A method for measuring capillary electrophoresis electroosmotic flow

A technology of capillary electrophoresis and electroosmotic flow, which is applied in the field of analytical chemistry, can solve problems such as long time consumption, low measurement accuracy, and difficulty in weak electroosmotic flow measurement, and achieve the effects of saving time, improving measurement accuracy, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

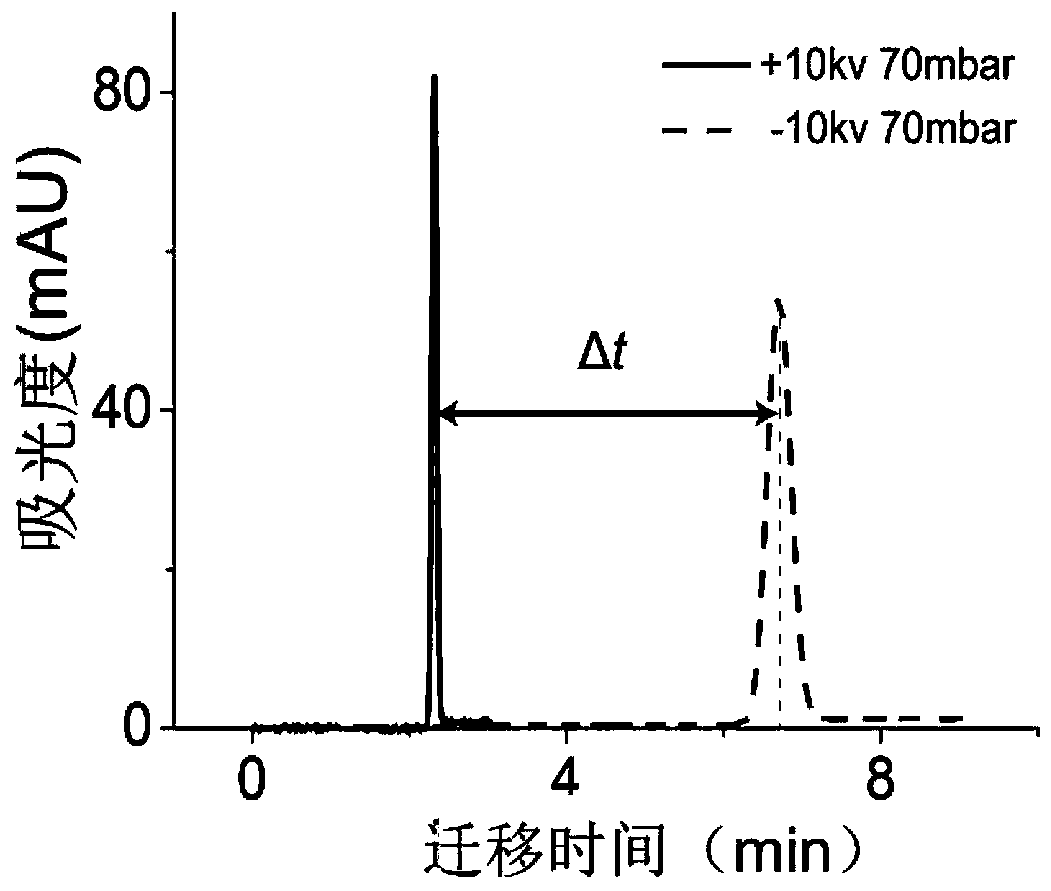

[0059] image 3 and Figure 4 Under the same conditions, the migration time diagrams using the traditional method and the method for measuring capillary electrophoresis electroosmotic flow according to the embodiment of the present invention are respectively shown. Among them, separation voltage: 10kV / -10kV; separation pressure: 70mbar; detection wavelength: 214nm; pressure during injection: 50mbar for 3 seconds; temperature: 25°C; buffer: phosphate buffer solution with pH7.

[0060] Both the traditional method and the method provided in the examples of the present invention use the same sample concentration, operating system and sample injection conditions. The neutral marker used is DMSO, the concentration is 1% (volume ratio), the operating system is phosphate buffer solution with pH=7, the total length of the capillary is 60 cm, the effective length is 50 cm, and the inner diameter is 75 μm.

[0061] The operation of the traditional method is as follows: the sample is in...

