Patents

Literature

31 results about "Disjoining pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disjoining pressure (symbol Πd), in surface chemistry, according to an IUPAC definition, arises from an attractive interaction between two surfaces. For two flat and parallel surfaces, the value of the disjoining pressure (i.e., the force per unit area) can be calculated as the derivative of the Gibbs energy of interaction per unit area in respect to distance (in the direction normal to that of the interacting surfaces). There is also a related concept of disjoining force, which can be viewed as disjoining pressure times the surface area of the interacting surfaces.

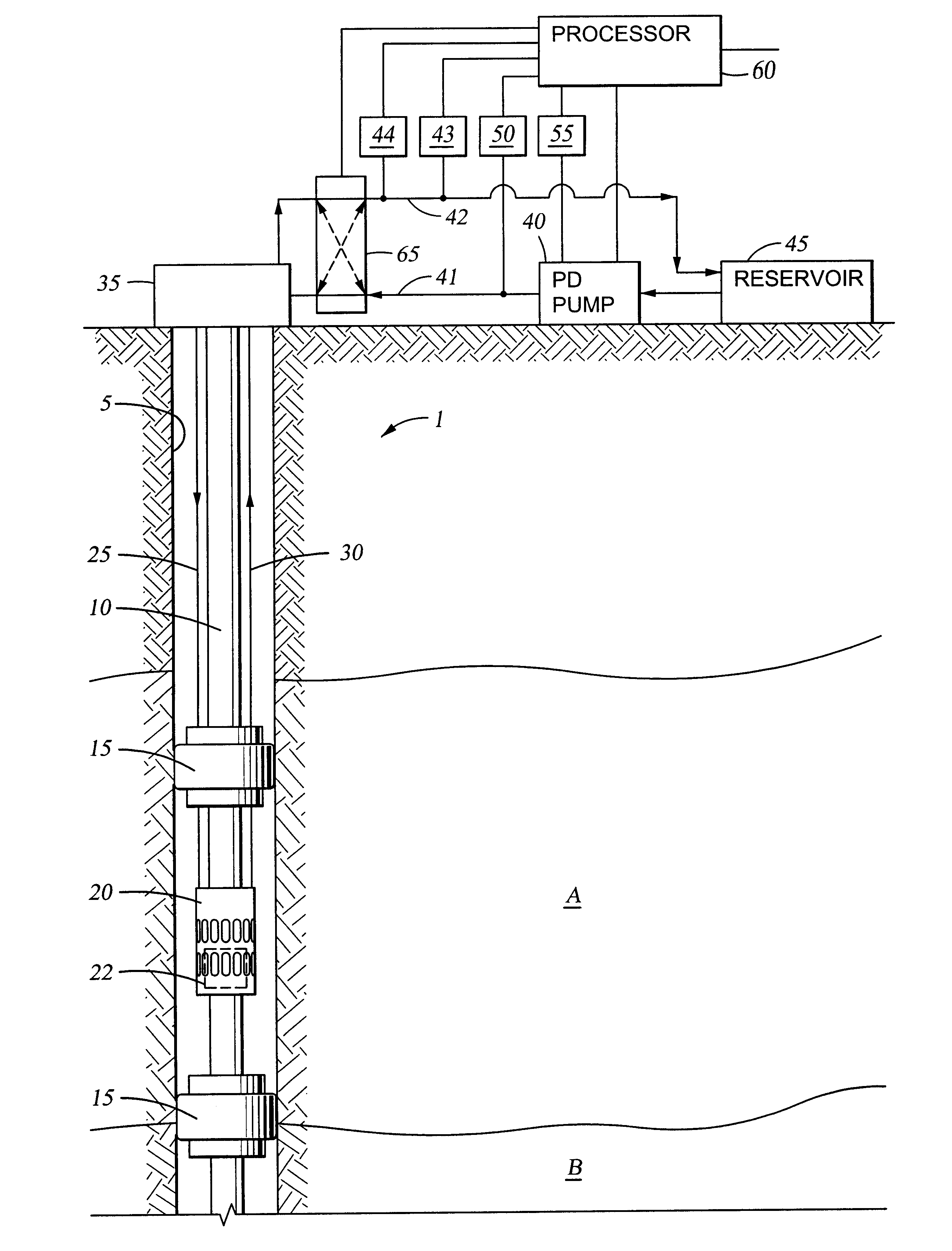

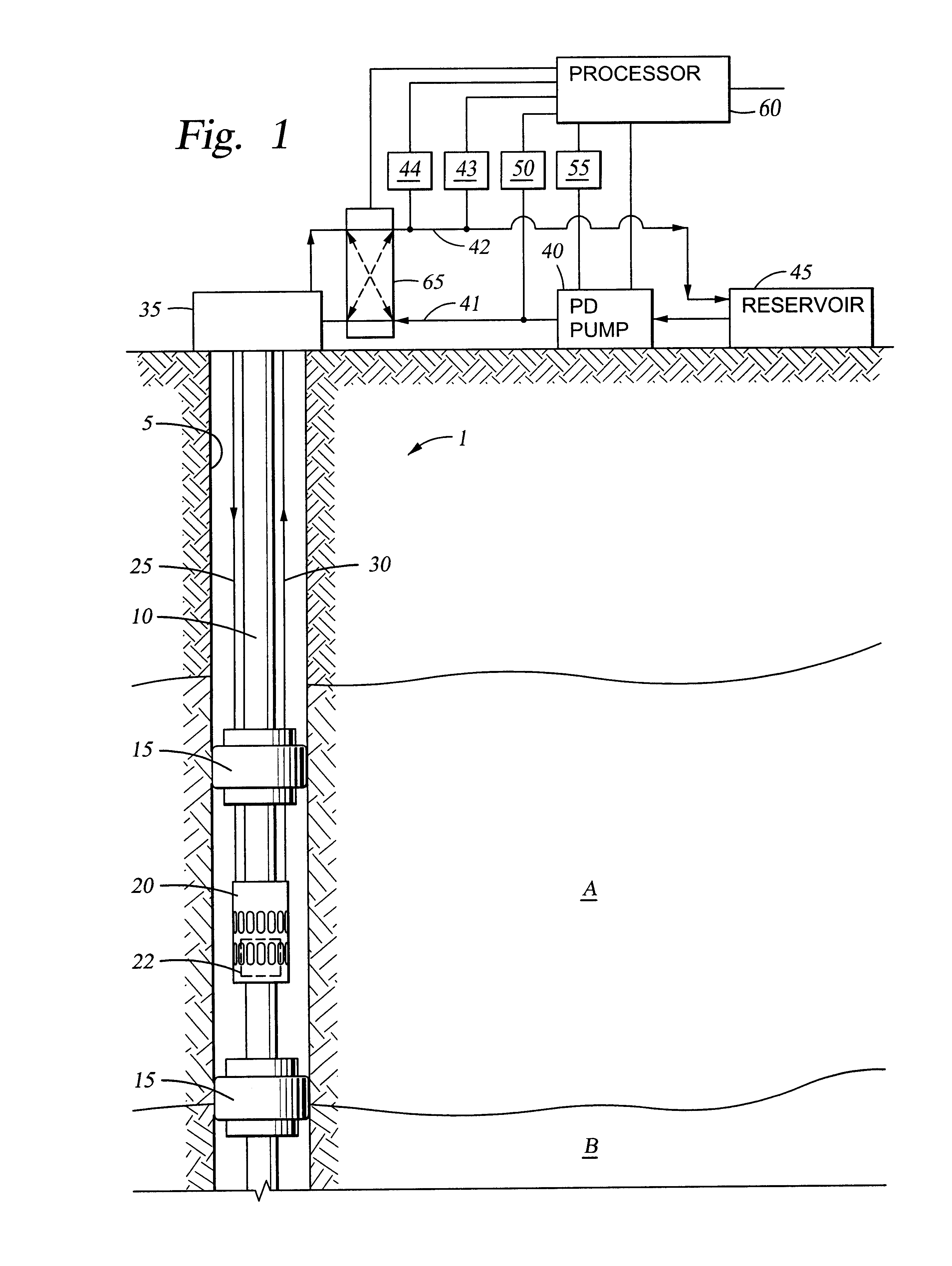

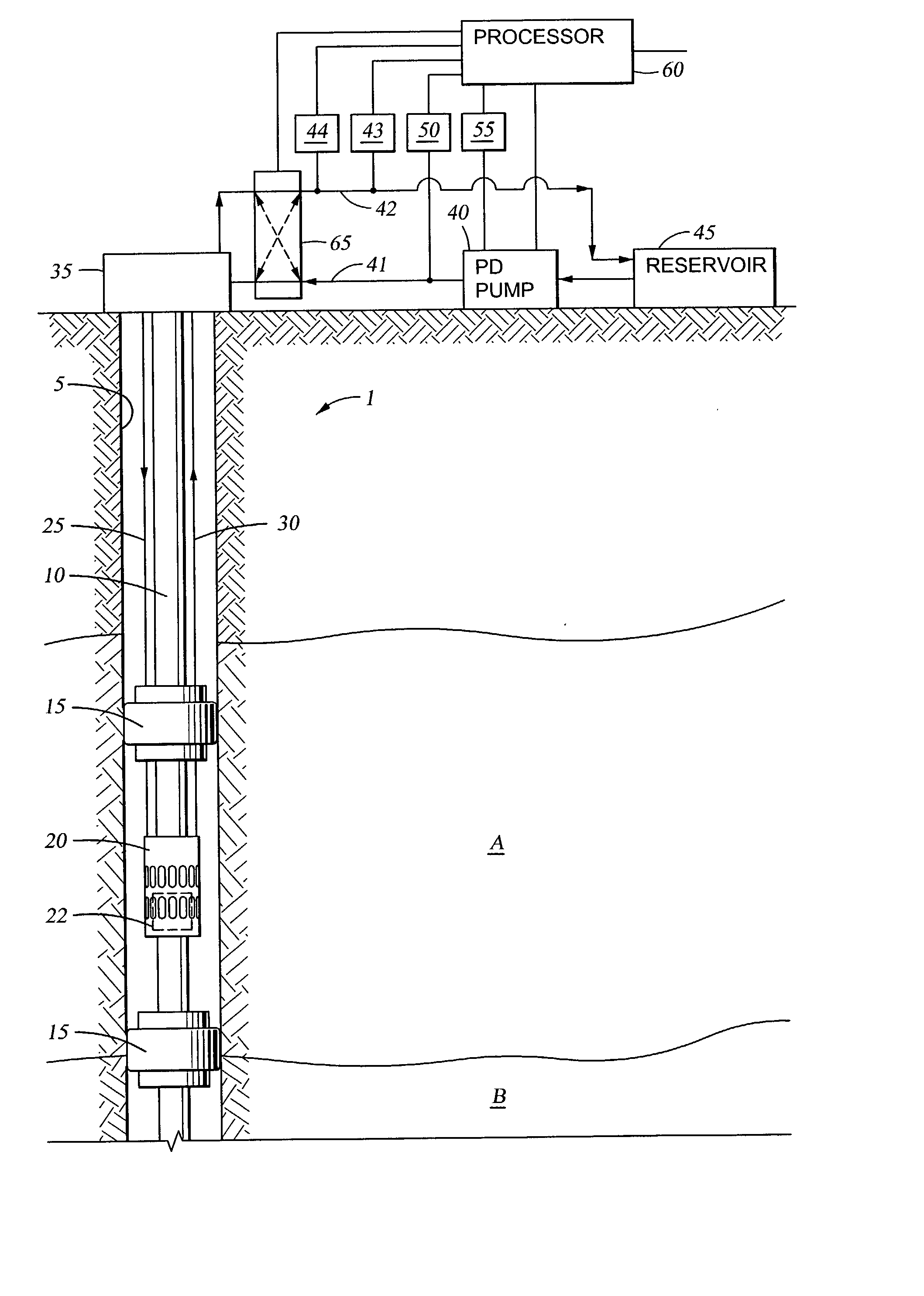

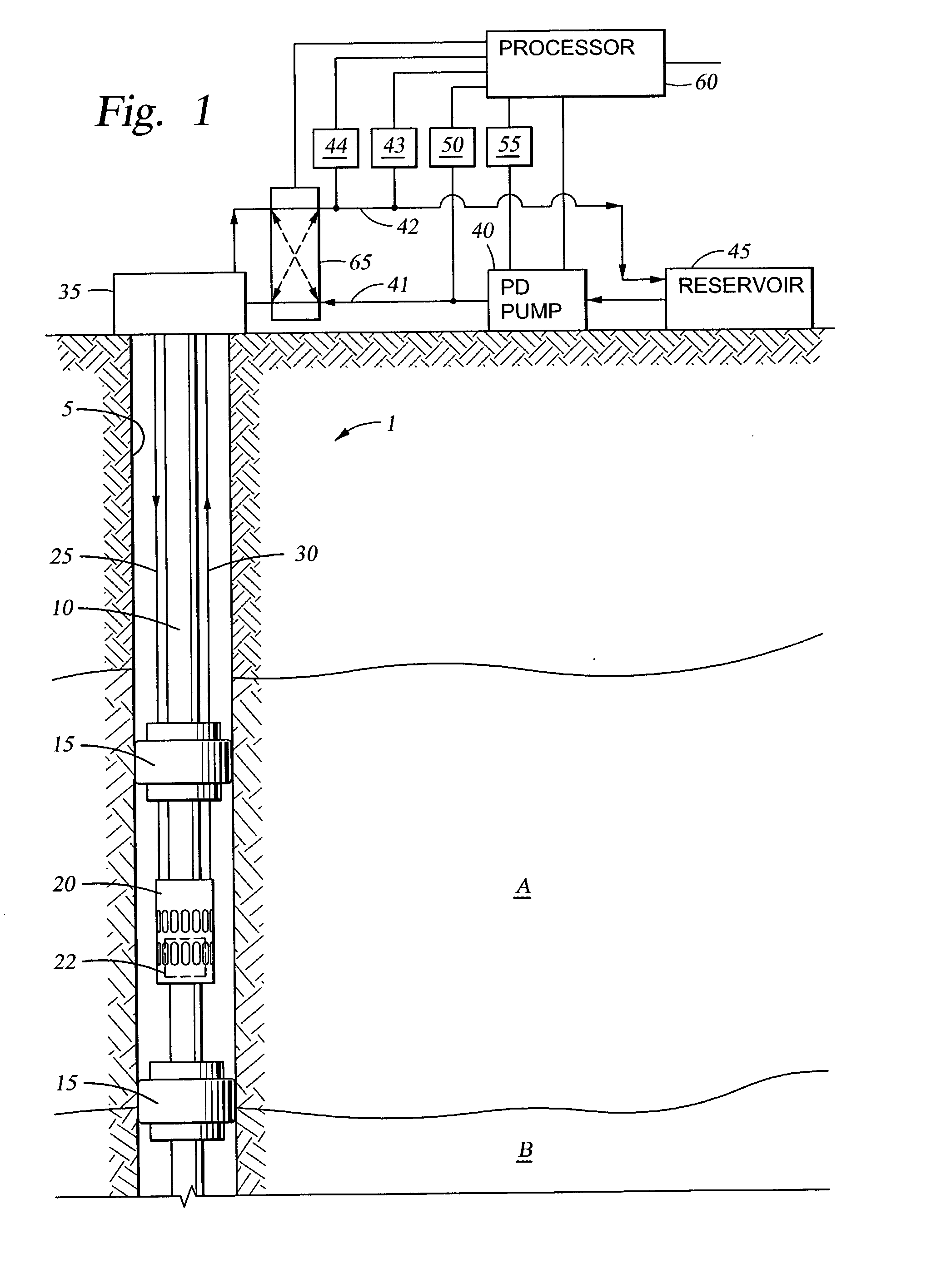

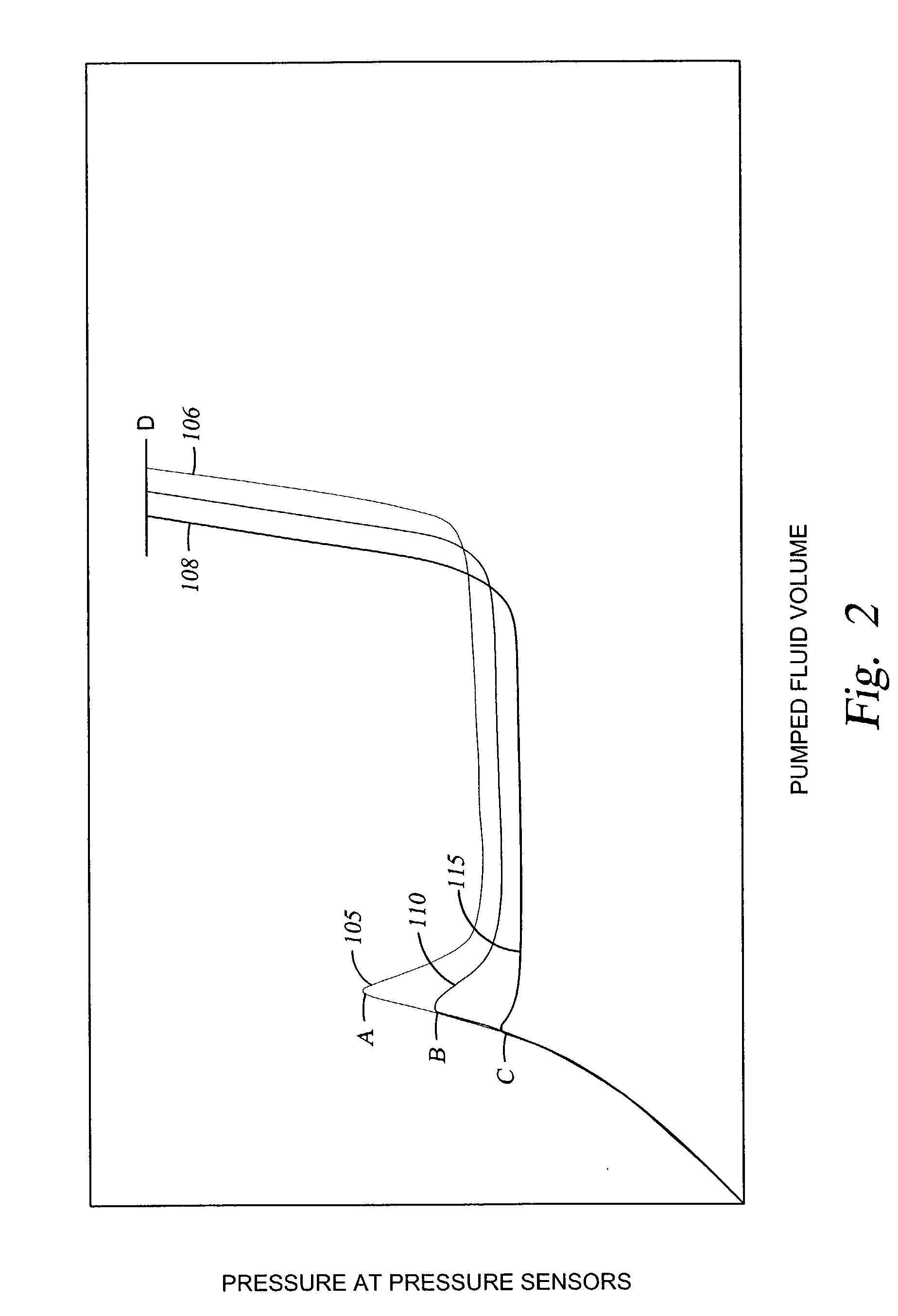

Method and system for controlling a downhole flow control device using derived feedback control

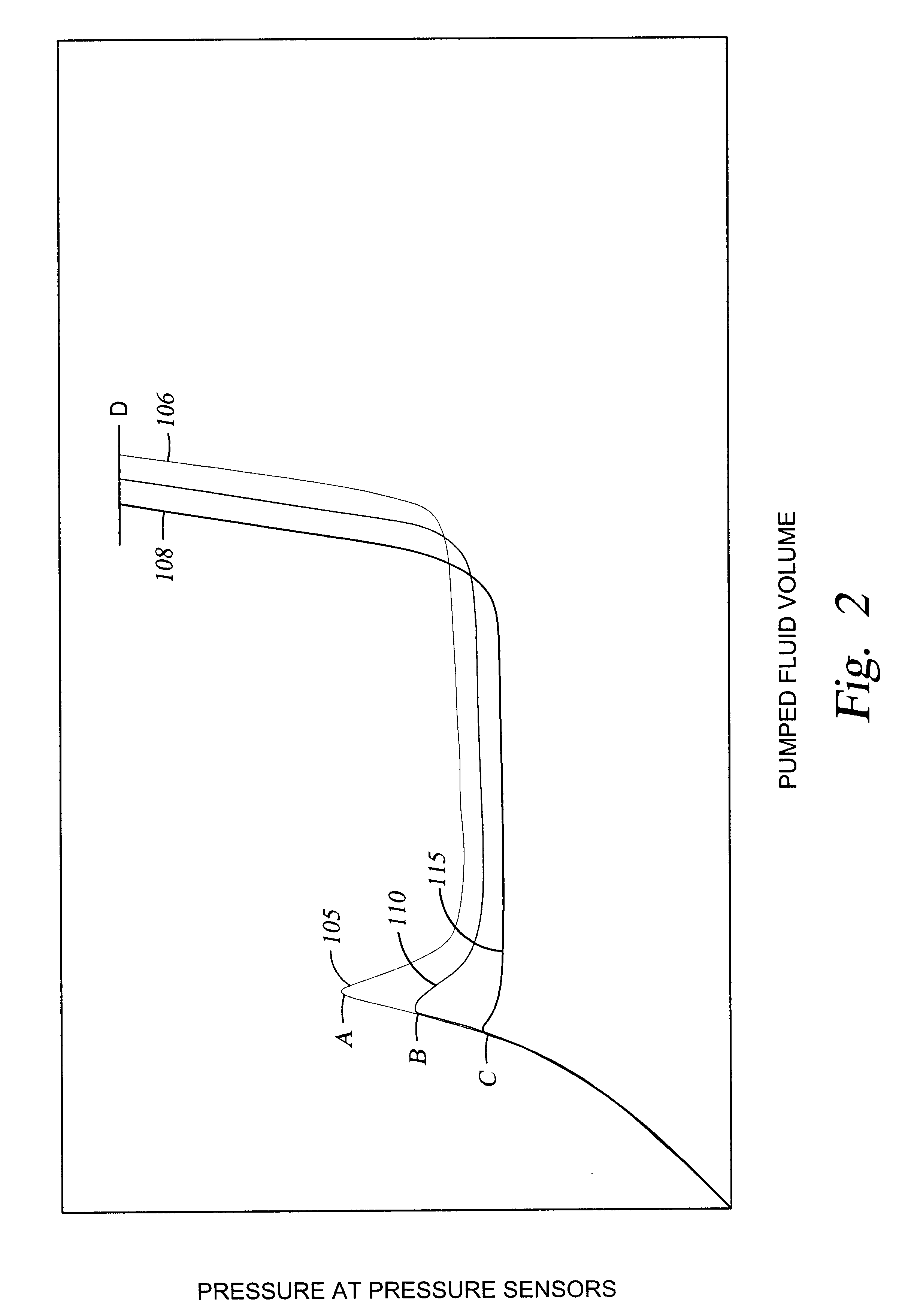

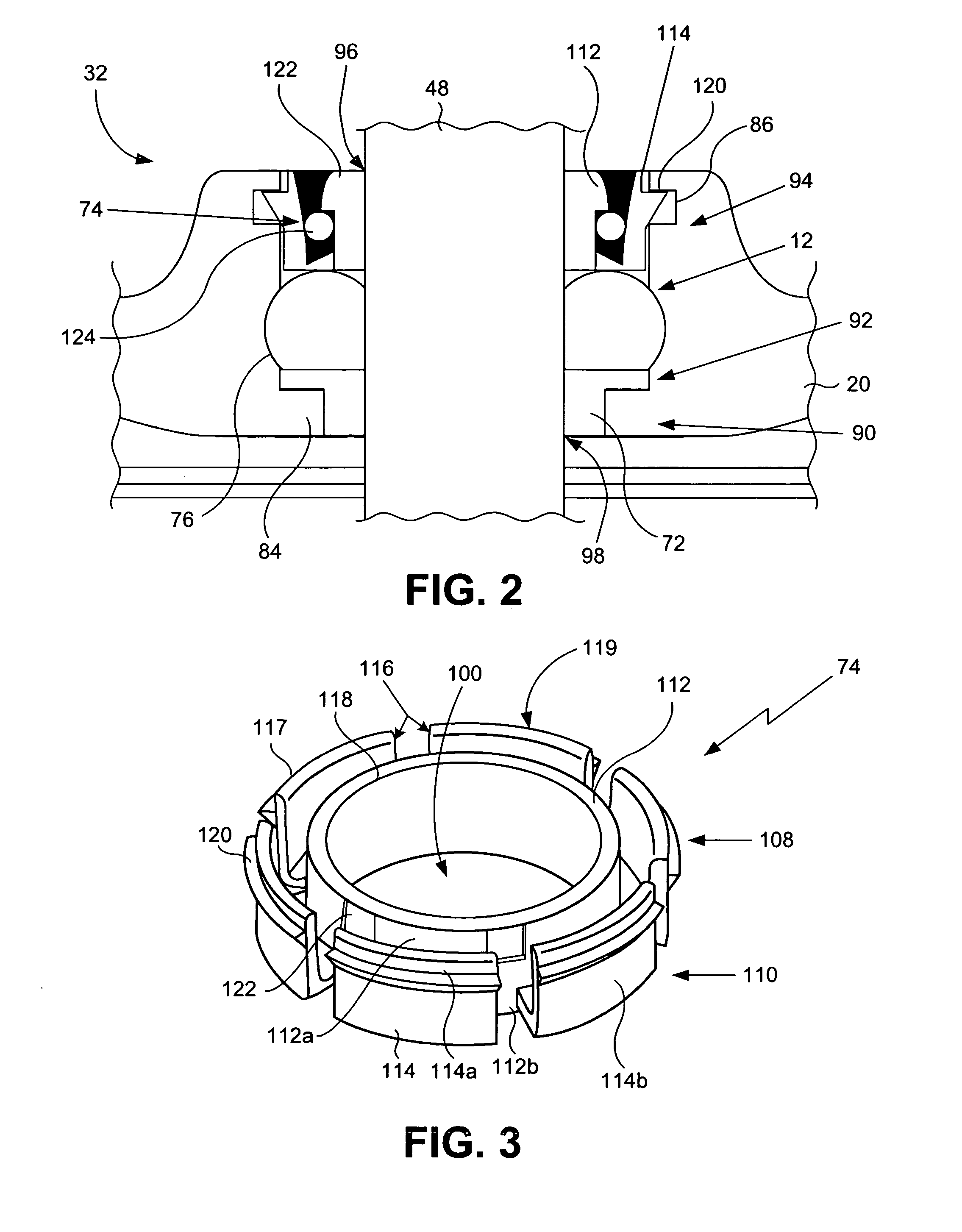

A system and methods for proportionally controlling hydraulically actuated downhole flow control devices using derived feedback control. The system comprises a downhole flow control device with a moveable element in a stationary housing. The moveable element is actuated by a balanced hydraulic piston. Hydraulic lines are fed to either side of the piston to effect actuation in either direction. A processor controlled, surface mounted hydraulic system supplies fluid to the piston. A pressure sensor measures supply pressure to the piston and a cycle counter indicates pump cycles and both sensors generate outputs to the processor. The downhole moveable element is cycled between end stops until successive moveable element breakout pressures are within a predetermined value as measured by the surface pressure sensor. A relationship is then derived between moveable element movement and pumped fluid volume and the relationship is used to move the moveable element to a predetermined position to control flow.

Owner:BAKER HUGHES HLDG LLC

Method and system for controlling a downhole flow control device using derived feedback control

A system and methods for proportionally controlling hydraulically actuated downhole flow control devices using derived feedback control. The system comprises a downhole flow control device with a moveable element in a stationary housing. The moveable element is actuated by a balanced hydraulic piston. Hydraulic lines are fed to either side of the piston to effect actuation in either direction. A processor controlled, surface mounted hydraulic system supplies fluid to the piston. A pressure sensor measures supply pressure to the piston and a cycle counter indicates pump cycles and both sensors generate outputs to the processor. The downhole moveable element is cycled between end stops until successive moveable element breakout pressures are within a predetermined value as measured by the surface pressure sensor. A relationship is then derived between moveable element movement and pumped fluid volume and the relationship is used to move the moveable element to a predetermined position to control flow.

