Flat cable adjustable rolling mechanism

A flat cable and frame technology, applied in the direction of metal rolling frame, metal rolling, metal rolling, etc., can solve the problem of difficult balance between thickness adjustment efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

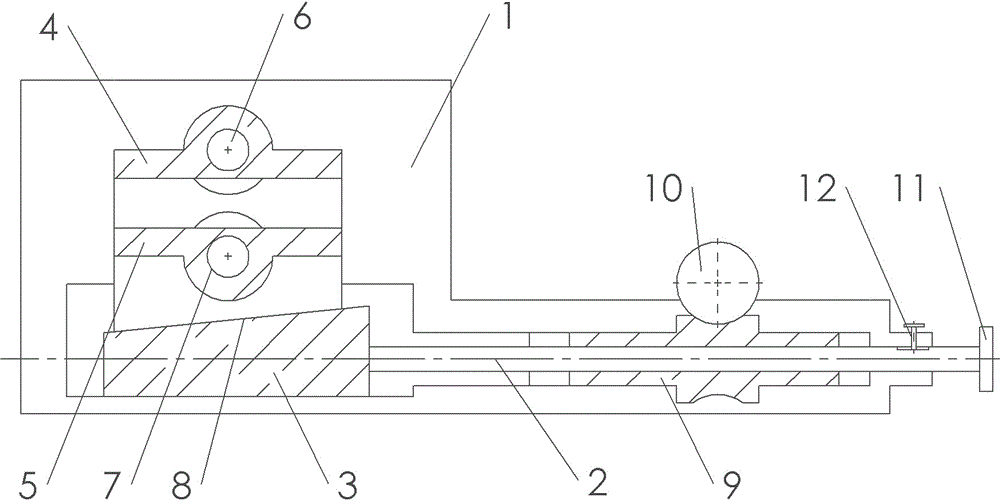

[0012] The reference signs in the drawings of the specification include: frame 1, pull rod 2, slider 3, upper roll frame 4, lower roll frame 5, upper roll 6, lower roll 7, inclined plane 8, worm gear sleeve 9, worm 10, fast Adjust handle 11, adjust pin 12.

[0013] The embodiment is basically as attached figure 1 As shown: there is a horizontal pull rod 2 running through the frame 1, and the left end of the pull rod is connected with a slider 3 through a pressure bearing. To move slides left and right in the dovetail.

[0014] An upper roll frame 4 and a lower roll frame 5 are arranged above the frame, on which the upper roll 6 and the lower roll 7 are connected through bearing rotation, the upper and lower rolls are driven by a motor to continuously rotate, and the copper wire passes between the upper and lower rolls and Rolled into a flat shape. The upper roll frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com