A local annealing equipment for fasteners

A local annealing and fastener technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of inconsistent annealing temperature, low workpiece pass rate, difficulty in ensuring installation consistency, etc., to achieve width consistency and improve processing Qualification rate and the effect of reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

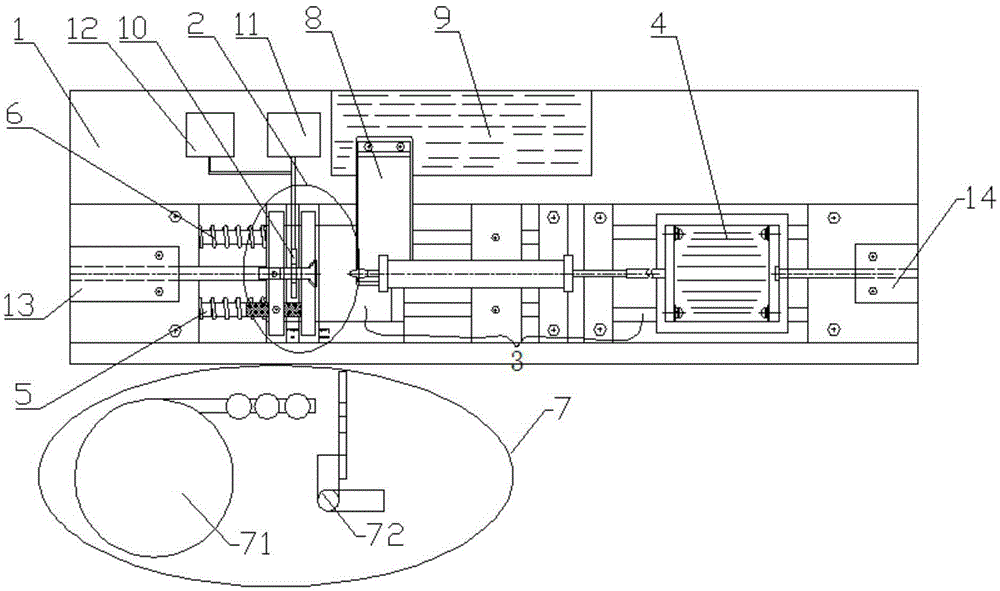

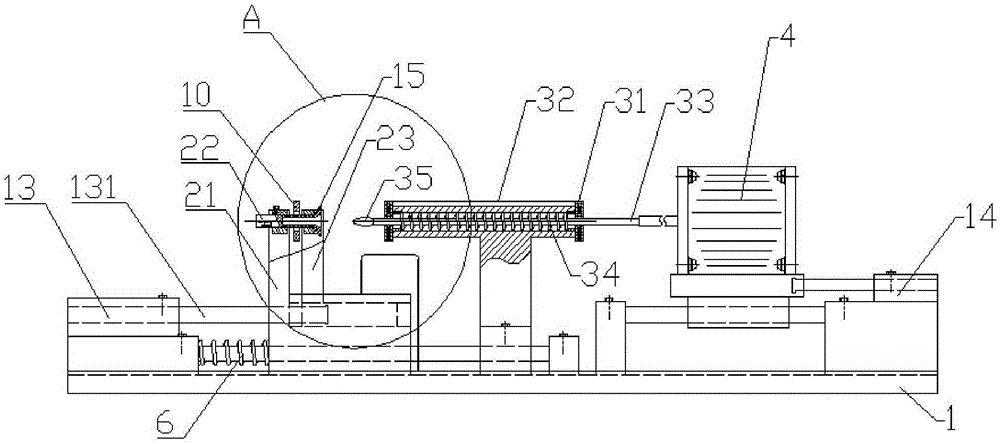

[0055] like Figure 1-4 As shown, a local annealing device for fasteners includes a positioning mechanism 2 located on a workbench 1, a flexible transmission mechanism 3, an automatic feeding mechanism 7 and a heating mechanism for heating fasteners.

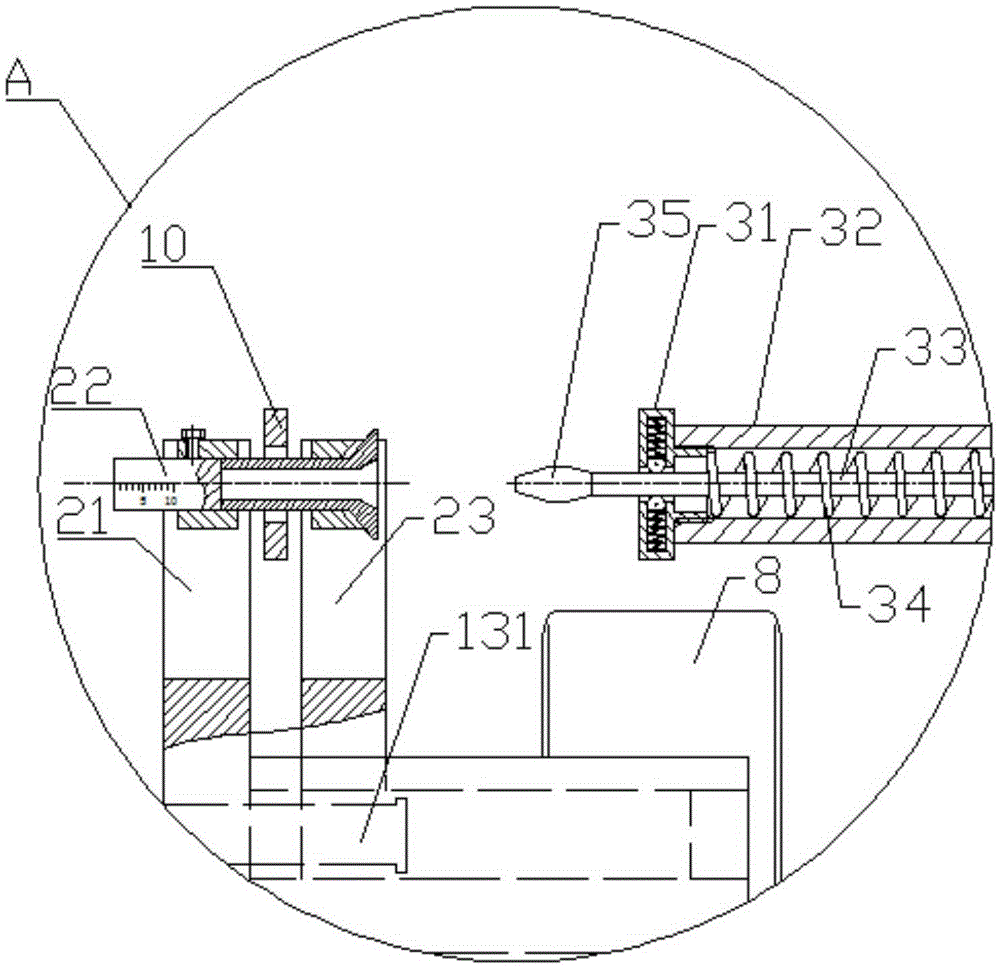

[0056] like Figure 3-9 As shown, the positioning mechanism 2 includes a fixed tool 21, a limit tool 16, a movable tool 23 slidingly fitted with the fixed tool 21, an upper measuring tool 22 and a lower measuring tool 24, and the movable tool 23 is provided with a support A positioning hole 231, the fixed tooling 21 is provided with a measurement positioning hole 211 corresponding to the supporting positioning hole 231;

[0057]Both the fixed tooling 21 and the movable tooling 23 are made of metal, which can shield the magnetic field of the heating coil 10, thereby protecting the unexposed fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com