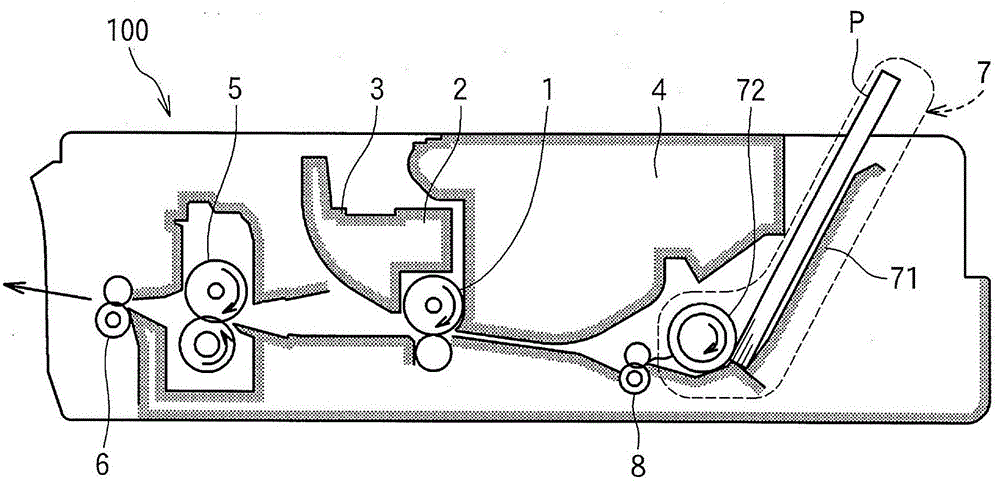

Sheet separating and feeding device and image forming device

A supply device and sheet material technology, applied in the direction of pile separation, electric recording technology using charge pattern, equipment for electric recording technology using charge pattern, etc., can solve the problem of enlargement, damage to the front end of paper, poor separation of paper feeding, etc. Problems, to achieve the effect of stable separation and prevent re-delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

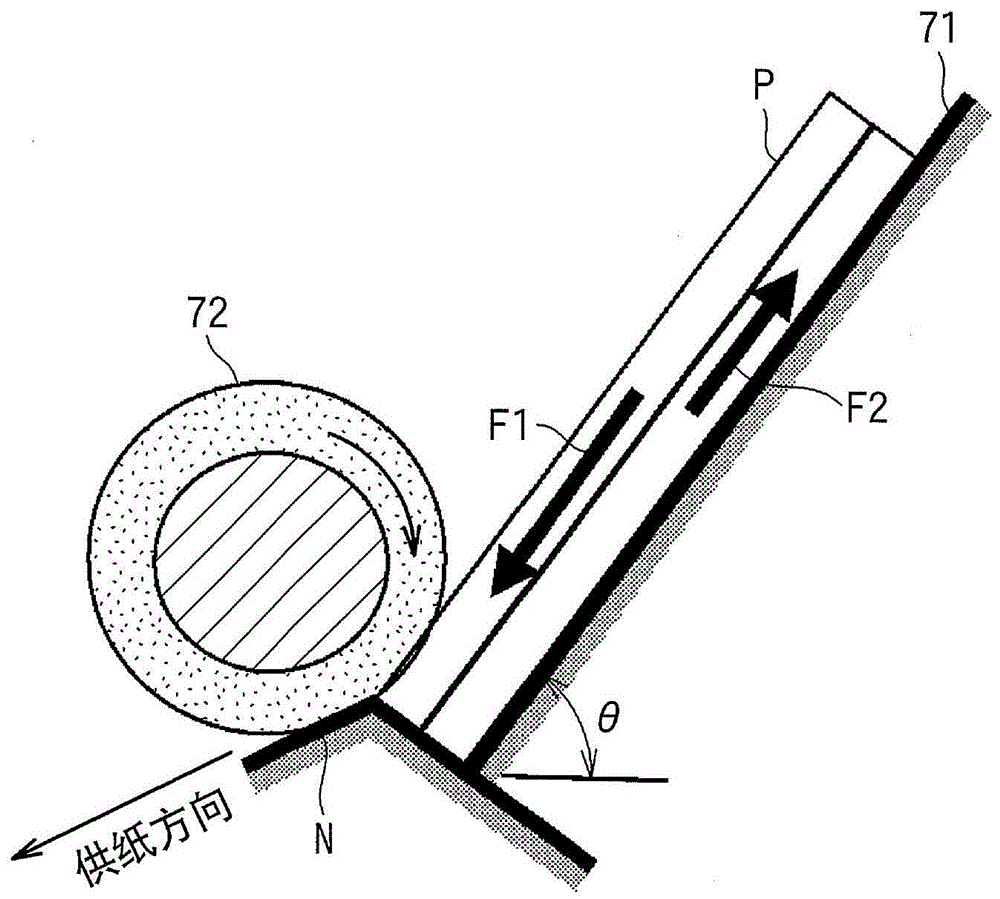

[0107] Fig. 4a is a perspective view of the sheet separating and supplying device according to the first embodiment. Fig. 4b is a central cross-sectional view in the direction of the rotation axis of the rotary conveyance unit 72 of the separation and supply device. In addition, FIG. 4c is an enlarged cross-sectional view of the guide part 77 which is a main part of the separation supply device. FIG. 4 d is a perspective view of the base supporting part 73 with the guiding part 77 .