Owner:BAKER HUGHES INC

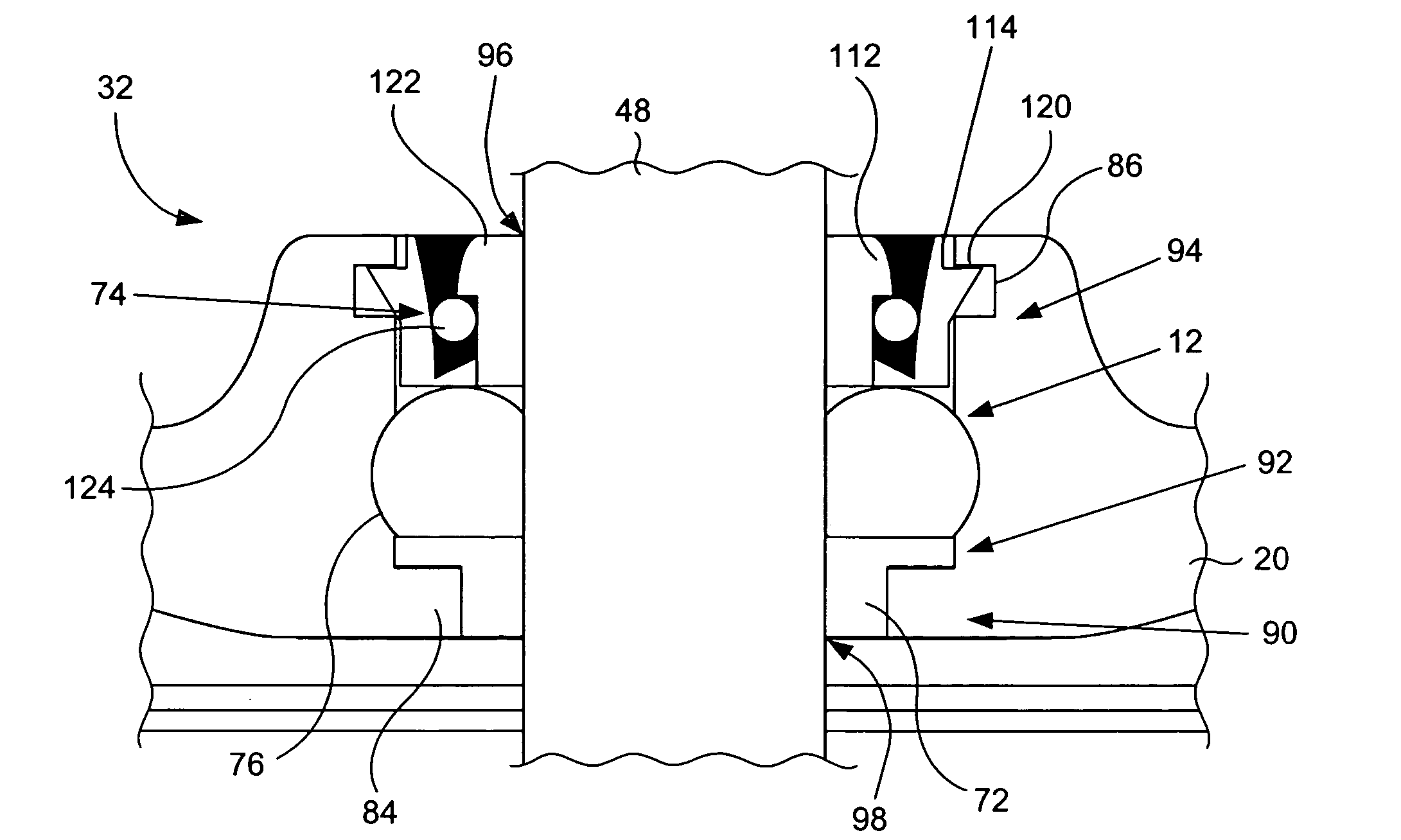

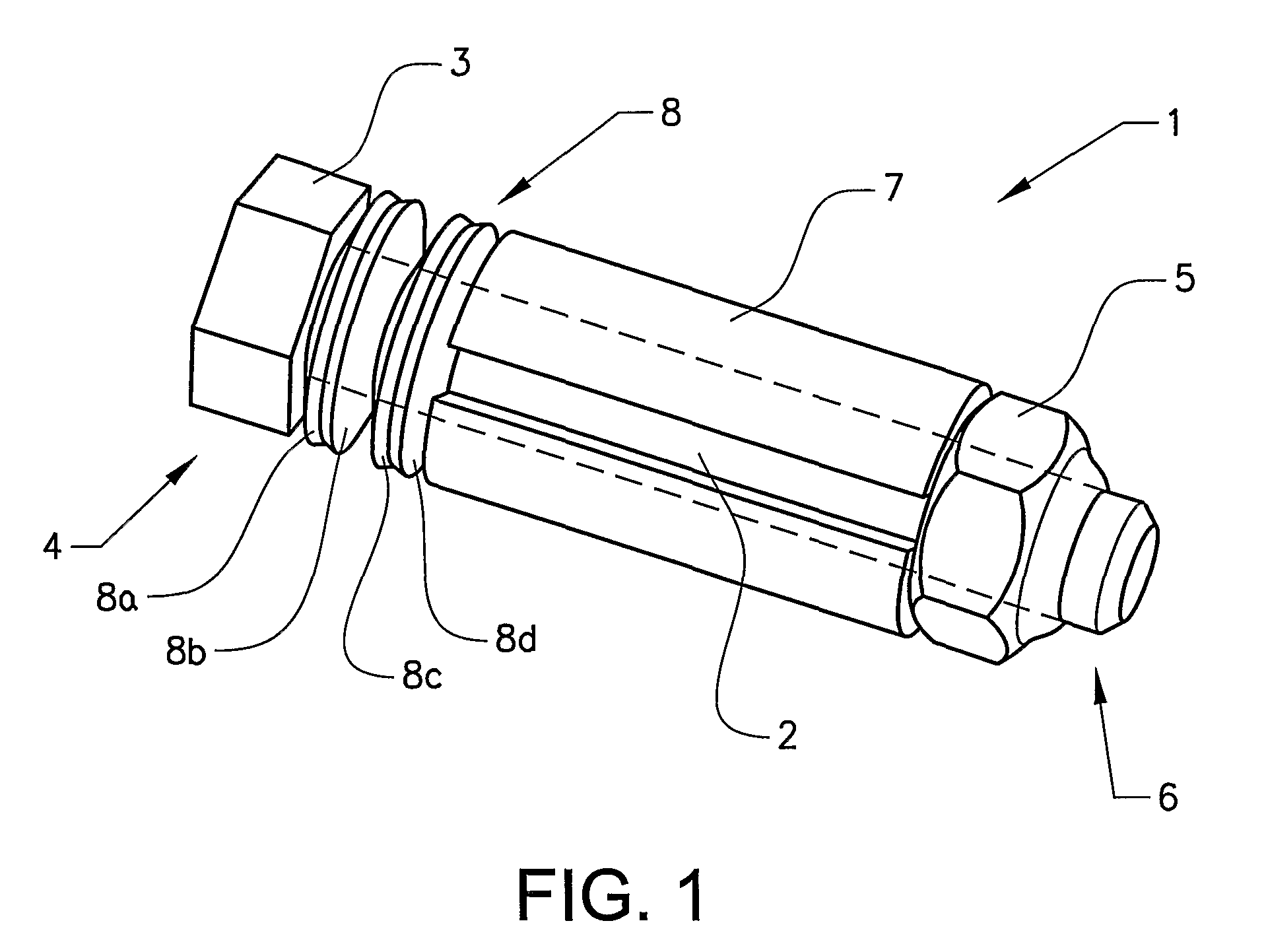

Flexible bushing assembly for spring brake push rod center seal

InactiveUS20070034465A1Improve abilitiesPrevent undesirable wearSpringsBrake actuating mechanismsEngineeringActuator

An improved bushing assembly for the center seal used with an adapter base separating pressure chambers in a spring brake actuator to allow a push rod to pass through an aperture therein without loss of pressurized fluid between the pressure chambers. The improved bushing assembly has a flexing component that allows for non-linear or flexing motion of the push rod, a sealing component for sealably engaging the push rod and a locking component for securing the bushing assembly inside the aperture. The improved bushing prevents damage to the sealing member and aperture from the non-linear push rod motion. The flexing component comprises a bushing member having an inner wall and outer wall that form a channel therebetween. The outer wall has engagement tabs to lockingly engage a groove in the aperture to secure the bushing assembly therein. A spring brake adapter is provided that utilizes the improved bushing assembly.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

Method of determining reservoir pressure

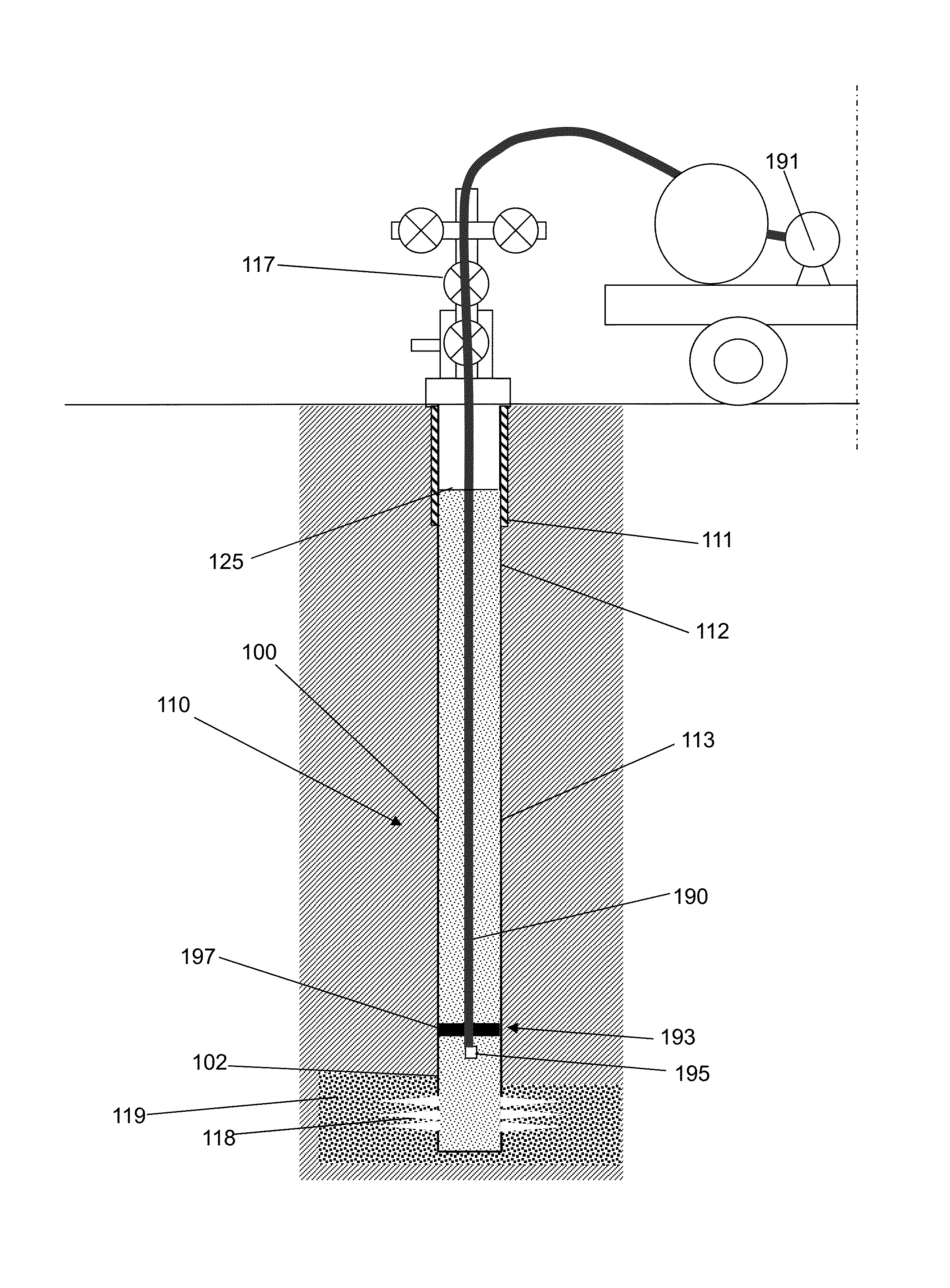

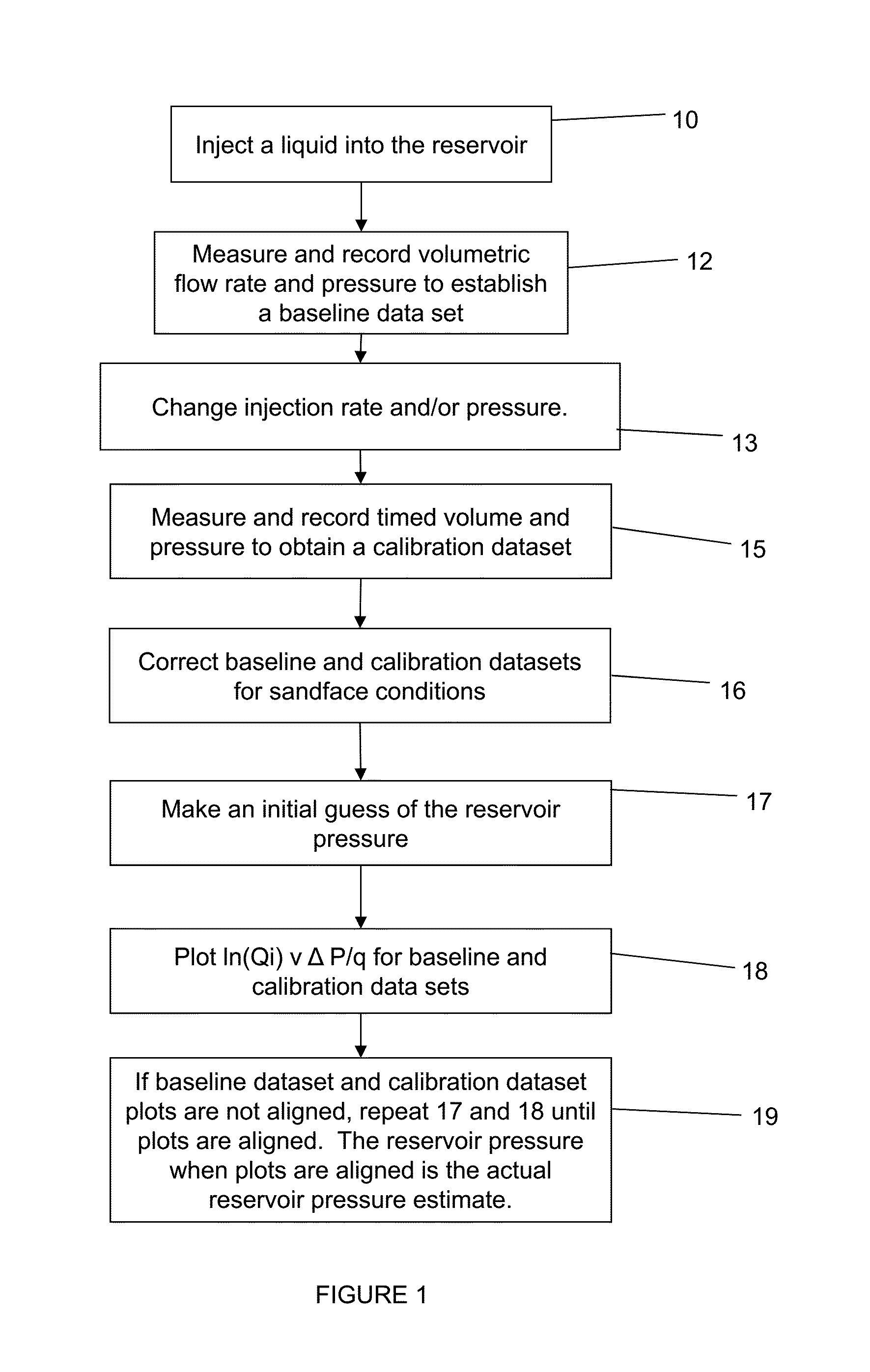

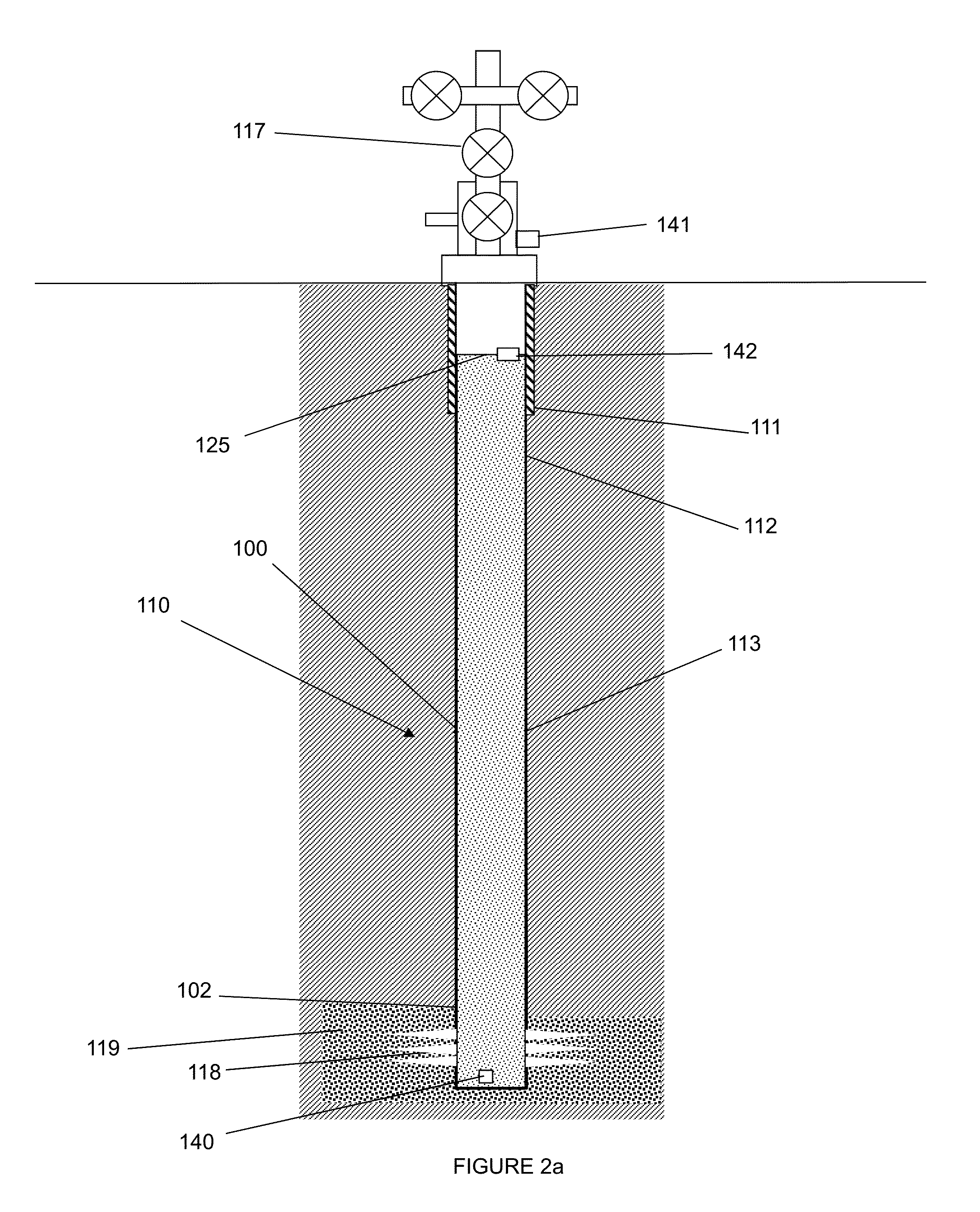

A well test method for use in tight gas reservoirs prior to hydraulic fracture stimulation. The method can use injection of water using low-rate surface pumps into the reservoir below parting pressure. The measured rates and pressures are converted to sandface rate and pressure datasets for each stage. The technique can utilize either surface or bottom-hole pressure sensors. The resulting sandface datasets are analyzed using the baseline / calibration method or other analysis appropriate to stage data to determine reservoir flow properties. The small-volume, staged well test enables estimation of the flow properties of reservoir, including pressure and permeability, in hours rather than days.

