Comprehensive utilization method of ionic membrane electrolytic saline solution waste liquid

An ionic membrane method and salt water technology, which is applied in the field of comprehensive utilization of ionic membrane electrolysis salt water waste liquid, can solve the problems of online pH meter measurement lag, short membrane life, waste, etc., and achieve the effect of improving comprehensive utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

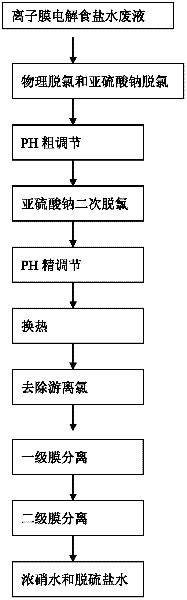

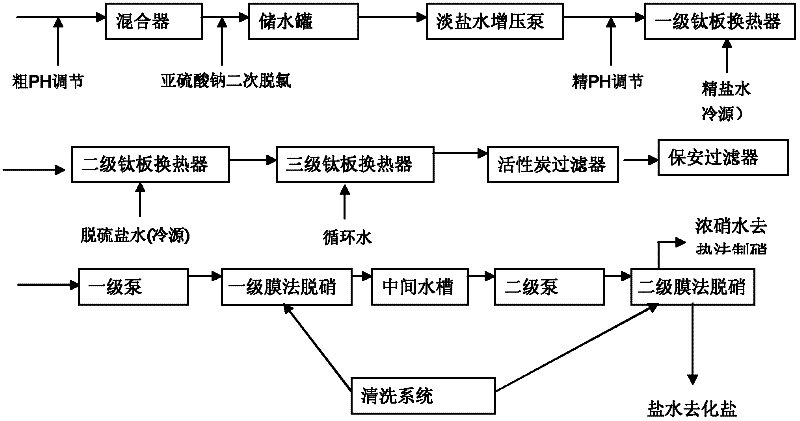

[0027] see figure 1 and figure 2 As shown, the comprehensive treatment and utilization method of electrolytic salt water waste liquid by ion membrane method specifically includes the following steps:

[0028] (1) Acidify the ion membrane electrolysis salt water waste liquid (light brine from the ion membrane electrolyzer) with a NaCl content of 190~230g / l, a temperature above 80°C, and a pH value of 2~5 to a pH value of 1.5~2.5 , use a vacuum pump to form a negative pressure to remove chlorine dissolved in light brine, and then add sodium sulfite to dechlorinate under alkaline conditions. After dechlorination, the pH of the system is 9~11, Na 2 SO 4 Content≤10±2g / l;

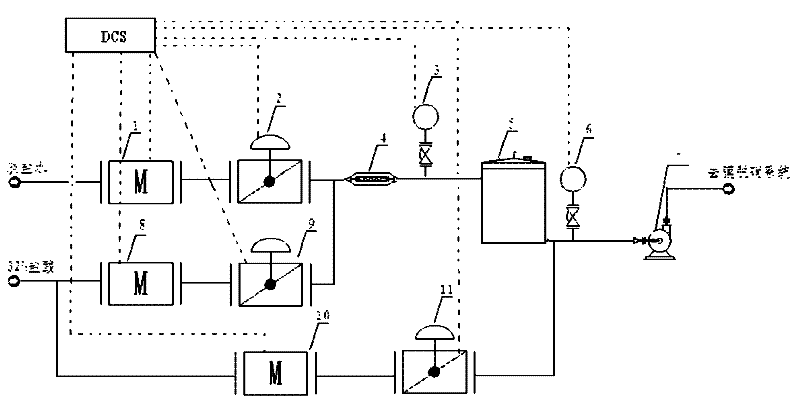

[0029] (2) Pre-set the pH value of the coarse pH detection and adjustment system in the automatic pH value control device of light brine to 8, and the DCS control system controls the addition of 32% hydrochloric acid by controlling the opening of the coarse adjustment valve, so that the The pH value of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com