Spinning and drawing device

A stretching device and spinning technology, applied in the direction of stretching and spinning, can solve problems such as poor effect, and achieve the effect of improving heating efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

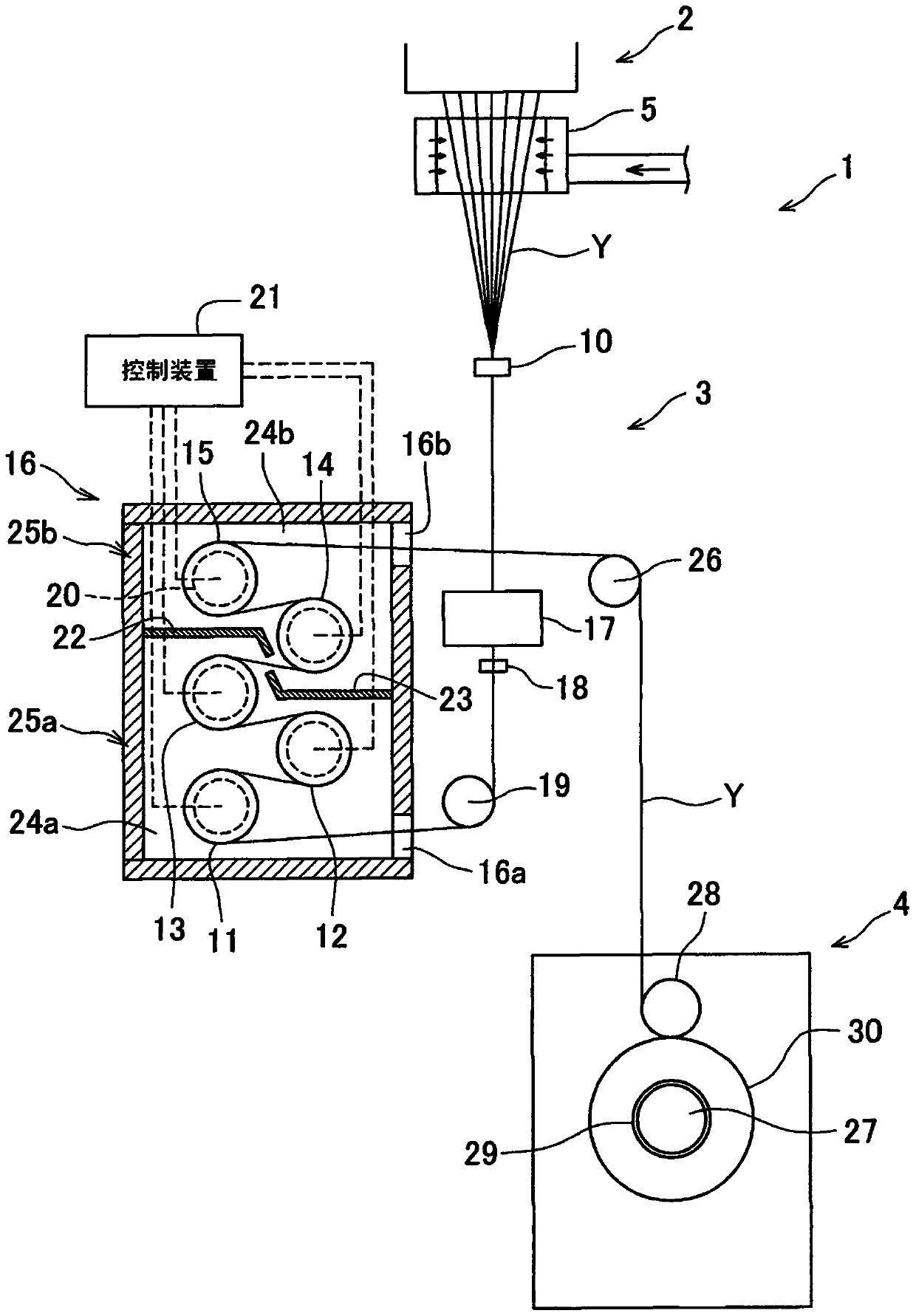

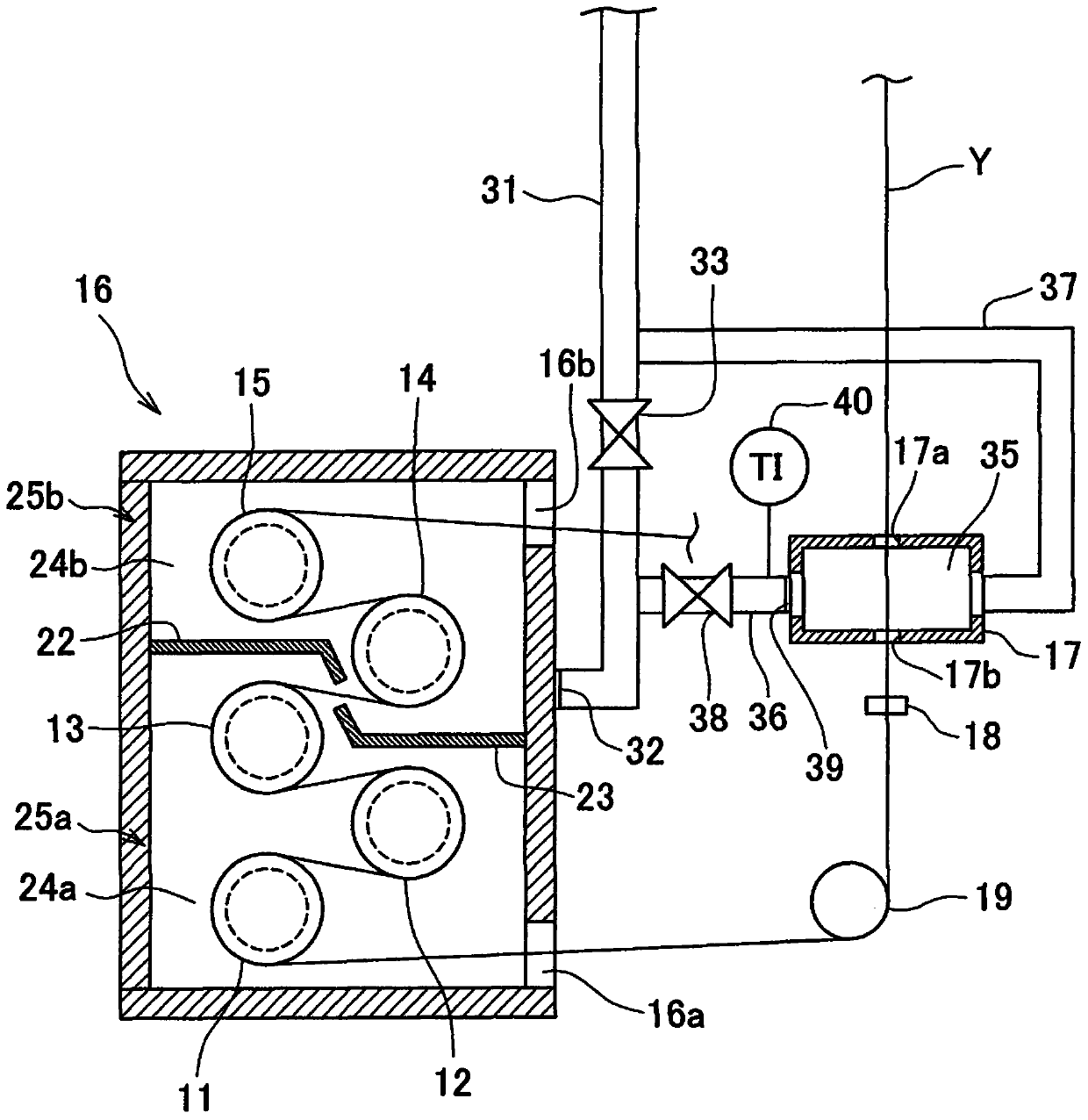

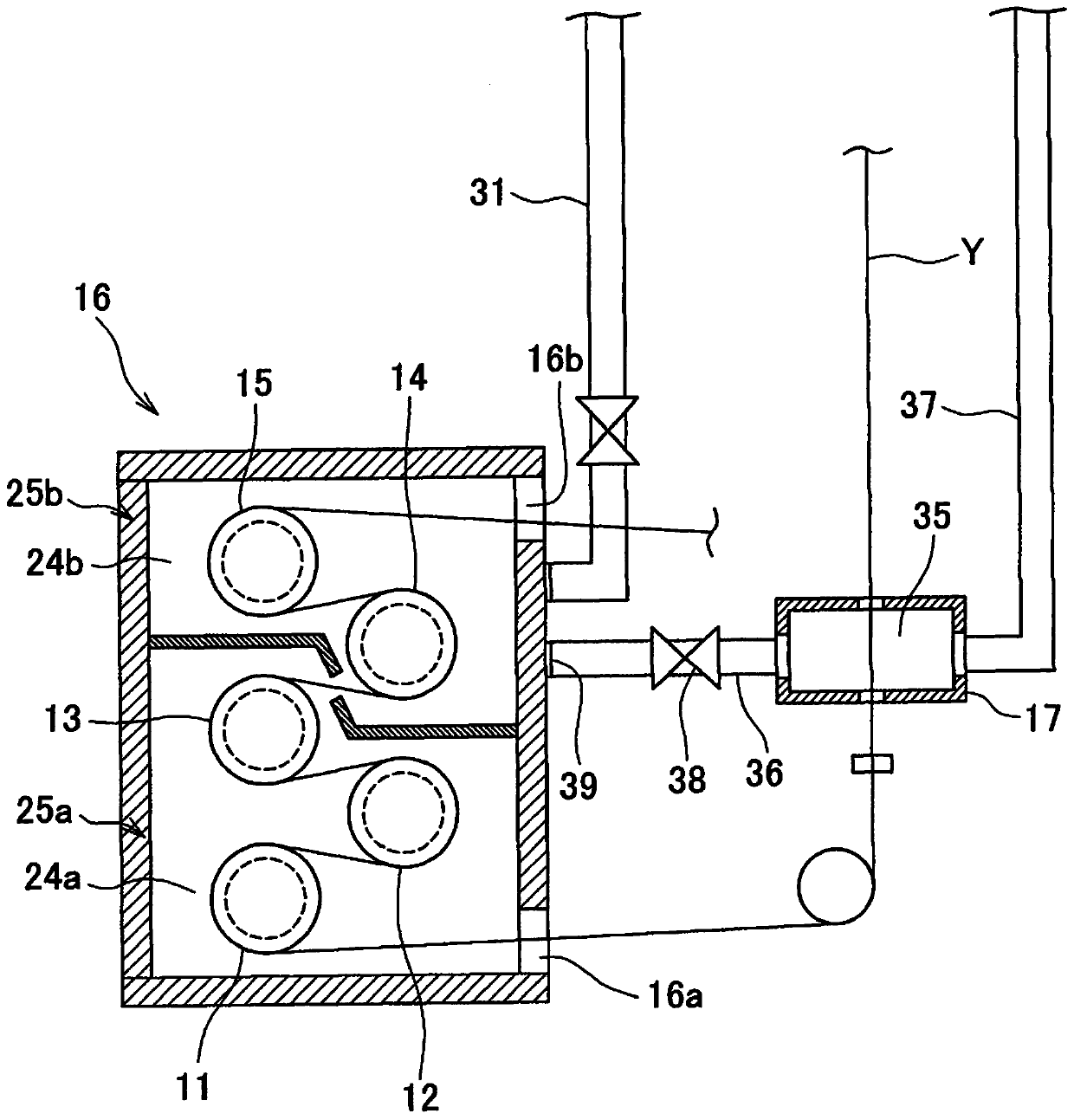

[0027] Next, embodiments of the present invention will be described. figure 1 It is a schematic configuration diagram of the spinning winder of this embodiment. Such as figure 1 As shown, the spinning winder 1 includes a spinning drawing device 3 and a yarn winding device 4 .

[0028] The molten fiber material such as polyester continuously spun from the spinneret of the spinning device 2 is solidified by blowing cooling air through the cooling cylinder 5 and becomes a plurality of yarns Y. The spinning and drawing device 3 is disposed below the cooling cylinder 5, and draws a plurality of yarns Y fed out from the cooling cylinder 5 downward. The spinning and drawing device 3 includes an oil guide 10 , five godet rolls 11 to 15 , an incubator 16 , a preheater 17 , and the like.

[0029] The finish guide 10 is a device for applying a finish to each of the plurality of yarns Y spun from the spinning device 2 . After being preheated by the preheating box 17 described later, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com