Die structure for reducing abrasion of hot forming steel plate punches

A technology of hot forming and steel plate, which is applied in the field of mold structure, high-strength and ultra-high-strength steel plate for punching, which can solve problems such as dripping, insufficient lubrication, and volatilization of lubricating fluid, and achieve stable quality and low modification cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment: the punching process of the boron steel plate, the workpiece is the B-pillar for automobiles. Steel plate material: boron steel 22MnB5, material thickness 1.2mm, length 1250mm, width 430mm, required punching D16mm;

[0023] The above-mentioned workpieces are specifically processed through the following steps:

[0024] The first step is to perform thermoforming processing on the workpiece to obtain the B-pillar of the workpiece after thermoforming;

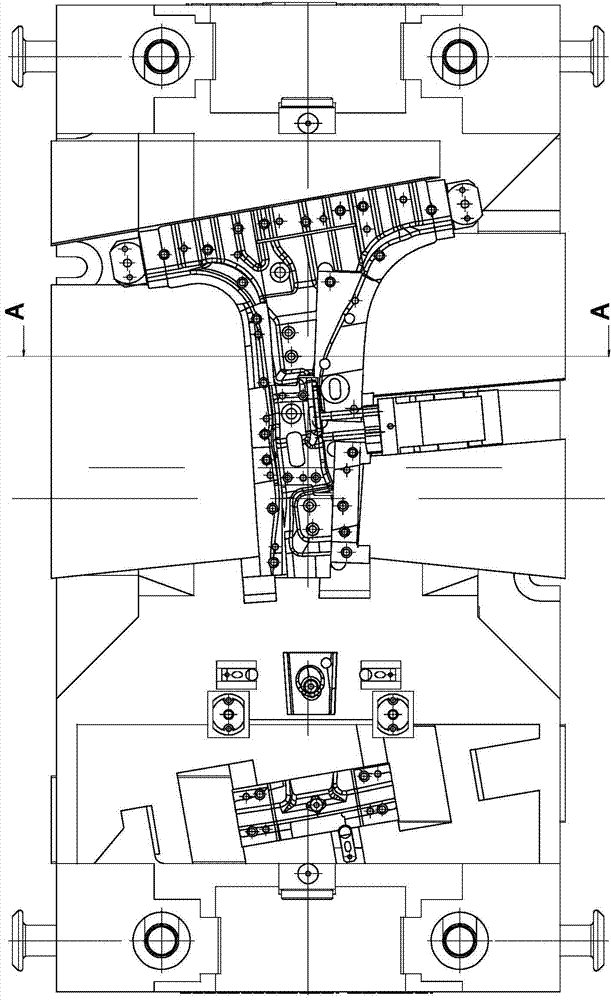

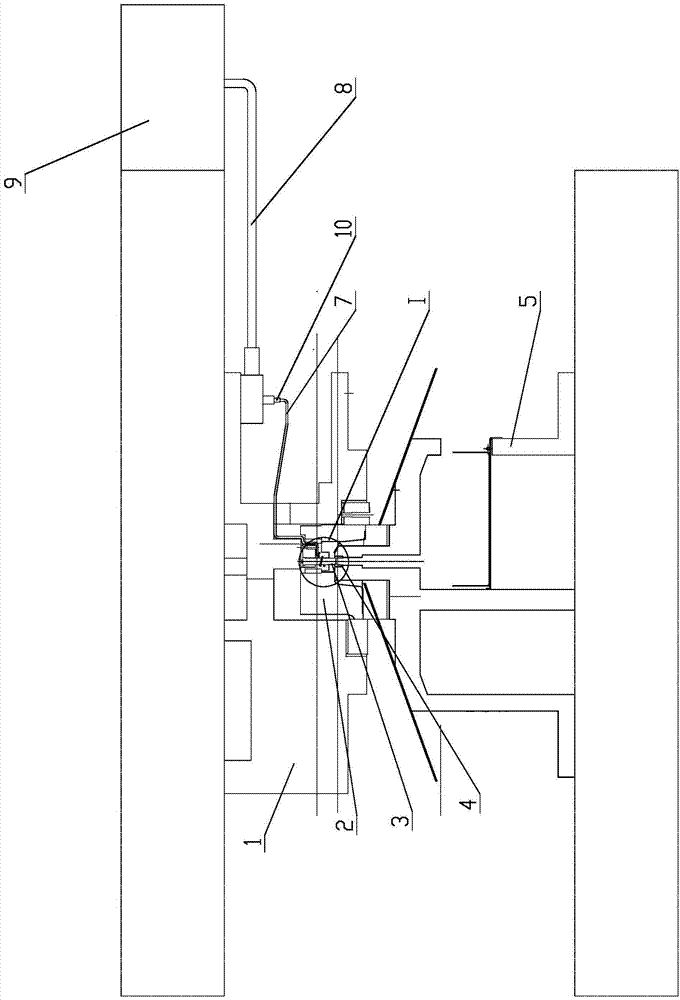

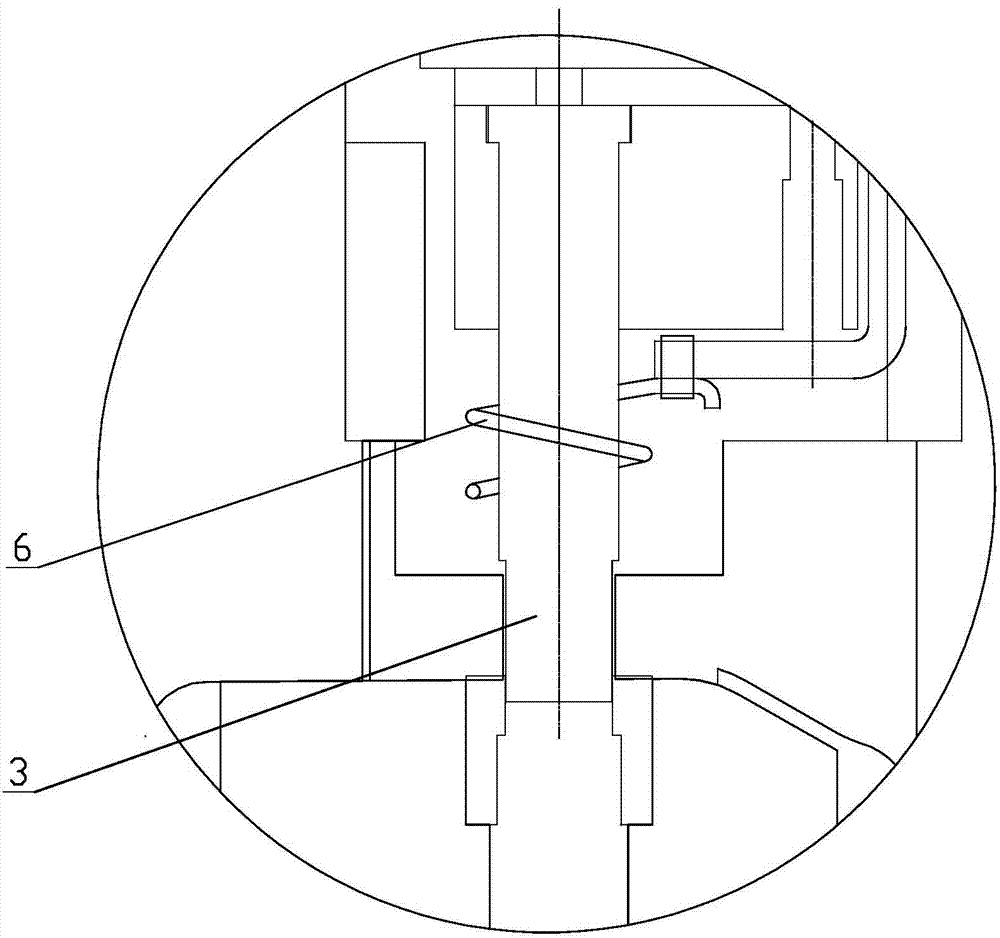

[0025] The second step is to punch the workpiece according to the final aperture size of the workpiece. The punching die consists of an upper die 1, a binder plate 2, an upper die punch 3, a lower die punching die set 4 and a lower die seat 5, and the upper die punch 3 is equipped with a lubricating wire 6, and a lubricating wire 6 The lubricating oil / lubricating fluid pipeline 7 connected to the lubricating source 9 is fixed with a clamp, and the lubricating wire 6 is 64 mm in length, wound on the punch 3 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com