A multifunctional rutting tester

A rutting test, multi-functional technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of limited scope of application of test results, inability to obtain data, etc., to achieve the effect of good applicability and promotion of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

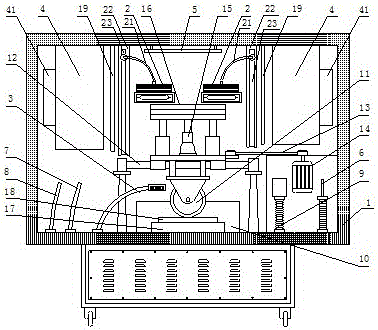

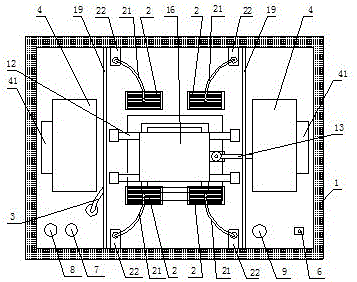

[0038] according to figure 1 and figure 2 As shown, this embodiment is illustrated: a multi-functional rutting tester, which is composed of a test box, an industrial computer and a console, and a rutting test assembly, an ultraviolet lamp 2, a shower head 3, a refrigeration device 4, and a heater are arranged inside the test box 5. Temperature sensor 6, oxygen nozzle 7, nitrogen nozzle 8, oxygen concentration sensor 9 and water tank 10, the industrial computer controls the rutting test components through the program software, and the console is used to control the switch and spray of the ultraviolet lamp 2 in the test chamber. The spraying, temperature and oxygen concentration of shower head 3.

[0039] An insulation layer 1 is arranged on the outer wall of the test box. Ensure that the temperature of the test chamber is constant during the test.

[0040] The water tank 10 is used to collect the water sprayed by the shower head and discharge the water out of the test chamb...

Embodiment 2

[0066] like figure 1 As shown, as a conversion embodiment of embodiment 1, the height of the ultraviolet lamp described in the technical solution of the present embodiment can be adjusted, vertical rods 22 are arranged symmetrically on the top of the test box, chute 23 is set on the vertical rods 22, and the moving rod One end of 21 is placed in the chute 23, and the other end fixes the ultraviolet lamp 2.

[0067] The adjustable distance between the ultraviolet lamp 2 and the test piece 18 is 300-700 mm.

[0068] By adjusting the position of one end of the moving rod in the chute, the height of the ultraviolet lamp can be adjusted, and then the distance between the ultraviolet lamp and the test piece can be adjusted, so as to achieve the purpose of adjusting the intensity of ultraviolet light irradiated by the ultraviolet lamp on the test piece. In the rutting test, the tester can determine the distance between the ultraviolet lamp and the test piece according to the actual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com