Manufacturing method of plastic lens

A manufacturing method and technology for plastic lenses, which are applied in applications, household appliances, other household appliances, etc., can solve problems such as easy to produce texture, and achieve the effect of less bad texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

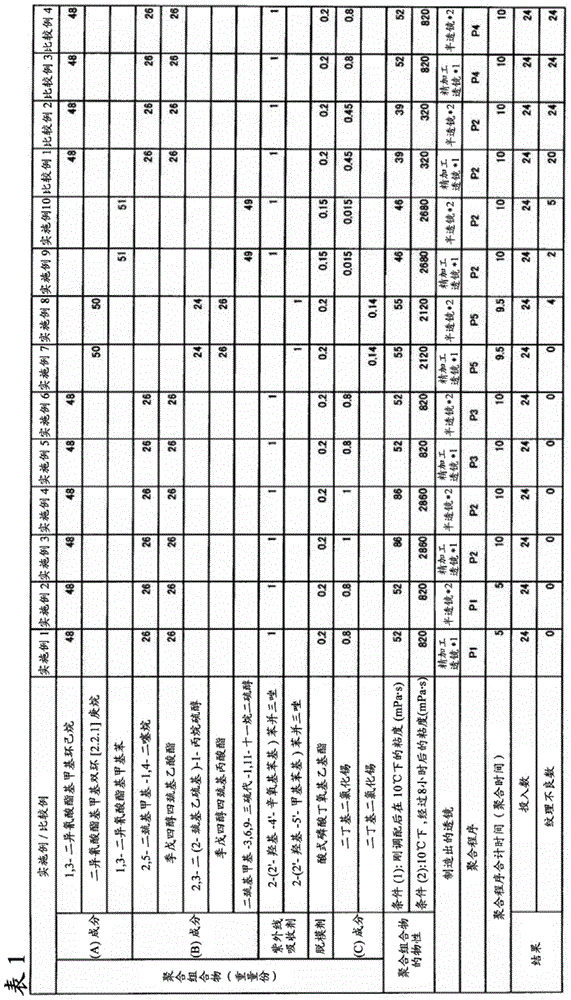

Embodiment 1~10、 comparative example 1~4

[0107] The polymer composition shown in the following Table 1 was cast, and then polymerized and cured in a mold for lens molding under the temperature rise conditions of the polymerization program described in the table to manufacture a plastic lens.

[0108]

[0109] *1 Finishing lens: diameter 70mm, lens power -6.00 diopters, center wall thickness 1.0mm, edge thickness 9.0mm

[0110] *2 Half mirror: diameter 70mm, lens base arc 136mm (curvature radius R), center wall thickness 4.0mm, edge thickness 8.0mm

[0111] (aggregation program)

[0112]P1: The initial temperature is 10°C, the temperature is raised to 40°C in 3.5 hours, then the temperature is raised to 125°C in 0.5 hours, and then kept at 125°C for 1 hour (5 hours in total, about 4 hours below 60°C).

[0113] P2: Keep at the initial temperature of 7.5°C for 5.0 hours, then raise the temperature to 55°C over 3.0 hours, then raise the temperature to 125°C over 1.0 hour, and then keep at 125°C for 1 hour (10 hours i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com