transmission

A technology of transmission and speed, applied in gear transmission, components with teeth, belts/chains/gears, etc., can solve the problems of slow response, unsmooth reverse gear, etc., and achieve the effect of convenient and quick reverse gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

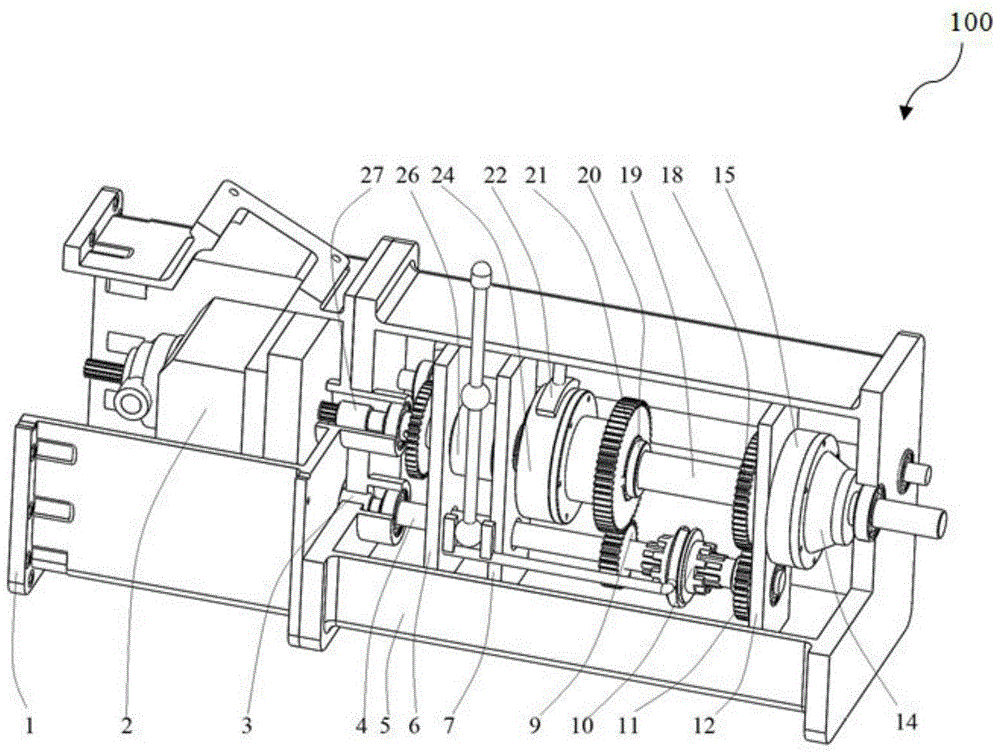

[0027] figure 1 It is a front view three-dimensional structural schematic diagram of the transmission of the present invention.

