Strand casting system

An equipment and continuous casting technology, applied in the field of continuous casting equipment, can solve the problems of undesired transition errors and reaction forces, and achieve the effects of easy assembly, simplified maintenance, and avoidance of orientation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

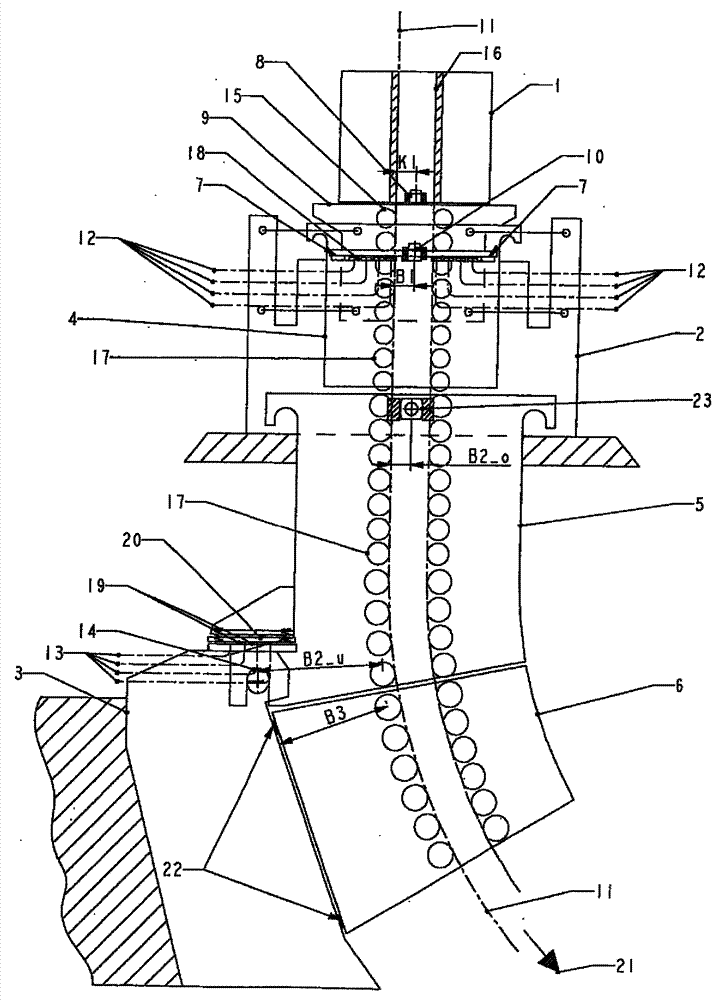

[0027] A vibrator base frame 2 is arranged below the casting table or turret. The vibrator vibration frame 9 that is supported on the vibrator base frame 2 and can be vibrated by the drive device of the vibrator base frame 2 belongs to the vibrator base frame 2, and the vibrator vibration frame 9 itself accommodates Cast crystallizer 1.

[0028] The first strand guide section 4 is connected to the vibrating frame of the vibrator or the continuous casting mould.

[0029] The other strand guides are formed by strand guide sections 5 , 6 etc., wherein only two strand guide sections are also shown in the figures, namely the second strand guide section 5 and the third strand guide section. Blank guide section 6.

[0030] Designated with 3 is the segment support frame on which the second strand guide segment 5 is supported with its underside, wherein the bearing point is designated with 14 .

[0031] The second strand guide section 5 is supported with its top side in the region o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com