Asphalt mixing device

A mixing device and asphalt technology, which is applied in roads, road repairs, roads, etc., can solve the problems that are difficult to meet the requirements of use, and the foaming effect of the foaming device is not ideal, and achieve the effect of guaranteeing the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

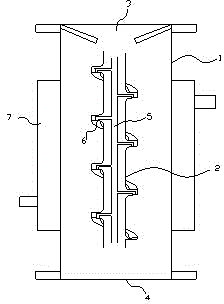

[0013] Reference figure 1 , The asphalt foaming device of the present invention is mainly composed of a middle-pass pipe 1 and a spiral stirring rod 2. The spiral stirring rod 2 is arranged inside the middle-pass pipe 1, and the spiral stirring rod 2 is driven by a motor.

[0014] One end of the middle-pass pipeline 1 is an asphalt inlet 3, during operation, high-temperature asphalt enters the pipeline from this inlet 3. In order to increase the pressure and speed when the asphalt enters, the inlet 3 is preferably designed in a bell mouth shape. The other end of the middle-pass pipe 1 is an asphalt outlet 4, and the asphalt is output through the outlet 4 after completing the foaming reaction in the pipe 1.

[0015] The inside of the spiral stirring rod 2 is provided with a through water channel 5, the input end of the through water channel is connected with a high-pressure water source, and the output end of the through water channel 5 is a water outlet hole 6 provided on a spiral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com