Water-saving washing machine

A washing machine, water-saving technology, applied in the field of washing machines, can solve the problems of high cost, easy to cause water splashing, poor drainage effect, etc., achieve the effect of simple structure, save water resources, and solve the problem of water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

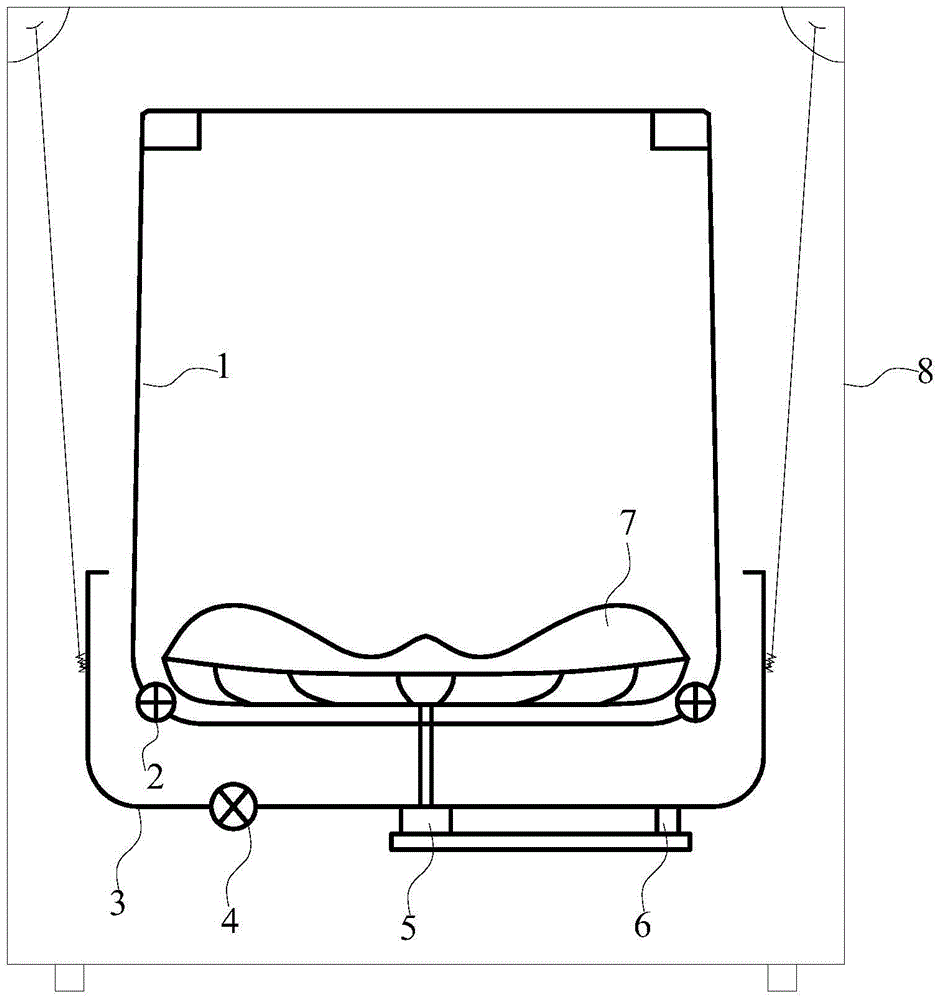

[0050] The present embodiment is a kind of water-saving washing machine, such as figure 1 As shown, the washing machine includes an inner tub 1 and an outer tub 3. The inner tub body 101 has no outlet holes. From the opening of the inner tub body 101 to the direction of the inner tub bottom 102, the diameter of the inner tub body 101 gradually increases; An inner drain 103 is arranged at the position, and a centrifugal drain valve 2 is arranged at the inner drain 103 .