Owner:BP CORP NORTH AMERICA INC

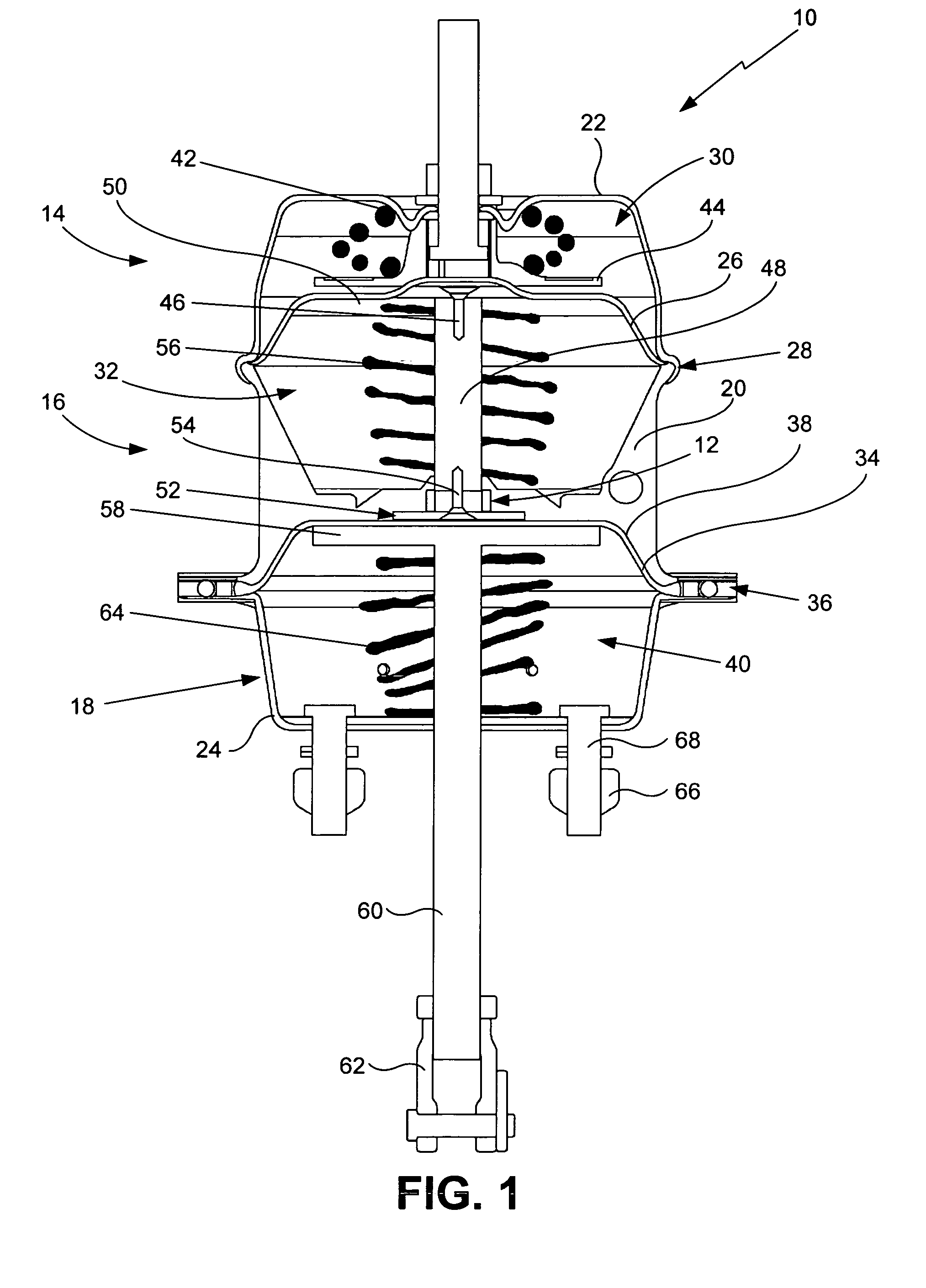

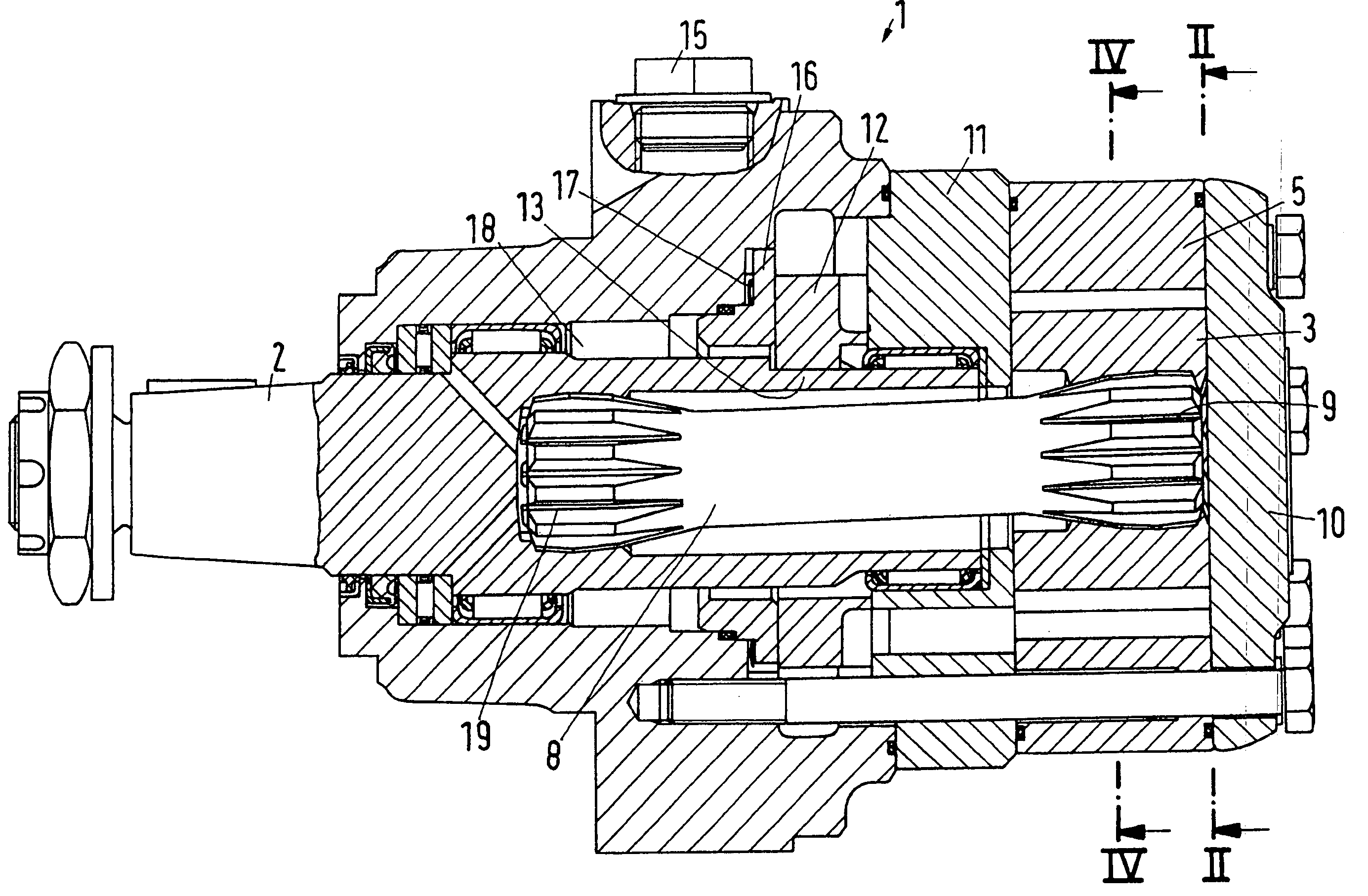

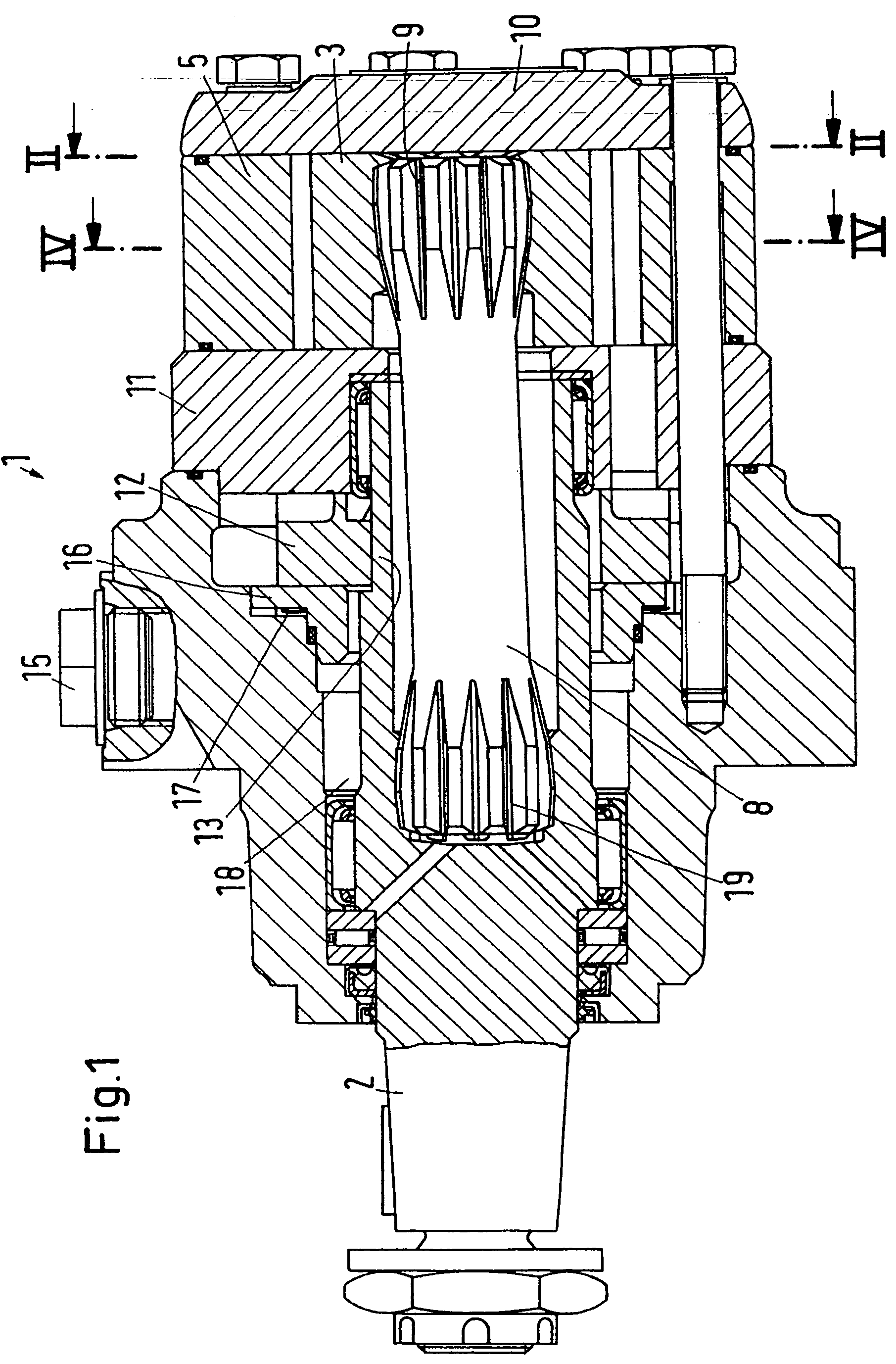

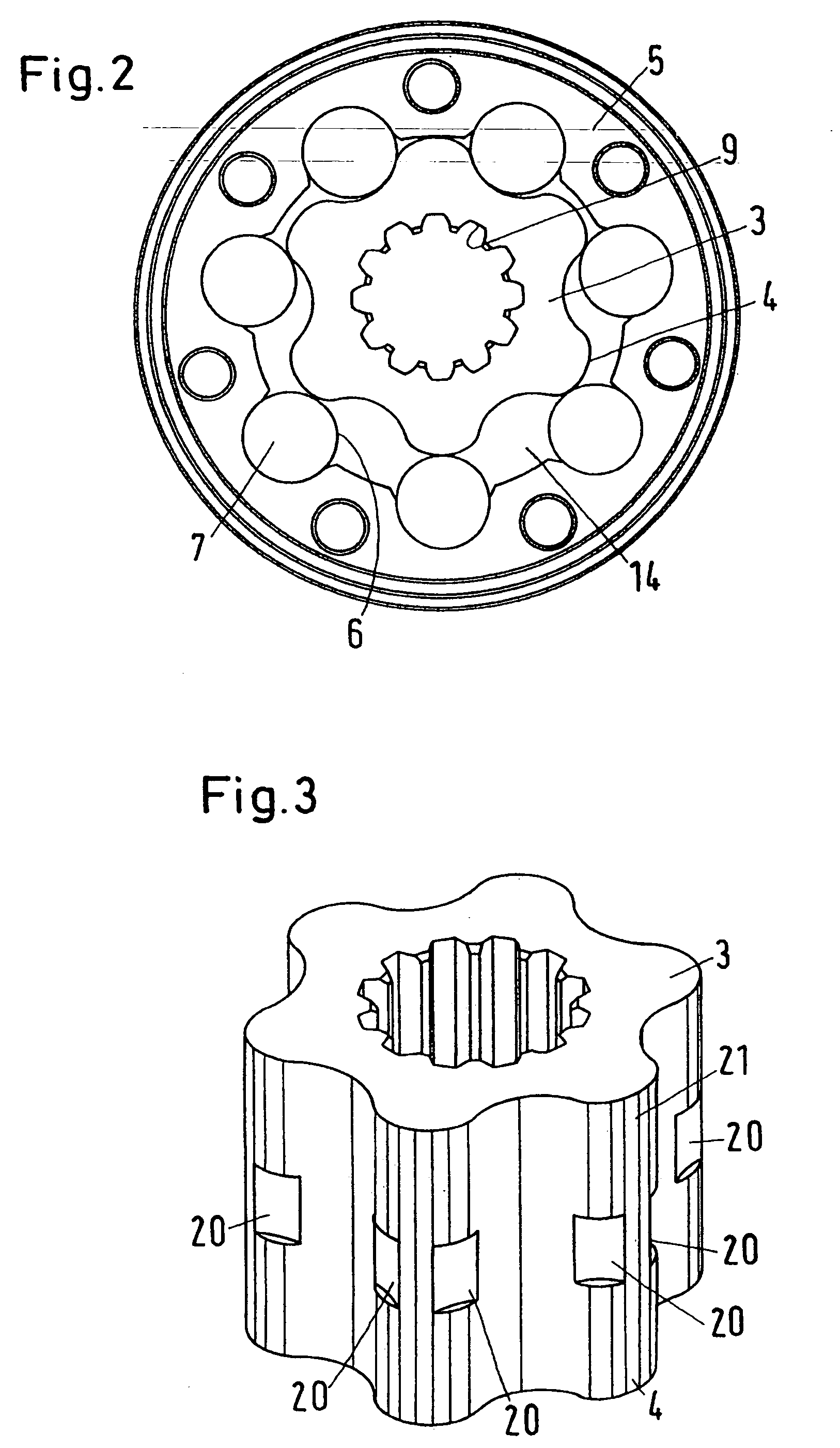

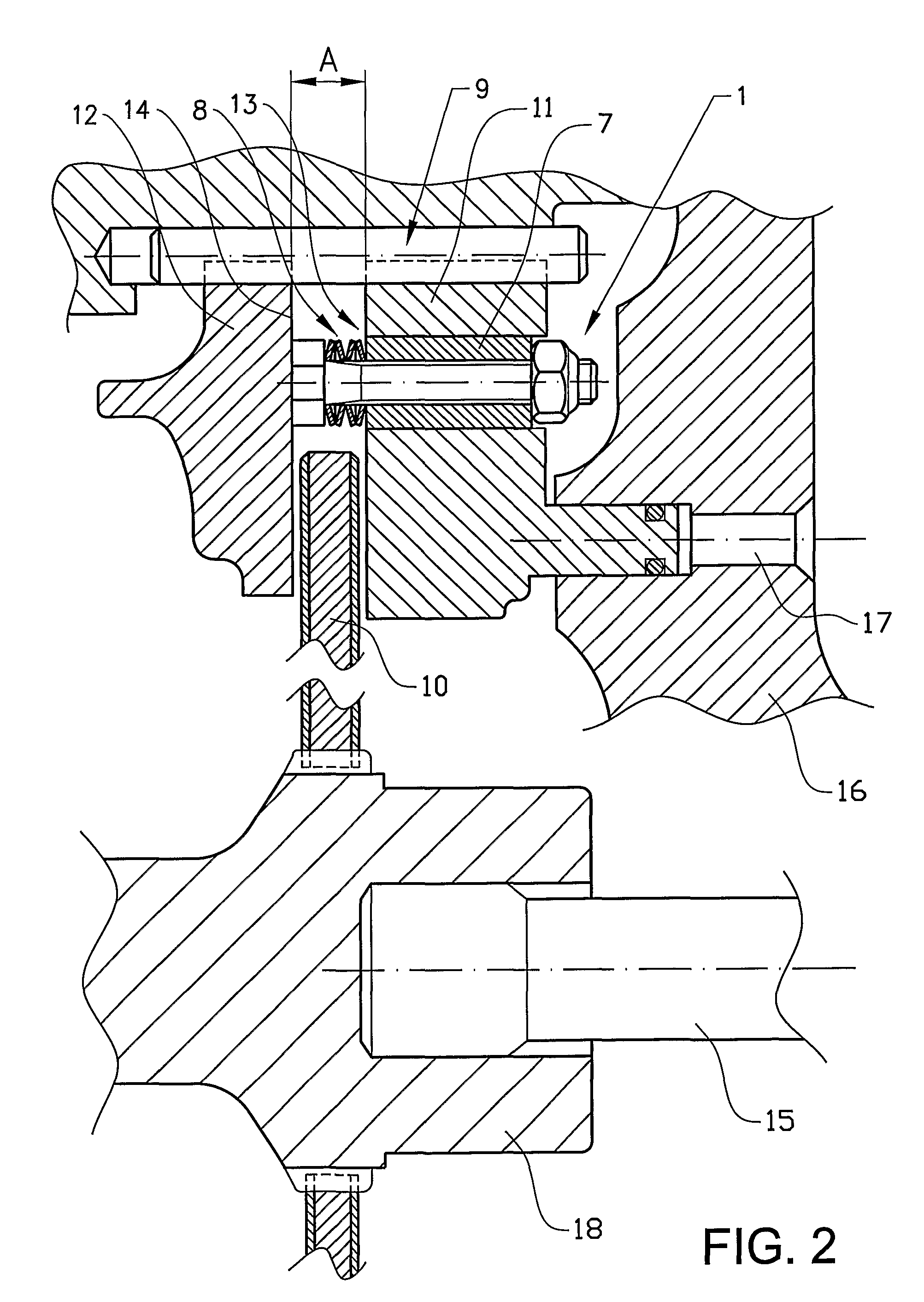

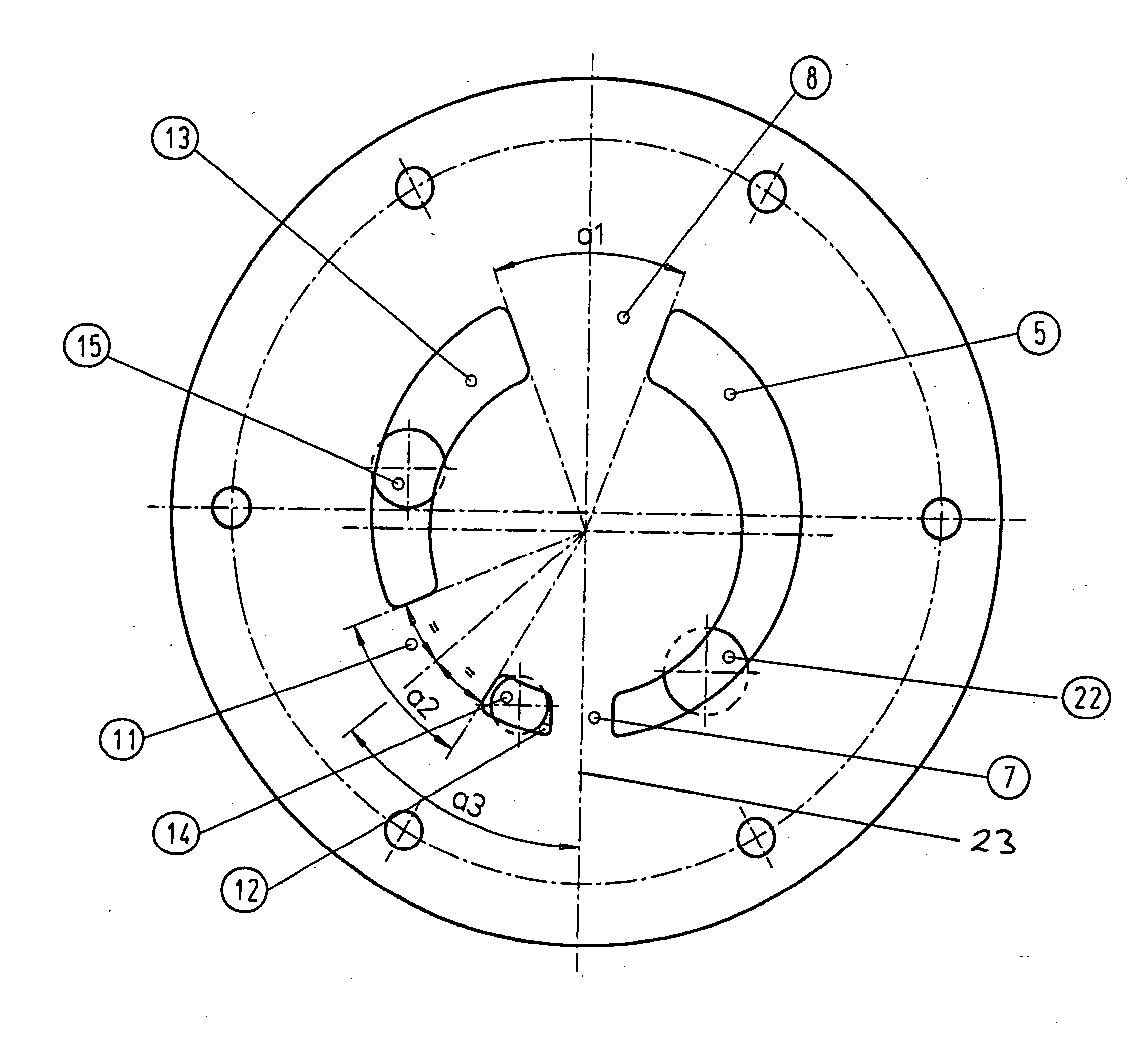

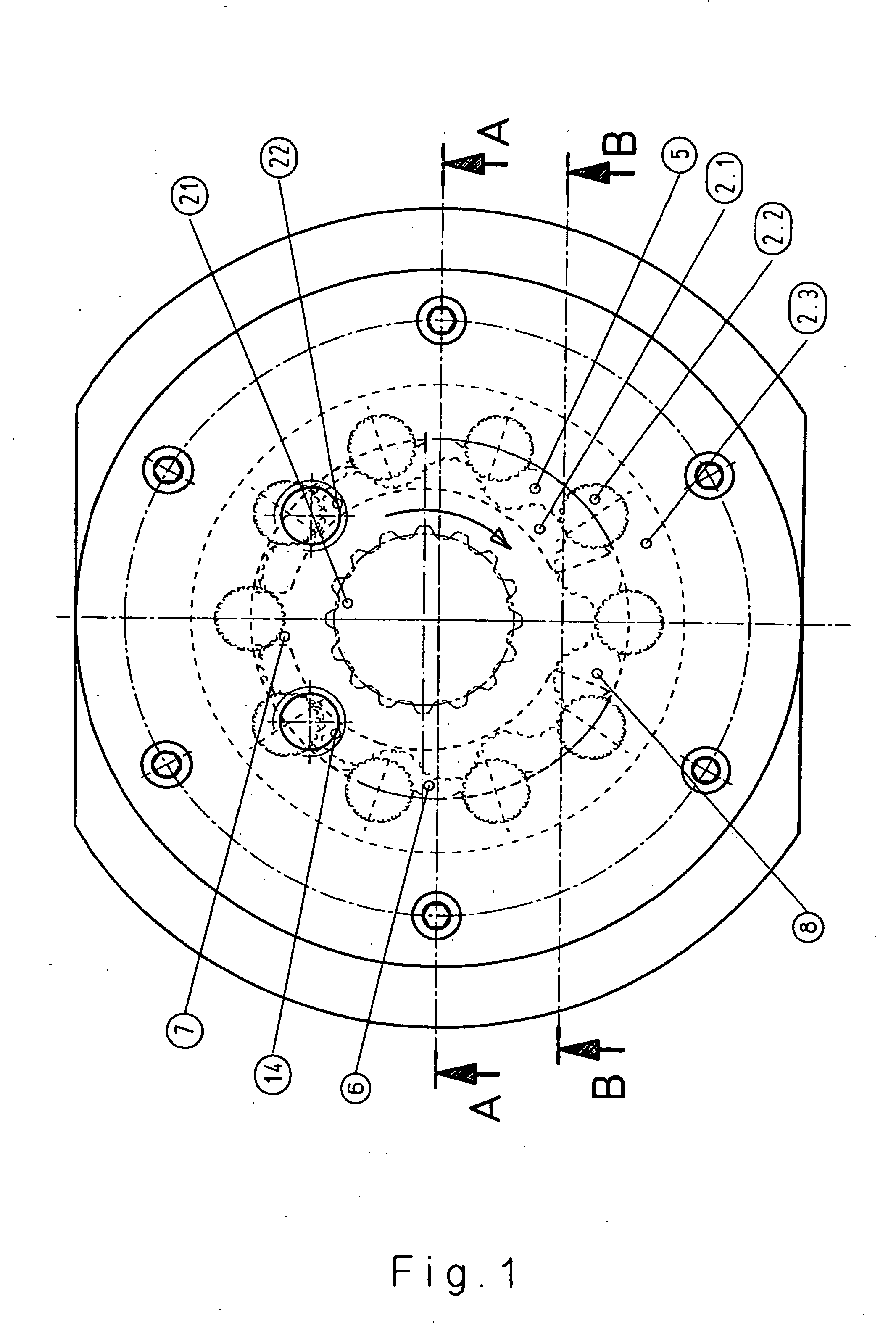

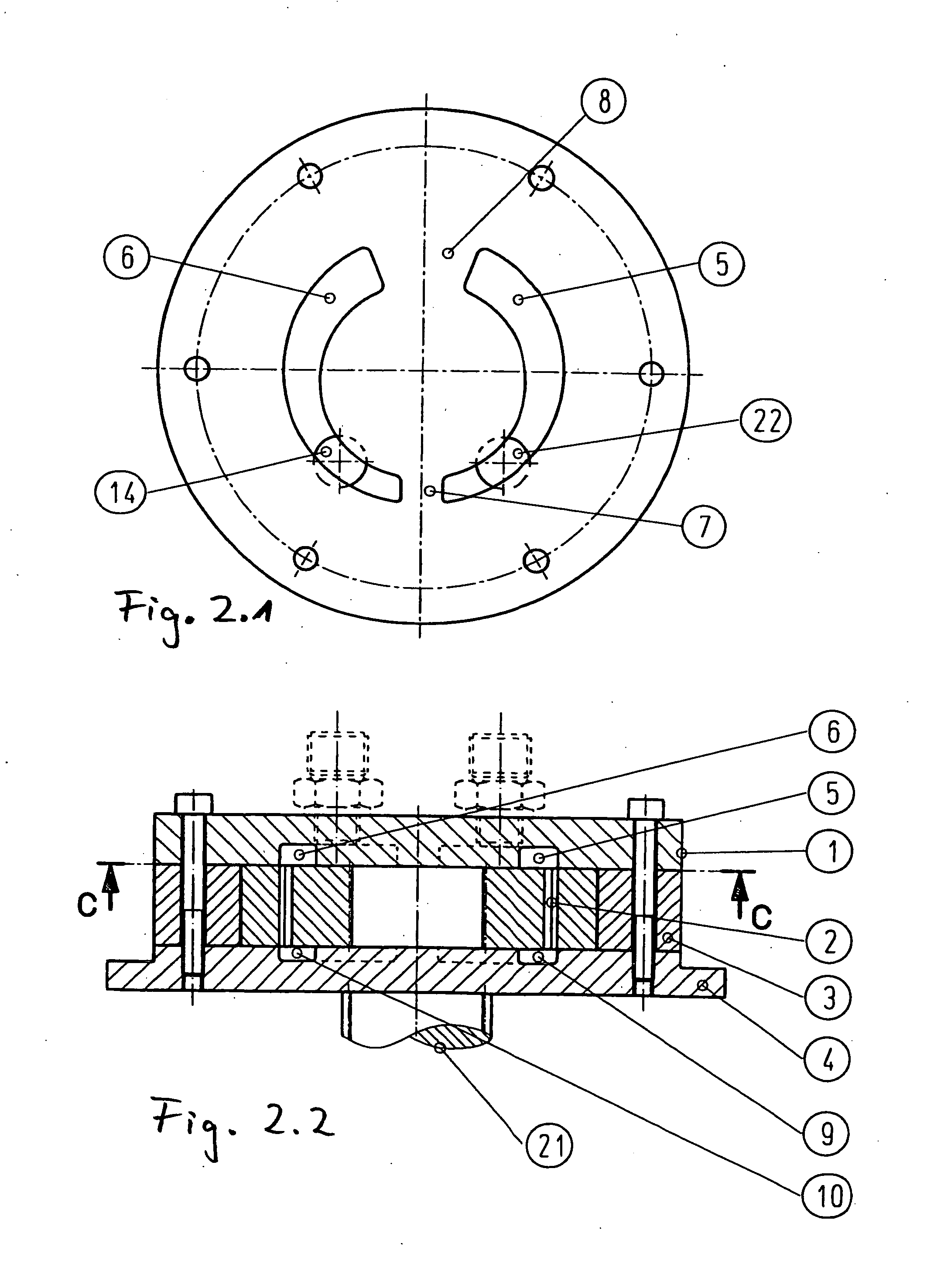

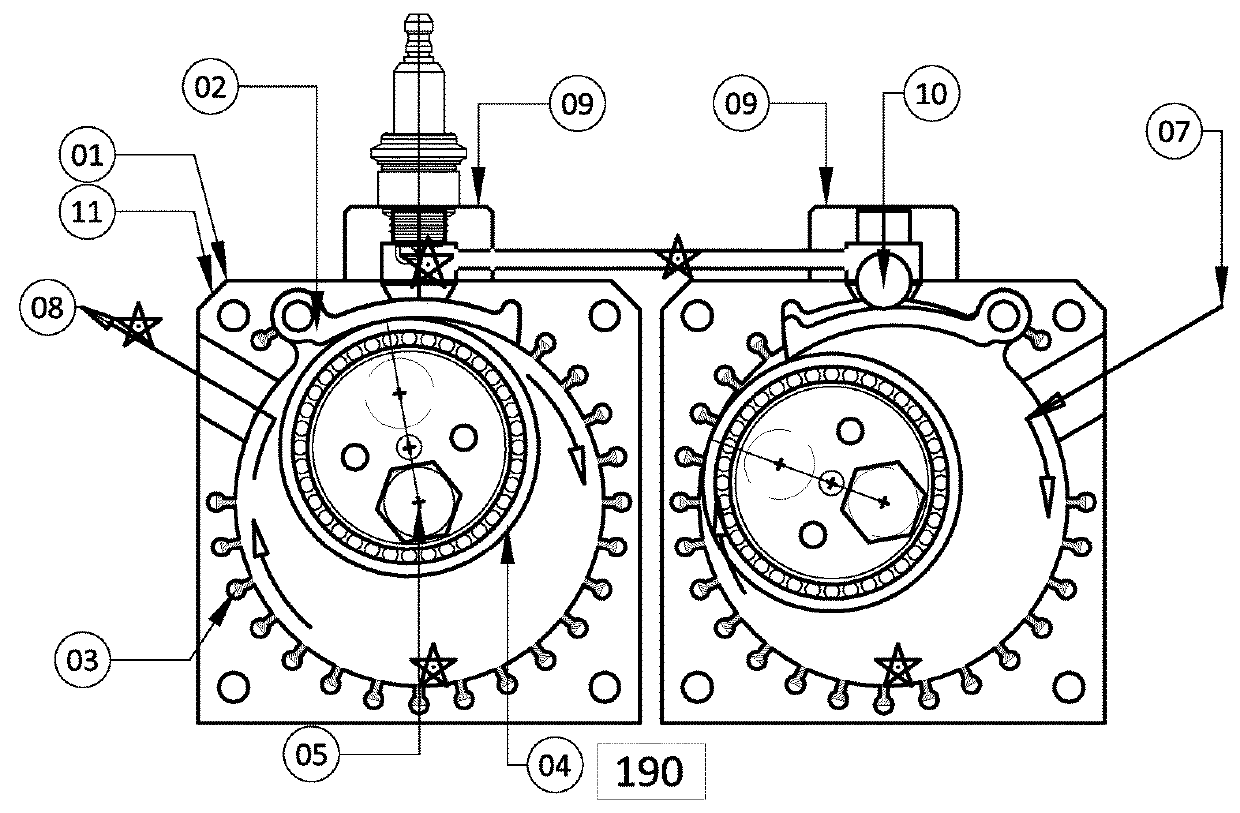

Hydraulic machine

ActiveUS20050180873A1Simple processAdd depthEngine of arcuate-engagement typeOscillating piston enginesLow speedGear wheel

The invention concerns a hydraulic machine with a set of teeth, having a toothed ring with an inner toothing and a gear wheel with an outer toothing, the gear wheel rotating and orbiting in the toothed ring, the inner toothing and the outer toothing touching each other in contact areas, thus separating pressure chambers, and with a valve arrangement controlling a connection between a connection arrangement having a high pressure connection and a low pressure connection, and the pressure chambers. It is endeavoured to achieve a stable operation, particularly with low speeds. For this purpose, each contact area is provided with an opening, which, at the time when a pressure chamber reaches an extreme value of its volume, produces a short-circuiting with the neighbouring pressure chamber.

Owner:WHITE DRIVE MOTORS & STEERING SP Z O O

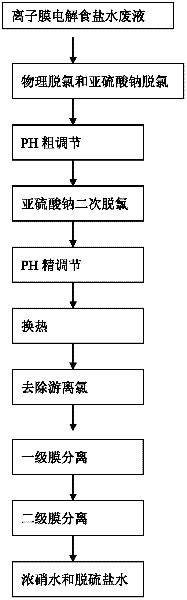

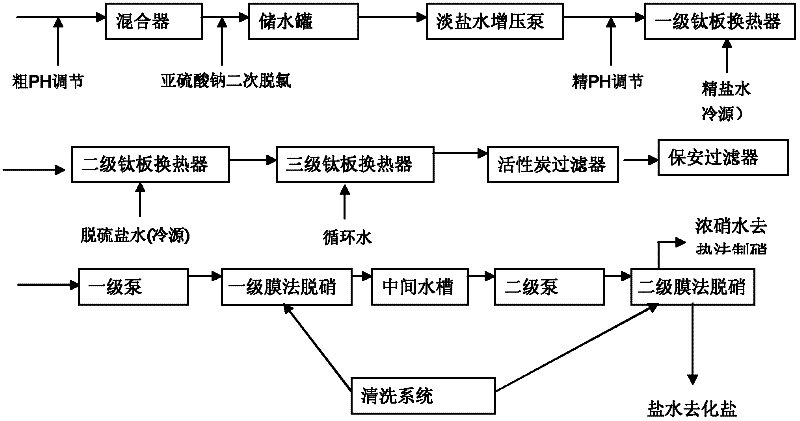

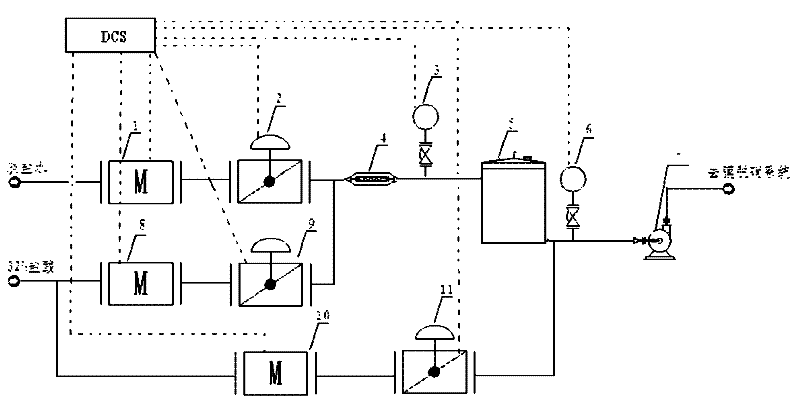

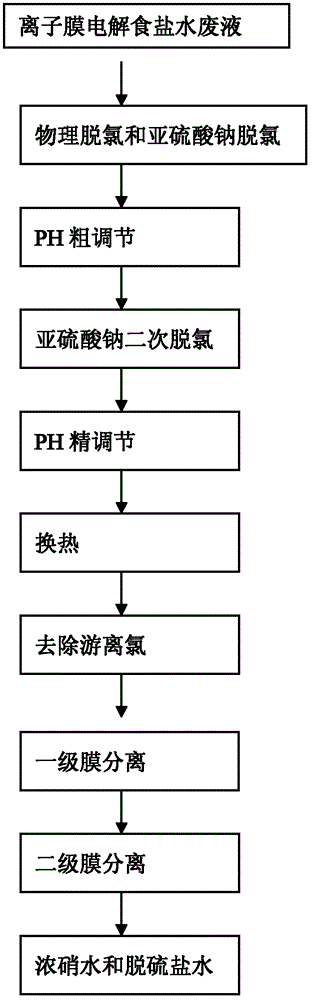

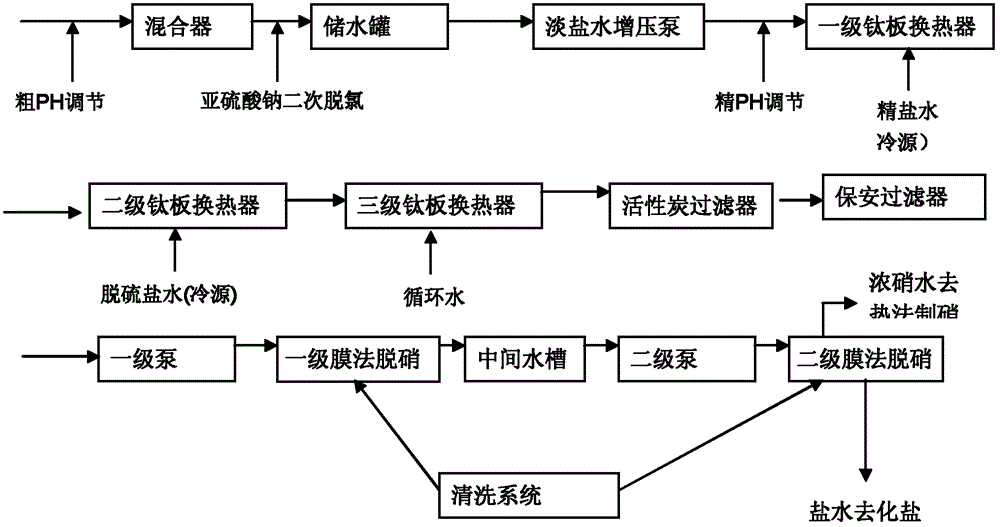

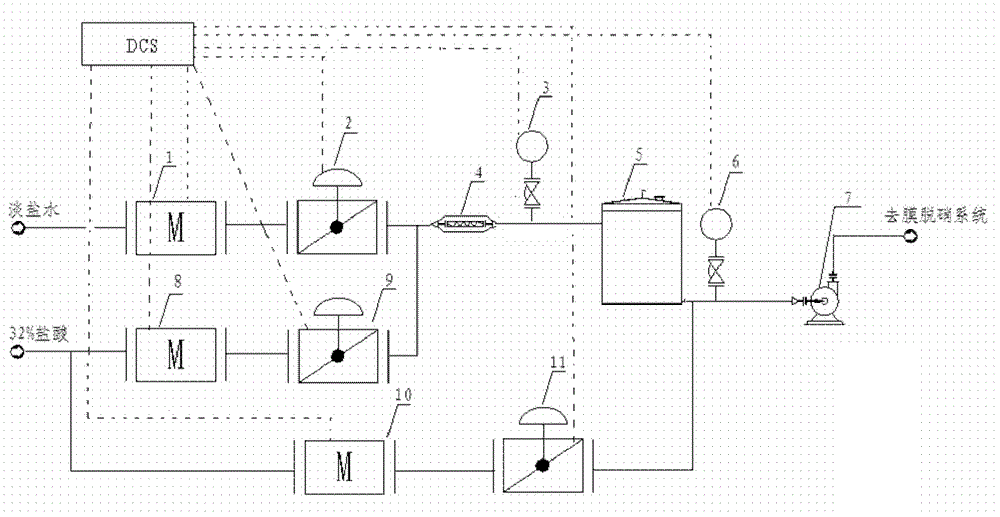

Comprehensive utilization method of ionic membrane electrolytic saline solution waste liquid

ActiveCN102502986AEfficient processing and utilizationEfficient use ofWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentComing outLiquid waste

The invention relates to a comprehensive utilization method of an ionic membrane electrolytic saline solution waste liquid, which comprises the step of sending dechlorinated dilute brine coming out of an electrolytic tank to a membrane process denitration device for denitration. The comprehensive utilization method is characterized by comprising the following steps of: pre-adjusting the pH value of a system to 3-8 by using a saline solution pH value automatic control device, exchanging the heat till the temperature of the system is 25-50 DEG C, removing free chlorine till the content of chlorine is less than or equal to 3 ppm, sending into a primary membrane separation system for primary membrane separation and controlling the primary membrane separation pressure to be not higher than 3.0MPa; and then sending into a secondary membrane separation system for secondary membrane separation, controlling the secondary membrane separation pressure to be not higher than 3.5 MPa, separating to obtain desulfurized brine and concentrated nitrate water, sending the dissolved desulfurized brine to an ionic membrane electrolytic saline solution device for reutilization and sending the concentrated nitrate water to a thermal method denitration device to prepare thenardite. The invention has the beneficial effects that as the two stages of membrane separation systems are adopted, the pressure is more stable, the membrane service life is long, and the separation effect is good; the content of sodium sulfate in the separated concentrated nitrate water can reach above 90 g / l, and the content of sodium sulfate in the desulfurized brine can reach below 3 g / l.