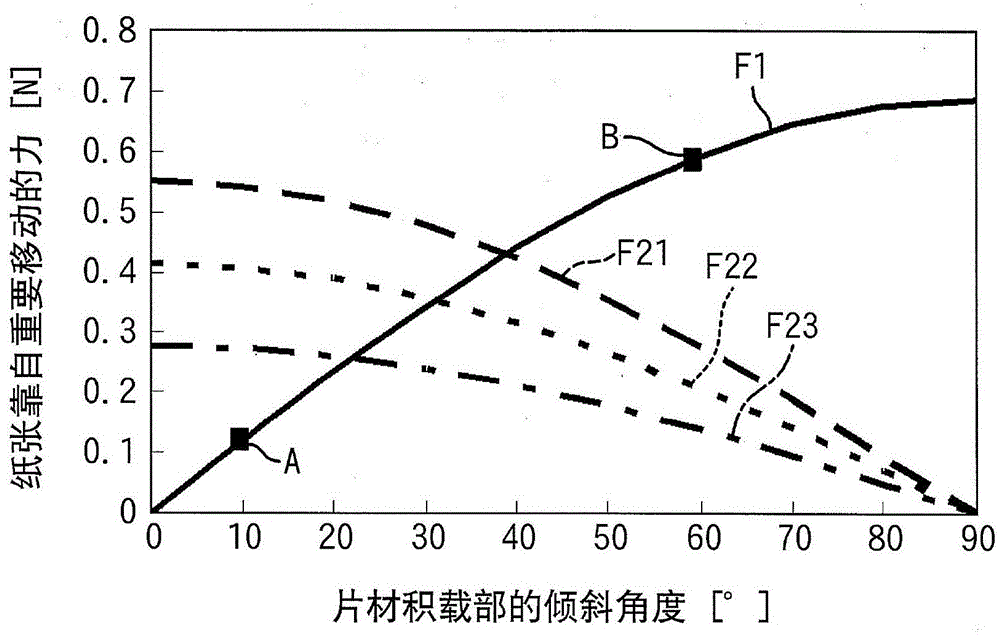

[0108] As shown in Fig. 4a and Fig. 4b, the sheet stacking part 71 is erected at a predetermined angle from the horizontal plane in a state in which the leading end in the feeding direction of the paper P is inclined downward, and the paper P can be stacked in multiple layers. stowage. The sheet stacking portion 71 is disposed so as to be oscillating (swinging) in a direction of contact (contact and separation) with respect to the rotary conveyance portion 72 around a support shaft 71 a at the ...

no. 2 Embodiment approach

[0124] Fig. 5a is a perspective view of a seat support portion 73B of the sheet separating and supplying device according to the second embodiment. In addition, Fig. 5b is a projection view when viewed from the upstream side toward the downstream side in the supply direction of the seat support portion 73B. Fig. 5c is a projected view of the base support portion 73B viewed from a direction perpendicular to the supply direction. It should be noted here that, in the subsequent drawings including Fig. 5a to Fig. 5c, the seat body and the friction part are appropriately omitted.

[0125] As shown in FIG. 5 b , the feature of the seat support portion 73B is that the shape of the top portion 78B of the guide portion 77B is an upward convex curved surface (R surface) when viewed from the supply direction. Accordingly, by reducing the conveyance resistance of the paper P, damage to the paper P can be suppressed, and wear of the guide portion 77B can be reduced.

[0126] In addition,...

no. 3 Embodiment approach

[0129] Fig. 6a is a perspective view of a seat support portion 73C of the sheet separating and supplying device according to the third embodiment. FIG. 6 b is a projection view of the base support portion 73C viewed from a direction perpendicular to the supply direction. The third embodiment is characterized in that the upstream guide surface 79C upstream in the supply direction is formed in a convex arc shape upward from the top 78C of the guide portion 77C. In addition, 80 C of downstream guide surfaces which are downstream in a supply direction are formed in the arc shape convex upward rather than the top part 78C of the guide part 77C.

[0130] By forming the upstream guide surface 79C in a convex arc shape facing upward, the entry angle of the leading edge of the paper when passing over the upper surface of the guide part 77C is relatively stable, and it is possible to prevent paper non-feeding caused by an increase in the transport load. prevent. In addition, by formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com