High oil stain resistance oil-water separation membrane and its preparation method and application

A technology of oil-water separation membrane and oil pollution, which is applied in separation methods, liquid separation, chemical instruments and methods, etc. It can solve the problems of low anti-pollution performance, high membrane separation pressure, and low membrane flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

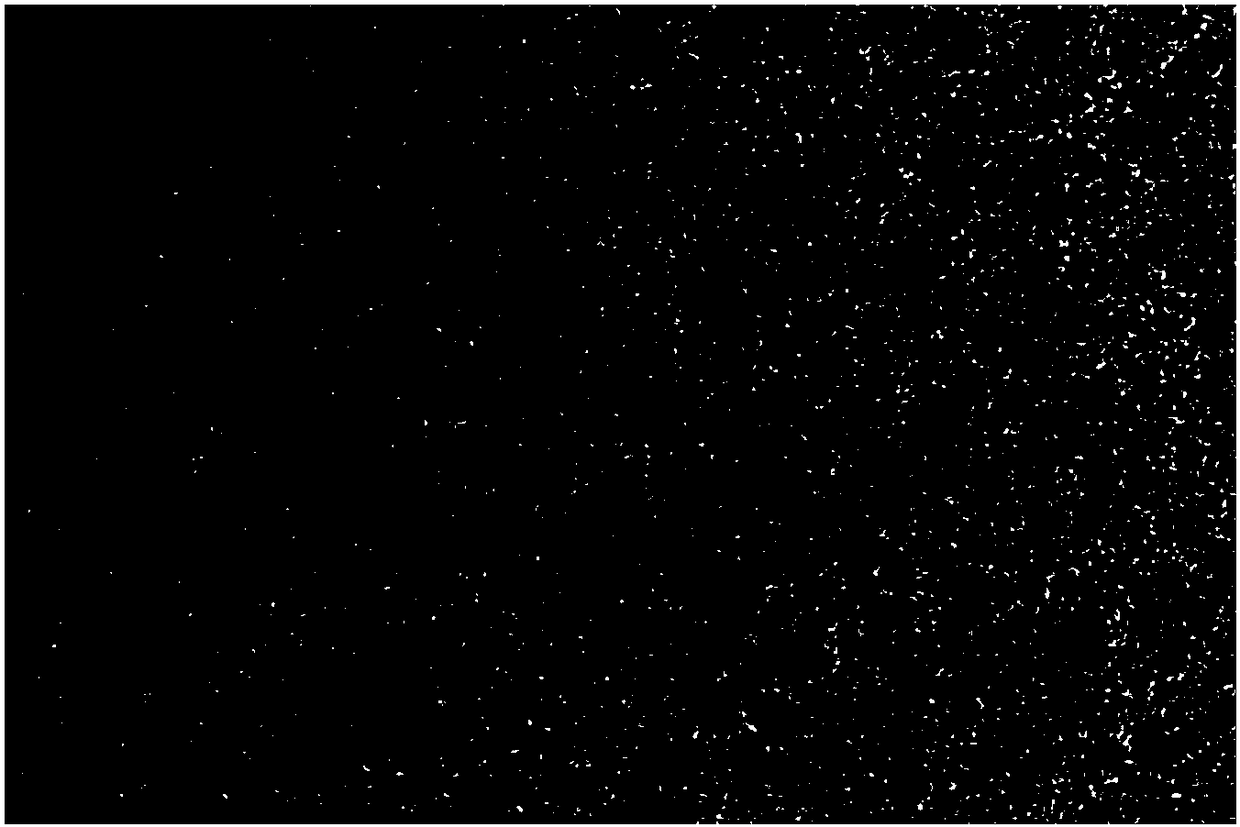

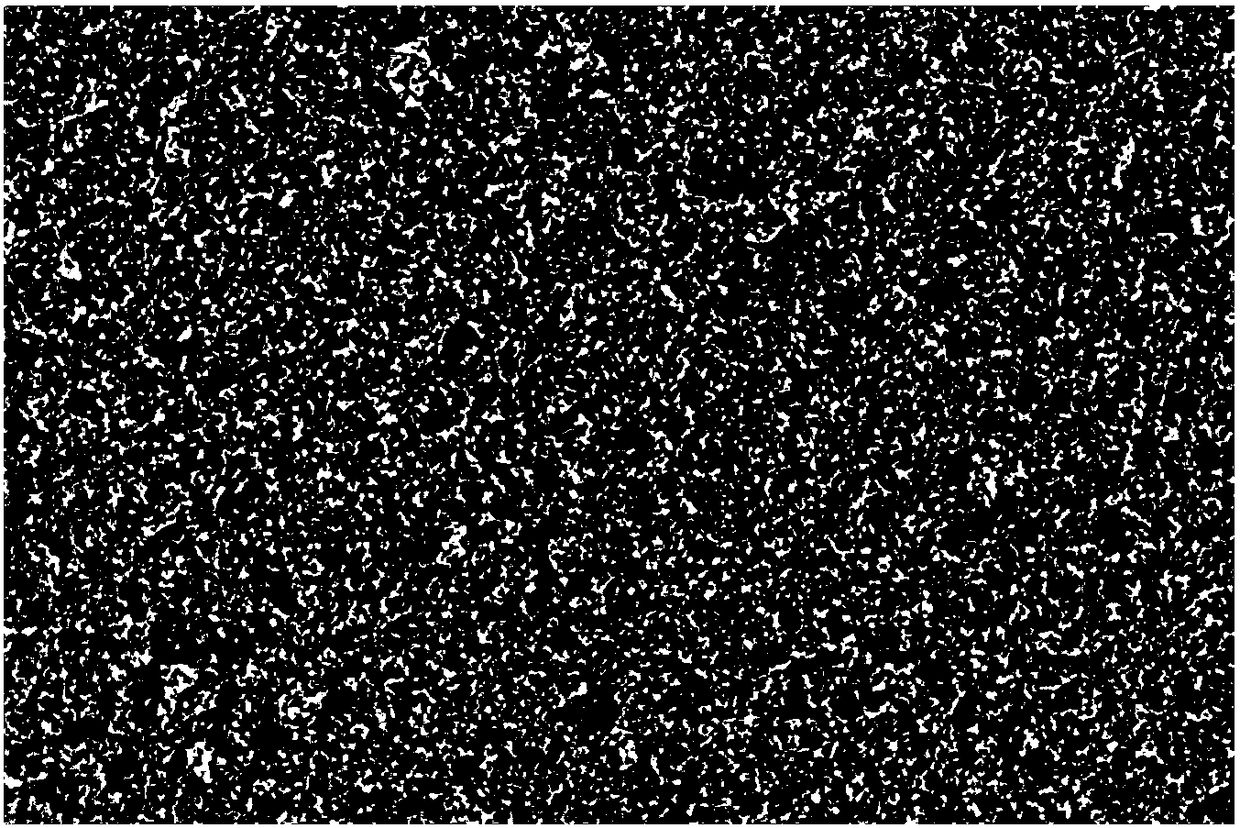

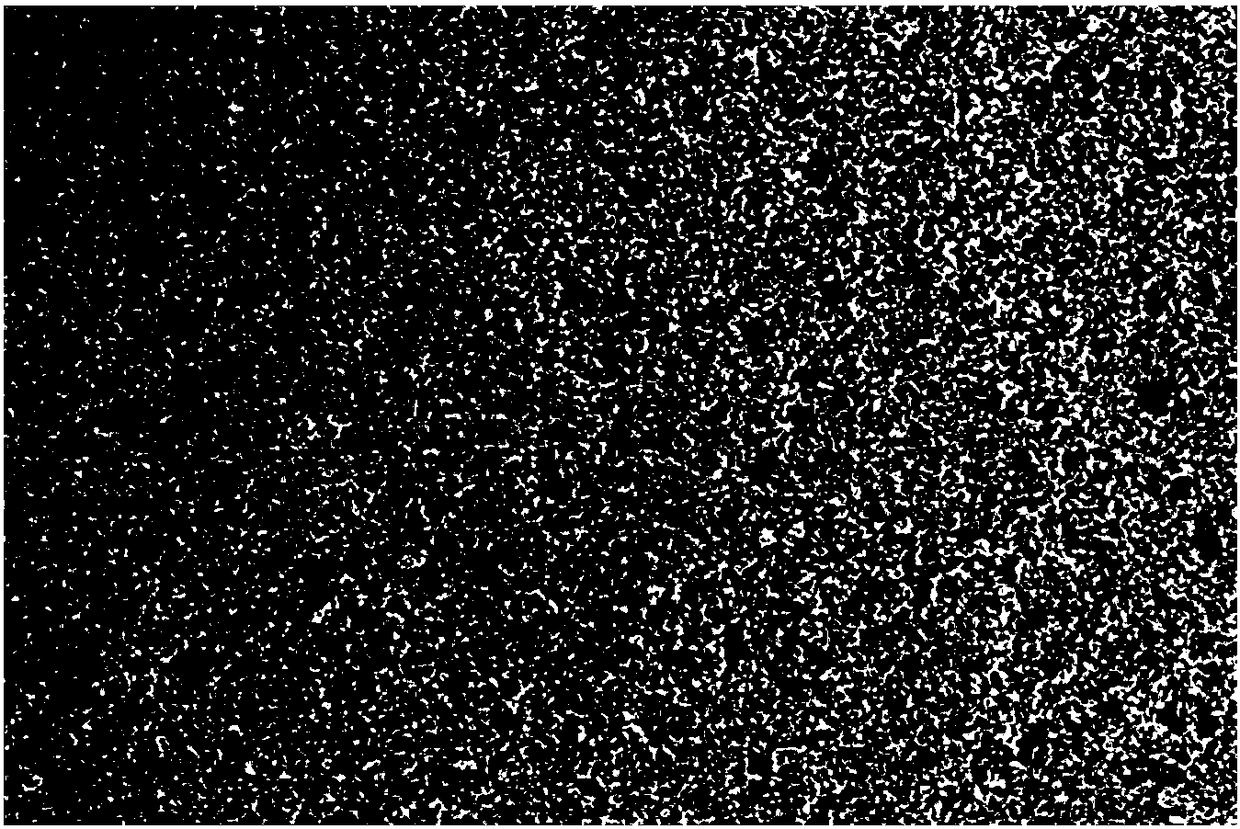

Image

Examples

Embodiment 1

[0036] (1) Preparation of fluorine-containing resin: take 8 g of methacrylic acid (MAA), 13 g of n-butyl acrylate (BA), 18 g of fluorine-containing monomer dodecafluoroheptyl methacrylate (G04), and azobisisobutyronitrile ( AIBN) 1g, propylene glycol methyl ether acetate (PMA) 60g;

[0037] Add 40% propylene glycol methyl ether acetate into the three-necked flask, and raise the temperature of the liquid in the bottle to 70°C under the stirring of the mechanical stirring blade;