Owner:CHINA PETROLEUM & CHEM CORP +1

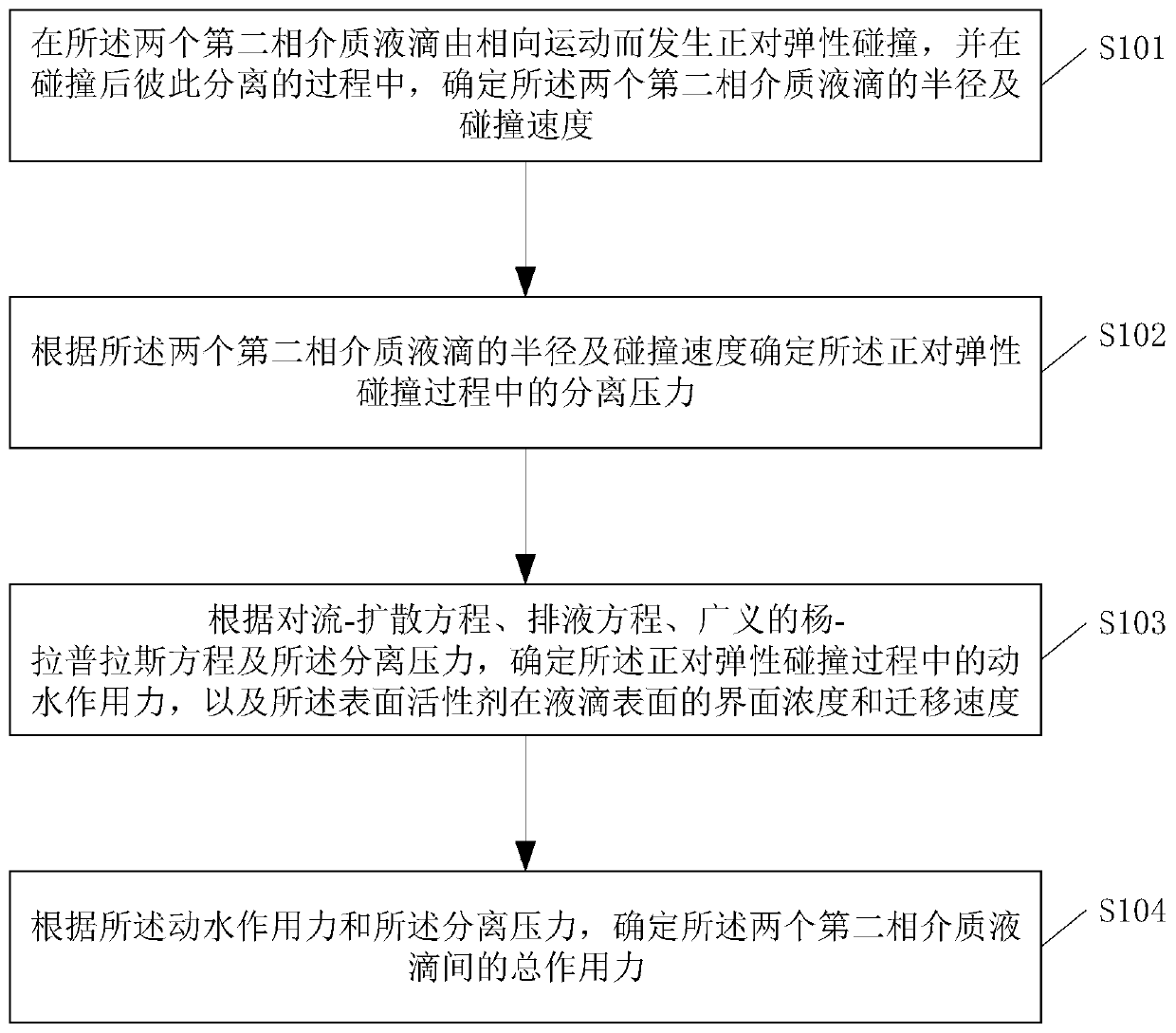

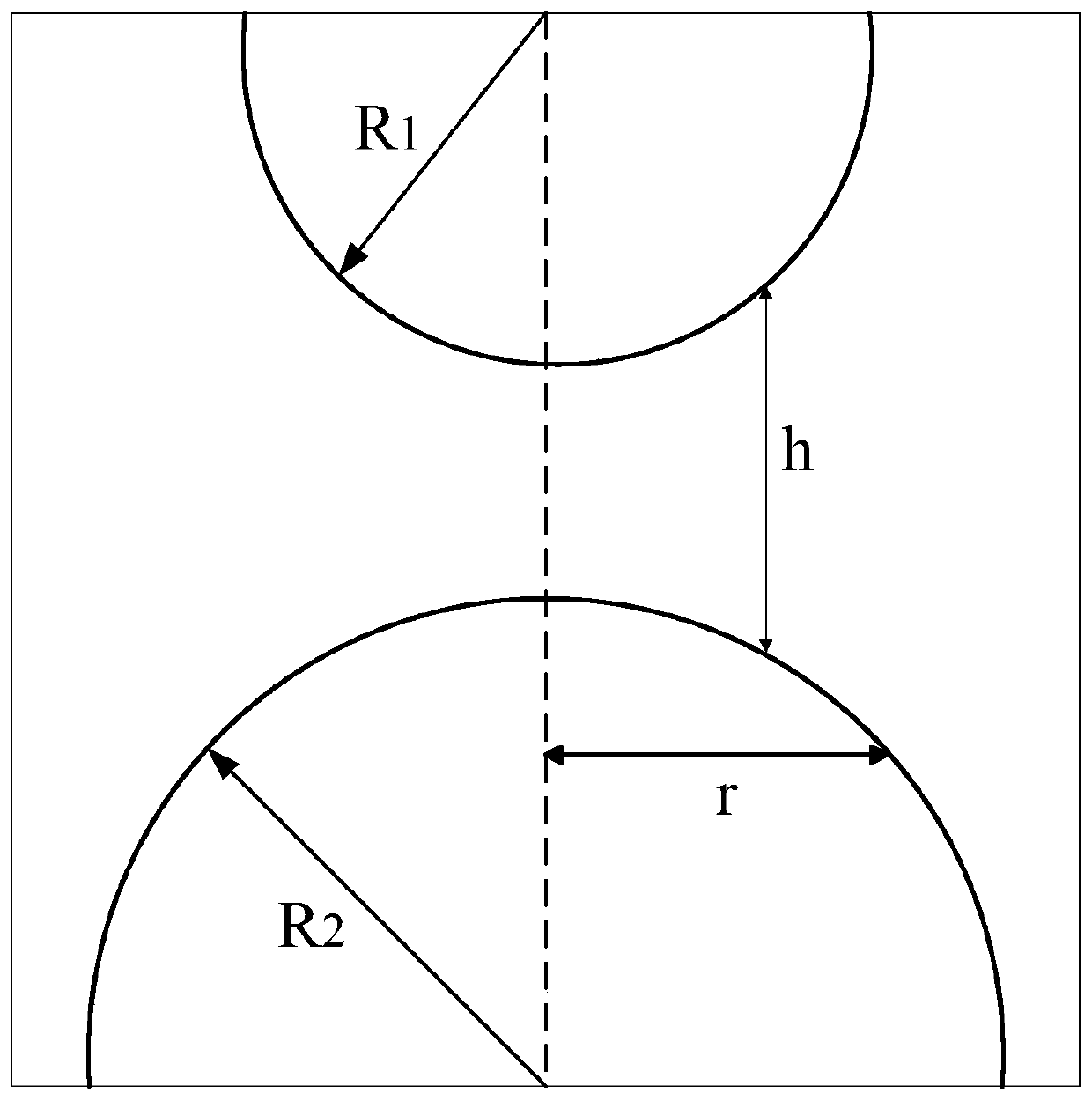

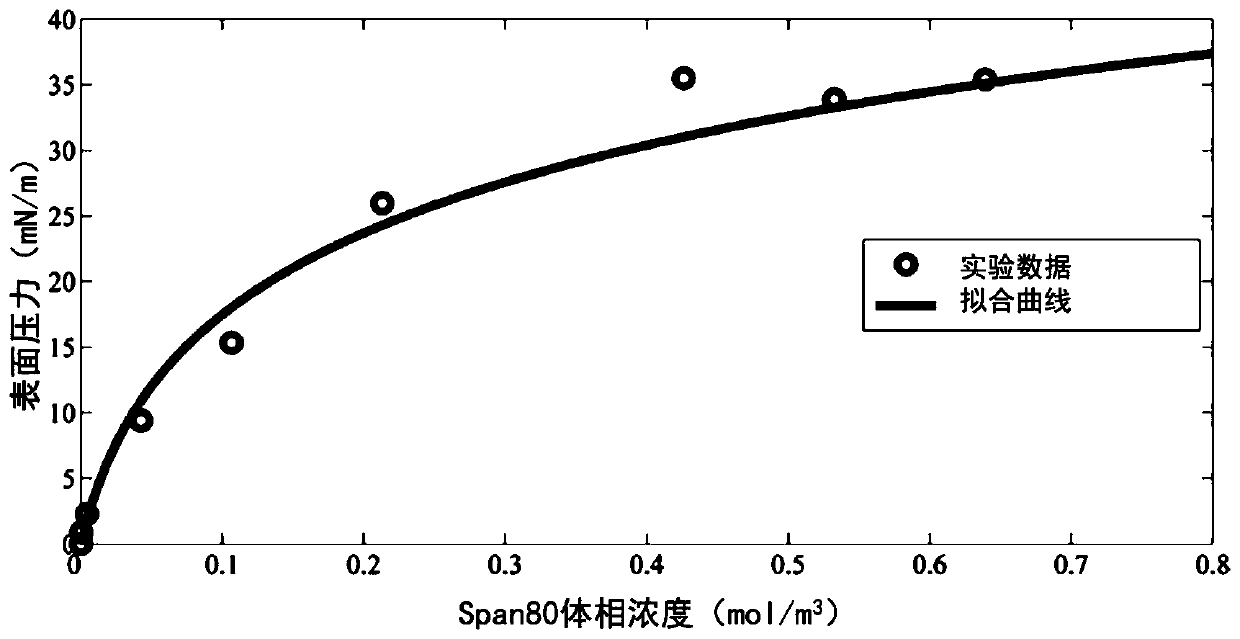

Method and device for predicting interaction among liquid drops adsorbing surfactant

InactiveCN110095386AAccurately predict the distributionSurface tension analysisDispersed mediaConvection–diffusion equation

The invention discloses a method and device for predicting interaction among liquid drops absorbing a surfactant. The method comprises that when two second-phase dielectric liquid drops make face-to-face elastic collision when moving towards to each other and separate from each other after collision, the radii and collision speed of the two second-phase dielectric liquid drops are determined; a separation pressure in the face-to-face elastic collision process is determined according to the radii and collision speed of the two second-phase dielectric liquid drops; according to a convection-diffusion equation, an drainage equation, a generalized Young-Laplace equation and the separation pressure, a dynamic water application force in the face-to-face elastic collision process and the interface concentration and migration speed of the surfactant in the surfaces of the liquid drops are determined; and according to the dynamic water application force and separation pressure, a total action force between the two second-phase dielectric liquid drops is determined. Thus, the action force between two liquid drops and distribution and migration of the surfactant in the two-phase interface ina disperse medium with the surfactant can be predicted accurately.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for subcritical fluid extraction of wolfberry seed oil

InactiveCN105886116AReduce manufacturing costReduce consumptionFatty-oils/fats productionEdible oils/fatsRoom temperatureOperability

The invention discloses a method for subcritical fluid extraction of wolfberry seed oil. The method comprises 1, sun-drying or baking wolfberry seeds obtained through fresh wolfberry juicing to obtain dry wolfberry seeds, 2, putting the dried wolfberry seeds and an extraction agent into an extraction reactor of a subcritical fluid extraction device according to a material dissolution mass-volume ratio of 1: 1-1: 20 and carrying out continuous extraction 1-20 times, for 10-150min every time, so that extract is obtained, 3, separating the extract in the step 2 through a decompression heating method under separation pressure of 0.10-1.95MPa at a separation temperature of 10-90 DEG C to obtain extract, and 4, standing the extract at the room temperature for 10-90min to obtain wolfberry seed oil. The method effectively reduces a production cost, shortens extraction separation time, reduces solvent consumption and energy consumption in a process, has simple processes, strong operability and high extraction efficiency, is environmentally friendly, has no pollution, has good safety and repeatability and realizes large-scale industrialized continuous production.

Owner:赵军

Device for producing liquid film capable of adjusting thickness

ActiveCN102520122AAdjustable thicknessFreely adjustable thicknessFlow propertiesPreparing sample for investigationLiquid layerPositive pressure

The invention discloses a device for producing a liquid film capable of adjusting thickness, which comprises an upper ring component and a lower ring component, The lower ring component comprises a metal conducting ring, a drainage layer, an annular cover plate and a soft pipe joint, a ring groove is provided on the upper surface of the metal conducting ring, the drainage layer and the ring groove form a sealed feed flow dead slot, the annular cover plate and an lower annular edge form an overflow groove, and the soft pipe joint enables external connection with a feed flow-pressure adjusting system and is communicated with the feed flow dead slot. When the feed flow-pressure adjusting system possesses positive pressure, liquid discharged by the drainage layer can press the liquid to be detected in the liquid film through the overflow groove, there by the liquid film is thickened; when the feed flow-pressure adjusting system possesses negative pressure, the air outside the film can not enter in the drainage layer, the liquid in the film overcomes the disjoining pressure and enters in the feed flow-pressure adjusting system through the drainage layer, thereby the liquid film is thinned. When the liquid film reaches the required thickness, a certain pressure difference is kept inside and outside the film, so that the adjustable and controllable liquid film thickness can be realized.

