A mask plate and alignment film rubbing method

A technology of mask plate and orientation film, applied in instruments, nonlinear optics, optics, etc., can solve the problems of friction angle deviation and rubbing cloth orientation damage, and achieve the effect of avoiding friction angle deviation and ensuring display uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the mask plate and alignment film rubbing method provided by the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] The shape and size of each film layer in the drawings do not reflect the true proportion of the mask, but are only intended to schematically illustrate the content of the present invention.

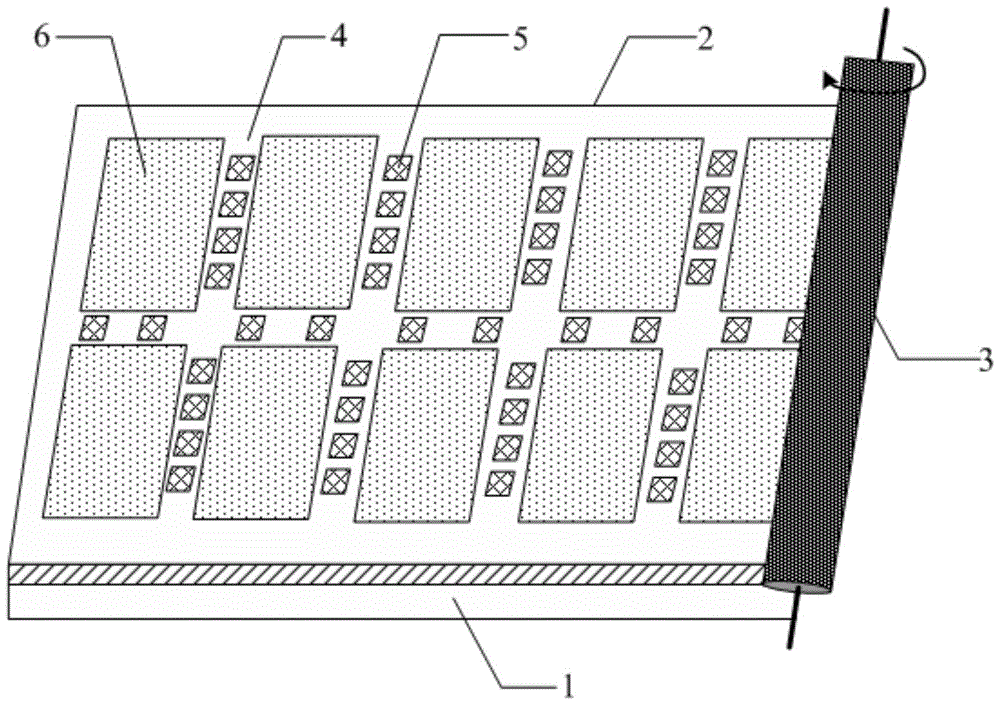

