Device for producing liquid film capable of adjusting thickness

A technology for generating devices and liquid films, which is applied in the field of measuring devices for the physical and chemical properties of foam films. It can solve the problems of difficult liquid films, long time consumption, and slow gravity drainage speed, etc., and achieves reversible drainage process and film thickness control. Accurate, easy to repeat experiments and compare the effects of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

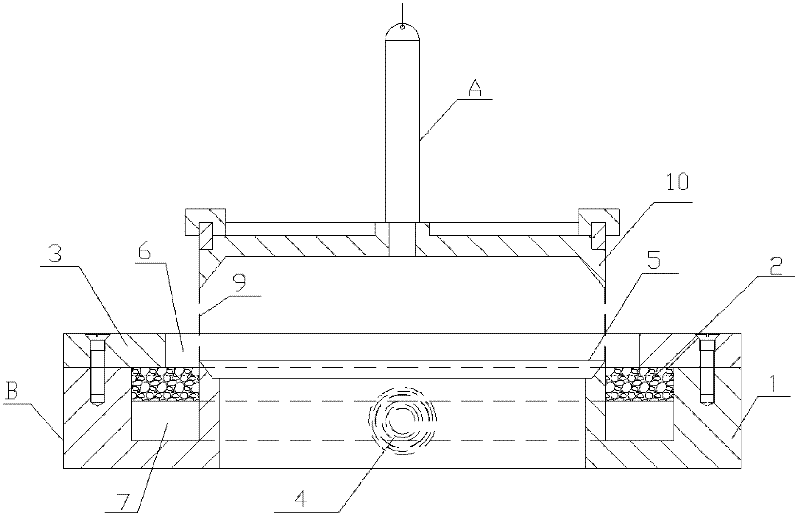

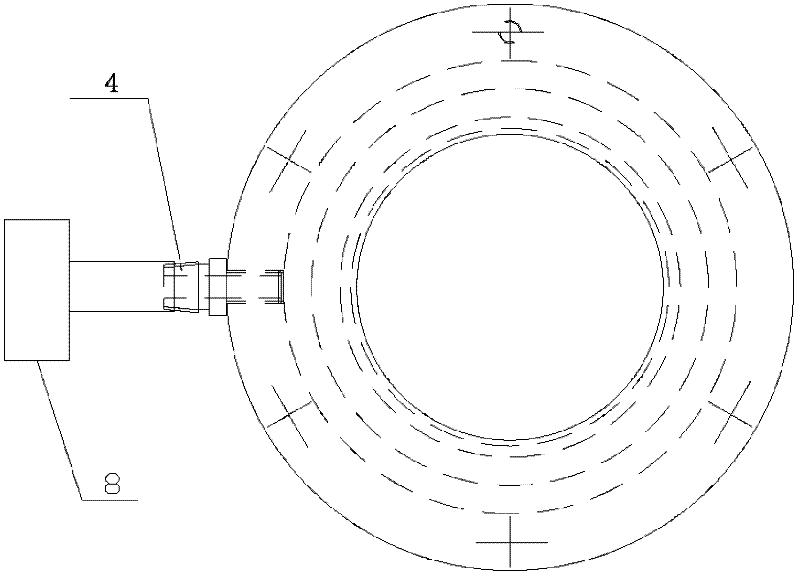

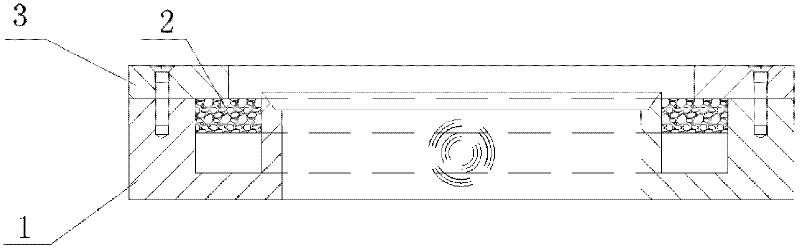

[0024] The liquid film generating device with adjustable thickness of the present invention, wherein the device includes an upper ring assembly and a lower ring assembly; the upper ring assembly is an inverted metal platter with a hollow bottom, and an upper ring is provided on the mouth of the platter knife edge; the lower ring component is a metal conductive ring, and the inner side of the conductive ring is provided with a lower annular knife edge opposite to the upper annular knife edge, and the upper annular knife edge and the lower annular knife edge are the same in size and coaxial; the metal conductive ring An annular groove is opened on the outer peripheral side of the lower annular knife edge, and the lower ring assembly also includes a liquid-conducting layer, an annular cover plate and a hose joint; the liquid-conducting layer is a porous material layer arranged on the upper part of the annular groove, and the liquid-conducting layer The upper surface of the upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com