Owner:PETROCHINA CO LTD

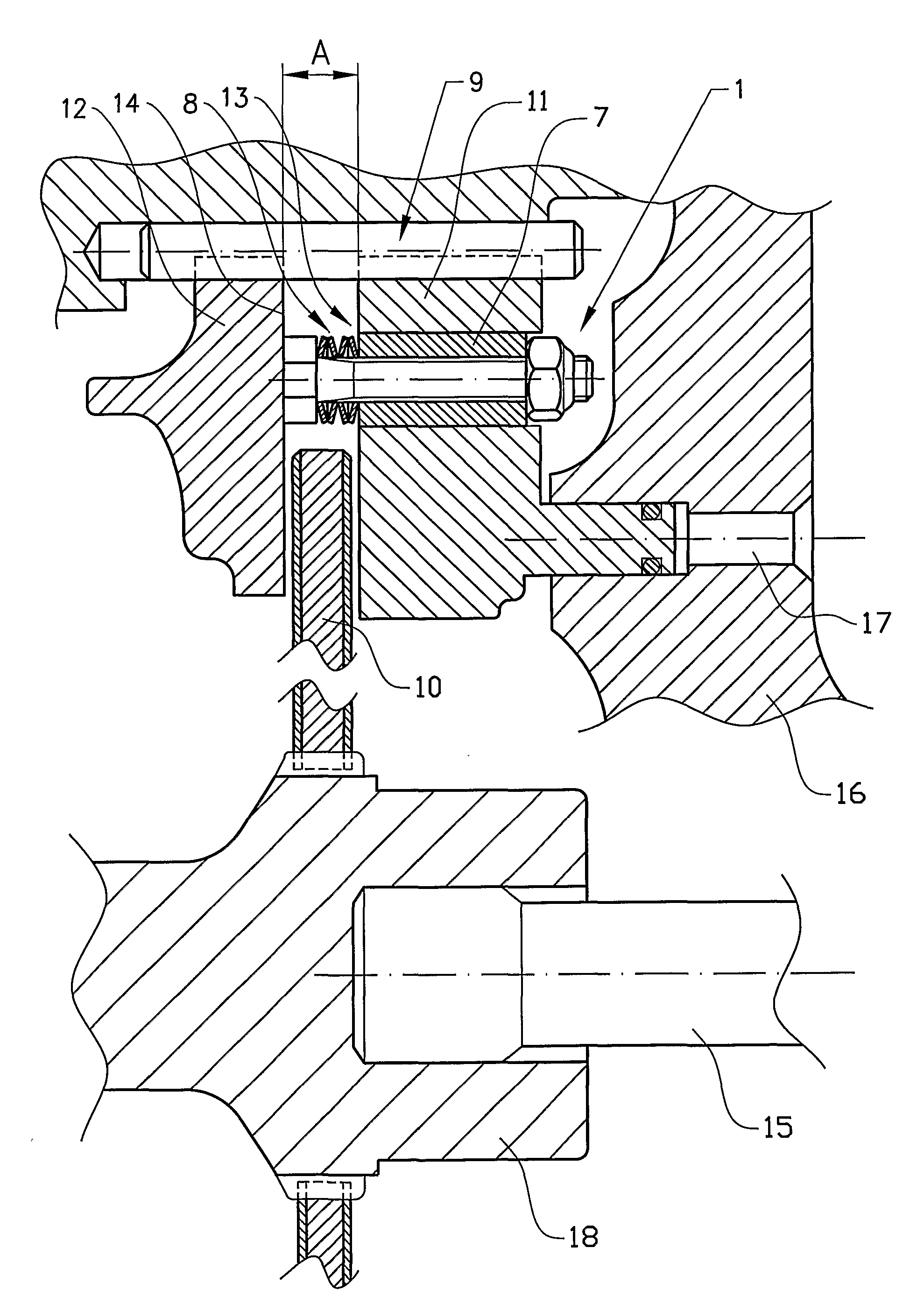

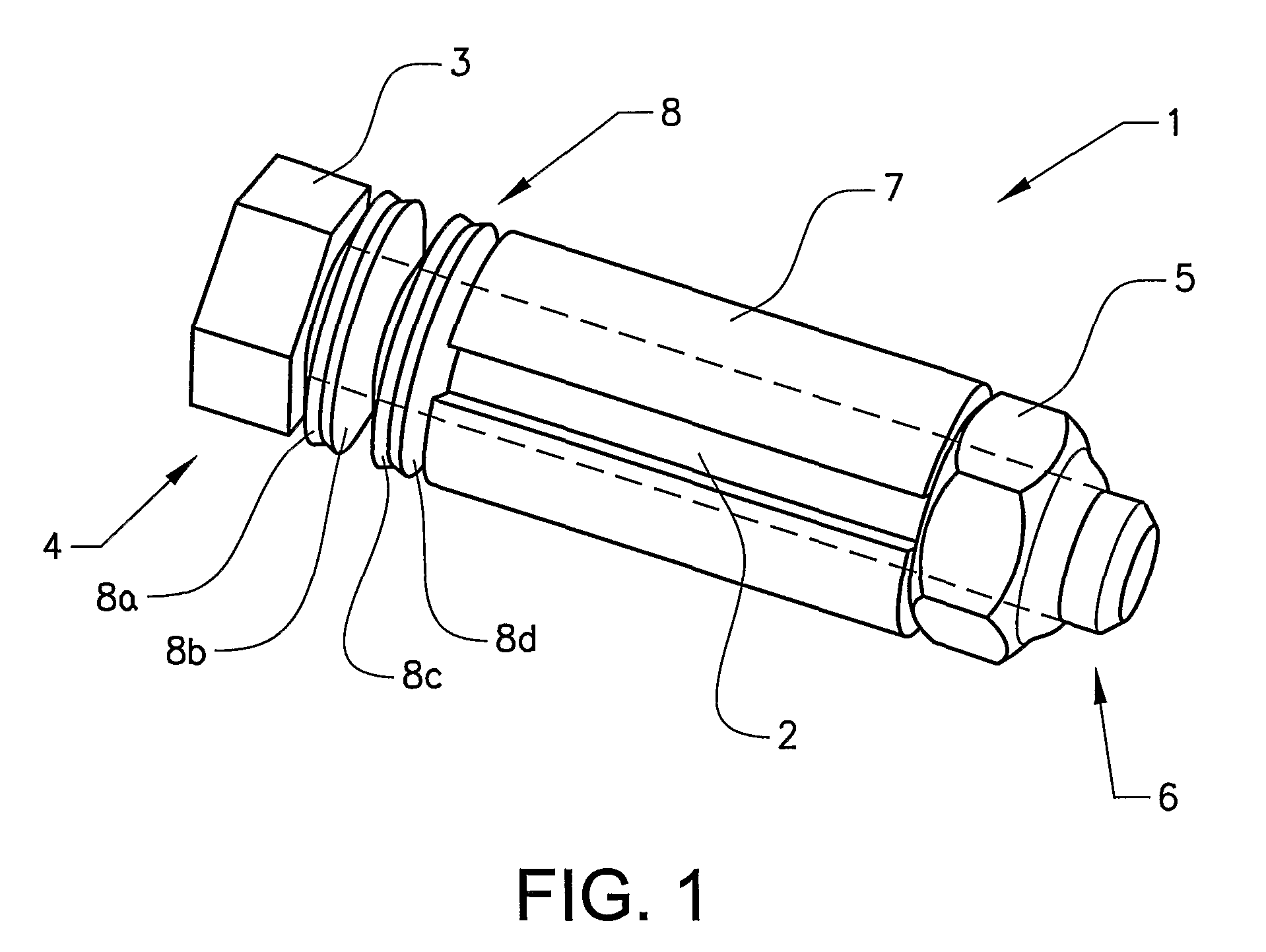

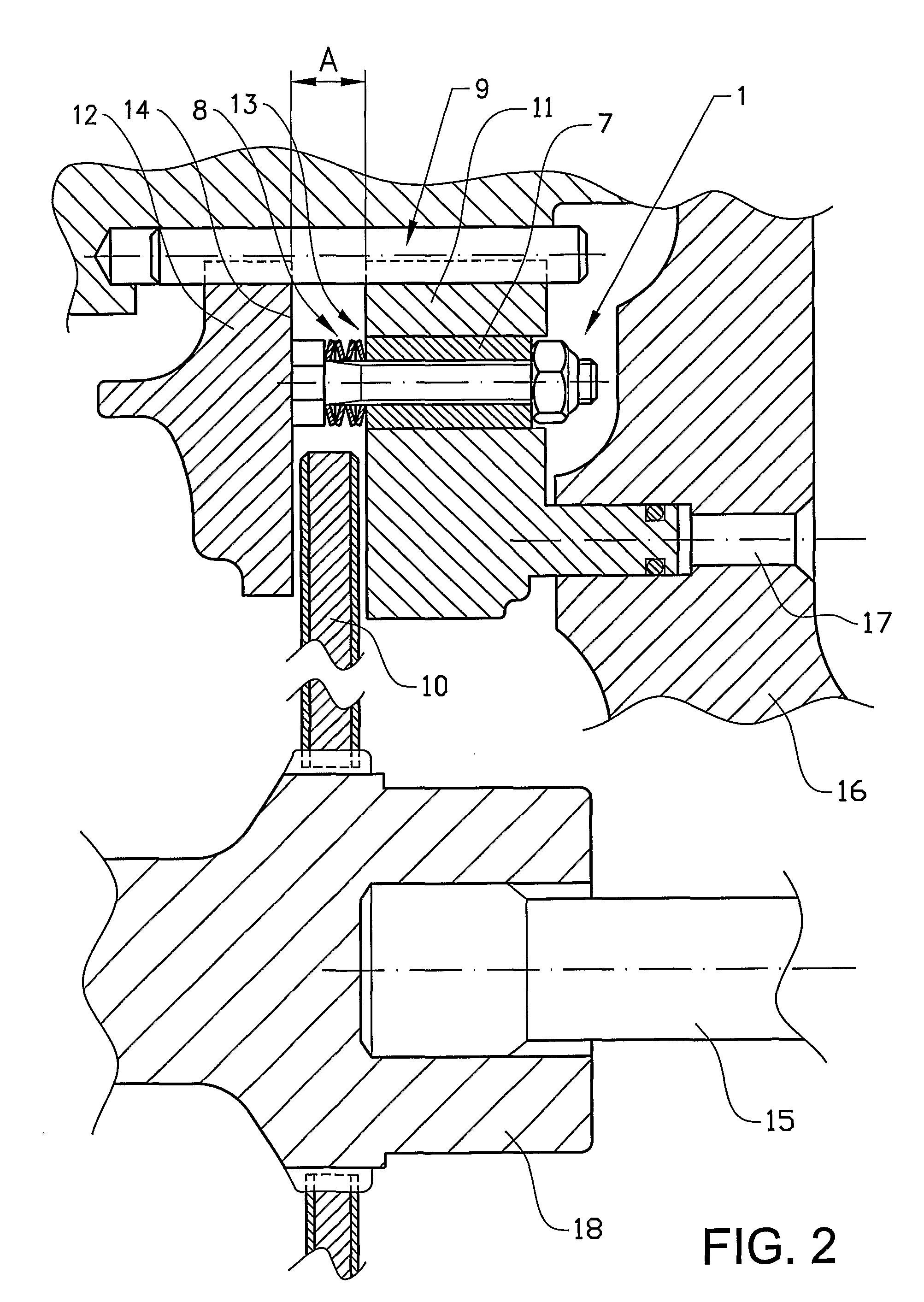

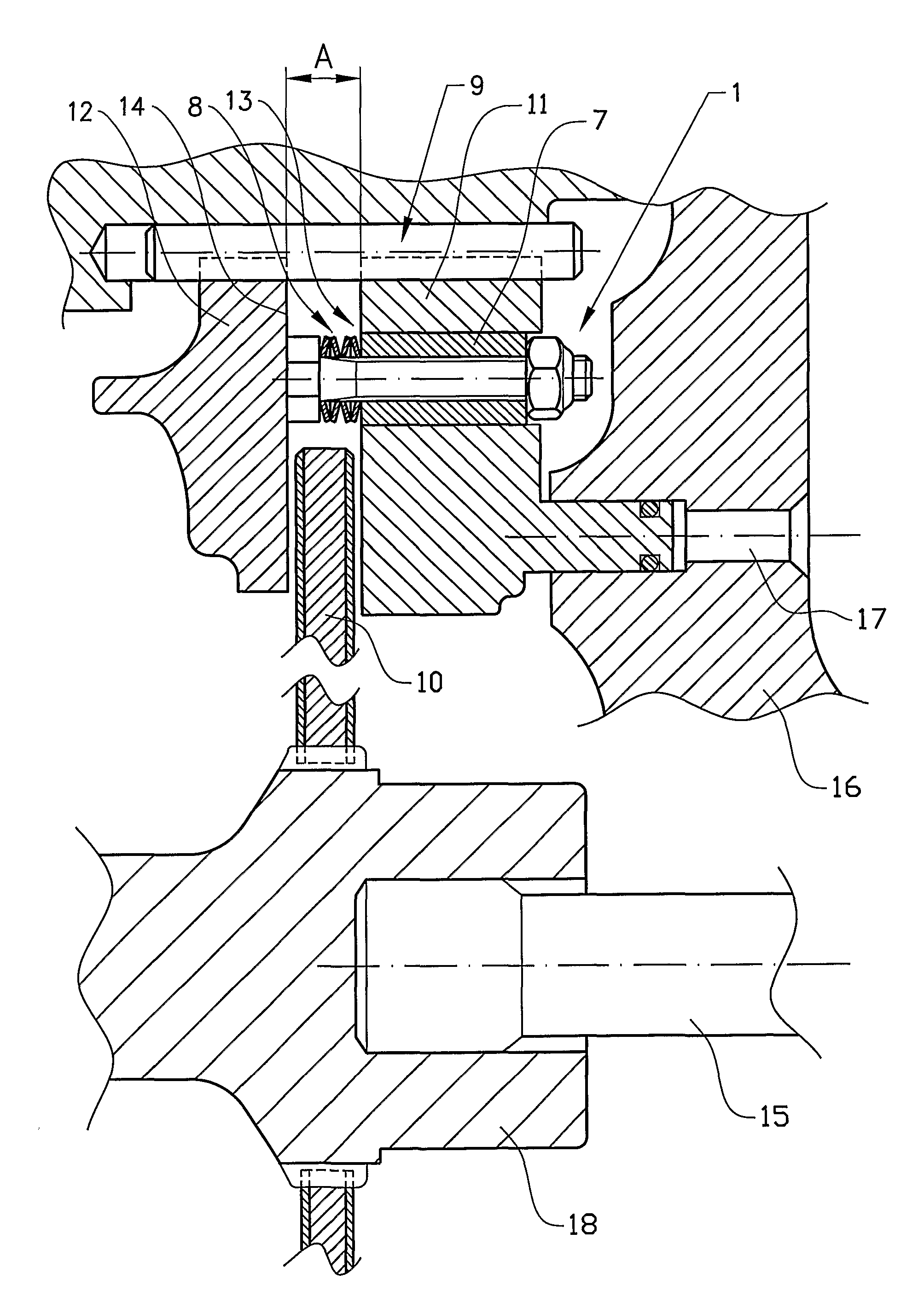

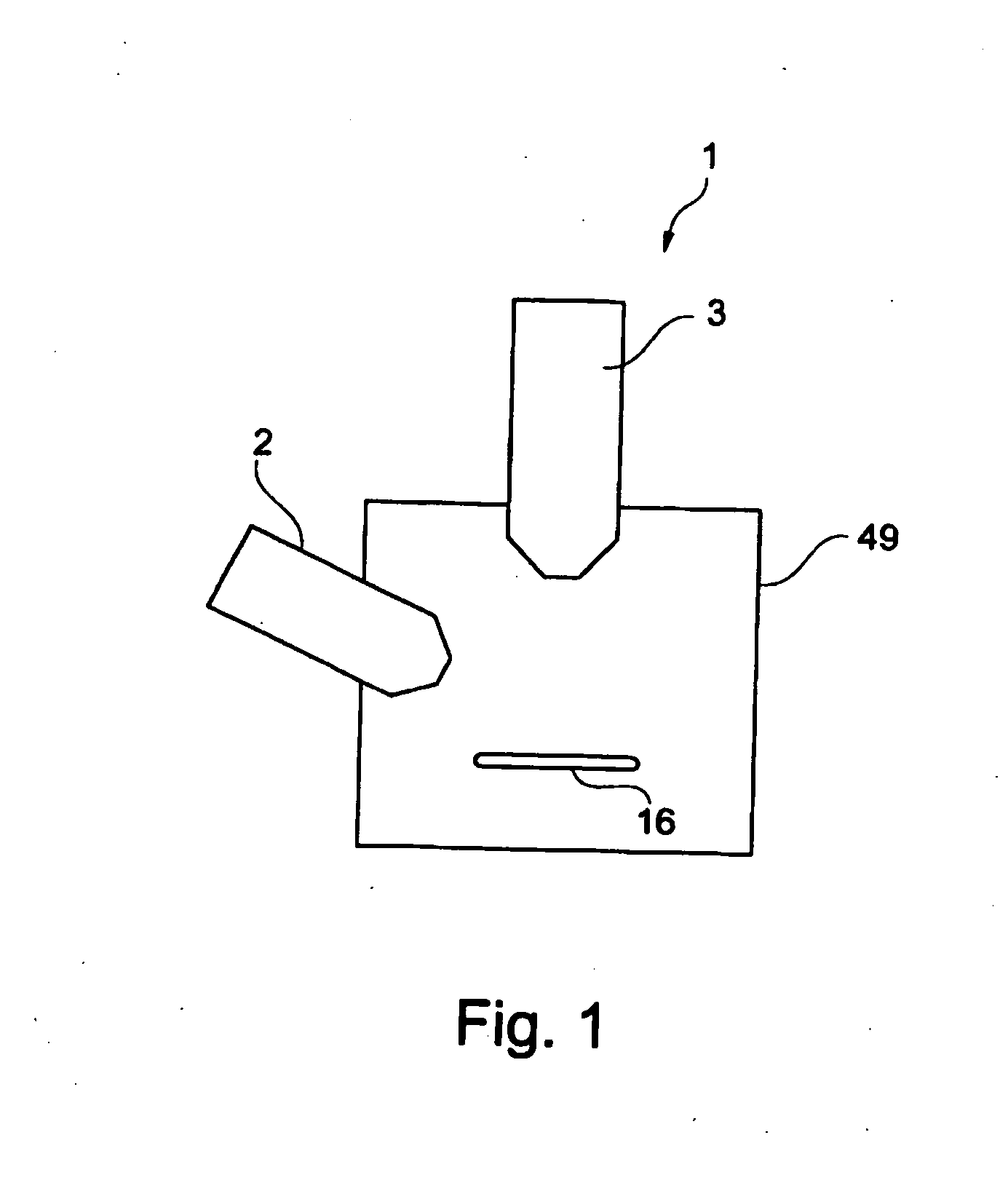

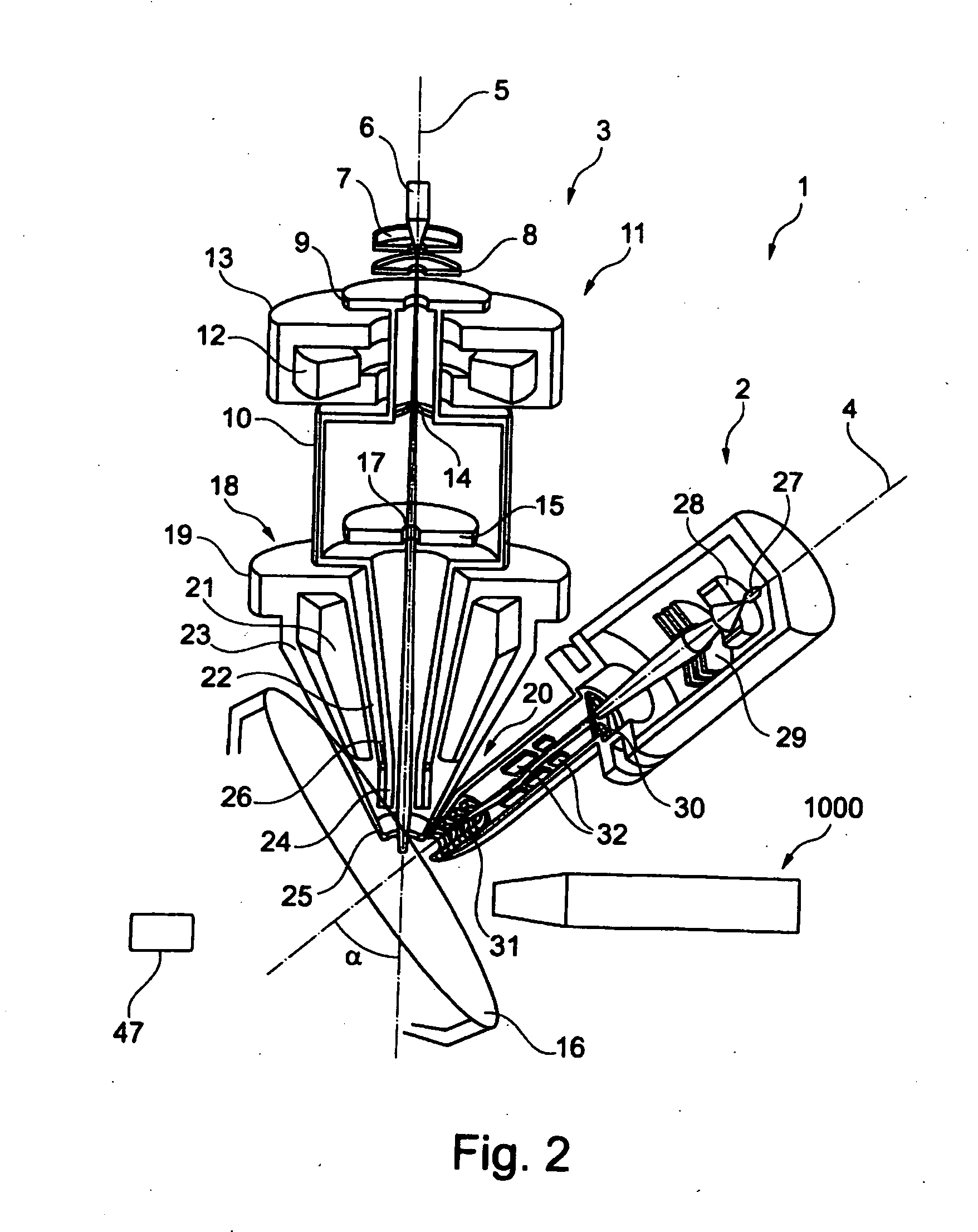

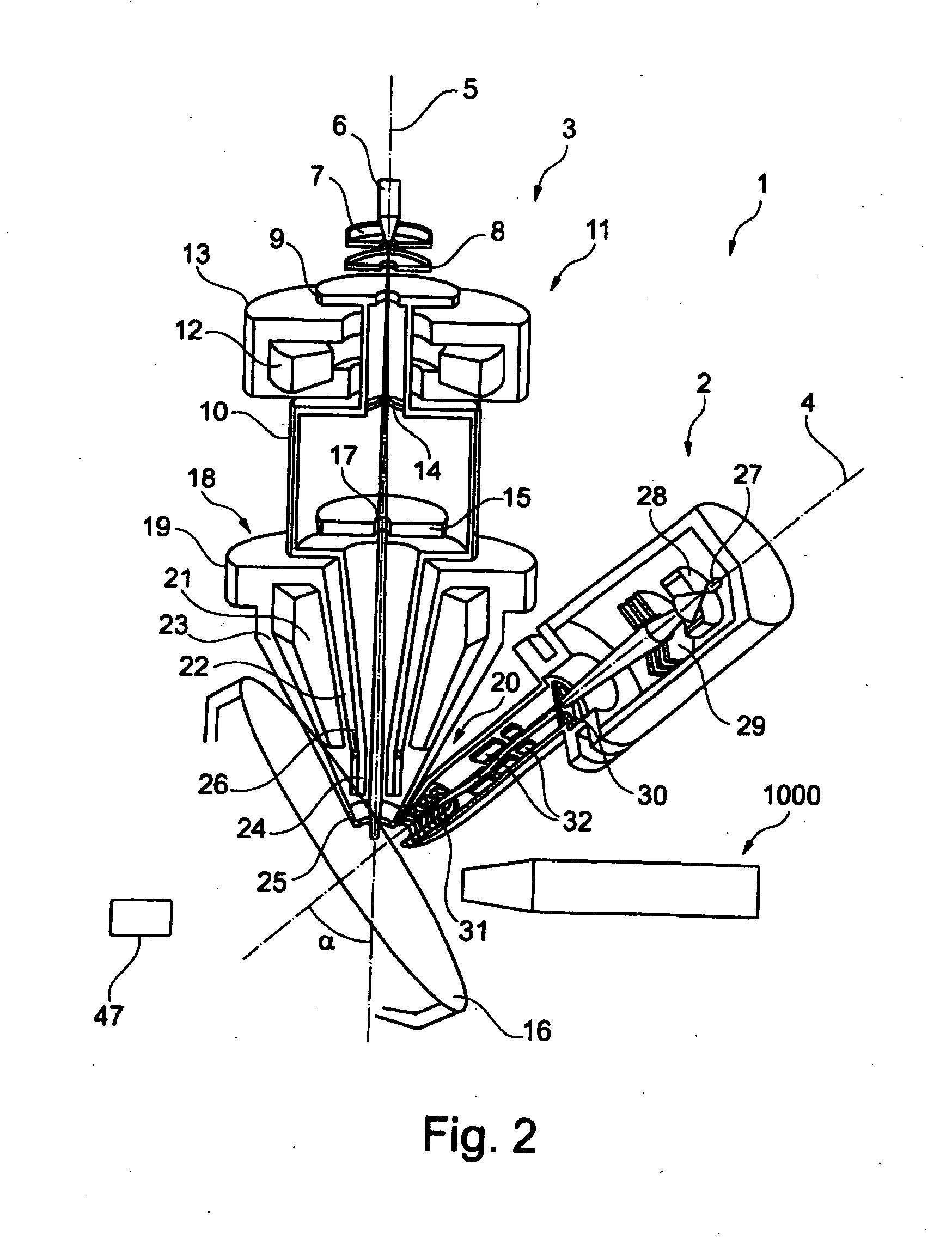

Arrangement for Reducing a Rotational Speed of a Rotating Member

InactiveUS20090071765A1Solution to short lifeSufficient spring effectAxially engaging brakesFriction clutchesRotation velocitySpring force

An arrangement for reducing a rotational speed of a rotating member includes a first and second pressure member arranged at a distance from each other and an opposite sides of the rotating member for movement relative to each other between a retracted position and a forward position engaging the rotating member. The arrangement includes an adjustment device including a friction structure forming a friction joint with one of the pressure members for maintaining a position relative to one another provided a maximum friction force is not exceeded. The arrangement further includes a spring acting on the friction structure for separating the pressure members after having been compressed. The spring has a gradually increasing spring force between a non-compressed state and a totally compressed state. An intermediate spring force value of the spring, which corresponds to compression of the spring to an extent less than the totally compressed state, equals a maximum friction force of the friction joint so that the friction structure is forced to move relative to the pressure member, with which it forms the friction joint, when the maximum friction force is exceeded.

Owner:VOLVO CONSTR EQUIP

Arrangement for reducing a rotational speed of a rotating member

InactiveUS8037979B2Minimize the numberReduce speedAxially engaging brakesFriction clutchesSpring forceEngineering

An arrangement for reducing a rotational speed of a rotating member includes a first and second pressure member arranged at a distance from each other and an opposite sides of the rotating member for movement relative to each other between a retracted position and a forward position engaging the rotating member. The arrangement includes an adjustment device including a friction structure forming a friction joint with one of the pressure members for maintaining a position relative to one another provided a maximum friction force is not exceeded. The arrangement further includes a spring acting on the friction structure for separating the pressure members after having been compressed. The spring has a gradually increasing spring force between a non-compressed state and a totally compressed state. An intermediate spring force value of the spring, which corresponds to compression of the spring to an extent less than the totally compressed state, equals a maximum friction force of the friction joint so that the friction structure is forced to move relative to the pressure member, with which it forms the friction joint, when the maximum friction force is exceeded.

Owner:VOLVO CONSTR EQUIP AB

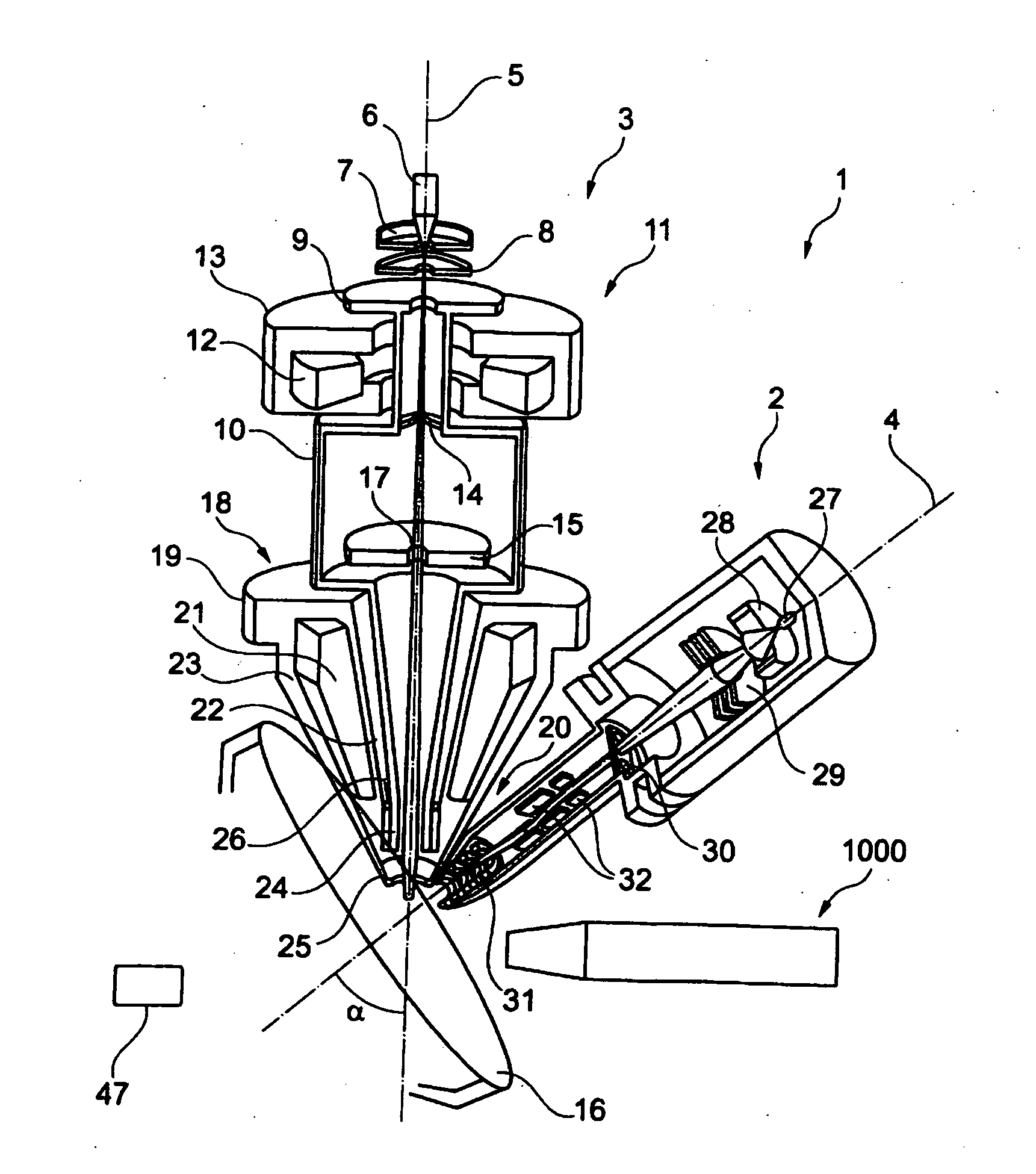

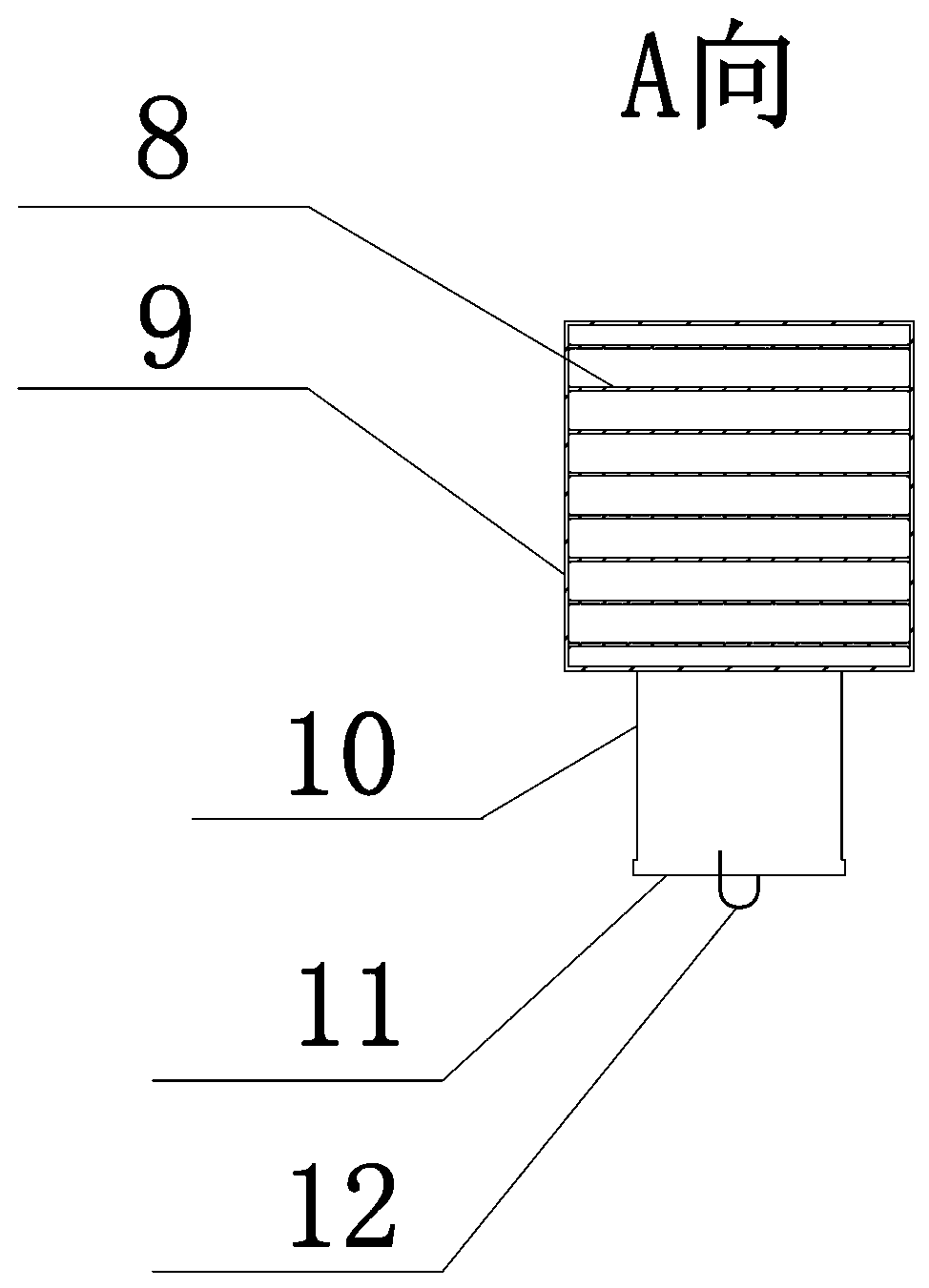

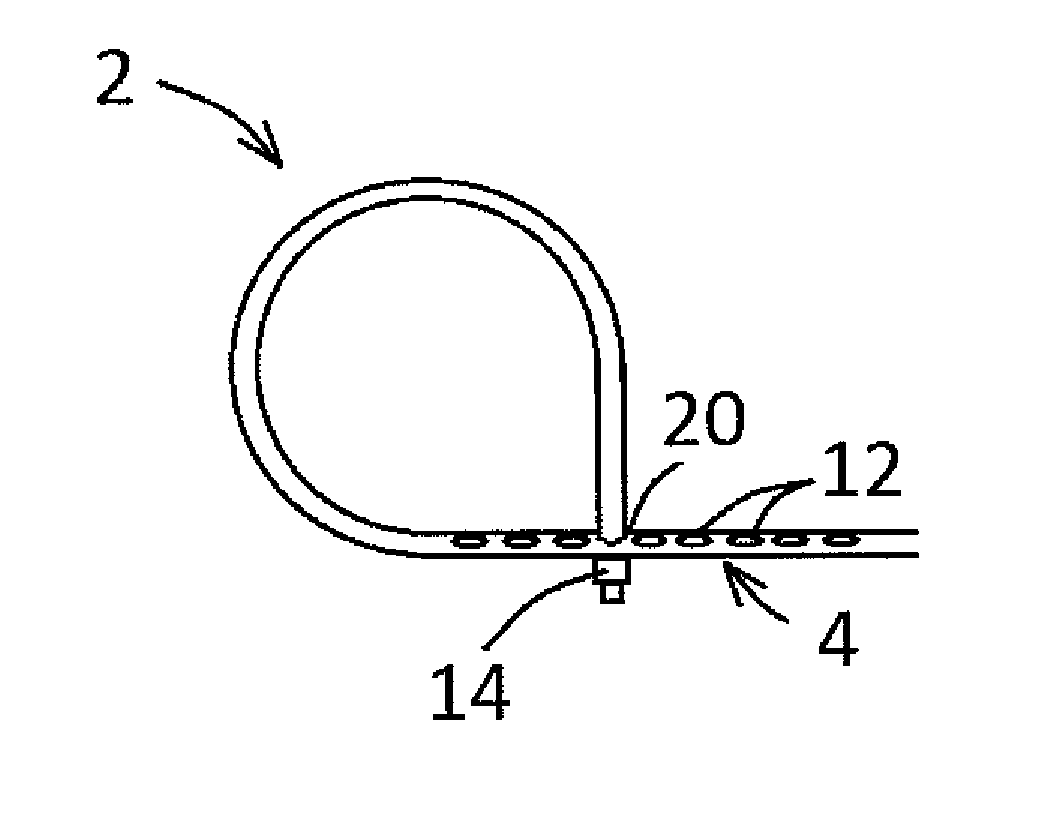

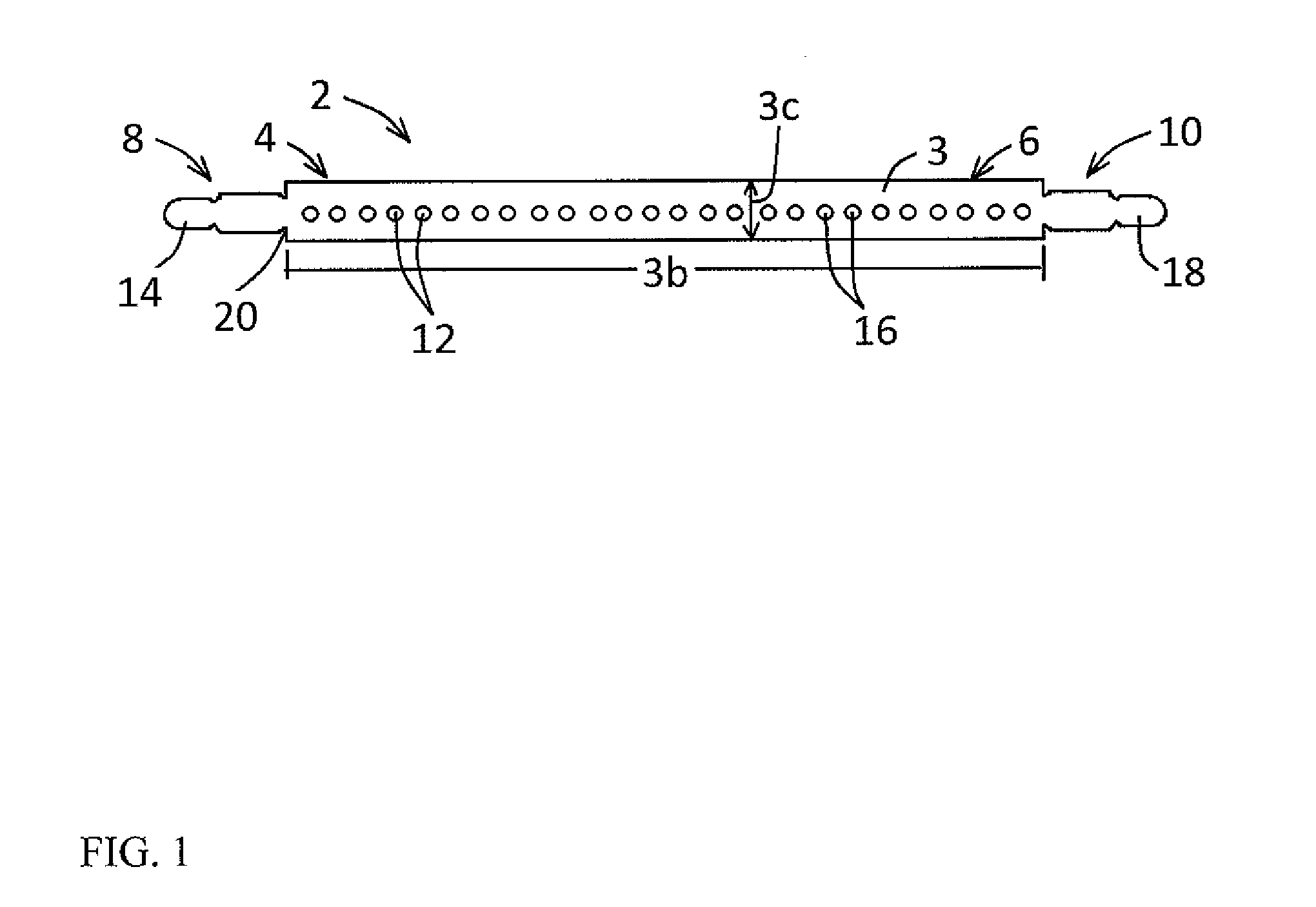

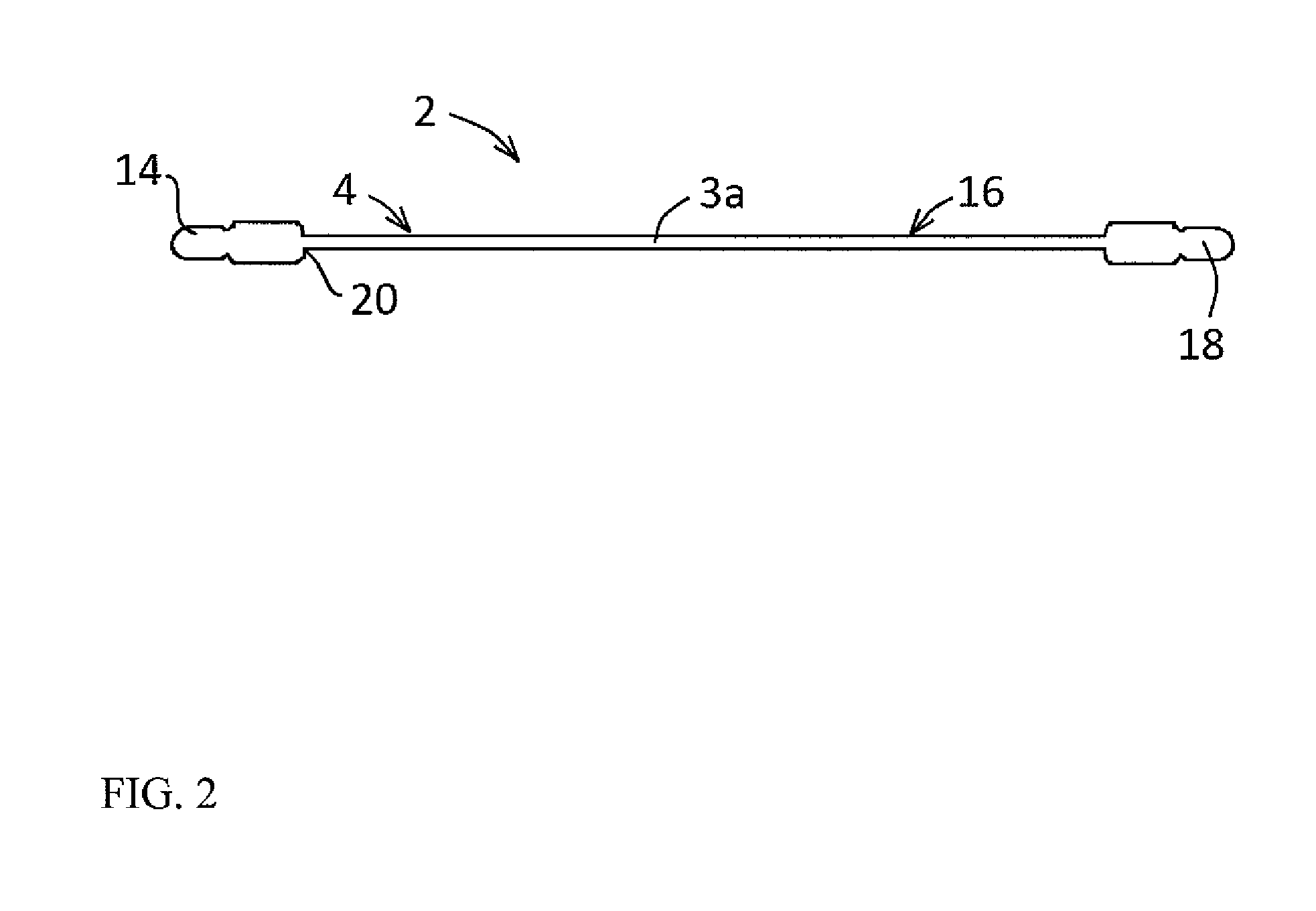

Apparatus for focusing and for storage of ions and for separation of pressure areas

ActiveUS20110220788A1Function be ensureStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsParticle beamDisjoining pressure

An apparatus for focusing and for storage of ions and an apparatus for separation of a first pressure area from a second pressure area are disclosed, in particular for an analysis apparatus for ions. A particle beam device may have at least one of the abovementioned apparatuses. A container for holding ions and at least one multipole unit are provided. The multipole unit has a through-opening with a longitudinal axis as well as a multiplicity of electrodes. A first set of the electrodes is at a first radial distance from the longitudinal axis. A second set of the electrodes is in each case at a second radial distance from the longitudinal axis. The first radial distance is less than the second radial distance. Alternatively or additionally, the apparatus may have an elongated opening with a radial extent. The opening has a longitudinal extent which is greater than the radial extent.

Owner:CARL ZEISS MICROSCOPY GMBH

Apparatus for focusing and for storage of ions and for separation of pressure areas

InactiveUS20160020064A1Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsParticle beamDisjoining pressure

An apparatus for focusing and for storage of ions and an apparatus for separation of a first pressure area from a second pressure area are disclosed, in particular for an analysis apparatus for ions. A particle beam device may have at least one of the abovementioned apparatuses. A container for holding ions and at least one multipole unit are provided. The multipole unit has a through-opening with a longitudinal axis as well as a multiplicity of electrodes. A first set of the electrodes is at a first radial distance from the longitudinal axis. A second set of the electrodes is in each case at a second radial distance from the longitudinal axis. The first radial distance is less than the second radial distance. Alternatively or additionally, the apparatus may have an elongated opening with a radial extent. The opening has a longitudinal extent which is greater than the radial extent.

Owner:CARL ZEISS MICROSCOPY GMBH

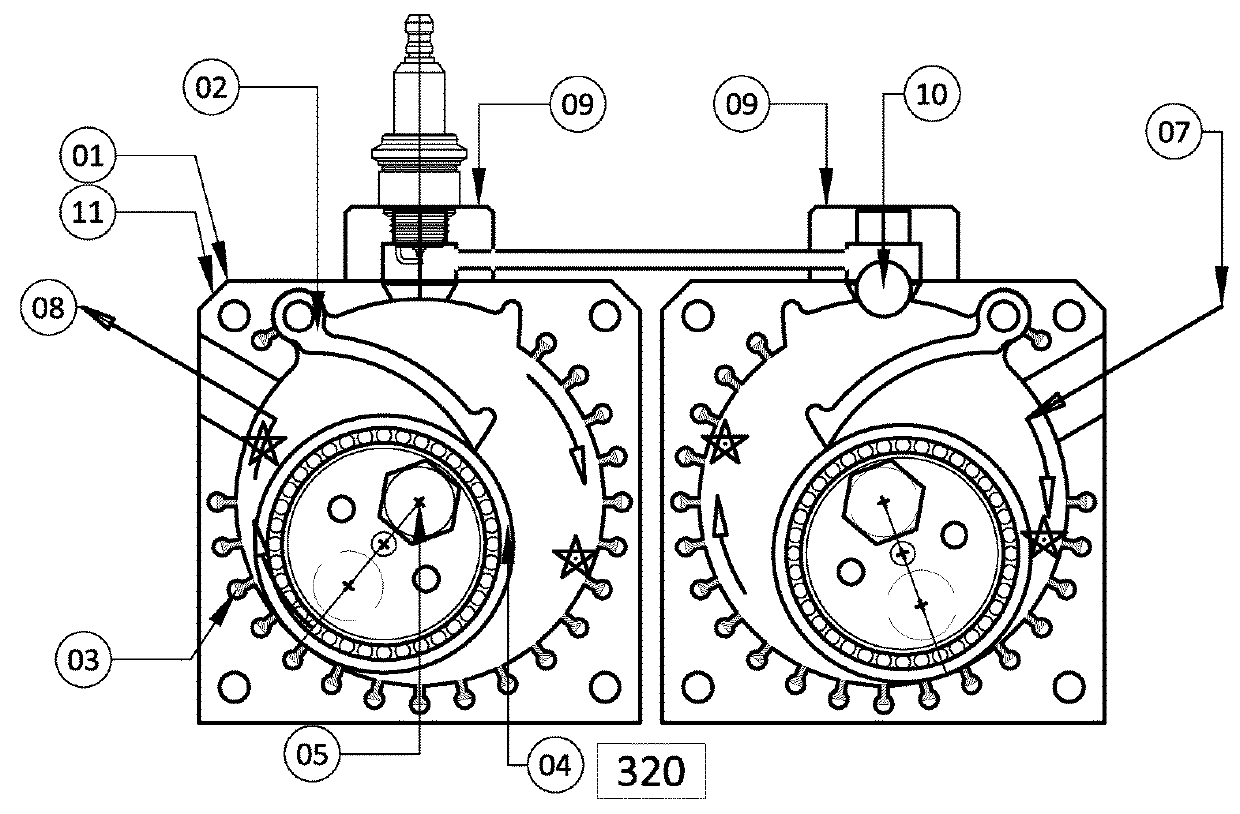

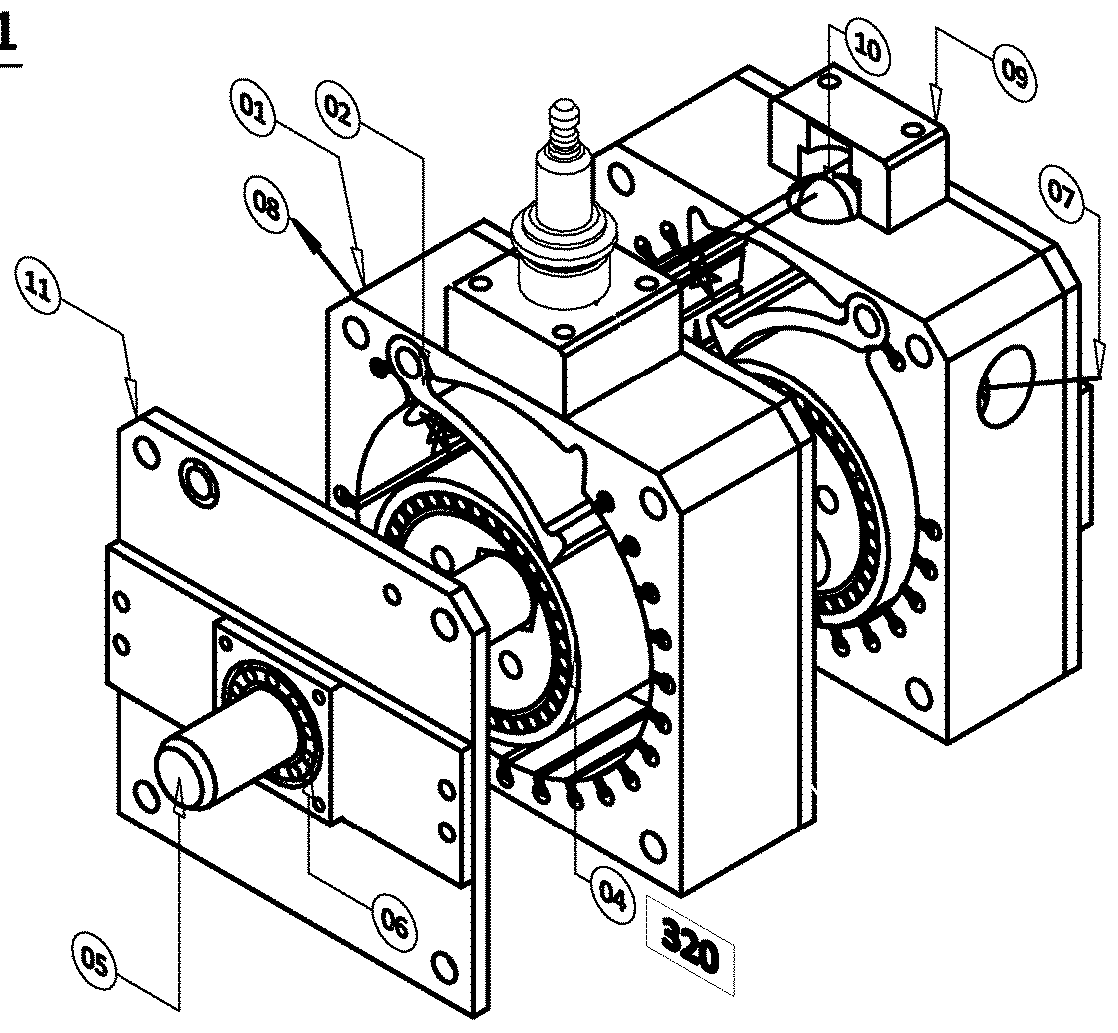

Double or multiple pump

InactiveUS20060280636A1Save powerShorten shift timeEngine of arcuate-engagement typeOscillating piston enginesHigh pressure chamberMechanical engineering

Disclosed is a pump for generating at least two volume flows having a different pressure. Said pump comprises a pump cover, a pump housing, and a wheel set that is eccentrically mounted therein. The pump housing is provided with a suction slot and a pressure slot which are separated from each other by means of a first sealing web and a second sealing sew that is located opposite therefrom. The pressure slot is subdivided into a high pressure chamber and a low pressure chamber with the air of at least one additional sealing web, each pressure chamber being provided with a delivery port.

