A Rotating Liquid Conductivity Measuring Electrode

A technology for measuring electrodes and conductivity, which is applied in the direction of measuring electrical variables, measuring resistance/reactance/impedance, measuring devices, etc., and can solve the problems that the influence of electrode polarization and theoretical errors cannot be completely eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

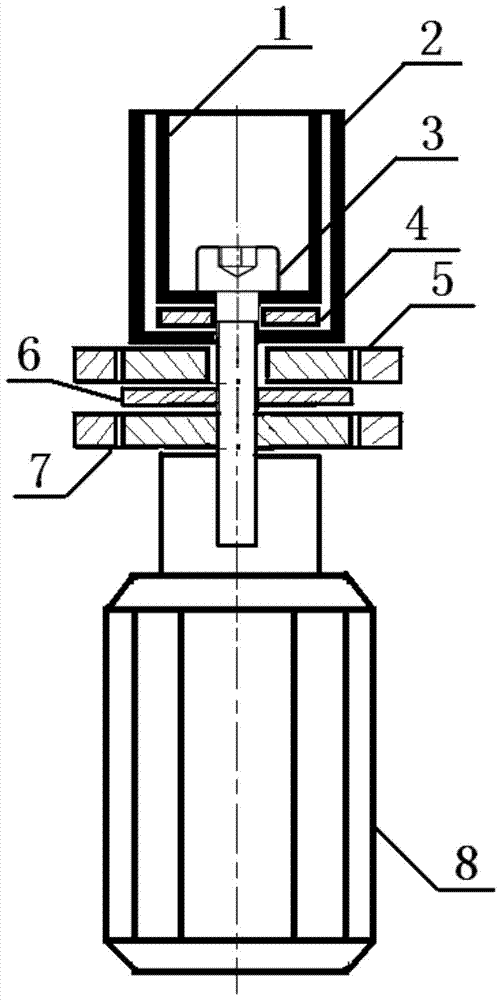

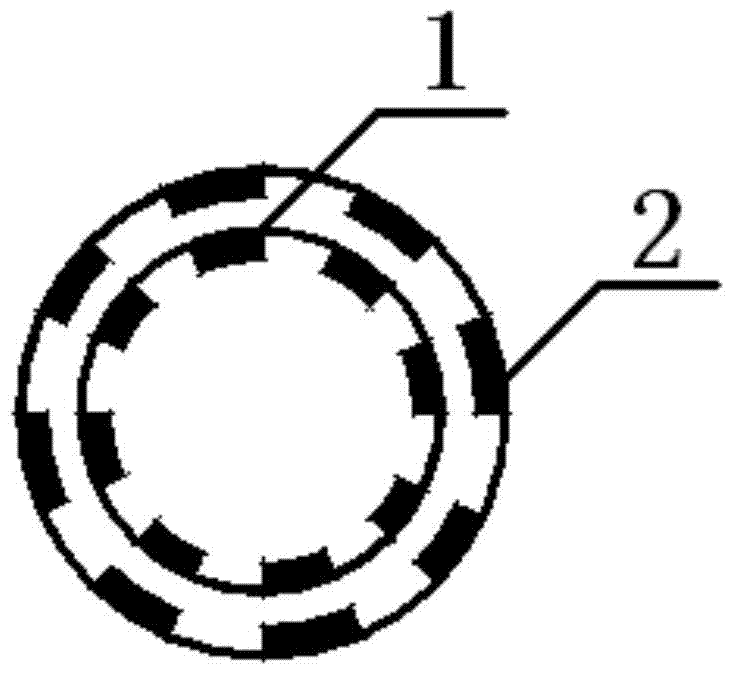

[0008] Attached below figure 1 And attached figure 2 The technical scheme of the present application is further described:

[0009] A rotary liquid conductivity measuring electrode consists of two electrodes, the first electrode 1 and the second electrode 2, two gaskets, the first gasket 4, and the second gasket 6, and two slip rings, the first slip ring. The ring 5 and the second slip ring 7, the micro motor 8 and the fixing screw 3 are composed; as figure 1 As shown in the upper part, the two electrodes, that is, the first electrode 1 and the second electrode 2 are cylindrical flat-bottomed straight cylinders with unequal diameters, and there is a gap between the cylindrical side walls of the two straight cylinders, and as shown figure 2 As shown, the same number of 6 or 8 gaps are equally spaced on the straight cylindrical side walls of the two electrodes, so that the same number of 6 or 8 electrodes are formed on the cylindrical side walls of the two electrodes claw; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com