Motor module and stabilizer with same

A module and stator technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of excessive external threading, low motor rotation accuracy, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

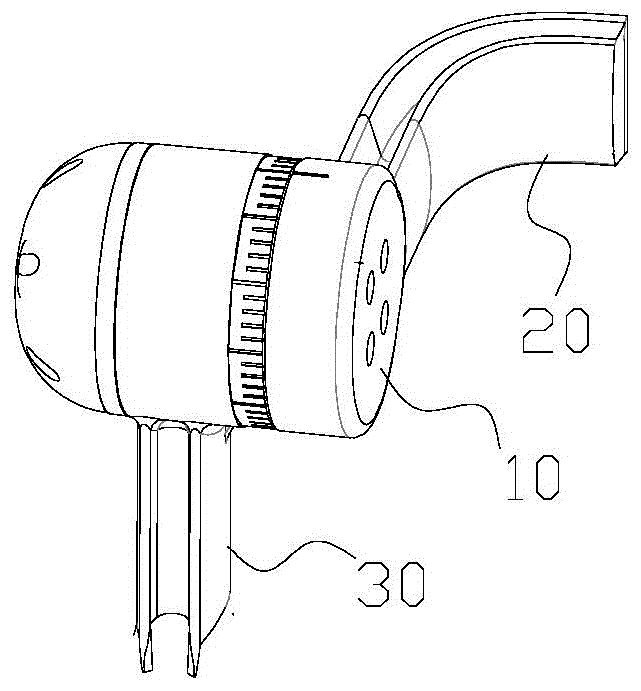

[0024] Please refer to details figure 1. The first embodiment provides a stabilizing device, which includes a first rotating member 20 and a second rotating member 30 rotationally connected with the first rotating member 20, and also includes a motor module 10, the first rotating member 20 and the motor module The stator 110 of the group 10 is fixedly connected, and the second rotating member 30 is fixedly connected with the rotor 120 of the motor module 10 . In the first embodiment, all motors used are three-phase brushless AC motors.

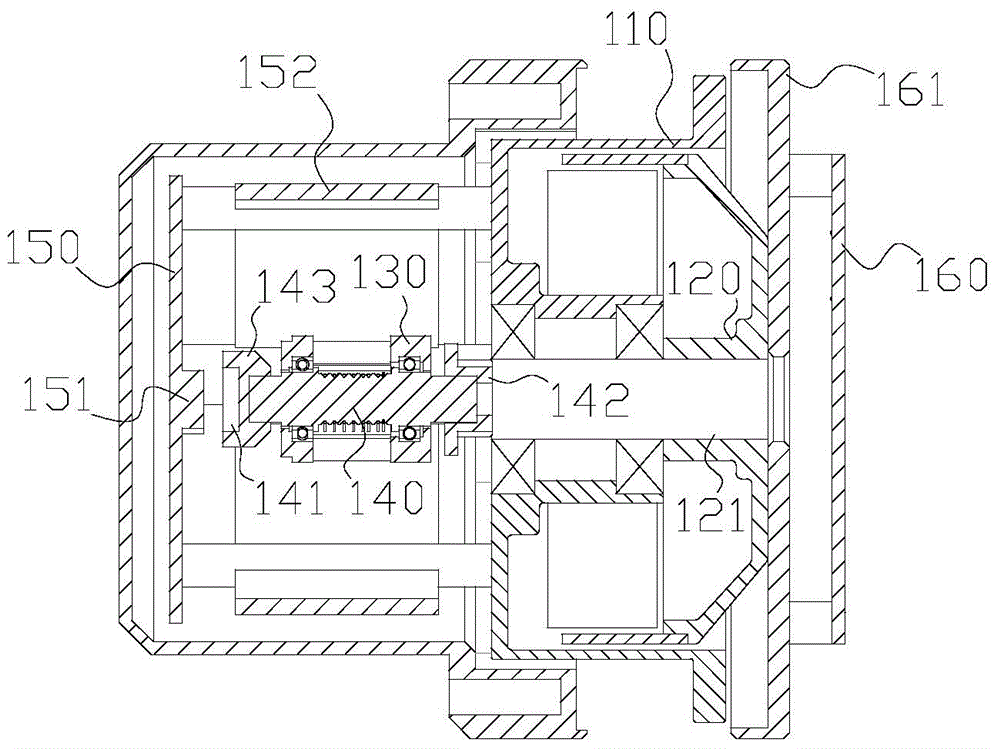

[0025] Please refer to details figure 2 . The motor module 10 includes a motor with a hollow shaft 121 , and the motor includes a stator 110 and a rotor 120 rotatably connected with the stator 110 . The motor module 10 also includes a conductive slip ring, a first connecting wire, a second connecting wire, a first circuit board 150 fixedly connected to the stator 110 and a second circuit board 160 fixed to the rotor 120 . In the first em...