Owner:GKN SINTER METALS GMBH & CO KG

Dynamic extraction treatment method of cut tobacco in heating non-combustion state

The invention provides a dynamic extraction treatment method of cut tobacco in a heating non-combustion state. The method concretely comprises the following steps of (1) taking tobacco raw materials for use; (2) putting the tobacco raw materials in the step (1) into a supercritical extraction device; adding a certain number of entrainers at certain extraction pressure and temperature; and after the extraction time is reached, taking out extracts to obtain the extracted cut tobacco (the extraction temperature is 40 to 50 DEG C; the time is 2 to 5h; the extraction pressure is 20 to 30 MPa; the separation pressure is 4 to 8 MPa; the entrainers are selected from 1,2-propanediol, glycerol or a mixture of 1,2-propanediol and glycerol; and the consumption of the entrainers is 5 to 20 percent of the materials); and (3) uniformly mixing the cut tobacco obtained in the step (2) with a moisture preservation agent; and then performing balancing treatment for a period of time.

Owner:CHINA TOBACCO ZHEJIANG IND

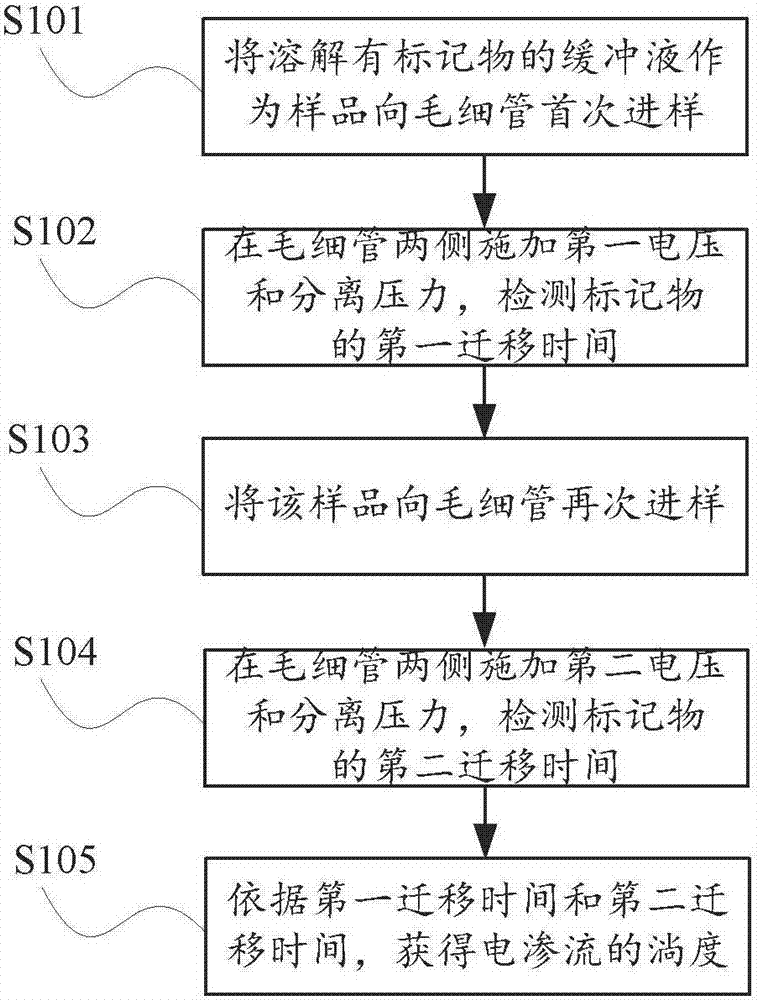

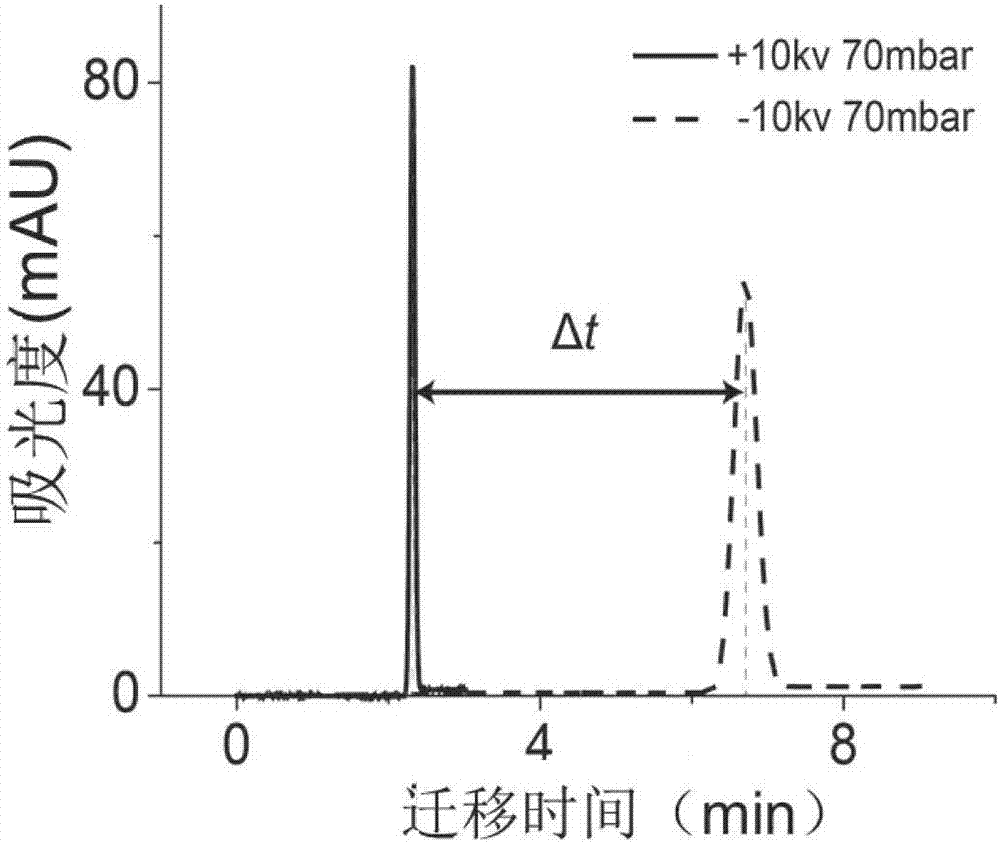

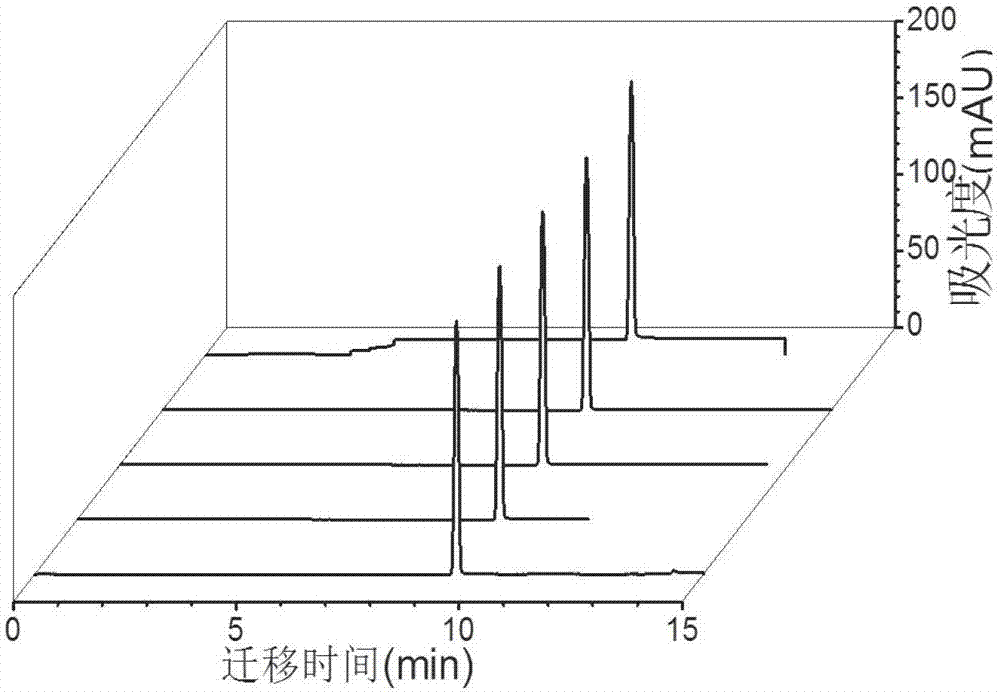

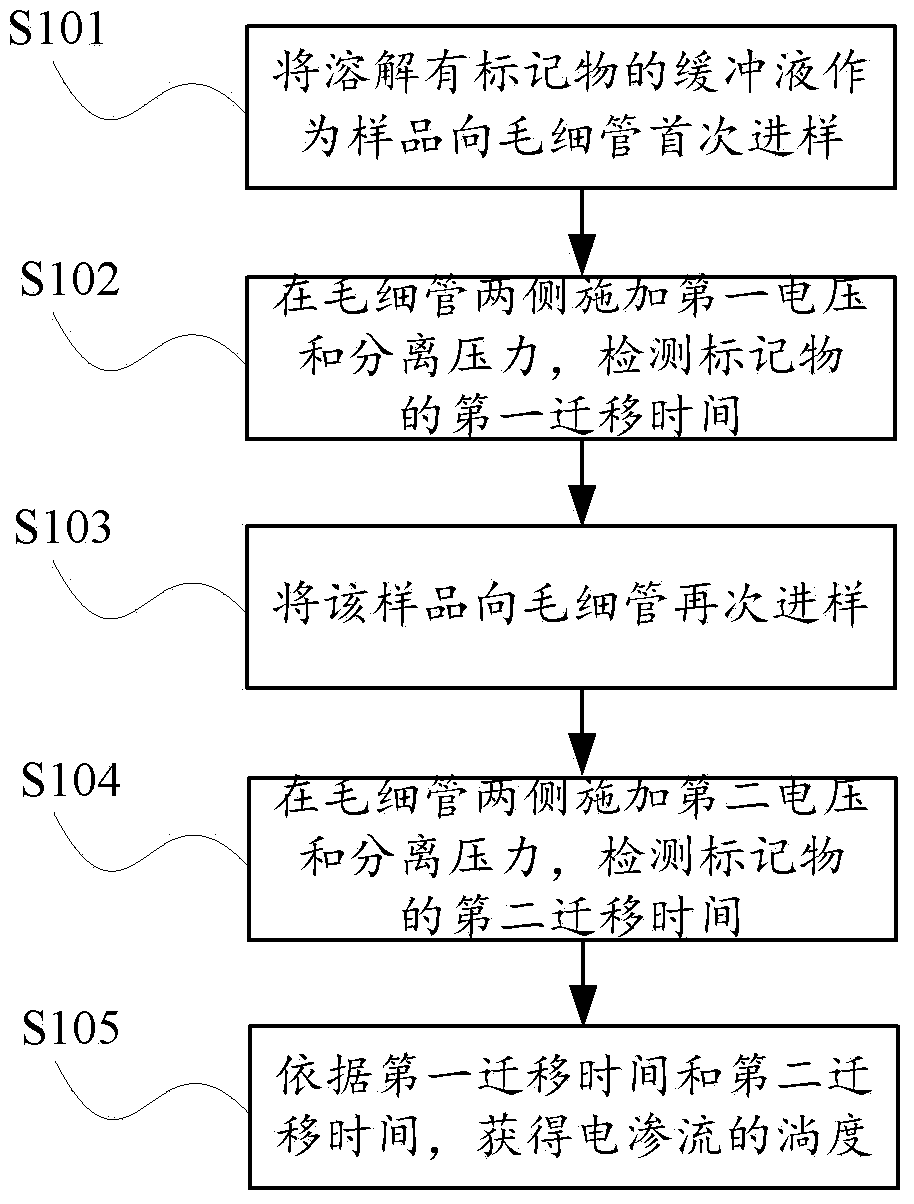

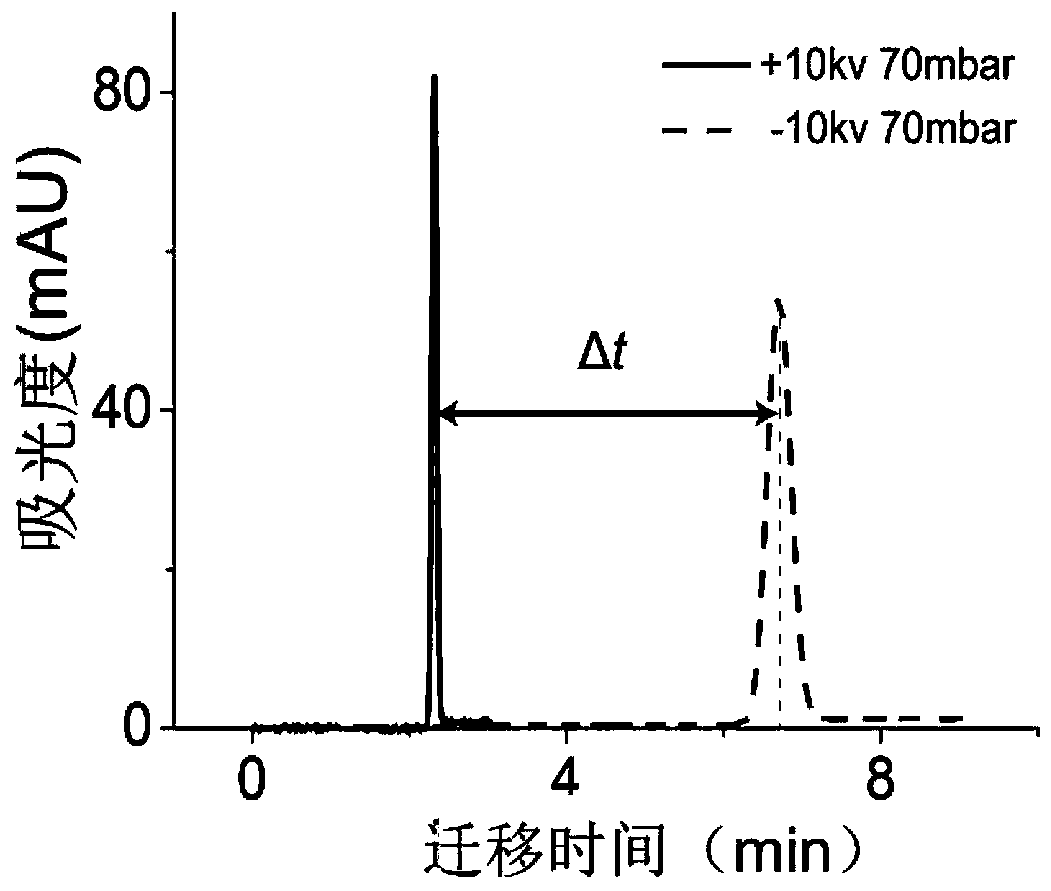

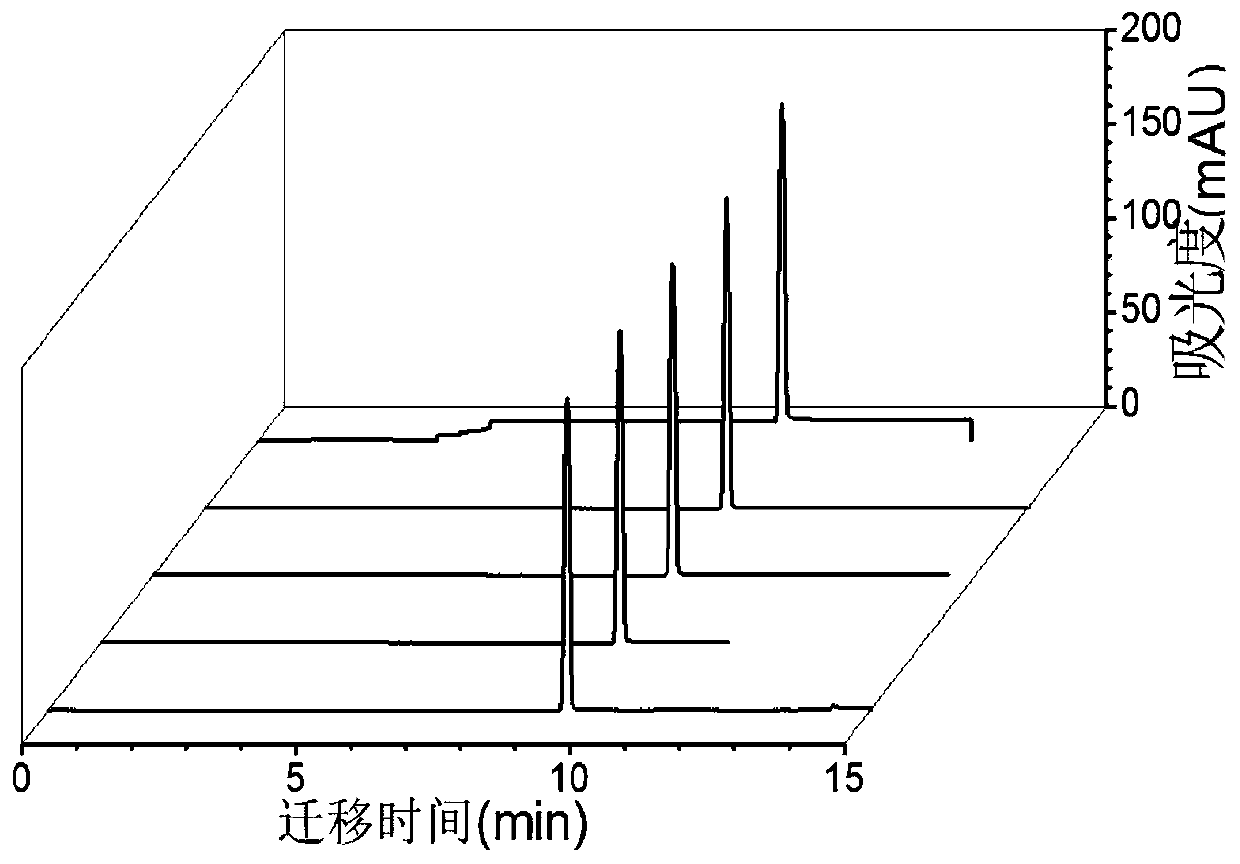

Method used for measuring capillary electrophoresis electroosmotic flow

InactiveCN108007994AHigh measurement accuracyHigh precisionMaterial analysis by electric/magnetic meansElectricityVoltage amplitude

The invention belongs to the field of analytical chemistry, and discloses a method used for measuring capillary electrophoresis electroosmotic flow. The method comprises following steps: a buffer containing a dissolved marker is introduced into a capillary tube as a sample; the two sides of the capillary tube are applied with a first voltage and a certain separation pressure 1, and a first migration time of the marker is detected; the sample in introduced into the capillary tube for a second time; the two sides of the capillary tube are applied with a second voltage, and a separation pressure2 equal to the separation pressure 1, and a second migration time is detected, wherein the direction of the separation pressure 1 and the direction of the separation pressure 2 are the same, the voltage amplitude of the first voltage is equal to that of the second voltage, and the polarity of the first voltage is opposite to that of the second voltage; and at last electroosmotic flow mobility is calculated based on the first migration time and the second migration time. The method is capable of increasing electroosmotic flow measuring precision, and realizing rapid measurement of weak electroosmotic flow of coated capillary tubes.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for extracting black wolfberry seed oil by virtue of subcritical fluid

InactiveCN105112156AReduce consumptionReduce energy consumptionFatty-oils/fats productionLycium barbarum fruitRoom temperature

The invention discloses a method for extracting black wolfberry seed oil by virtue of subcritical fluid. The method comprises the steps: (1) placing dry black wolfberry seeds and an extracting agent into an extraction kettle of a subcritical fluid extraction apparatus according to a mass-volume ratio of 1:1 to 1: 20, continuously extracting for 1 to 20 times to obtain extract, wherein the extraction time is 10 to 15 minutes per time; (2) separating the extract in the step (1) by utilizing a pressure reduction heating method under the condition that the separation pressure is 0.10 to 1.95 MPa and the separation temperature is 10 to 90 DEG C, to obtain an extraction solution; (3) standing the extraction solution for 10 to 90 minutes under the room temperature, to obtain the black wolfberry seed oil. By adopting the method, not only can the production cost be effectively reduced, the extraction and separation time is shortened, and the consumption of solvent and energy consumption in the process flow can be reduced; moreover, the method is simple in process flow, high in operability, high in extraction efficiency, environment-friendly, pollution-free, good in safety and repeatability and capable of realizing the industrialized continuous mass production.

Owner:QINGHAI TIBET BIOTECH CO LTD

Full cycle rotary engine combination

A rotary engine including a compressor unit and an expander unit, a stator having cylindrical inner wall with intake and outlet ports, a hinged gate which fits into the stator inner wall, multiple sealing-strips being loosely embedded within the stator inner wall and backed by elastic force, an eccentrically rotating rotor with a freely rotatable rotor-sleeve which engages with the hinged gate while separating pressure and non-pressure area incident to the expansion and contraction of the working space, the above components being sandwiched between end-plates, perfect dynamic sealing without solid sliding friction, a gate-operated valve conducting the working fluid from the compressor unit into the expander unit via conduit ports in duly timing. The combination of the two units performs a full and extended power cycle simultaneously during each revolution of a common straight shaft.

Owner:XIA ZHONG AI

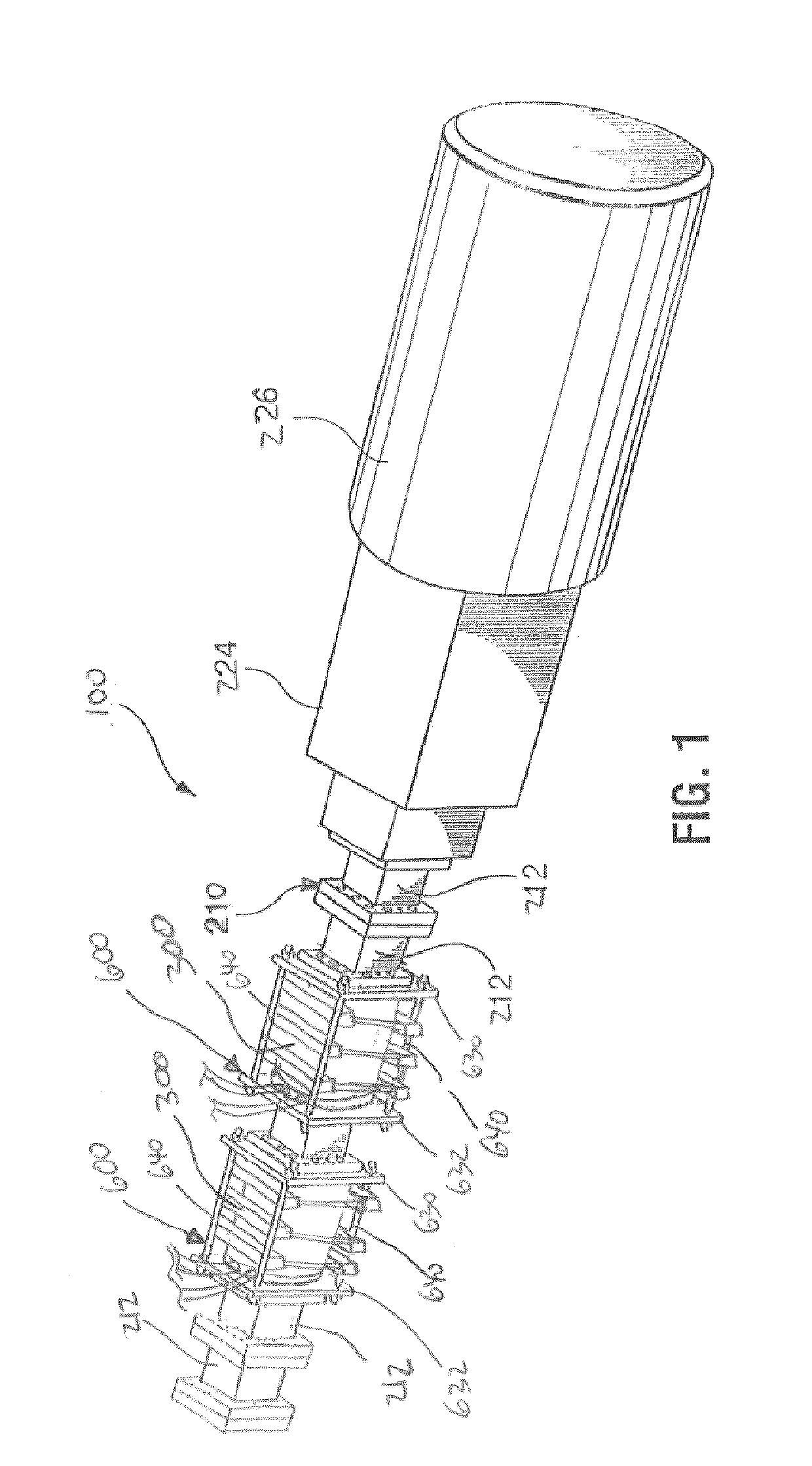

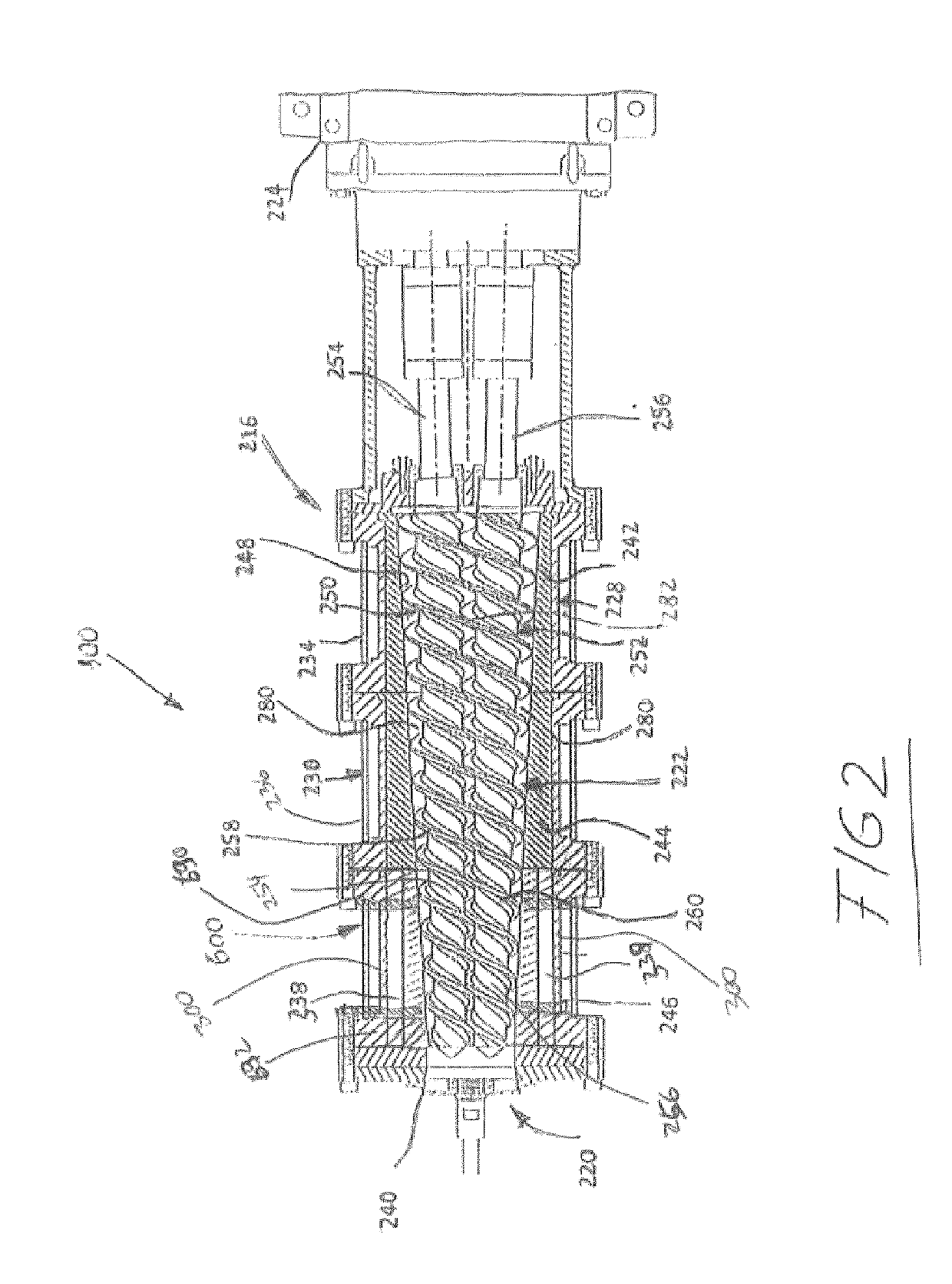

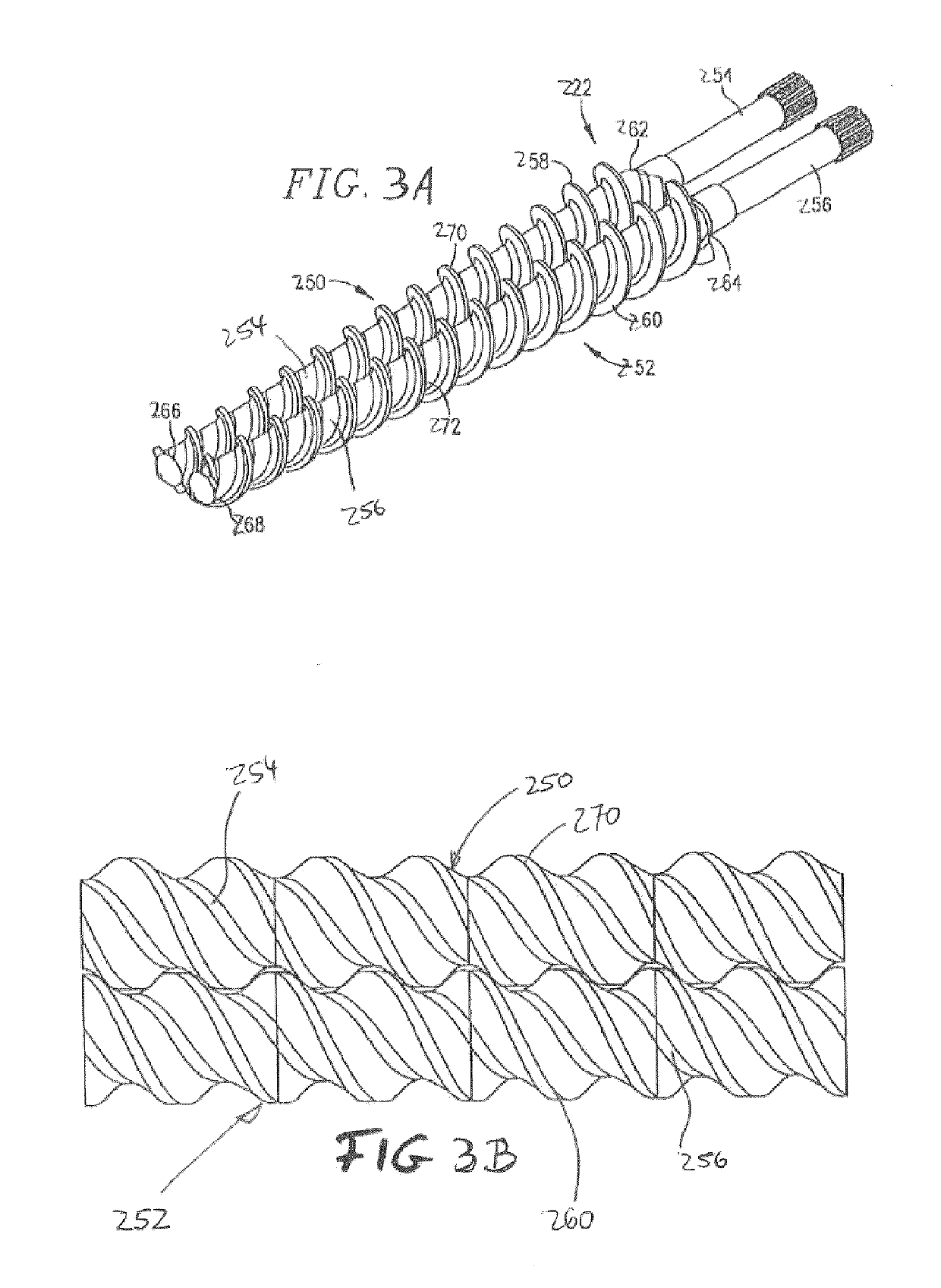

Filter for extruder press

InactiveUS20190143247A1Improve operationEasy maintenanceFiltration separationPressesEngineeringMaterial Perforation

