Pressure sampling device for separation of active coke particles and regenerative gas

A technology for separating pressure and sampling devices, applied in sampling devices, sampling, measuring devices, etc., can solve problems such as reduced efficiency, increased difficulty in making acid, and affecting the efficiency of activated coke to release regeneration gas, so as to improve reliability and reduce The effect of the probability of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

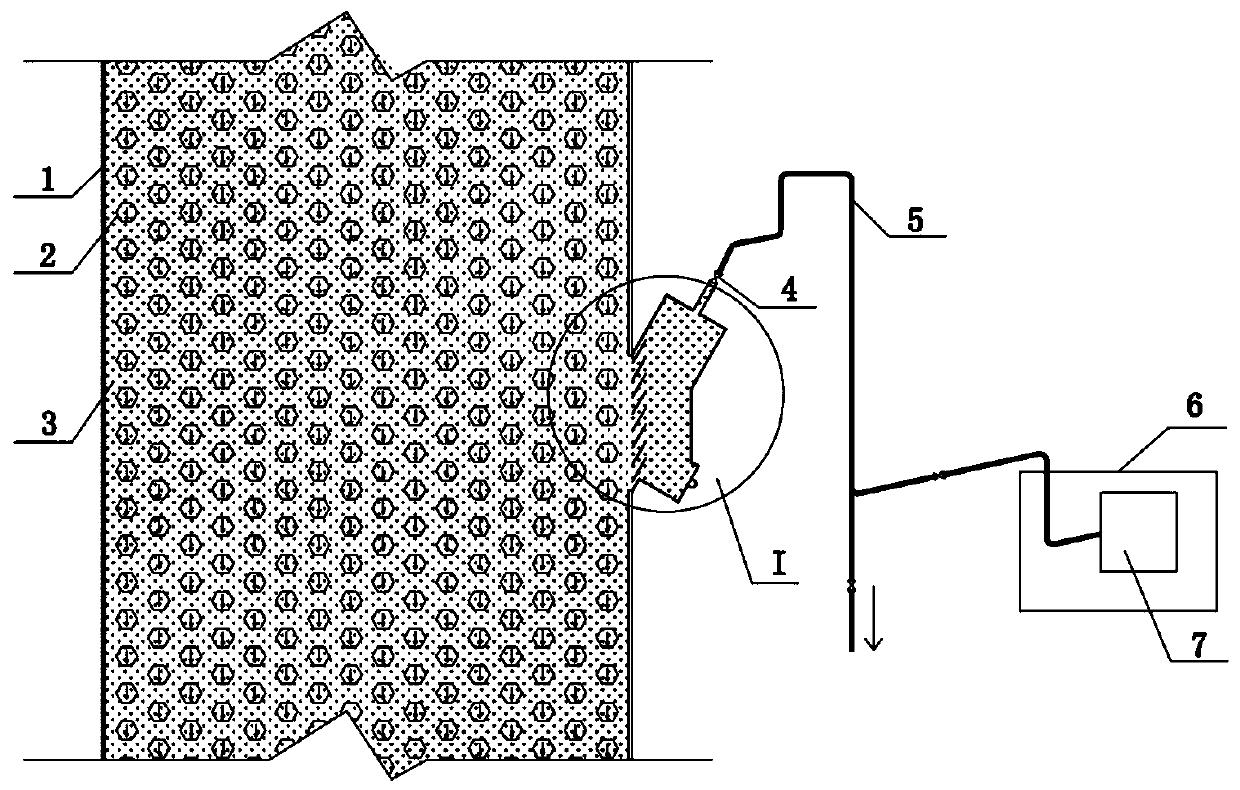

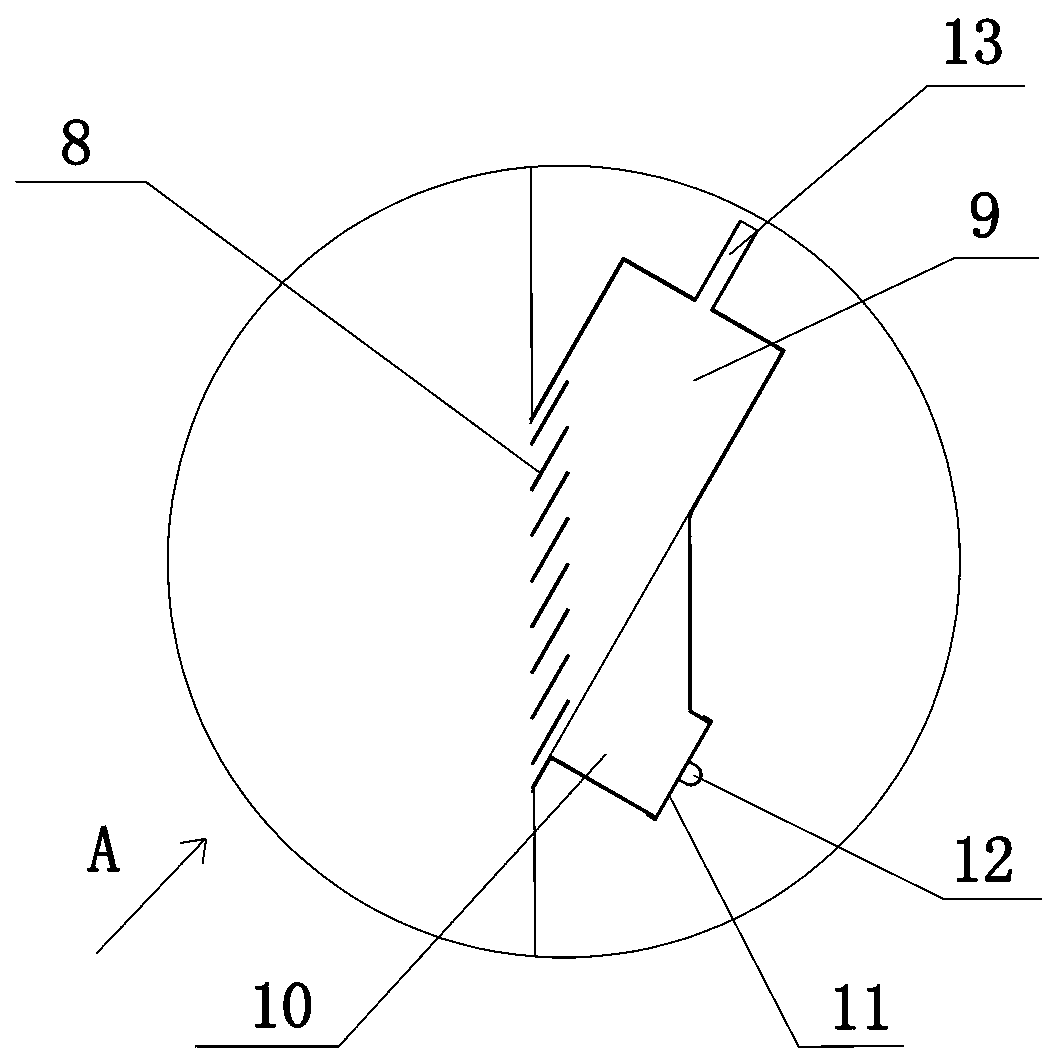

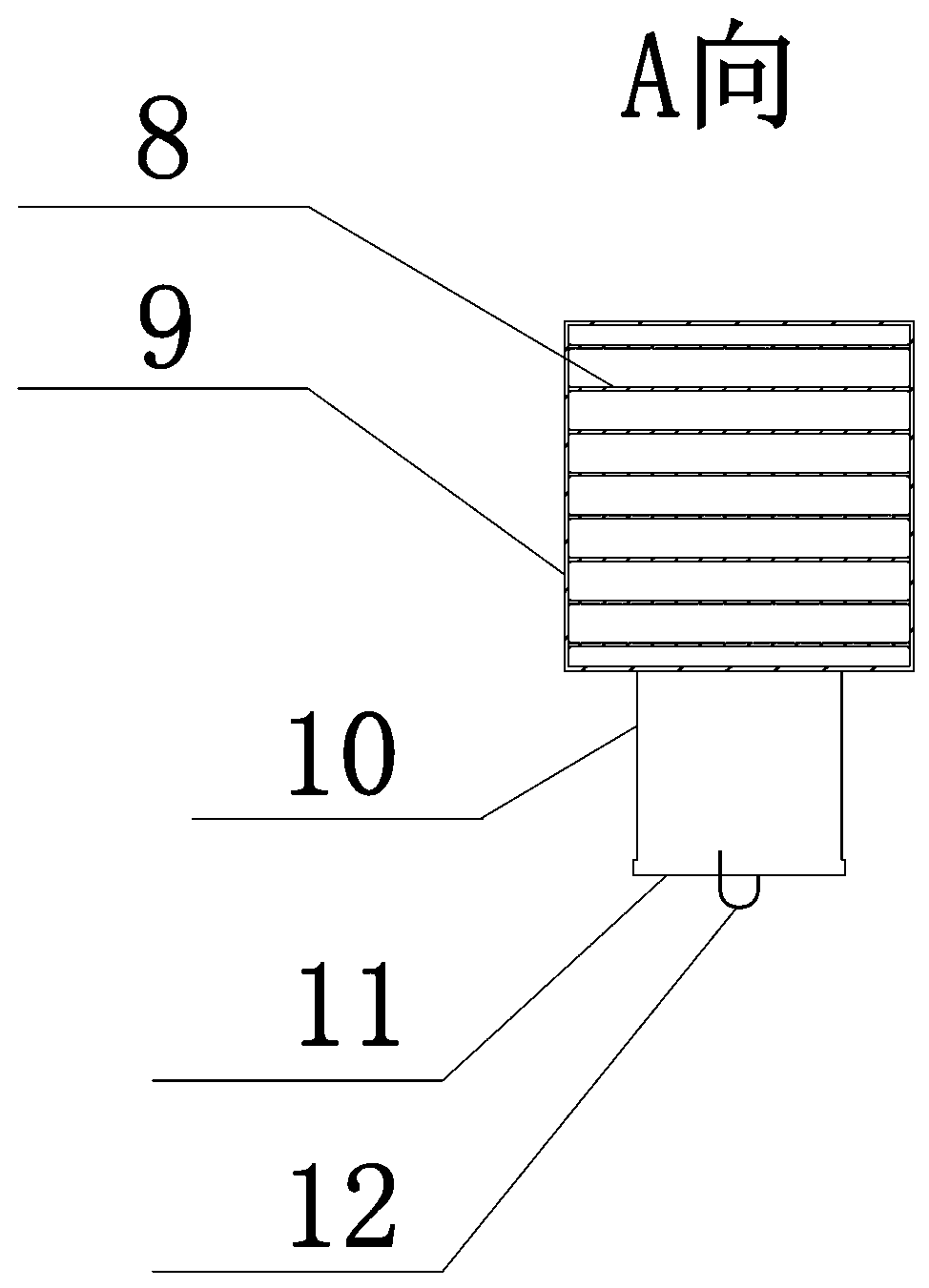

[0019] like Figure 1-3 As shown, a pressure sampling device for separating active coke particles and regeneration gas according to the present invention is characterized in that it includes a sample gas buffer box arranged on the side wall of the gas-solid sealing plate 1 for sealing active coke particles 2 and regeneration gas 3 9. A set of gas-solid separation material guide and air-introduction plate 8 arranged on the side wall of the gas-solid sealing plate 1 and the connection surface of the sample gas buffer box 9, and a joint arranged at the upper end of the sample gas buffer box 9 13. The sampling tube 5 connected to this joint 13 is set in the inspection ash storage box 10 at the bottom of the sample gas buffer box 9, and the inspection cover 11 at the opening of the inspection ash storage box 10 is installed here, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com