[0051] When the washing machine is draining or dehydrating, the inner tub 1 rotates, and the centrifugal drain valve 2 is opened. At the same time, the clothes are attached to the wall of the inner tub under the action of centrifugal force, and the inner tub 1 with a small top and a large bottom will make water accumulate under the action of centrifugal force. To the bottom of the inner tub 102, to avoid water splashing from the mouth of the inner tub, and drain out of the tub through the centrifugal drain val...

Embodiment 2

[0077] This embodiment is another water-saving washing machine, which is provided with the same inner tub 1 and outer tub 3 as the first embodiment.

[0078] In this embodiment, the same pulsator 7, clutch 5 and motor 6 as in Embodiment 1 can also be installed; and an outer drain is provided at the bottom of the outer tub, and an outer drain valve 4 can also be set at the drain.

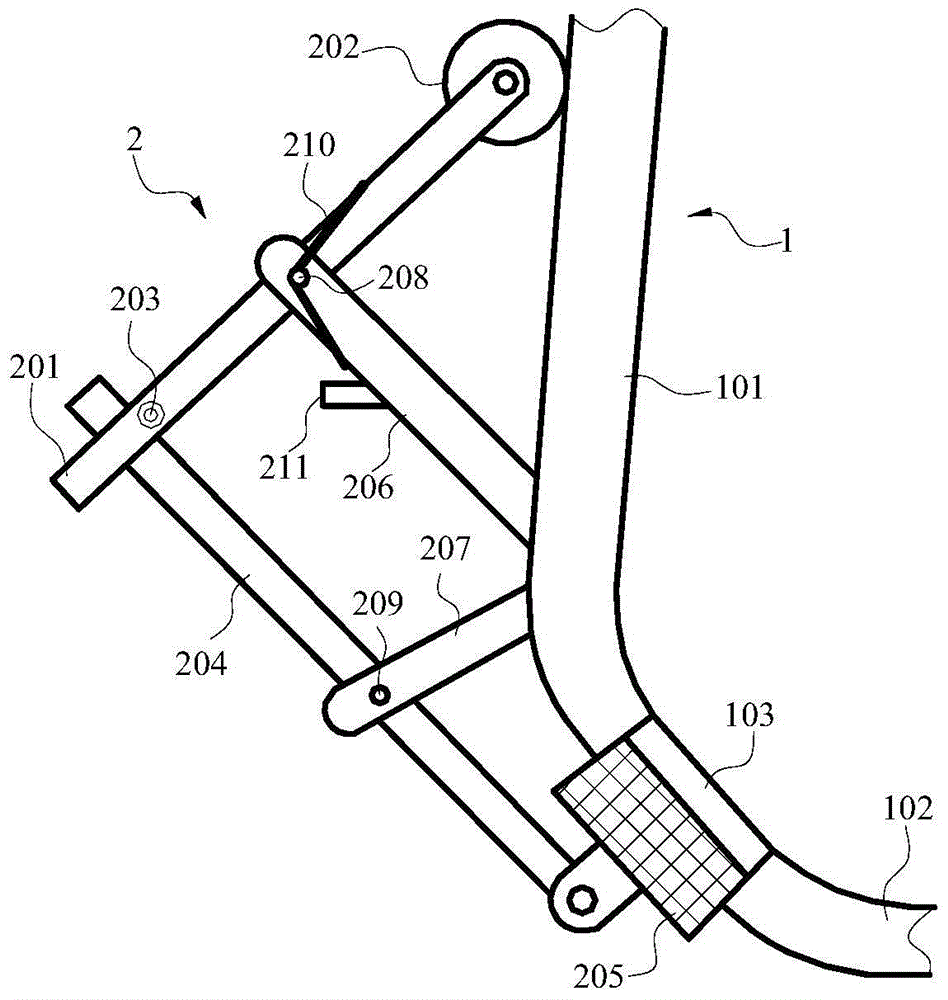

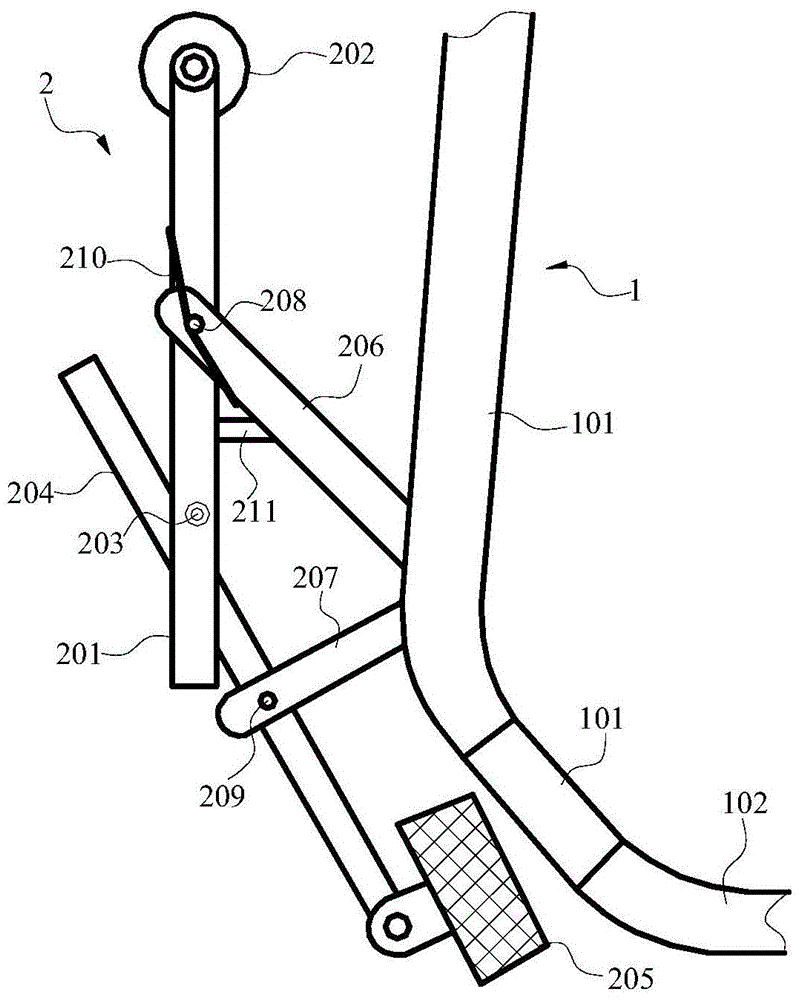

[0079] In addition, the centrifugal drain valve 2 in this embodiment includes: a support, an upper connecting rod 201 and a lower connecting rod 204, such as Figure 5 shown.