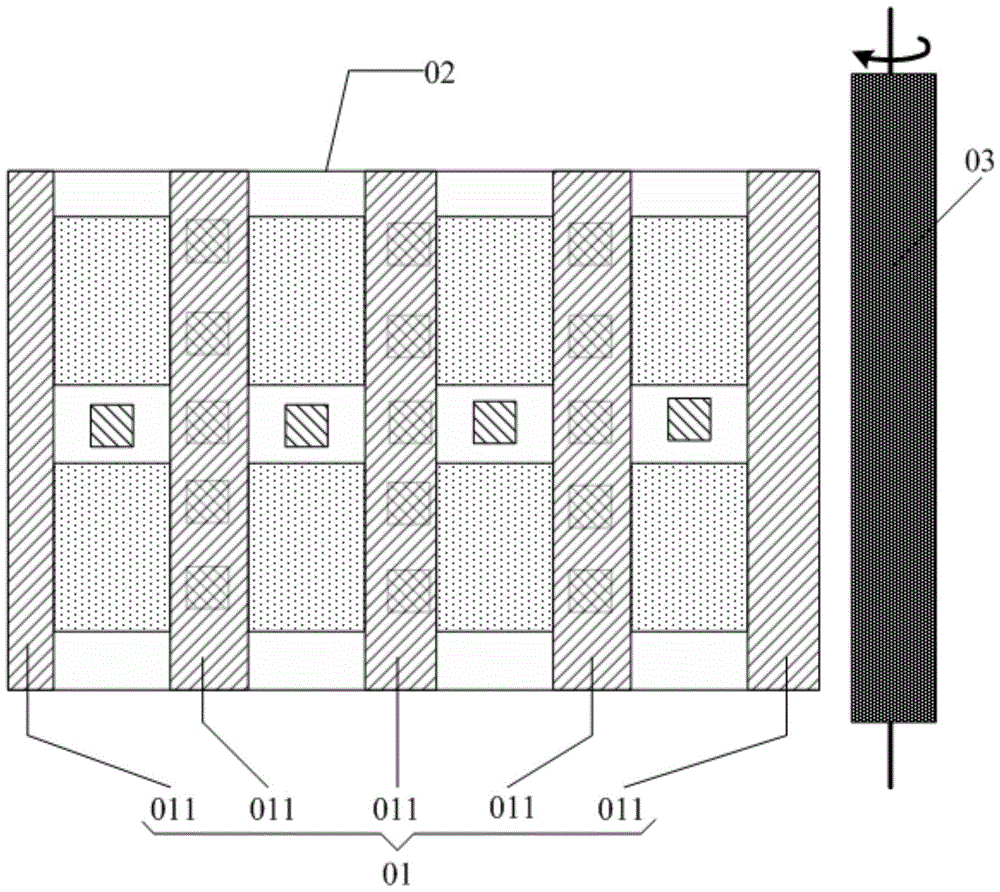

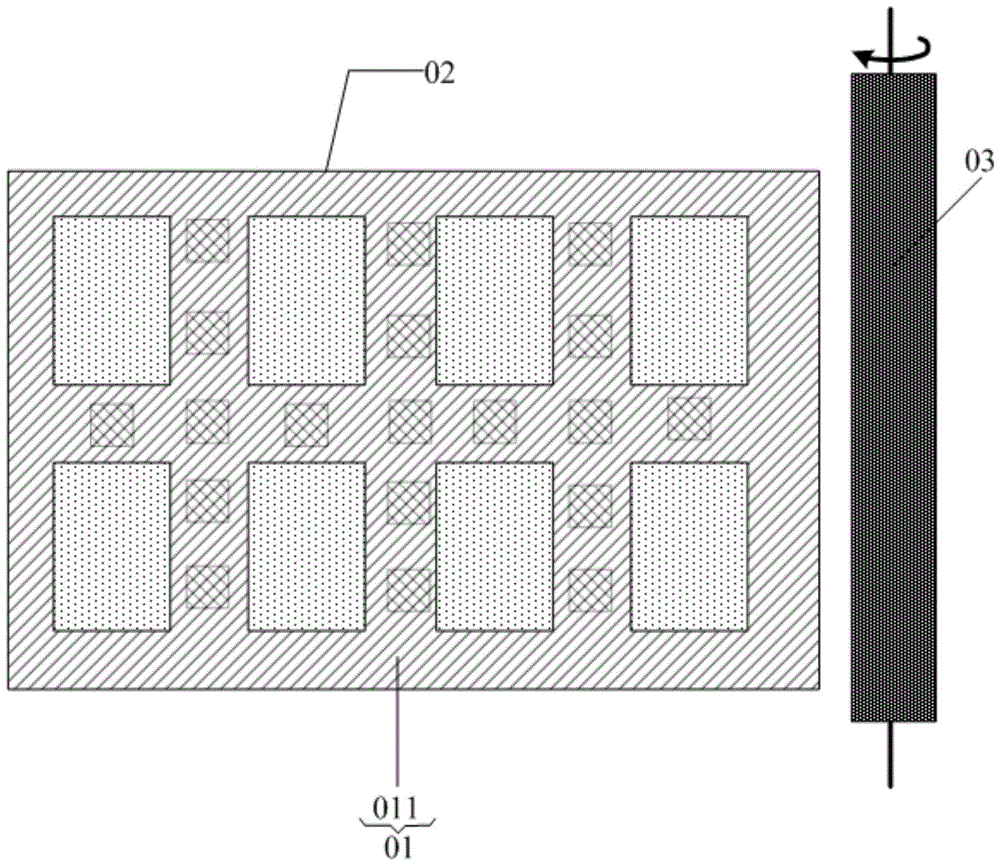

[0036] A mask plate provided by an embodiment of the present invention, such as Figure 2a and Figure 2b As shown, the mask plate 01 is used to cover the non-display area of the substrate 02 when rubbing the alignment film on the substrate 02;

[0037] The mask plate 01 includes at least one backing plate 011; wherein,

[0038] One side of the backing plate 011 is a horizontal plane, and the other side has at least a pattern matching the partial pattern of the non-display area at the covering position;

[0039] The thickness of the backing plate 011 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com