Embodiment 2

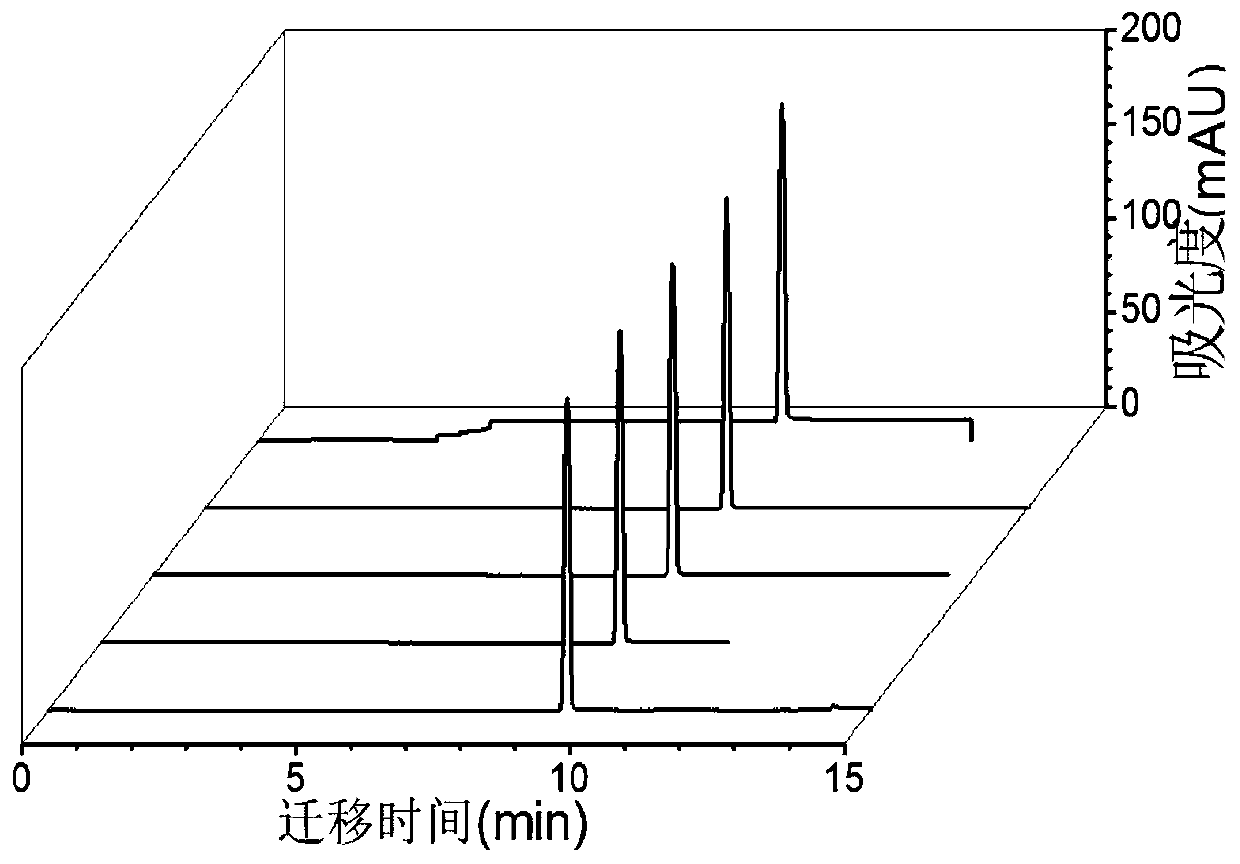

[0078] During the electrophoresis analysis process, keep other conditions unchanged, only change the separation pressure, analyze under the separation pressure conditions of 50mbar, 60mbar, 70mbar, 80mbar, and 90mbar respectively, and do five sets of parallel experiments under each separation pressure condition. To explore whether different separation pressures have an effect on the performance of measuring electroosmotic flow. Examples 2 and 1 use the same experimental conditions, including the same capillary length, capillary inner diameter, operating system and samples.

[0079] Process according to the steps described in Example 1, and analyze at separation pressures of 50mbar, 60mbar, 70mbar, 80mbar, and 90mbar respectively. The results obtained are shown in Table 2. Figure 5 shown.

[0080] Table 2

[0081]

[0082]

[0083] It can be concluded from Table 2 that the change of the set value of the separation pressure basically has no effect on the accuracy of th...

Embodiment 3

[0086] During the electrophoresis analysis process, keep other conditions unchanged, only change the voltage, respectively in the voltage conditions of 8kV / -8kV, 10kV / -10kV, 12kV / -12kV, 15kV / -15kV, 18kV / -18kV, 20kV / -20kV Under each voltage condition, three sets of parallel experiments were done. It was investigated whether different analytical voltages had an effect on the performance of measuring electroosmotic flow. Example 3 and Example 1 use the same experimental conditions, the same capillary length, inner diameter, operating system and samples.

[0087] The experimental results are shown in Table 3. Figure 6 shown.

[0088] table 3

[0089]

[0090]

[0091] It can be concluded from Table 3 that the change of the voltage setting value basically has no effect on the stability and accuracy of the electroosmotic mobility measured by the method of the embodiment of the present invention, and there is no certain correlation between the two. From Figure 6 It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com