[0080] Wherein, the support is fixed on the outer wall of the inner barrel body 101, and the support is provided with upper and lower fulcrums; the upper end of the upper link 201 is connected with a counterweight 202, and the middle part of the upper link 201 is hinged with the upper fulcrum 208, The lower end of the upper connecting rod 201 is provided with a slider 203; the middle part of the lower connecting rod 204 is hi...

Embodiment 3

[0093] This embodiment is also a water-saving washing machine, which is provided with the same inner tub 1 and outer tub 3 as in Embodiment 1, such as Image 6 shown.

[0094] In this embodiment, the same pulsator 7, clutch 5 and motor 6 as in Embodiment 1 can also be installed; and an outer drain is provided at the bottom of the outer tub, and an outer drain valve can also be set at the drain.

[0095] In addition, the centrifugal drain valve 2 in this embodiment includes: a valve block 203' and a valve body 201', the valve body 201' is affixed to the inner bucket bottom 102 at the inner drain port 103, and the valve body 201' is located at In the gap between the inner barrel 1 and the outer barrel 3, the valve body 201' is provided with a valve cavity and a valve port 202', the size of the valve cavity gradually becomes smaller from top to bottom, the valve cavity is connected with the inner drain port 103, and the valve port 202' facing downward, the size of the valve bloc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap