A Construction Method of Diagonal Entry in Bias-Pressure Tunnel

A construction method and tunnel technology, which is applied to tunnels, earthwork drilling, mining equipment, etc., can solve problems such as complex stress conditions, unsuitable use, and high requirements for construction organization, so as to ensure safety and feasibility, and reduce side slopes Height, effect of alleviating incongruity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

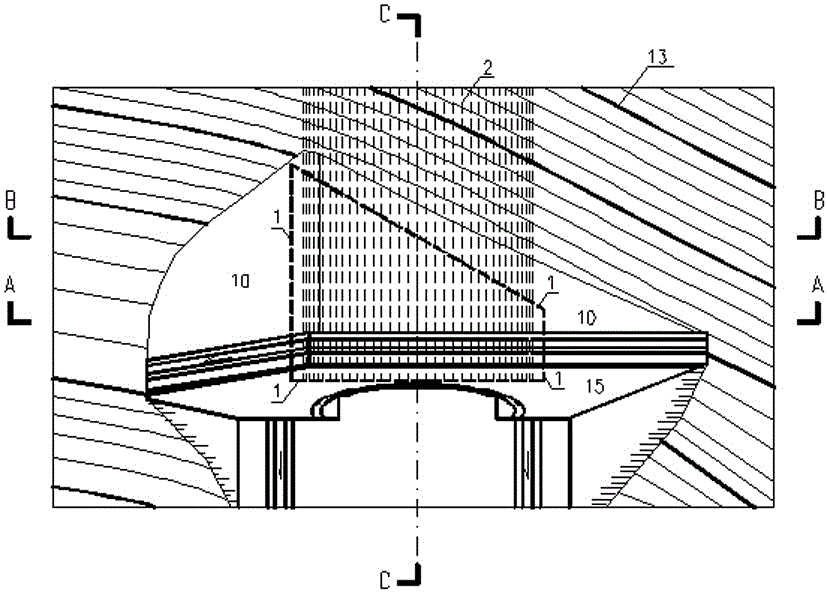

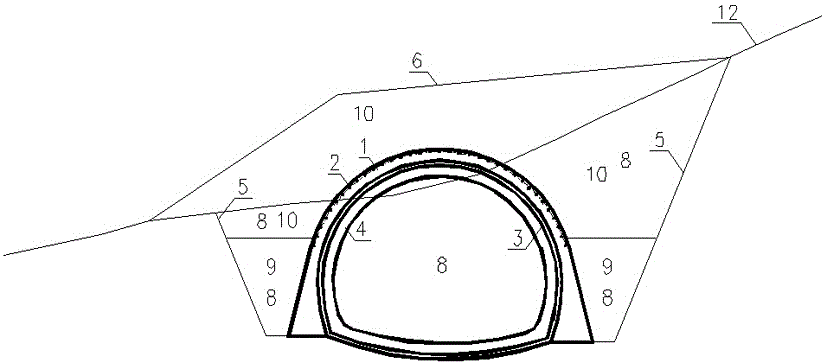

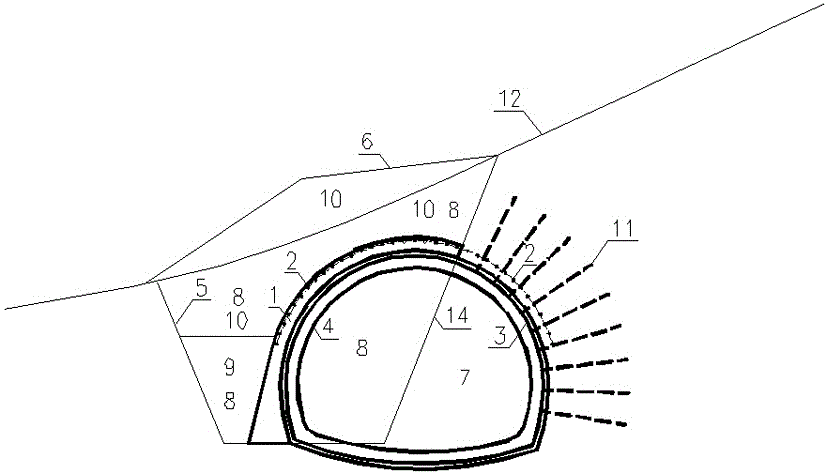

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. A construction method for oblique tunnel entry in a biased tunnel, comprising the following steps:

[0029] (1) According to the principle that the height of the inner slope of the tunnel entrance should not be too high and the thickness of the surrounding rock covering layer of the outer spandrel should not be too thin, the appropriate oblique entrance angle should be determined, and the temporary side of the entrance should be determined according to the geological conditions of the tunnel entrance. Slope rate. Then, start the hole construction, open and cut the soil layer 8, form the oblique entry into the hole 14 and the temporary side slope 5 on the left and right side of the tunnel.

[0030] (2) The construction opening is ahead of the large pipe shed to form an advanced pre-support. Firstly, the trapezoidal arch 1 of the large p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com