Front and back function combination device of frame circuit breaker

A frame circuit breaker and function technology, which is applied in the field of the function combination device before and after the frame circuit breaker, can solve the problems of easy bumping and crushing, poor reliability and unsafety of the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

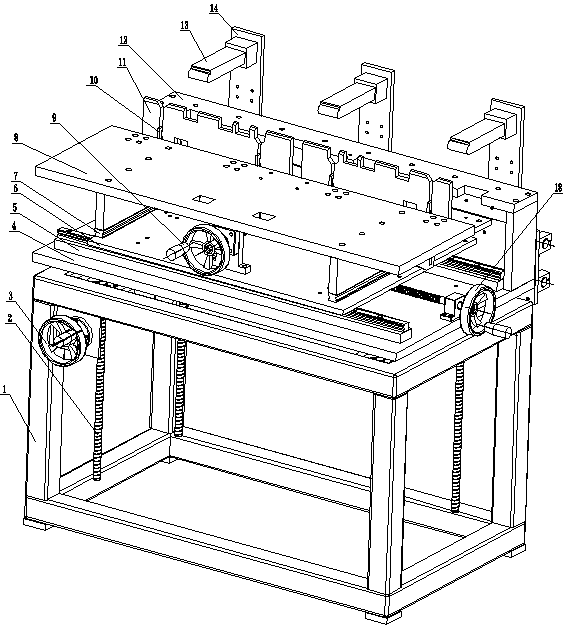

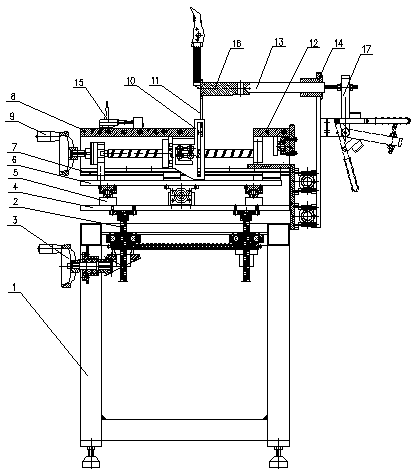

[0010] As shown in the figure, the present invention includes a mounting frame, a left and right platform, a main platform and a rear platform. There is a lifting handwheel screw 3 to manipulate the lifting platform 4 to move up and down in the mounting frame 1 through the lifting screw 2. There is a The left and right hand wheel screw mandrels 18 manipulate the left and right platforms 6 to move along the left and right tracks 5 on the elevating platform 4, and a front and rear hand wheel screw mandrel 9 manipulates the main platform 8 to move along the front and rear tracks 7, and the front function fixture 15 is installed on the main platform 8. The rear side of lifting platform 4 is fixed with a rear platform 12, and the height of rear platform 12 is consistent with main platform 8, and a rear support 14 is fixed on the side of rear platform 12, and rear support 14 is provided with movable top block 13, and rear function fixture 17 can be used in addition. Clamp top block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com