Separation device for reducing punching wear of hot-formed steel plate

A separation device and thermoforming technology, applied in the direction of piercing tools, forming tools, metal processing equipment, etc., can solve the problems of long production intervals, dripping, insufficient lubrication, etc., and achieve efficient processing, stable quality, simple and effective manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings.

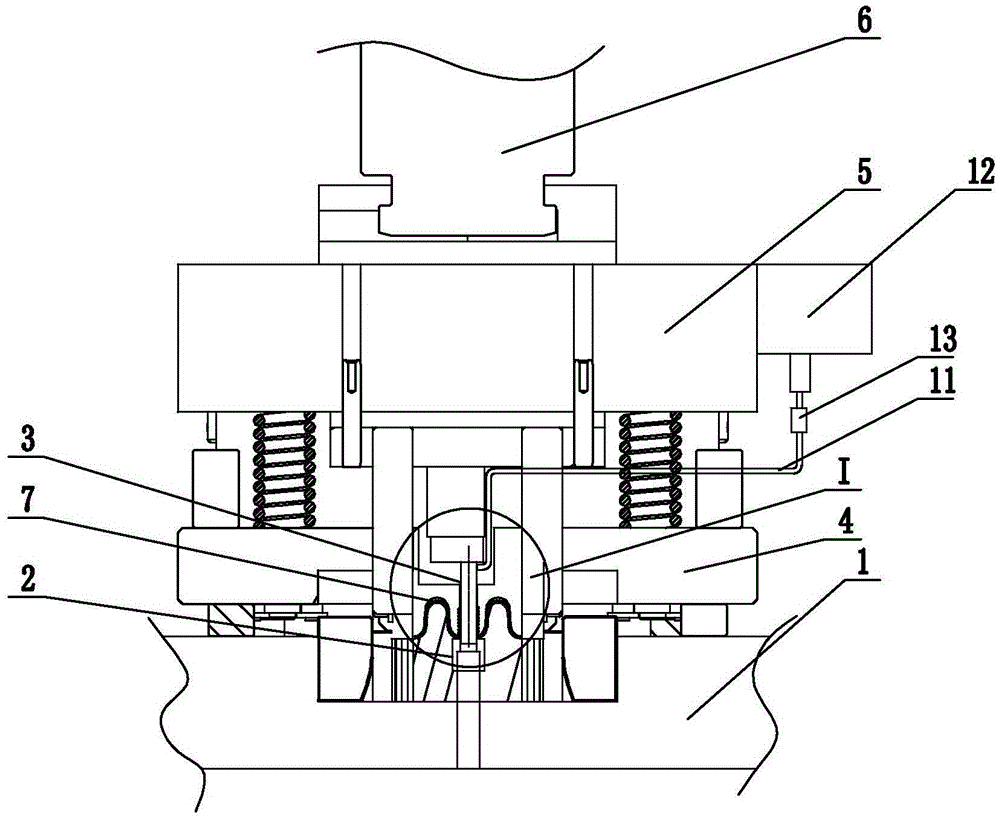

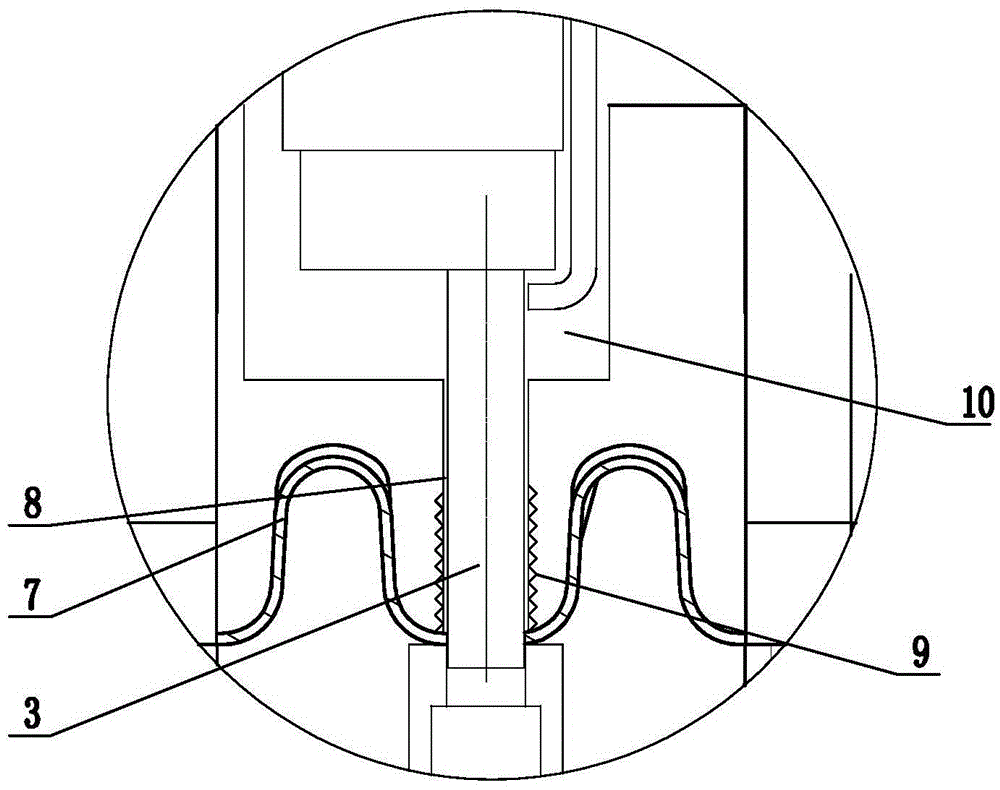

[0017] like Figure 1 ~ Figure 2 As shown: the separation device for reducing the wear of hot-formed steel plate punching includes a static separation insert 1, a punching die set 2, a punch 3, a binder block 4, a dynamic separation insert 5, and a hydraulic drive system 6. Work piece 7, through hole 8, internal thread 9, installation groove 10, lubricating oil / lubricating fluid pipeline 11, lubricating source 12, flow control valve 13, etc.

[0018] like figure 1 , figure 2 As shown, the present invention includes a static separation insert 1 and a dynamic separation insert 5, the upper part of the dynamic separation insert 5 is connected to a hydraulic drive system 6, a punching die set 2 is arranged on the static separation insert 1, and the dynamic separation insert 5 is located at Above the static separation insert 1, a pressing block 4 and a punch 3 are arranged on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com