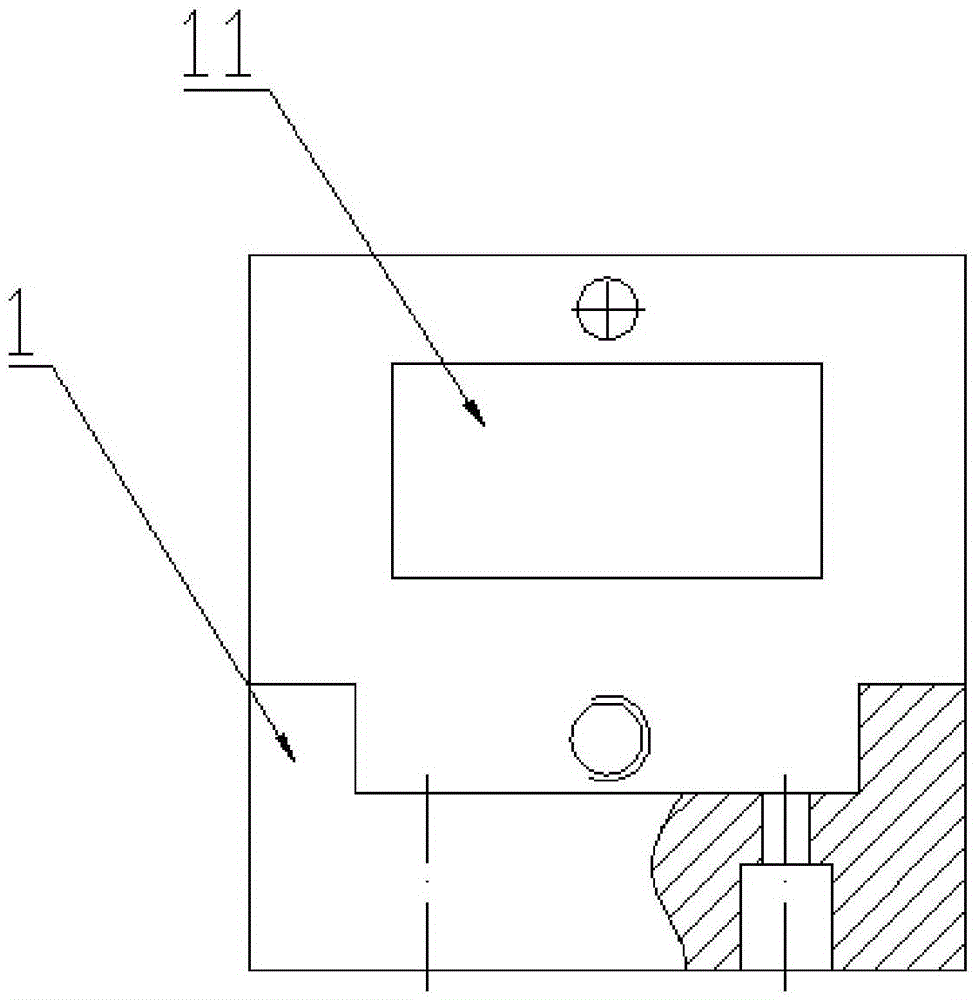

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-7 As shown, a local annealing positioning device for fasteners includes a rotating part 6, a fixed part 1, a movable part 2 slidingly fitted with the fixed part 1, and an upper measuring part 31 and a lower measuring part 32. The fixed part Both the part 1 and the movable part 2 are made of metal, which can shield the magnetic field of the heating coil, thereby protecting the unexposed workpiece from being heated.

[0032] The fixed part 1 is L-shaped by the first vertical component and the first horizontal component, and the movable part 2 is L-shaped by the second vertical component and the second horizontal component. In the first horizontal direction of the fixed part 1 There is a U-shaped groove on the part, and the movable part 2 is placed in the U-shaped groove and is slidably connected with it. There are two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com