Low-temperature plasma methane activation and oil shale pyrolysis coupling method and device

A low-temperature plasma and oil shale technology, applied in the energy field, can solve problems such as lack of coupling effect, poor coupling effect, complex reaction process, etc., and achieve improved conversion rate, increased electron density, and increased probability of collision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

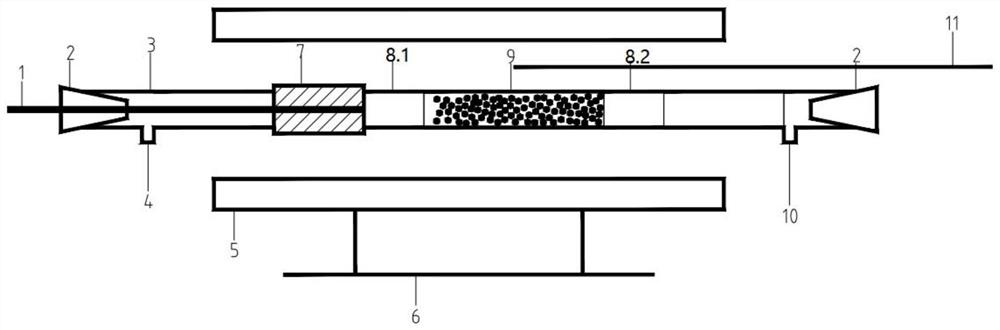

[0063] A low-temperature plasma methane activation and oil shale pyrolysis coupling device, such as figure 1 As shown, including quartz tube reactor 3, high voltage electrode 1 (stainless steel tube) and external electrode 7 (stainless steel mesh);

[0064] Silica gel plugs 2 are respectively provided at both ends of the quartz tube reactor 3 to ensure the tightness of the device;

[0065] An annular discharge gap, a raw material area 9 and a refining area are arranged in the quartz tube reactor 3;

[0066] The lower sides of both ends of the quartz tube reactor 3 are also equipped with a gas inlet 4 and a gas outlet 10 respectively, and the methane-rich mixed gas and carbon dioxide gas enter the quartz tube reactor 3 from the gas inlet 4 to ensure that the methane-rich mixed gas and carbon dioxide gas are in the quartz tube reactor 3. Helical flow in tube reactor 3;

[0067] The high-voltage electrode 1 stainless steel tube is inserted into the quartz tube reactor 3 through...

Embodiment 2

[0073] A low-temperature plasma methane activation and oil shale thermal decoupling device, which is basically the same as in Example 1, the only difference is that: the quartz tube reactor 3 does not have a refining zone and quartz wool on both sides; and the raw material The other side of the zone 9 is a gas outlet 10, and the two are separated by quartz wool 8.2.

Embodiment 3

[0075] A method for low-temperature plasma methane activation and oil shale thermal decoupling is carried out using the device in Example 2, and the quartz tube reactor adopts a tubular structure, and quartz is used to make a tubular barrier medium (outer diameter 25mm, tube wall 5mm), the grounding electrode is a stainless steel mesh (30mm in length), the high voltage electrode is a stainless steel rod (8mm in diameter), the pole spacing is 6mm, and the length of the low temperature plasma tubular reactor is 260mm;

[0076] The specific steps of the method for coupling low-temperature plasma methane activation and oil shale pyrolysis are as follows:

[0077] Raw material preparation: Catalyst I (Ni / Al 2 o3 , wherein Ni load is 9%) 0.6g, Liushuhe oil shale 3.0g;

[0078] (1) first willow river oil shale is packed in the raw material area of quartz tube reactor, and catalyst 1 is placed in the annular discharge gap of quartz tube reactor;

[0079] (2) Connect gas system and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com