Die Structure for Reducing Punch Wear of Hot Formed Steel Plate

A hot forming and steel plate technology, applied in the direction of forming tools, piercing tools, manufacturing tools, etc., can solve the problems of insufficient lubrication, dripping, no lubrication, etc., and achieve the effect of low modification cost and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: punching process of boron steel plate, the workpiece is B-pillar for automobile. The material of the steel plate: boron steel 22MnB5, the material thickness is 1.2mm, the length is 1250mm, the width is 430mm, and the required punching hole is D16mm; the above workpieces are processed through the following steps:

[0023] The first step is to perform hot forming processing on the workpiece to obtain the B-pillar of the workpiece after hot forming;

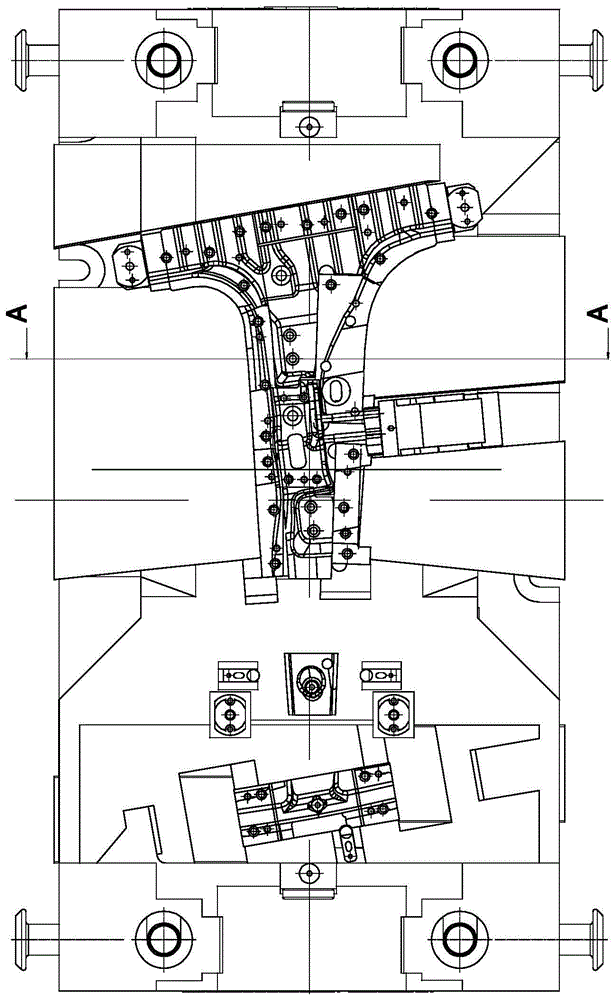

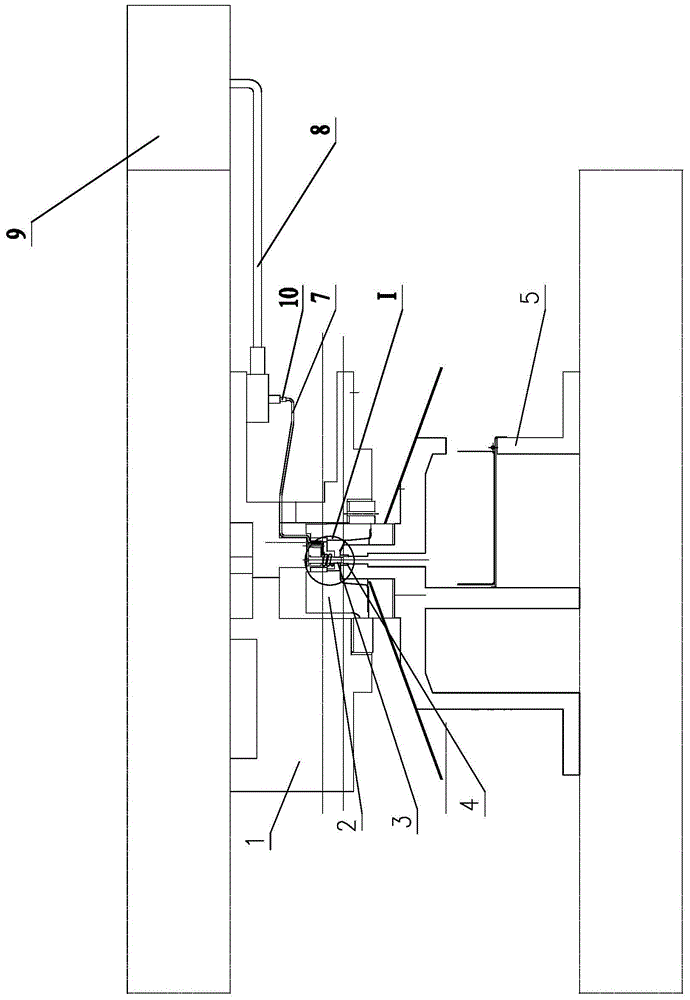

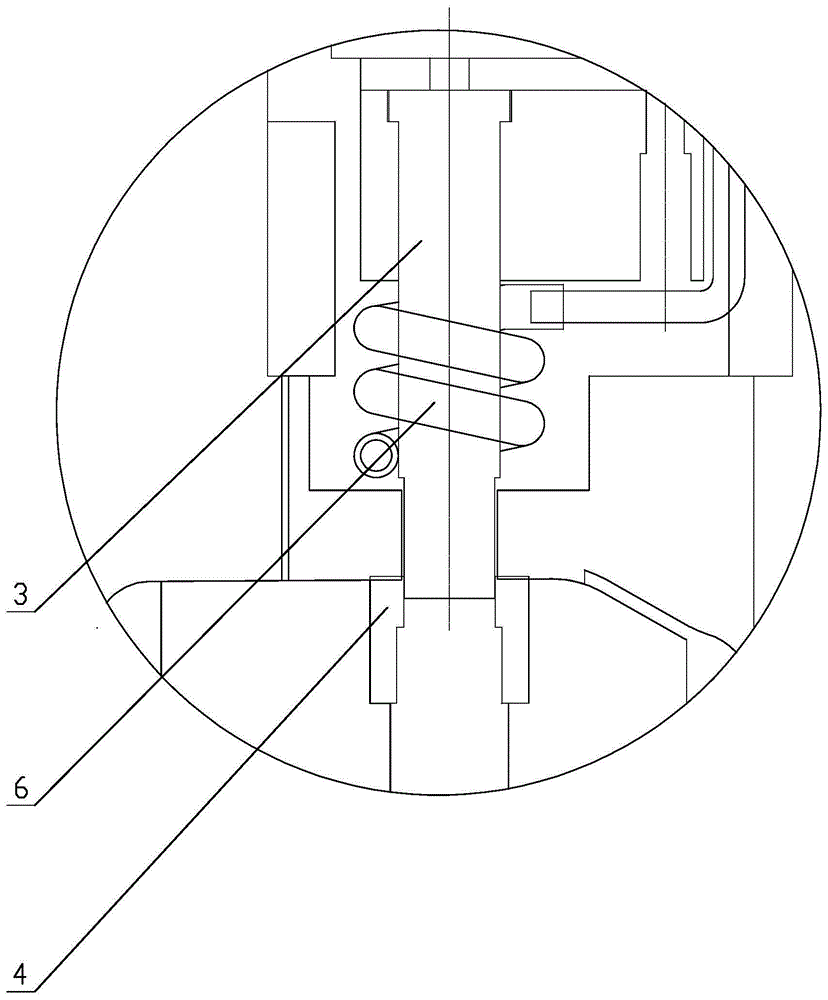

[0024] In the second step, as shown, according to the final aperture size of the workpiece, the workpiece is punched. The punching die is composed of an upper die 1, a pressing plate 2, an upper die punch 3, a lower die punching concave die sleeve 4 and a lower die seat 5. The upper die punch 3 is provided with a lubricating conduit 6 and a lubricating conduit 6 Interfering with the lubricating oil / lubricating fluid pipeline 7 connected to the lubricating source 9, the lubricating fluid / lubricating oil finally flows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com