Swinging liquid conductivity measurement electrode

A technology for measuring electrodes and electrical conductivity, which is used in the measurement of electrical variables, resistance/reactance/impedance, measurement devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

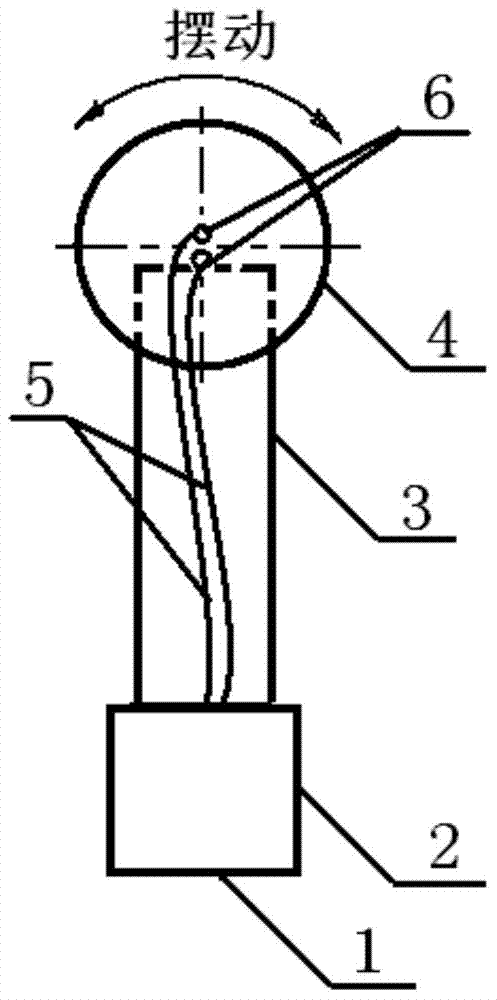

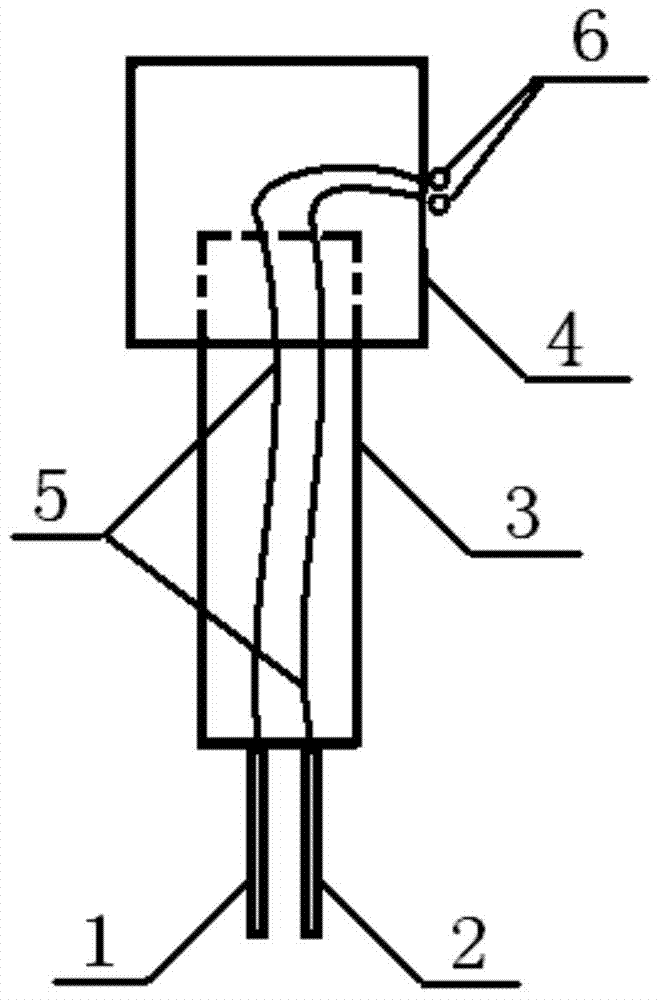

[0008] Attached below figure 1 And attached figure 2 The technical scheme of the present application is further described:

[0009] A swing-type liquid conductivity measuring electrode is composed of two electrode ends, the first electrode end 1, the second electrode end 2, the electrode arm 3, the swing mechanism 4, the lead wire 5 and the connecting terminal 6; the two electrode ends are the second electrode end The first electrode terminal 1 and the second electrode terminal 2 are flat metal sheets, which are parallel to each other with a gap and face directly. The two electrode terminals, namely the first electrode terminal 1 and the second electrode terminal 2, are fixedly installed on the electrode arm 3 and pass The electrode arm 3 is mechanically connected to the swing mechanism 4, and the two electrode ends, namely the first electrode end 1 and the second electrode end 2, pass through the inner hollow of the electrode arm 3 through the lead wire 5 and are elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com