Embodiment 2

[0031] The difference between the second embodiment and the first embodiment is that the conductive slip ring is arranged inside the hollow shaft 121, the stator part 130 of the conductive slip ring and the hollow shaft 121 are fixed to each other, and the rotor part 140 of the conductive slip ring and the hollow shaft 121 rotate connect.

Embodiment 3

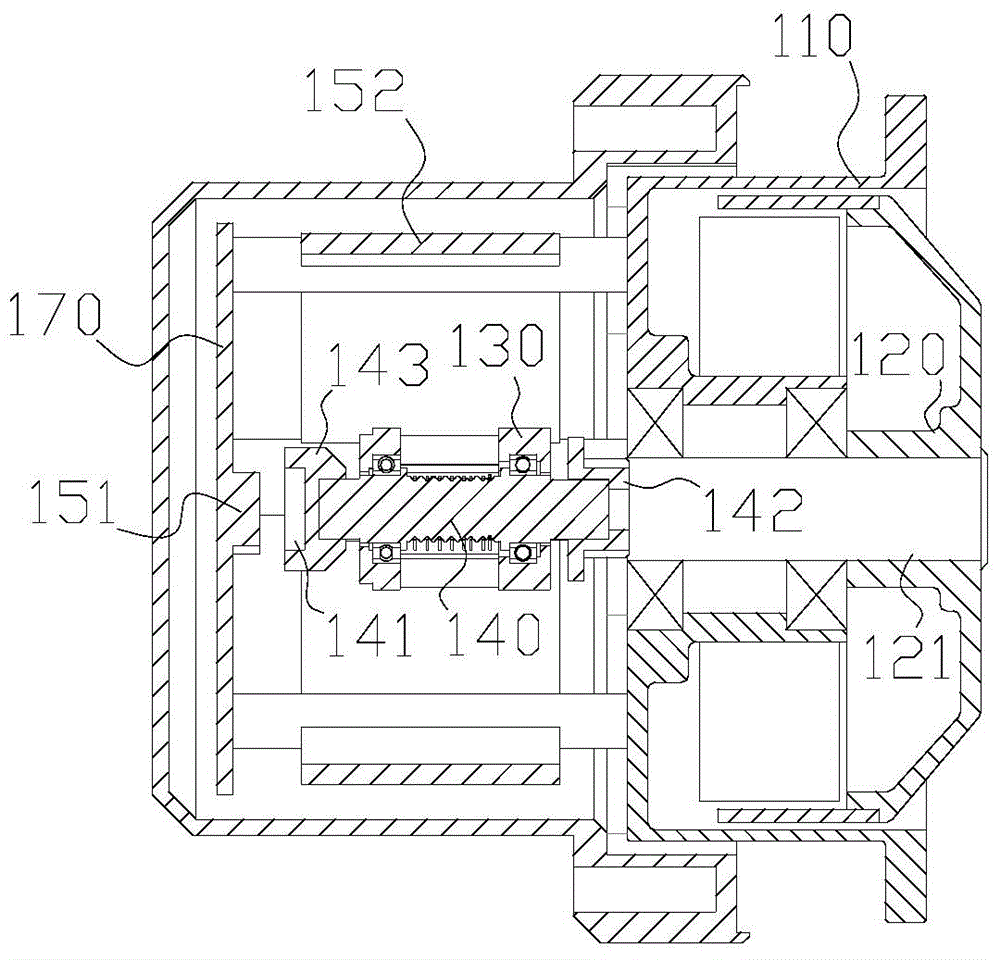

[0033] The difference between the third embodiment and the first embodiment is that, please refer to image 3 , the motor module 10 has only one circuit board 170 , and the circuit board 170 is arranged on one side of the motor stator 110 . The motor module 10 also includes a conductive slip ring, a first connection wire, a second connection wire, and a circuit board 170 fixedly connected to the stator 110; The connected rotor part 140, the circuit board 170 is connected to the stator part 130 through the first connecting wire, and the second connecting wire connected with the rotor part 140 runs through the hollow shaft 121, and the hollow shaft 121 is fixedly connected with the rotor 120; the rotor part A magnetic steel 141 is provided at one end of 140 close to the circuit board 170 , and an encoder chip 151 is provided on the circuit board 170 corresponding to the magnetic steel 141 , and there is a gap between the magnetic steel 141 and the encoder chip 151 . The motor m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com