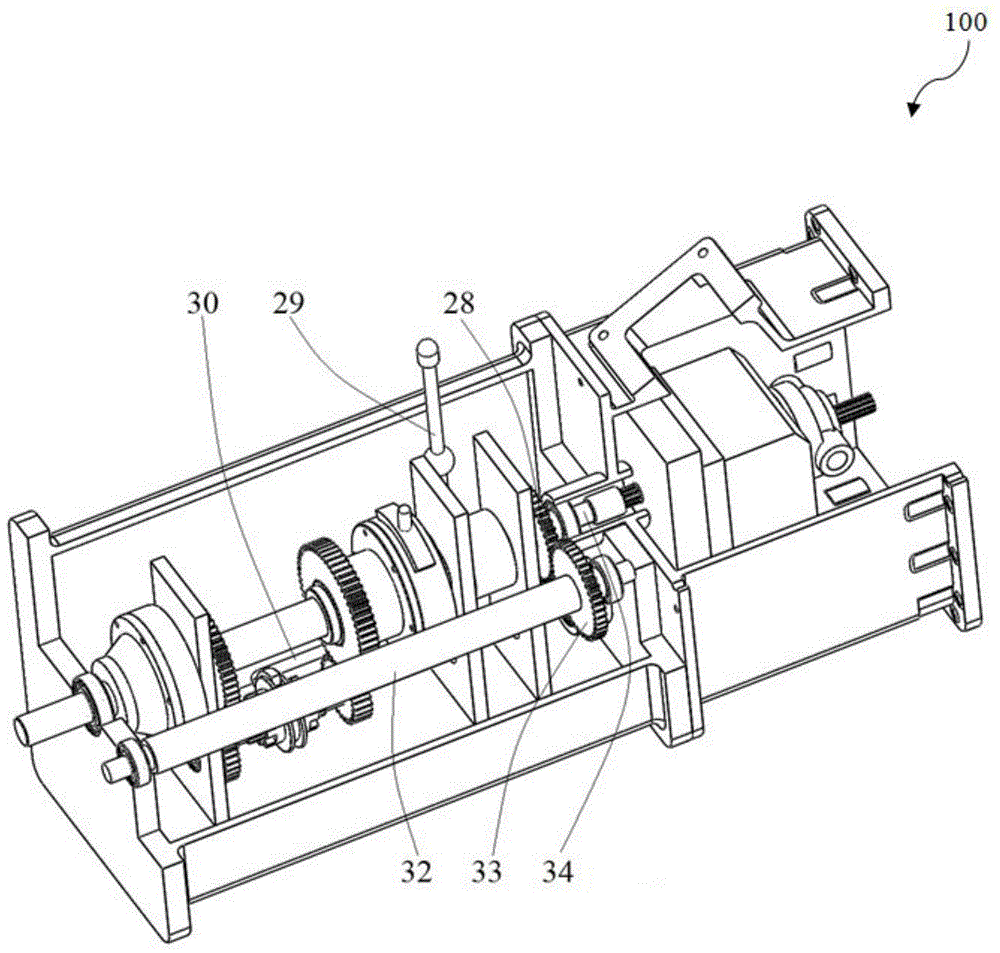

[0028] figure 2 It is a rear view three-dimensional structure schematic diagram of the transmission of the present invention.

[0029] The transmission 100 includes a power part, a mechanical transmission part, a confluence part, a reverse gear part, and a rear power output part.

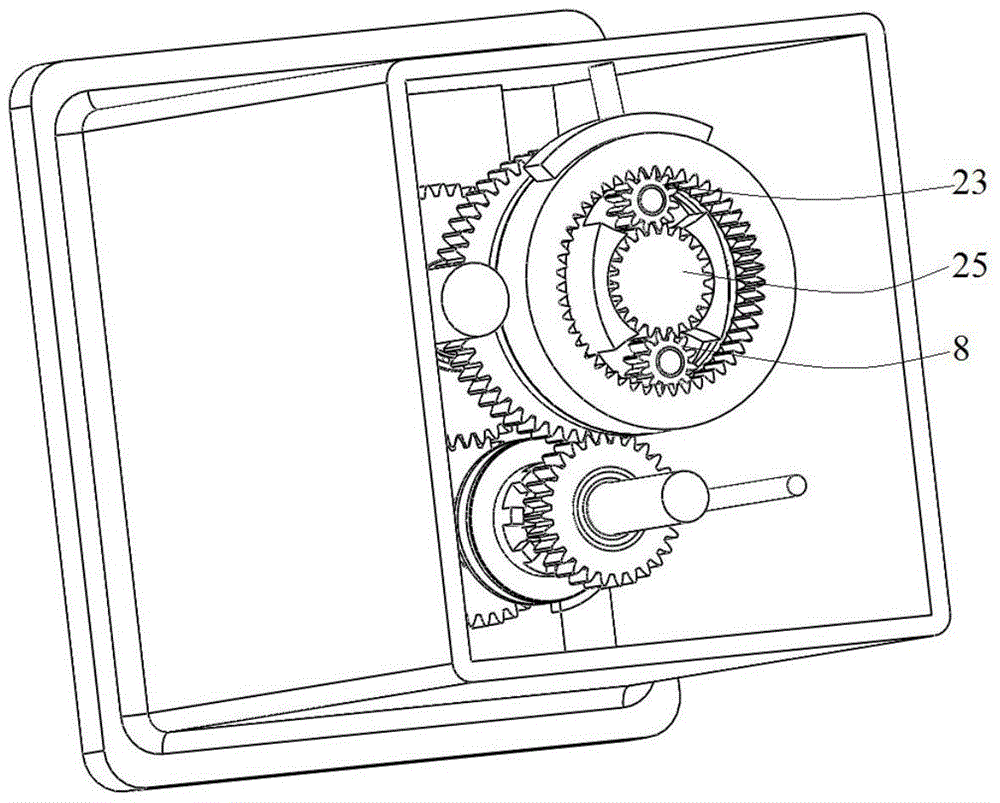

[0030] The power part is used to provide power, including hydraulic combination pump 2 , hydraulic input shaft 4 and mechanical input shaft 34 . The mechanical transmission part is used to transmit mechanical power, including the sun gear pinion 25 , the ring gear 24 , the brake 22 , the first planetary gear 8 , the second planetary gear 23 , and the output shaft 19 of the planetary carrier. The converging part is used to merge the hydraulic power into the mechanical power to realize the forward speed change of the vehicle, and includes the first converging transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com