Accurate measurement method for resilience of memory alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

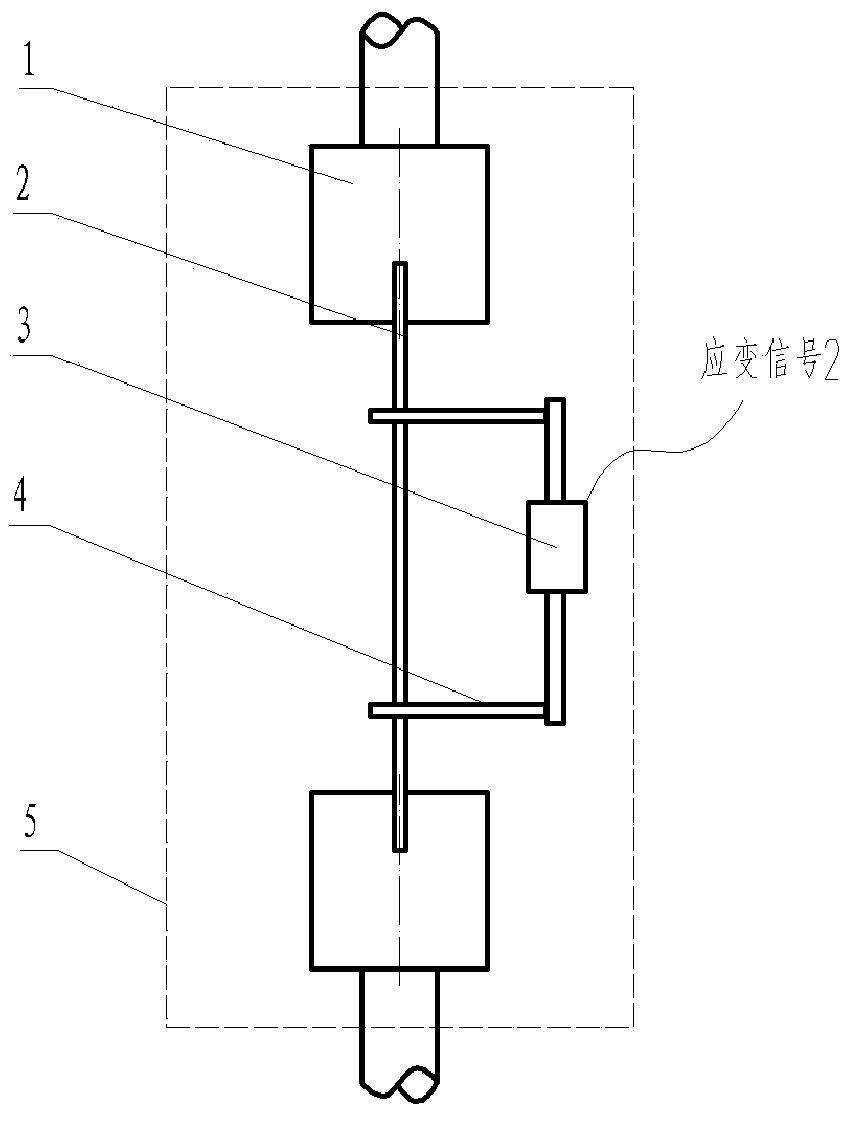

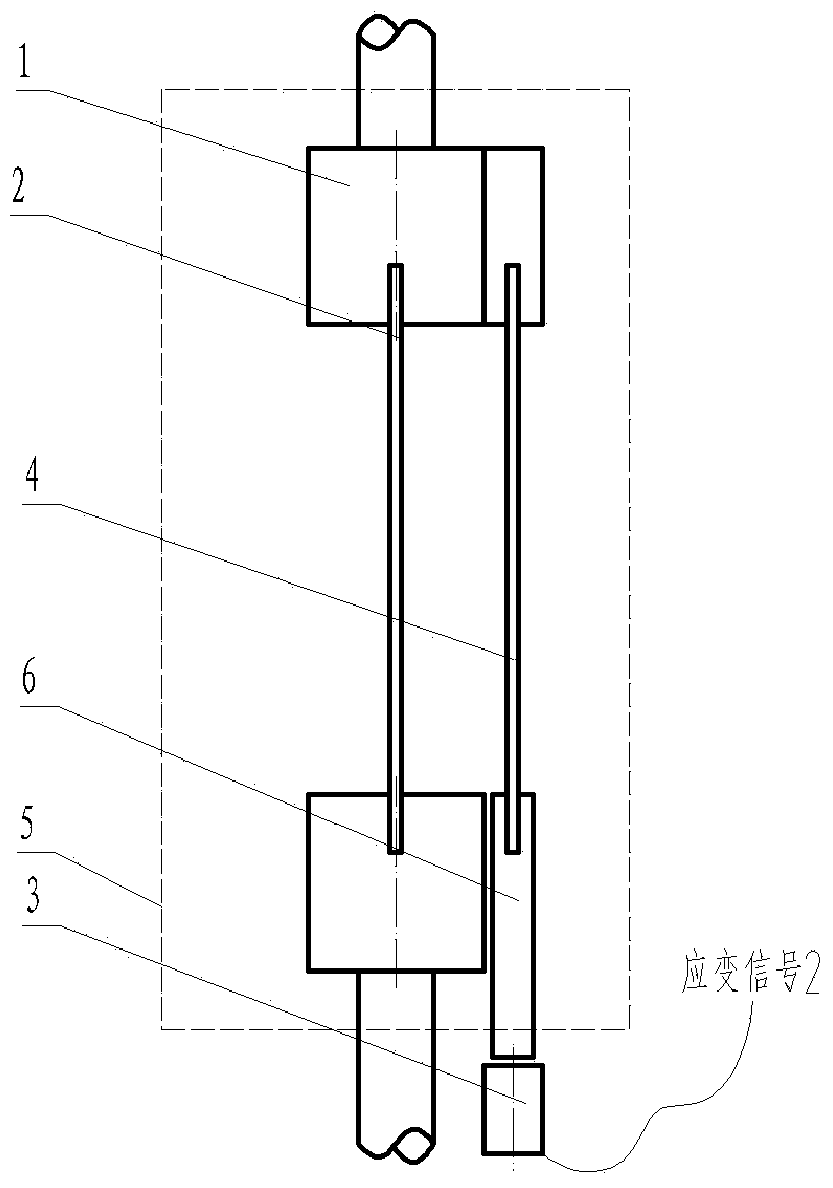

[0021] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

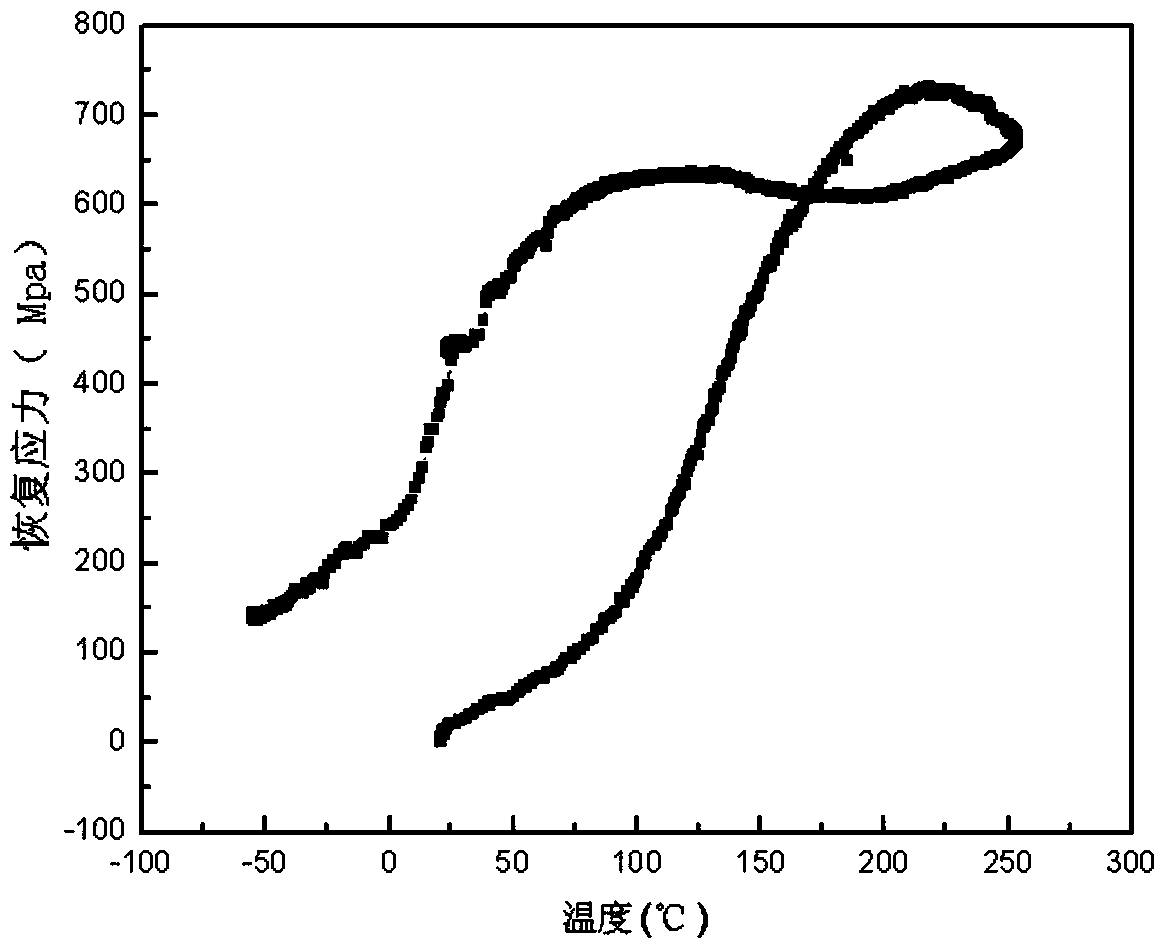

[0022] See attached Figure 2~3 As shown, the memory alloy tested in this embodiment is Ni47Ti44Nb9 bar and wire, and the nominal composition of the bar is Ni47Ti44Nb9. Φ1mm.

[0023] In this example, the WDT-5 microcomputer-controlled electronic universal material testing machine made in China is used, with a maximum load of 5kN, a test temperature range of -100°C to 200°C, and a test system of KPTestV4.3 and related software. Choose the built-in sensor, the sensor uses imported electronic extensometer, and the working temperature is -100℃~200℃.

[0024] The steps of the precise testing method of this memory alloy resilience are:

[0025] (1) Fix the two ends of the bar or wire sample 2 on the upper and lower chucks 1 of the self-kinetic stretching machine respectively, and then install the built-in displacement sensor 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com