A solid / fluid separation module (300) and press comprises at least one filter unit (301) for a solid / fluid separating press having a barrel with a core opening (112) for at least one conveyor screw. The filter unit includes a pair of end plates (321,322) and a plurality of intermediate filter plates (314) placed one behind the other and sealingly compressed into a plate stack (310) between the end plates. Each intermediate plate (314) has at least one drainage perforation (362) separate from the core opening, the core opening and drainage perforation each extending from a front face to a back face of the intermediate filter plate. In the filter unit, all end plates and barrel plates are aligned such that the core openings form the core passage of the filter block and such that the drainage perforations form an internal fluid collection chamber (338) within the filter unit.

Owner:GREENFIELD SPECIALTY ALCOHOLS

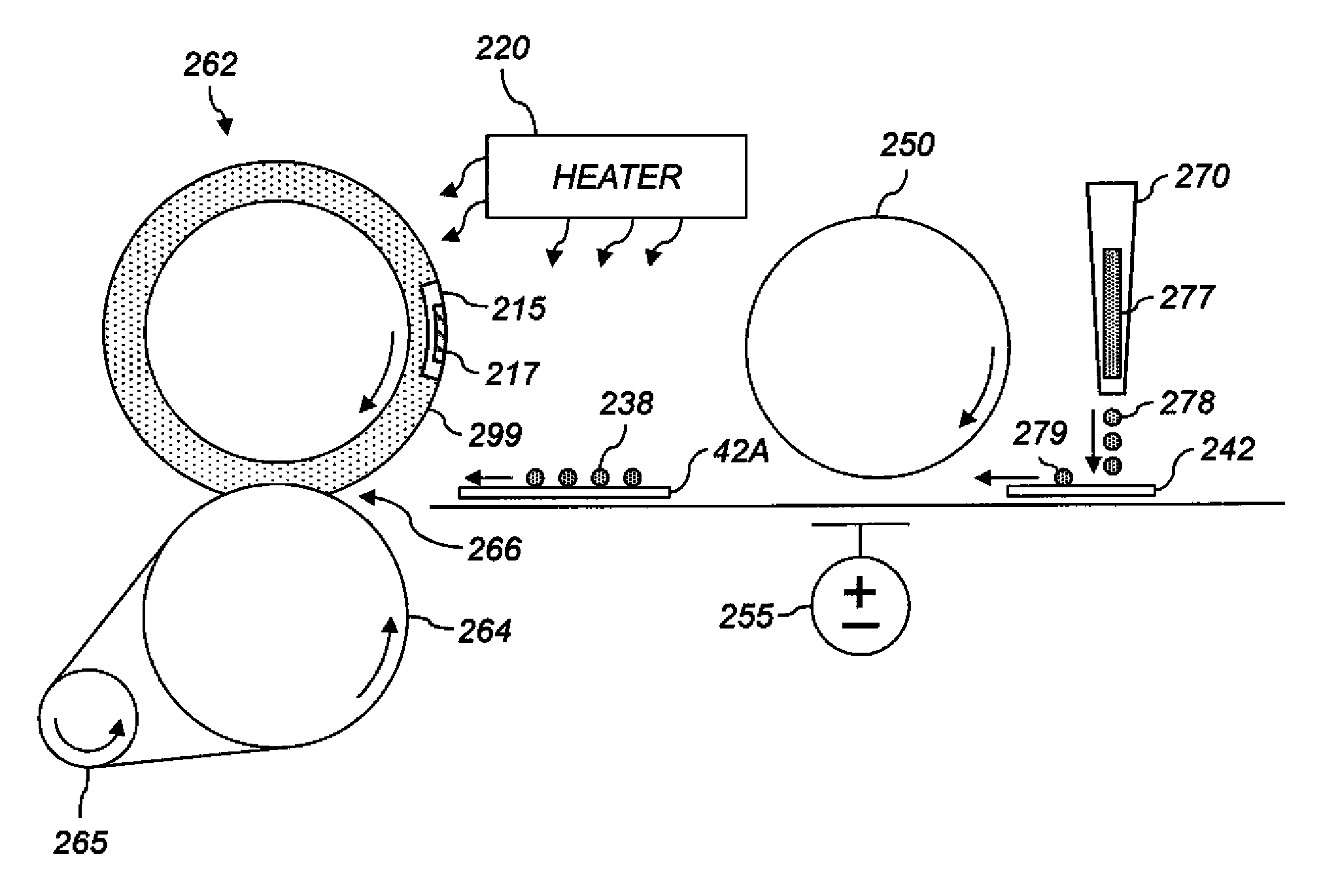

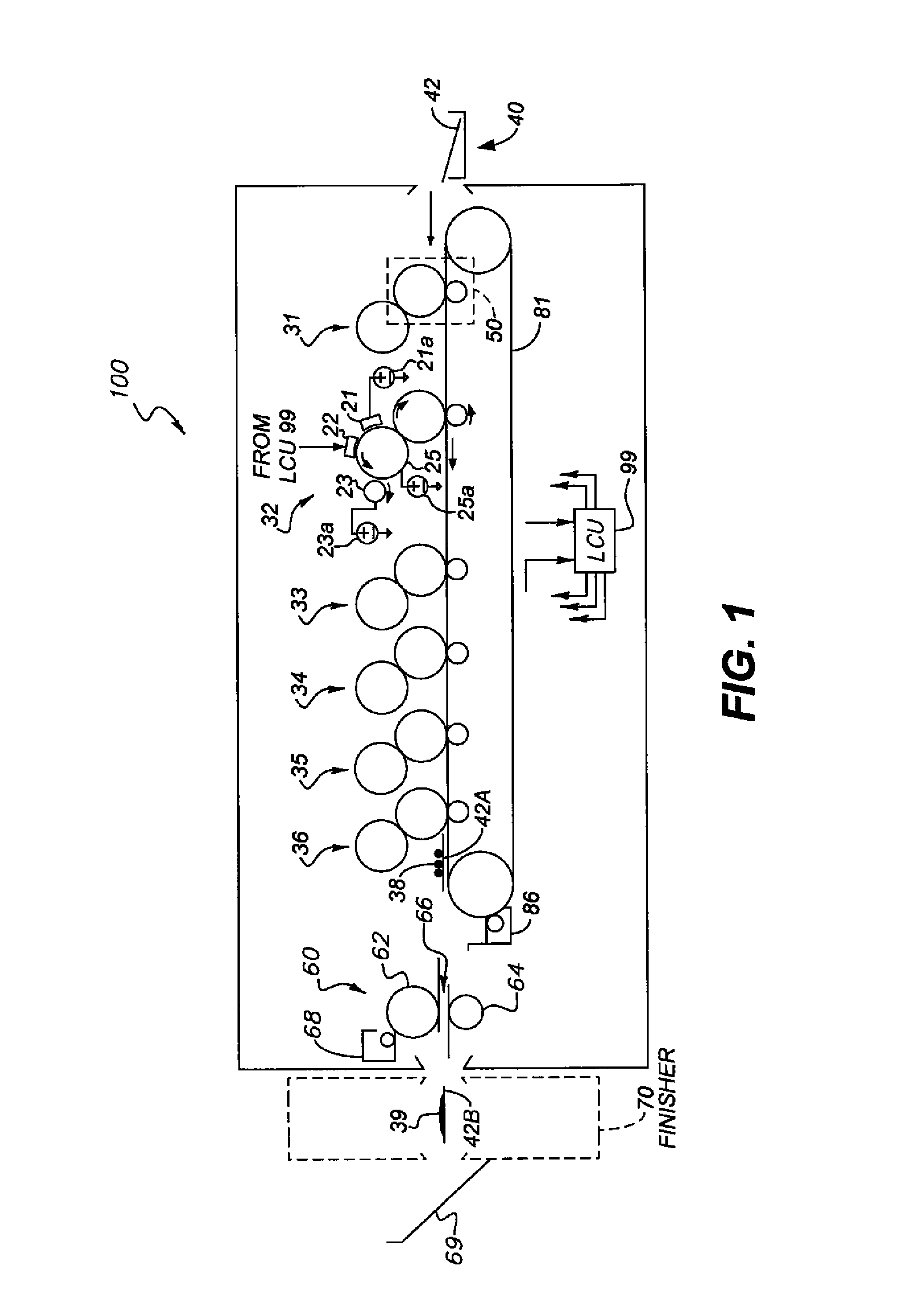

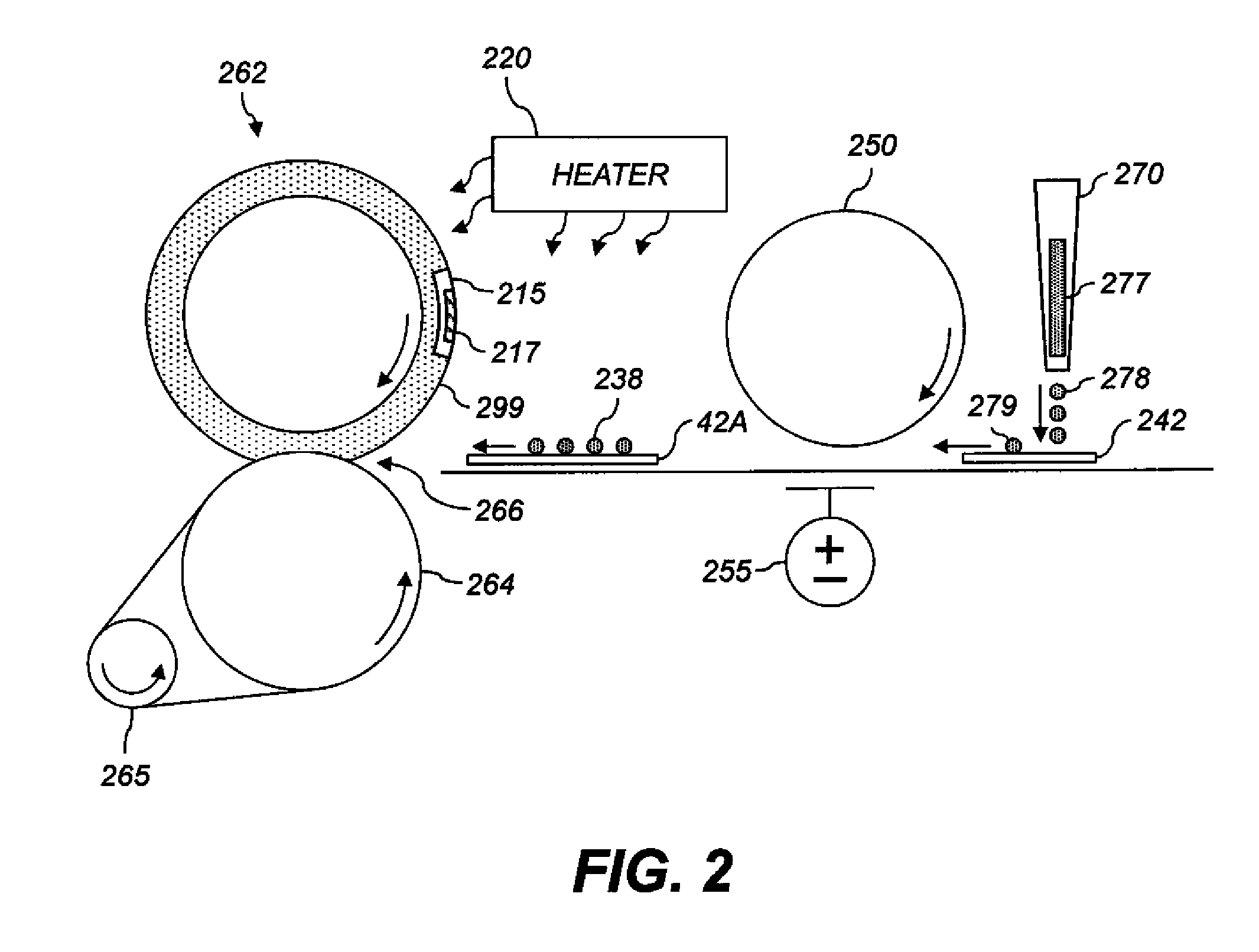

Producing gloss-watermark pattern on fixing member

InactiveUS8639168B2Electrographic process apparatusElectrographic processes using charge patternYoung's modulusDisjoining pressure

Owner:EASTMAN KODAK CO

High oil stain resistance oil-water separation membrane and its preparation method and application

ActiveCN106178600BImprove surface roughnessPass smoothlyNon-miscible liquid separationWastewaterOil water

The invention provides an oil-water separation membrane with high oil stain resistance, which has a porous structure and is super-hydrophilic and super-oleophobic. The contact angle of water on the surface of the film is 3-10 degrees while the contact angle of oil liquid under water is 140-165 degrees. The invention also discloses a preparation method of the membrane. The method particularly includes the steps of preparing fluorine-containing resin, preparing a membrane material, and performing scrape coating to form the membrane. The invention also provides an application of the membrane in separation of an oil-water mixture system. The membrane is good in oil removal effect, strong in oil stain resistance, high in film flux and low in separation pressure. The membrane allows low-pressure operations, is low in energy consumption and cost, and has excellent oil removal effects when being applied in various types of wastewater.

Owner:WUXI LAHIGH ENG DESIGN

Pressure sampling device for separation of active coke particles and regenerative gas

PendingCN110068489AWith graying functionReduce the probability of dust accumulationWithdrawing sample devicesPreparing sample for investigationGas solidMixed states

The invention belongs to the field of automatic environmental detection and particularly relates to a pressure sampling device for separation of active coke particles and regenerative gas. The deviceis characterized by comprising a sampled gas buffering tank arranged on a side wall of a gas-solid sealing plate for sealing the active coke particles and the regenerative gas, a group of gas-solid separating and guiding plates arranged at a connection surface of the side wall of the gas-solid sealing plate and the sampled gas buffering tank, a joint arranged at the upper end of the sampled gas buffering tank, a sampling tube connected to the joint, an inspection ash storing box arranged at the lower part of the sampled gas buffering tank, an inspection cover arranged at the opening of the inspection ash storing box and a disassembly and assembly lifting ring arranged on the inspection cover. The device disclosed by the invention has the advantages that under the circumstance of not influencing the operating state of the active coke particles, the purpose of introducing the gas in the gas-solid mixed state into a pressure transmitter can be realized and the online real-time detection is completed.

Owner:中冶北方(大连)工程技术有限公司

Means to Associate a First Object and a Second Object

ActiveUS20150047172A1Improve securityAdjustability is providedSnap fastenersTravelling sacksMechanical engineeringDisjoining pressure

The invention uses a strap to provide a way to associate a first item with a second item. The first item may be, for example, a high chair and the second a toy. The strap is provided with two sets of openings one near each end of the strap, and a tab, post, “T” or other shape near each end of the strap. The shape is inserted through one of the openings and is secured there by its shape, the shape of the opening, and the material with which that portion of the strap is made. The strap is made of nontoxic material and at least in part of material that is flexible and resilient, having a durometer reading of between about 40 and 60 Shore A. The strap may be equipped with at least one breakaway point, usually set for a breakaway pressure between about 3 and 7 pounds.

Owner:LIL SIDEKICK INC

A method for measuring capillary electrophoresis electroosmotic flow

InactiveCN108007994BHigh measurement accuracyHigh precisionMaterial analysis by electric/magnetic meansElectricityVoltage amplitude

The invention belongs to the field of analytical chemistry, and discloses a method used for measuring capillary electrophoresis electroosmotic flow. The method comprises following steps: a buffer containing a dissolved marker is introduced into a capillary tube as a sample; the two sides of the capillary tube are applied with a first voltage and a certain separation pressure 1, and a first migration time of the marker is detected; the sample in introduced into the capillary tube for a second time; the two sides of the capillary tube are applied with a second voltage, and a separation pressure2 equal to the separation pressure 1, and a second migration time is detected, wherein the direction of the separation pressure 1 and the direction of the separation pressure 2 are the same, the voltage amplitude of the first voltage is equal to that of the second voltage, and the polarity of the first voltage is opposite to that of the second voltage; and at last electroosmotic flow mobility is calculated based on the first migration time and the second migration time. The method is capable of increasing electroosmotic flow measuring precision, and realizing rapid measurement of weak electroosmotic flow of coated capillary tubes.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

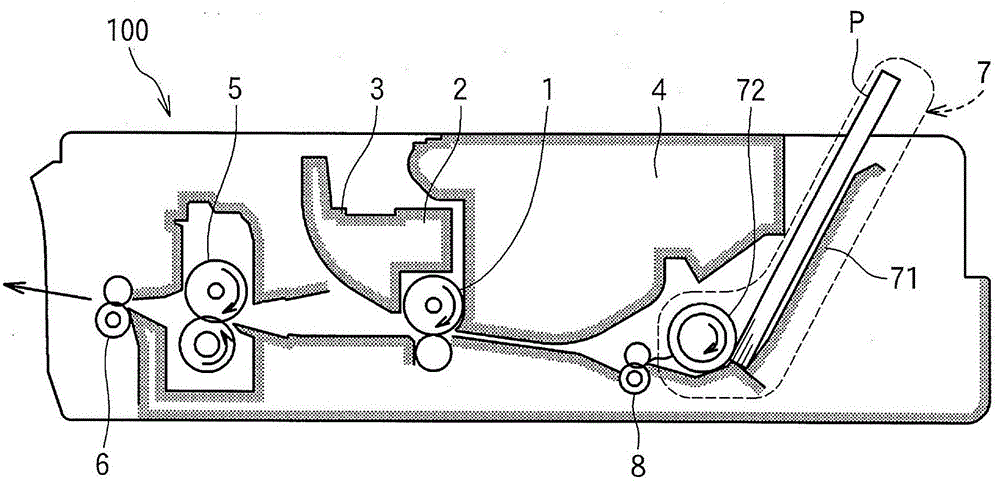

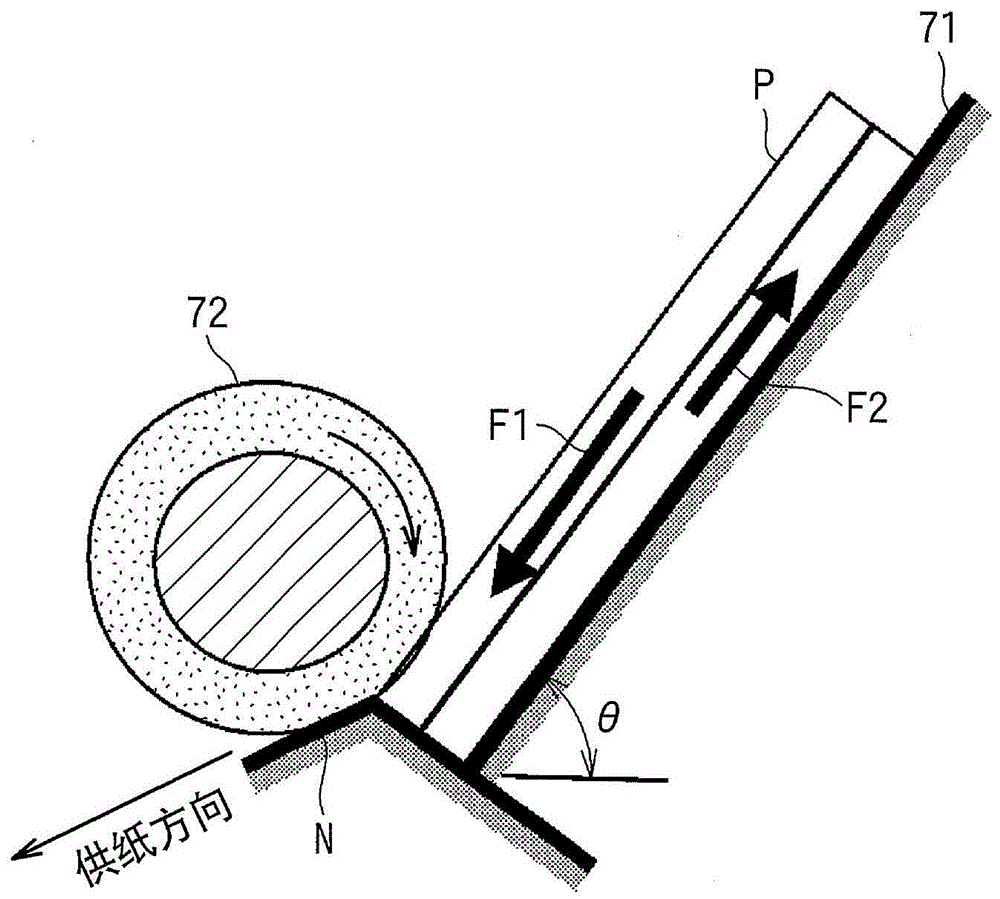

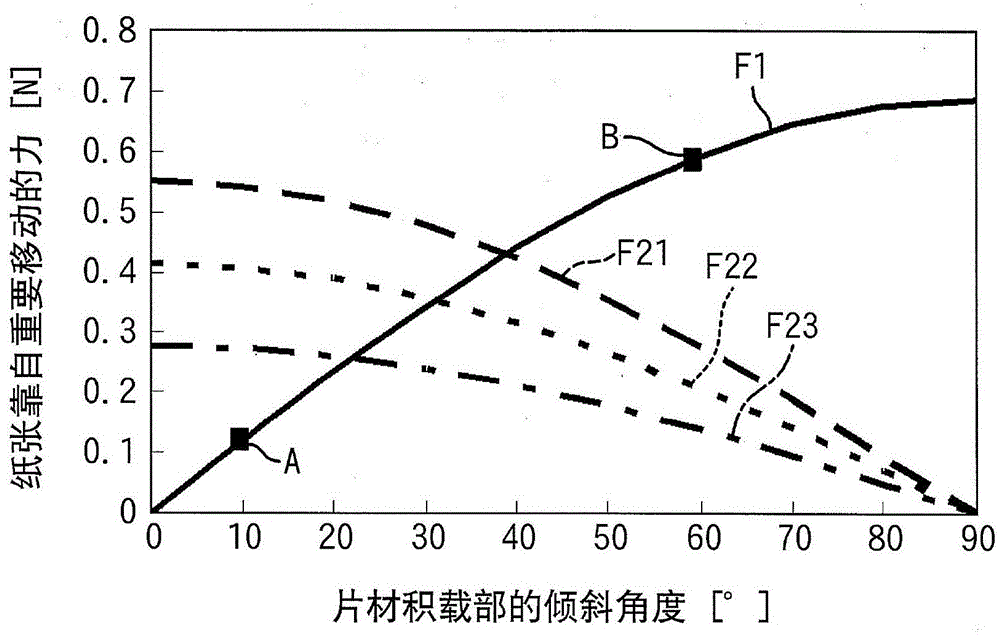

Sheet separating and feeding device and image forming device

ActiveCN104229505BPrevent beam entryAvoid duplicationElectrographic process apparatusArticle separationEngineeringDisjoining pressure

Owner:RICOH KK

Comprehensive utilization method of ionic membrane electrolytic saline solution waste liquid

ActiveCN102502986BEfficient processing and utilizationEfficient use ofWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentLiquid wasteComing out

The invention relates to a comprehensive utilization method of an ionic membrane electrolytic saline solution waste liquid, which comprises the step of sending dechlorinated dilute brine coming out of an electrolytic tank to a membrane process denitration device for denitration. The comprehensive utilization method is characterized by comprising the following steps of: pre-adjusting the pH value of a system to 3-8 by using a saline solution PH value automatic control device, exchanging the heat till the temperature of the system is 25-50 DEG C, removing free chlorine till the content of chlorine is less than or equal to 3 ppm, sending into a primary membrane separation system for primary membrane separation and controlling the primary membrane separation pressure to be not higher than 3.0 MPa; and then sending into a secondary membrane separation system for secondary membrane separation, controlling the secondary membrane separation pressure to be not higher than 3.5 MPa, separating to obtain desulfurized brine and concentrated nitrate water, sending the dissolved desulfurized brine to an ionic membrane electrolytic saline solution device for reutilization and sending the concentrated nitrate water to a thermal method denitration device to prepare thenardite. The invention has the beneficial effects that as the two stages of membrane separation systems are adopted, the pressure is more stable, the membrane service life is long, and the separation effect is good; the content of sodium sulfate in the separated concentrated nitrate water can reach above 90 g / l, and the content of sodium sulfate in the desulfurized brine can reach below 3 g / l.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supercritical fluid extraction method of high-purity sterol

InactiveCN1111168CHigh purityGood effectDistillation separationSteroids preparationVegetable oilSterol

The preparation method of refined high-purity sterol by utilizing supercritical fluid is characterized by using by-product obtained in the course of processing vegetable oil as raw material, according to that sterol and other components are different in soubility in supercritical fluid making purification and refinement, and its optimum extraction agent is CO2, extraction pressure is 15-35 MPa, extraction temp. is 32-75 deg.C, separation temp. is 40-60 deg.C, separation pressure is 4-6MPa, and in the course of extraction the synergist alcohol or ketone can be added. The obtained sterol is high in purity and yield.