[0038] 20% propylene glycol methyl ether acetate, 30% methacrylic acid, 30% n-butyl acrylate, 40% azobisisobutyronitrile and 50% fluorine-containing monomer dodecafluoroheptyl methacrylate Mix evenly to make the first mixed solution, drop the first mixed solution into the three-necked flask with a dropping funnel, continue to react for 1.5 hours after the dropwise addition, and keep the liquid temperature in the bottle at 70°C;

[0039] 20% propylene glycol methyl ether acetate, 70% methacrylic acid, ...

Embodiment 2

[0046] (1) Preparation of fluorine-containing resin: Take 6 g of methacrylic acid (MAA), 15 g of n-butyl acrylate (BA), 25 g of fluorine-containing monomer dodecafluoroheptyl methacrylate (G04), and azobisisobutyronitrile ( AIBN) 2g, propylene glycol methyl ether acetate (PMA) 52g;

[0047] Add 35% propylene glycol methyl ether acetate into the three-necked flask, and raise the temperature of the liquid in the bottle to 65°C under the stirring of the mechanical stirring blade;

[0048] 25% propylene glycol methyl ether acetate, 35% methacrylic acid, 35% n-butyl acrylate, 45% azobisisobutyronitrile and 45% fluorine-containing monomer dodecafluoroheptyl methacrylate Mix evenly to make the first mixed solution, drop the first mixed solution into the three-necked flask with a dropping funnel, continue to react for 2 hours after the dropwise addition, and keep the liquid temperature in the bottle at 65°C;

[0049] 25% propylene glycol methyl ether acetate, 65% methacrylic acid, 65...

example 3

[0056] (1) Preparation of fluorine-containing resin: take 15 g of methacrylic acid (MAA), 10 g of n-butyl acrylate (BA), 30 g of fluorine-containing monomer dodecafluoroheptyl methacrylate (G04), and azobisisobutyronitrile ( AIBN) 3g, propylene glycol methyl ether acetate (PMA) 42g;

[0057] Add 45% propylene glycol methyl ether acetate into the three-necked flask, and raise the temperature of the liquid in the bottle to 75°C under the stirring of the mechanical stirring blade;

[0058] 15% propylene glycol methyl ether acetate, 25% methacrylic acid, 25% n-butyl acrylate, 35% azobisisobutyronitrile and 55% fluorine-containing monomer dodecafluoroheptyl methacrylate Mix evenly to make the first mixed solution, drop the first mixed solution into the three-necked flask with a dropping funnel, continue to react for 1 hour after the dropwise addition, and keep the temperature of the liquid in the bottle at 75°C;

[0059] 15% propylene glycol methyl ether acetate, 75% methacrylic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com