Owner:SHANGHAI JIAO TONG UNIV

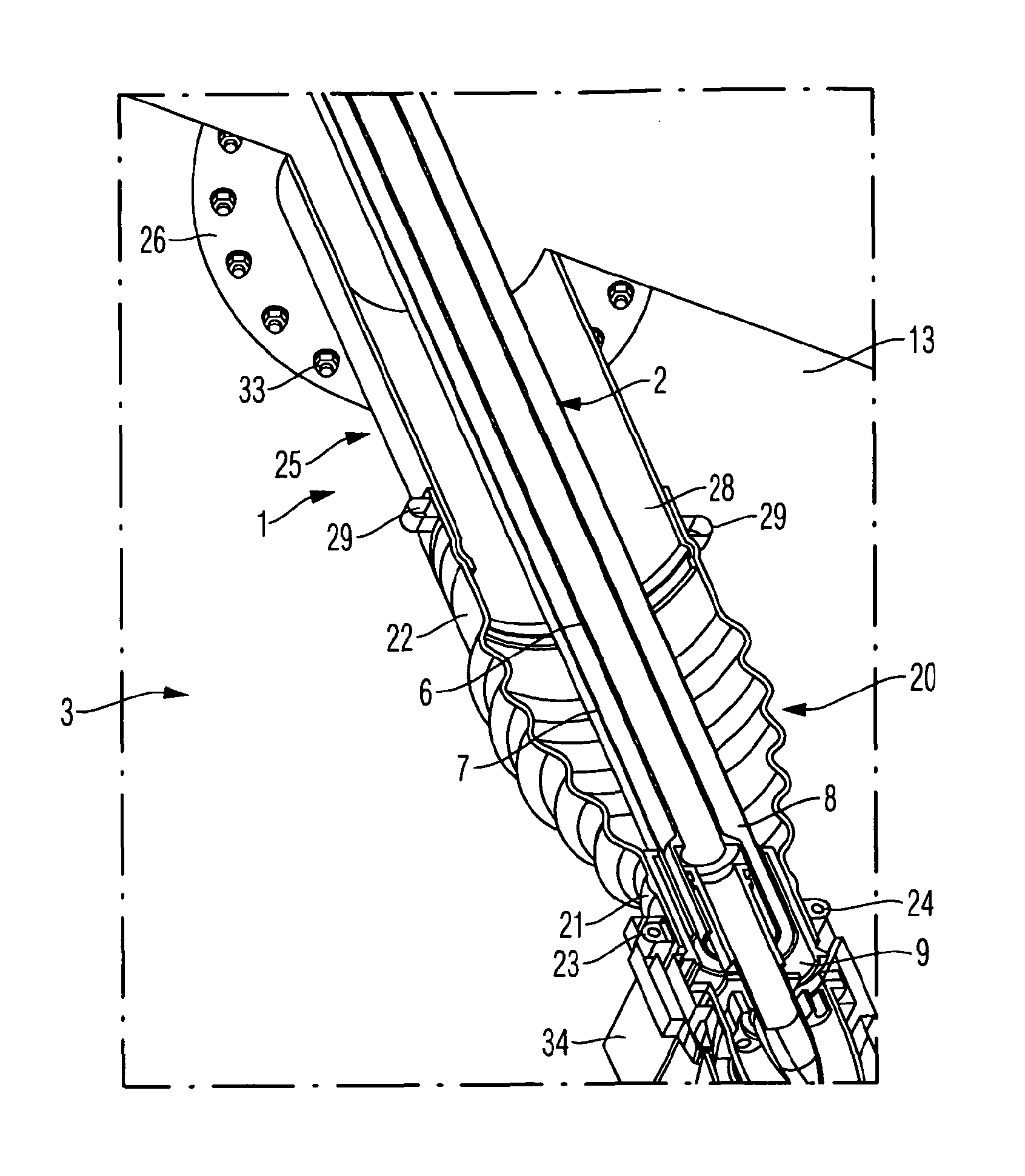

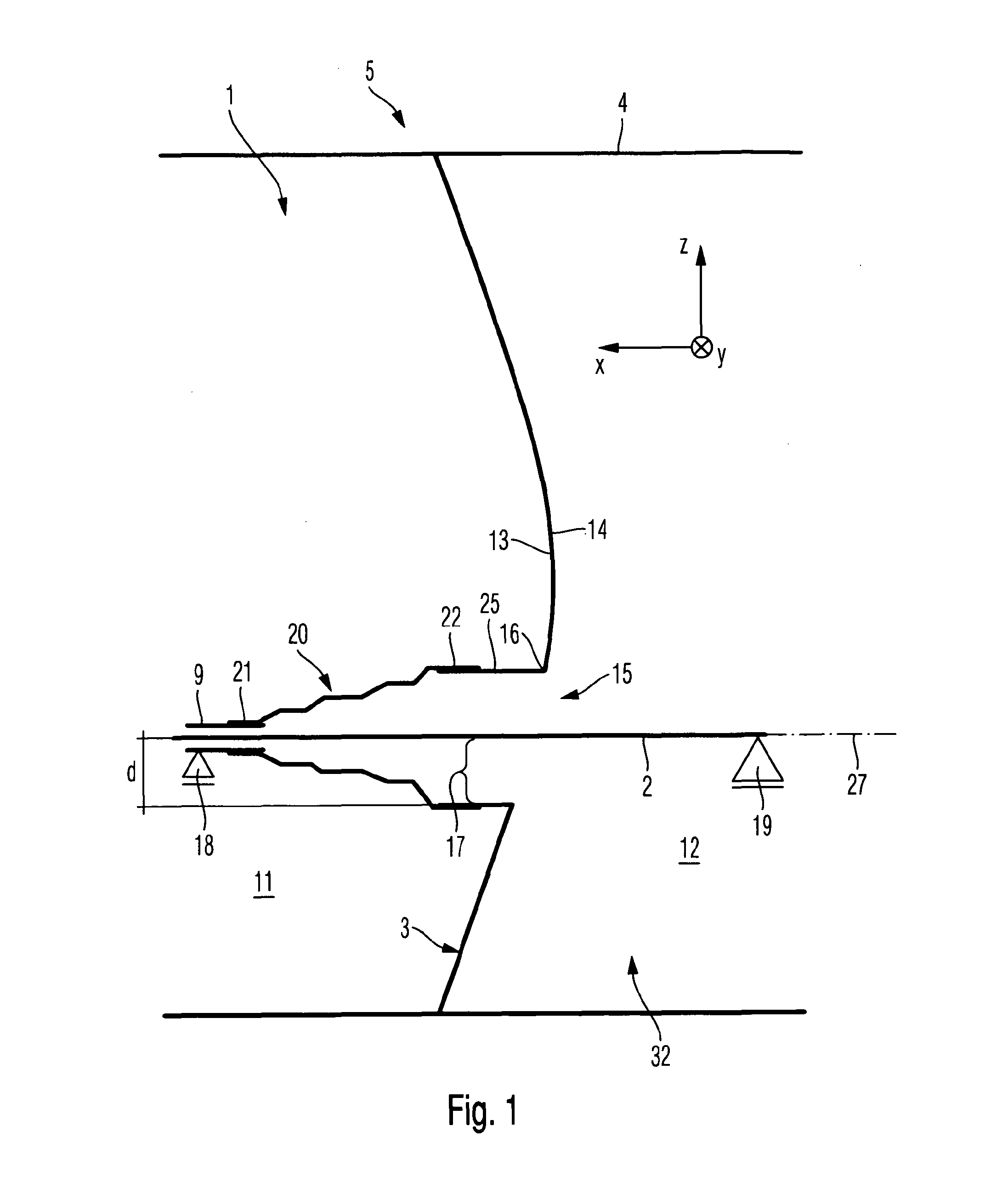

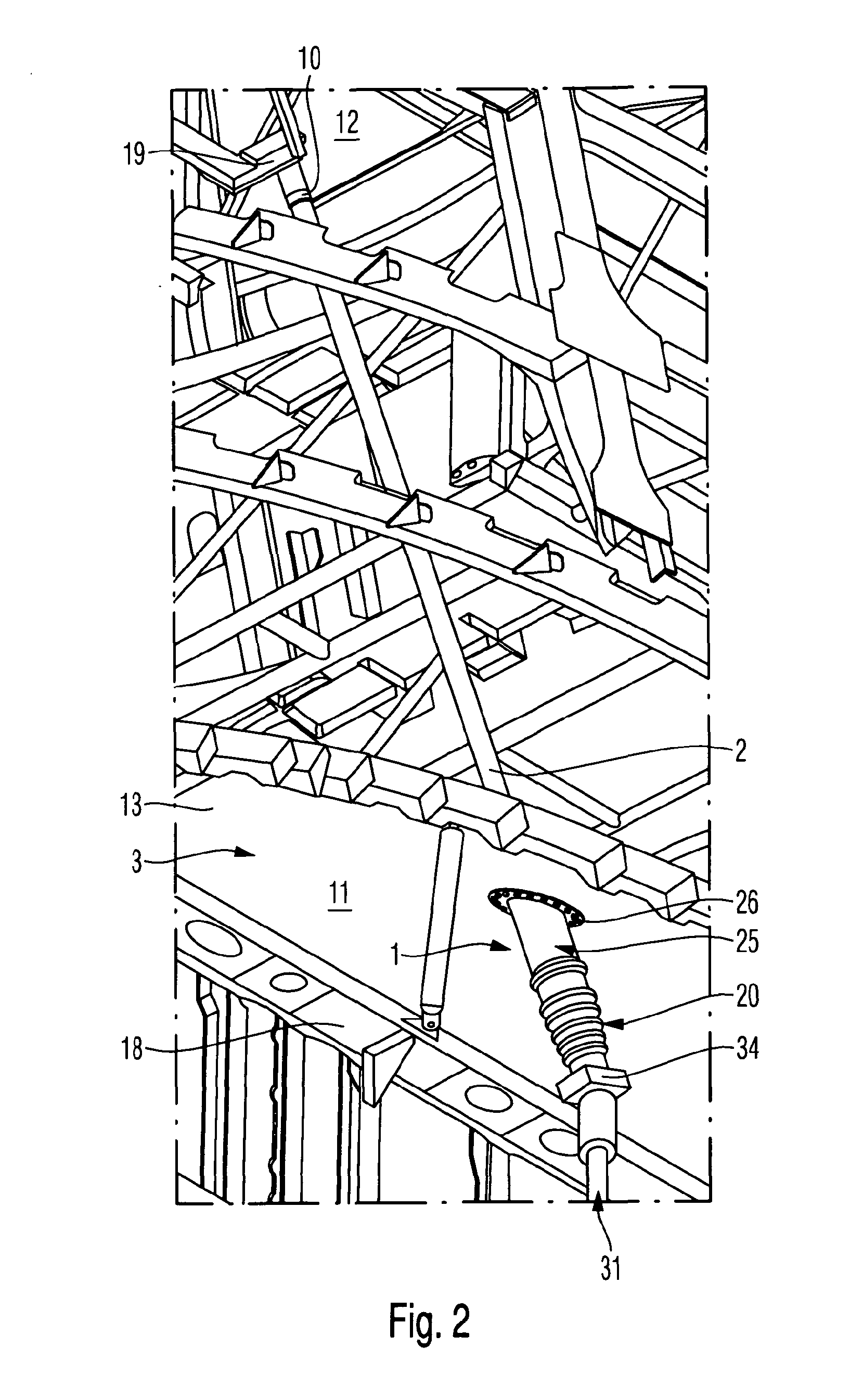

Arrangement for passing a line in a load-free manner through a pressure frame of a fuselage of an aircraft or spacecraft

The present invention provides an arrangement for passing a line in a load-free manner through a pressure frame of a fuselage of an aircraft or spacecraft, including an opening penetrating the pressure frame, through which opening the line is passed, the line being mechanically decoupled from the pressure frame; and a flexible sealing device arranged outside the opening at least in portions, which sealing device is simultaneously operatively connected to the line and the pressure frame for the pressure-tight separation of a first side from a second side of the pressure frame. The present invention also provides a fuselage for an aircraft or spacecraft having an arrangement of this type and an aircraft or spacecraft having an arrangement of this type or having a fuselage of this type.

Owner:AIRBUS OPERATIONS GMBH

Coloring agent for textile fabric

InactiveCN108824027AGood coloring effectNot easy to fadeDyeing processBulk chemical productionDisjoining pressureDibutyltin dilaurate

The invention discloses a coloring agent for textile fabric. The coloring agent for the textile fabric is prepared from the following components: polypropylene glycol, aloe extracting solution, dibutyltin dilaurate, alum, hydroxypropyl methyl cellulose, polyvinylpyrrolidone, acetic ether and blocked polyisocyanate, wherein the aloe extracting solution is prepared by using the following preparationmethod: firstly loading aloe leaf dry powder in a supercritical extraction kettle, feeding carbon dioxide, performing extraction separation by using supercritical carbon dioxide, wherein an extraction temperature is 35-50 DEG C, an extraction pressure is 8-25 MPa, extraction time is 1-3 hours, a flow rate of the carbon dioxide is 1-10 L / h, and a flow rate of an entrainer is 1-5 ml / min; and decompressing the supercritical carbon dioxide containing an extract, separating an extraction product, wherein a separating temperature is 25-50 DEG C, and a separating pressure is 2-10 MPa, and collectingthe obtained extraction product, namely the aloe extracting solution. The coloring agent is good in colorability, difficult to color fading, bright in color and lustre, and harmless to a human body.

Owner:FOSHAN YIXIANG DISI CLOTHING DESIGN CO LTD

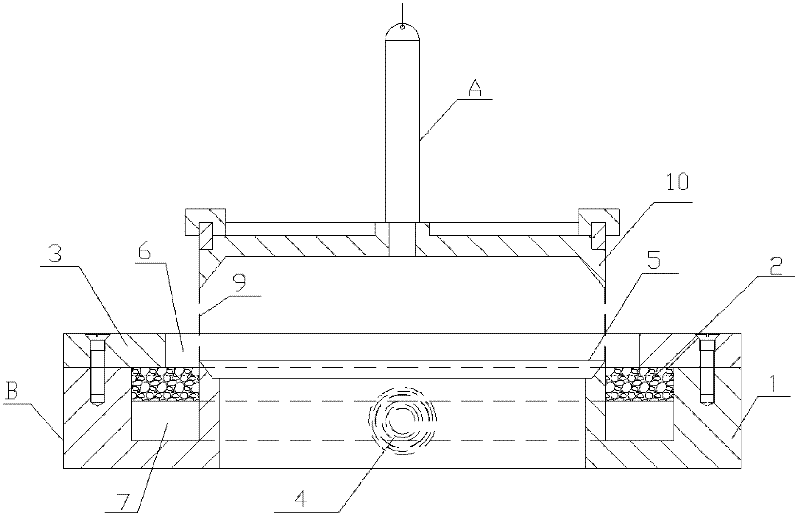

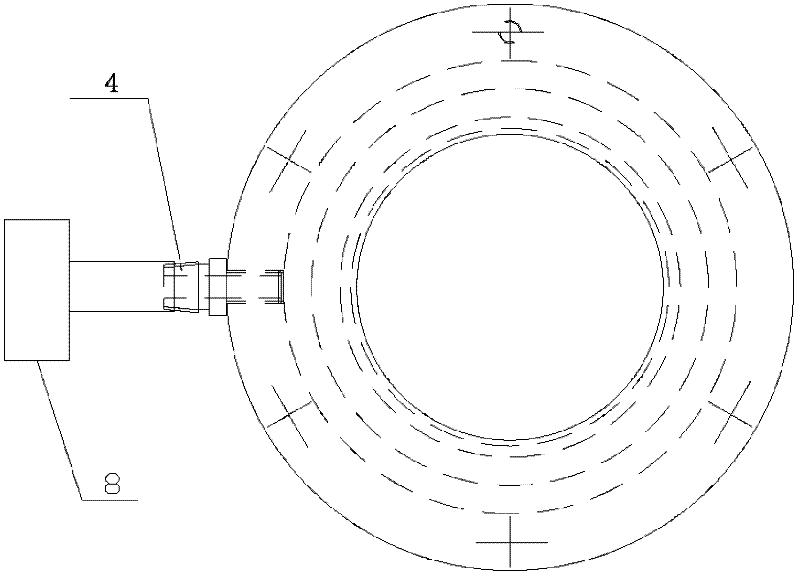

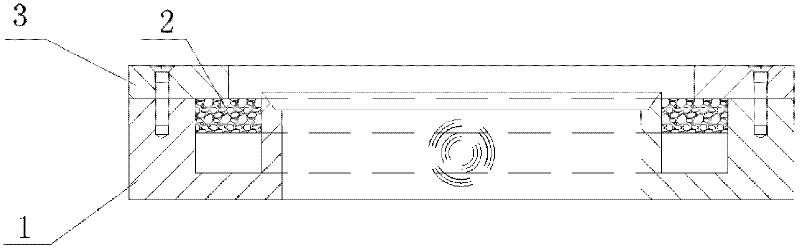

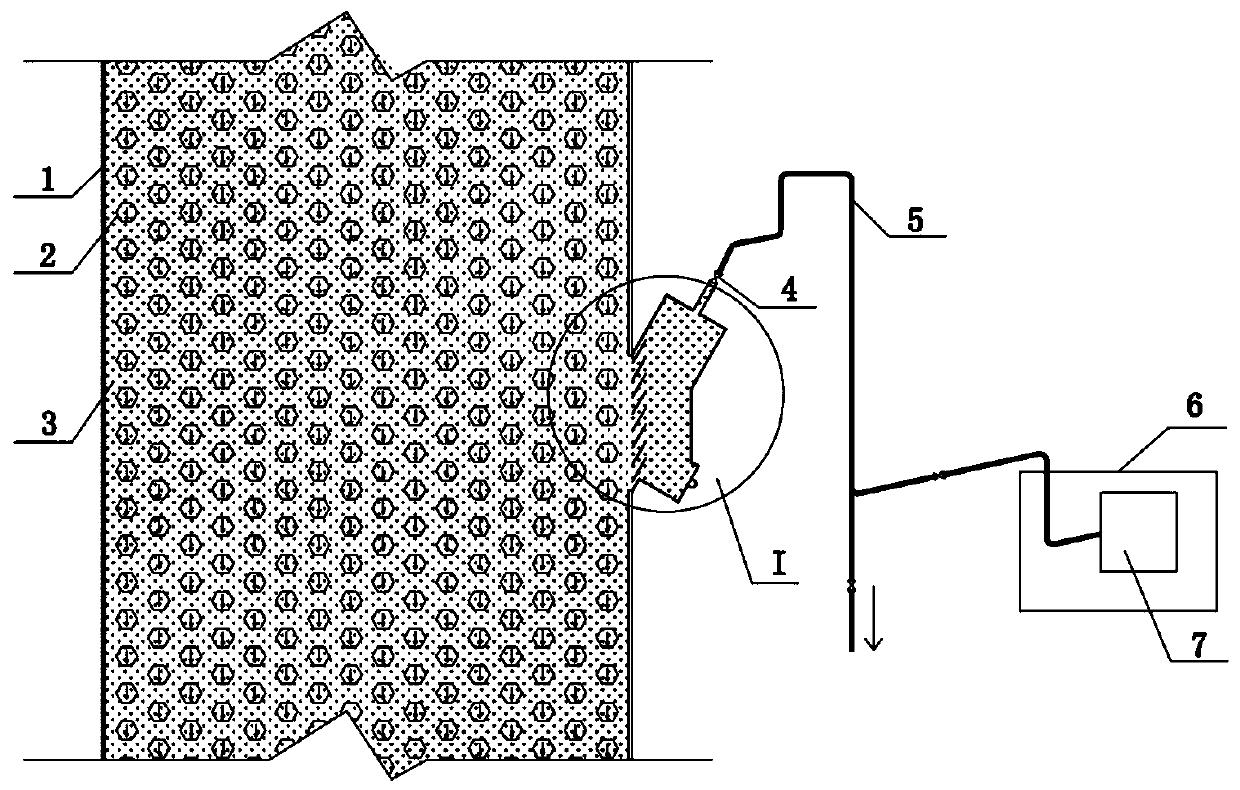

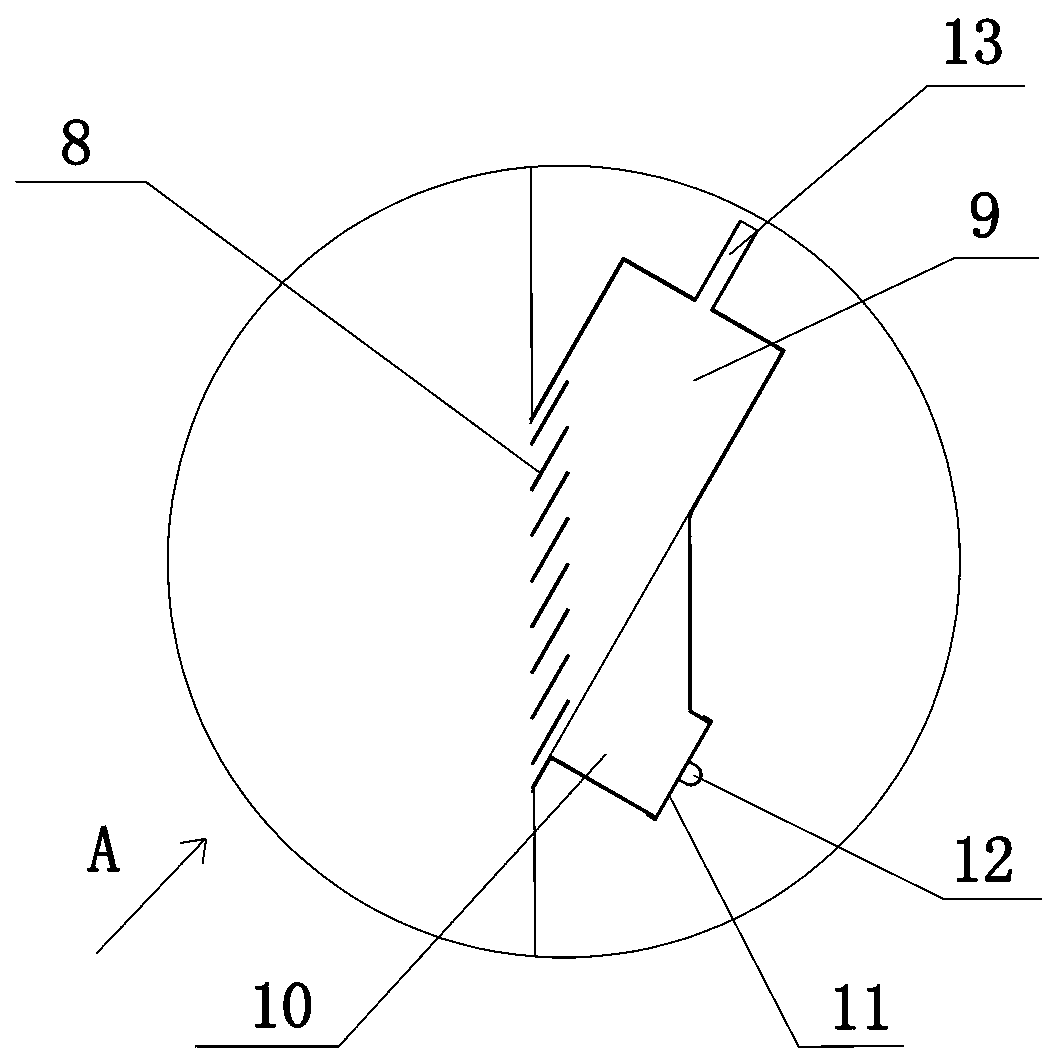

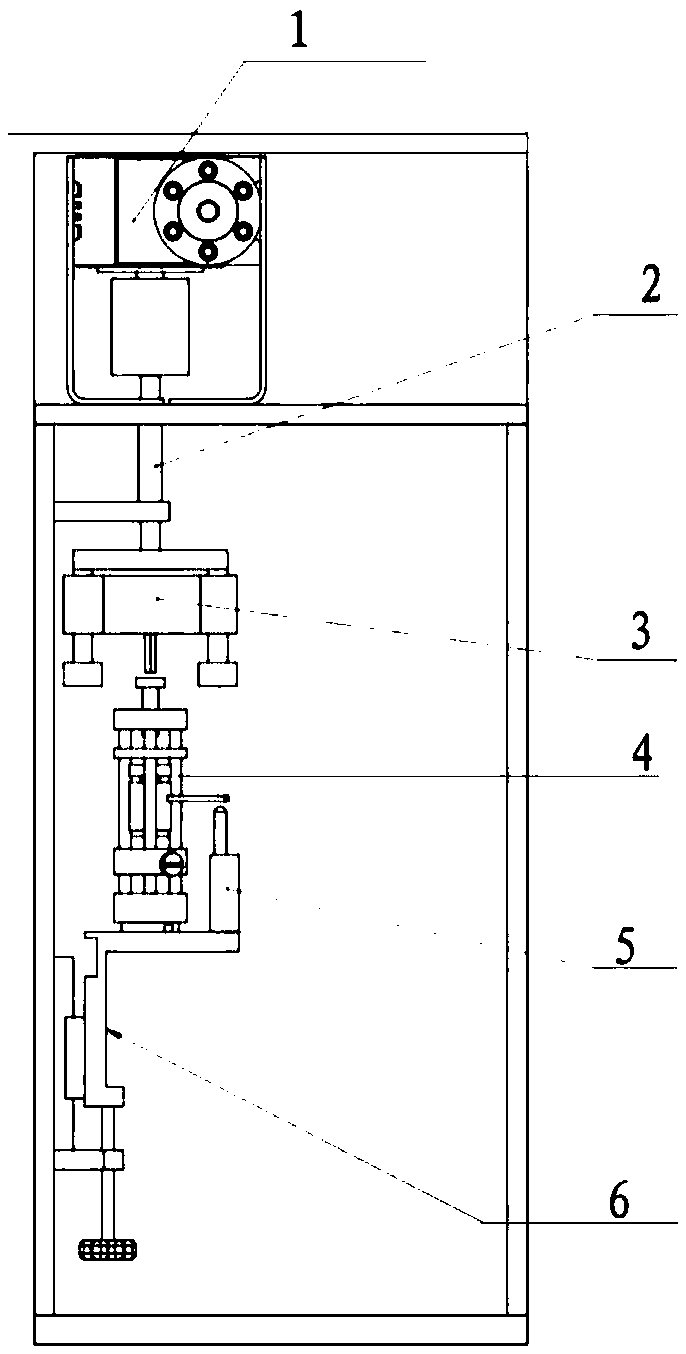

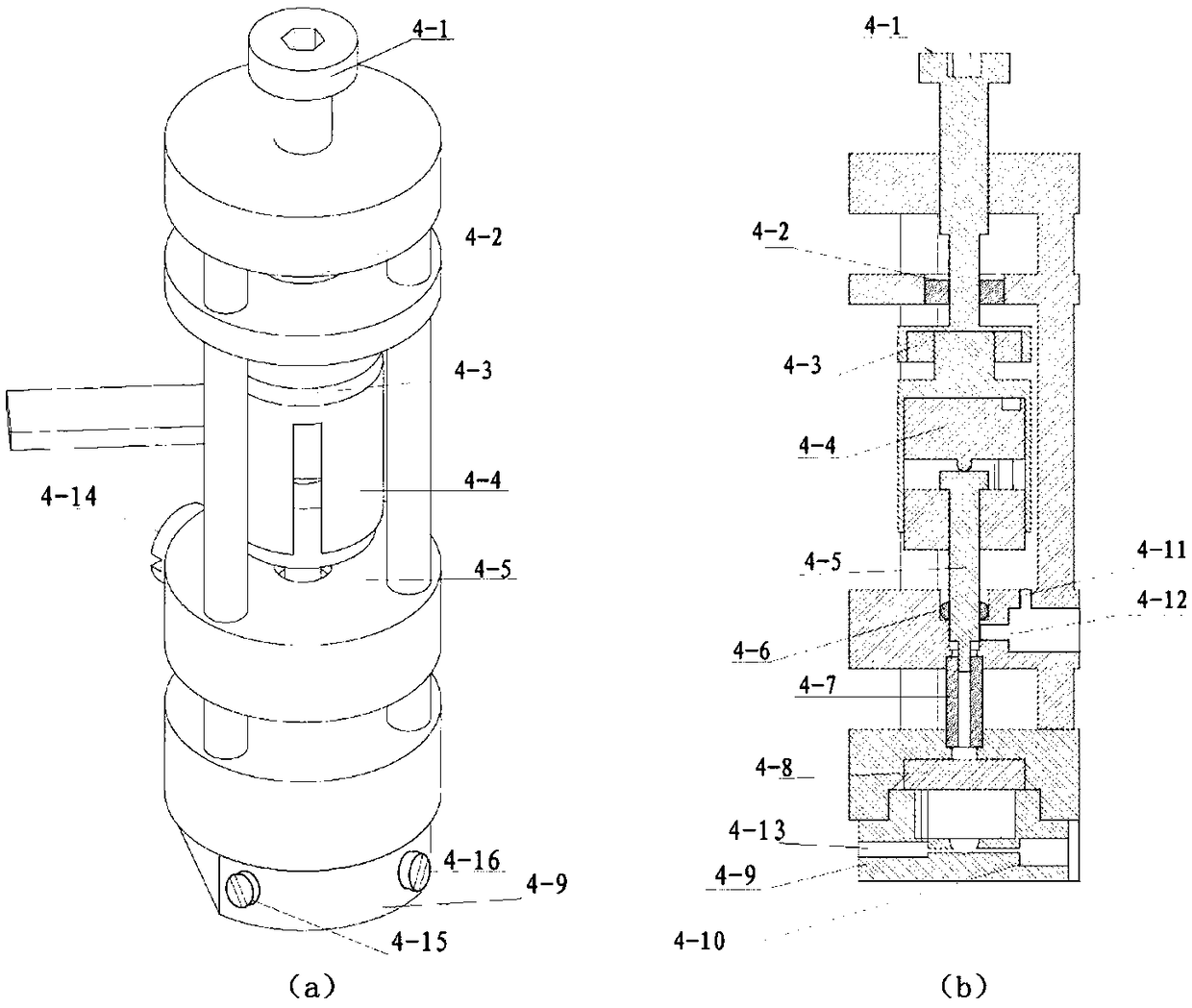

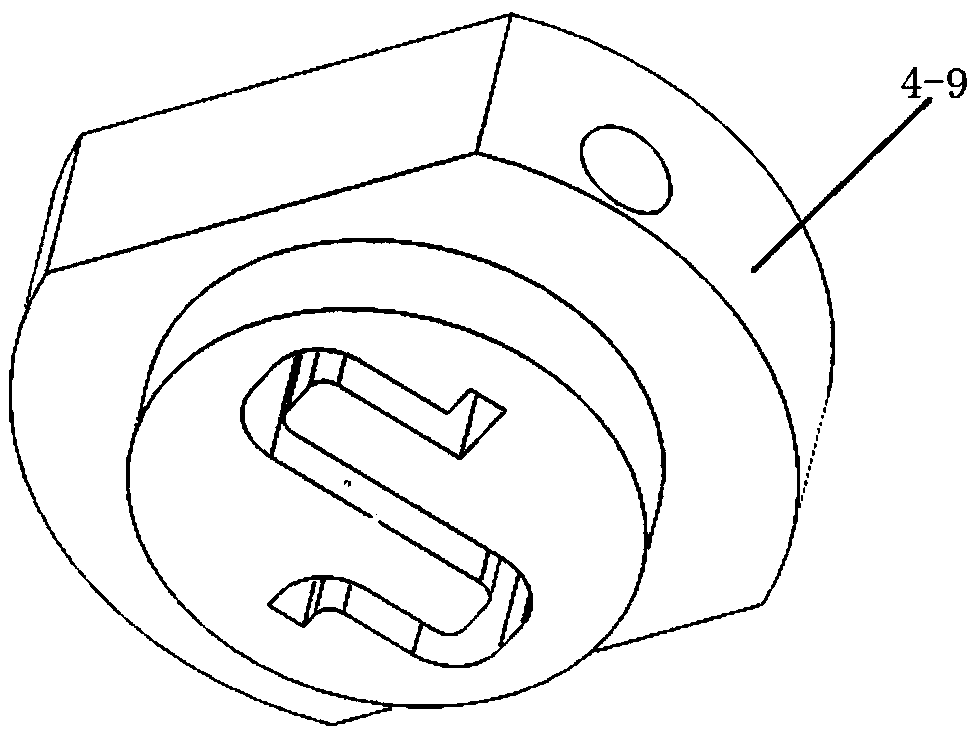

Micro-loess unsaturated suction control loading device and method for separable pressure chamber

ActiveCN109060851AKeep open and closeHigh-precision structure scanningMaterial analysis using wave/particle radiationMiniaturizationEngineering

The invention discloses a micro-loess unsaturated suction control loading device and micro-loess unsaturated suction control loading method for a separable pressure chamber. The device comprises a power device, a detachable pressure chamber and a support assembly arranged in order from top to bottom, wherein a soil sample is arranged in the detachable pressure chamber, a support assembly on one side of the detachable pressure chamber is provided with a displacement sensor for measuring vertical displacement of the soil sample, and the power device is disposed above the detachable pressure chamber for providing a rotational driving force to the detachable pressure chamber. The device has the advantages of simple structure, simple operation, miniaturization of the whole structure, and can separate the sample in the unsaturated state from the loading equipment for scanning with high precision CT.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com