Loudspeaker and method of manufacturing bulkhead portion of loudspeaker

A loudspeaker and baffle technology, applied in sensor parts, speaker transducer fixing, sensors, etc., can solve problems such as unfavorable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In this context, the term forward direction refers to the direction in which sound waves are mainly emitted from the loudspeaker. In contrast, a backward direction refers to the opposite of a forward direction. Correspondingly, the terms front and rear refer to the sides of the loudspeaker in the direction of the forward direction or the rearward direction, but the sides are normal to the front and rear of the enclosure. Furthermore, the term axial is used herein to describe the dimension in which sound waves are emitted forward or backward.

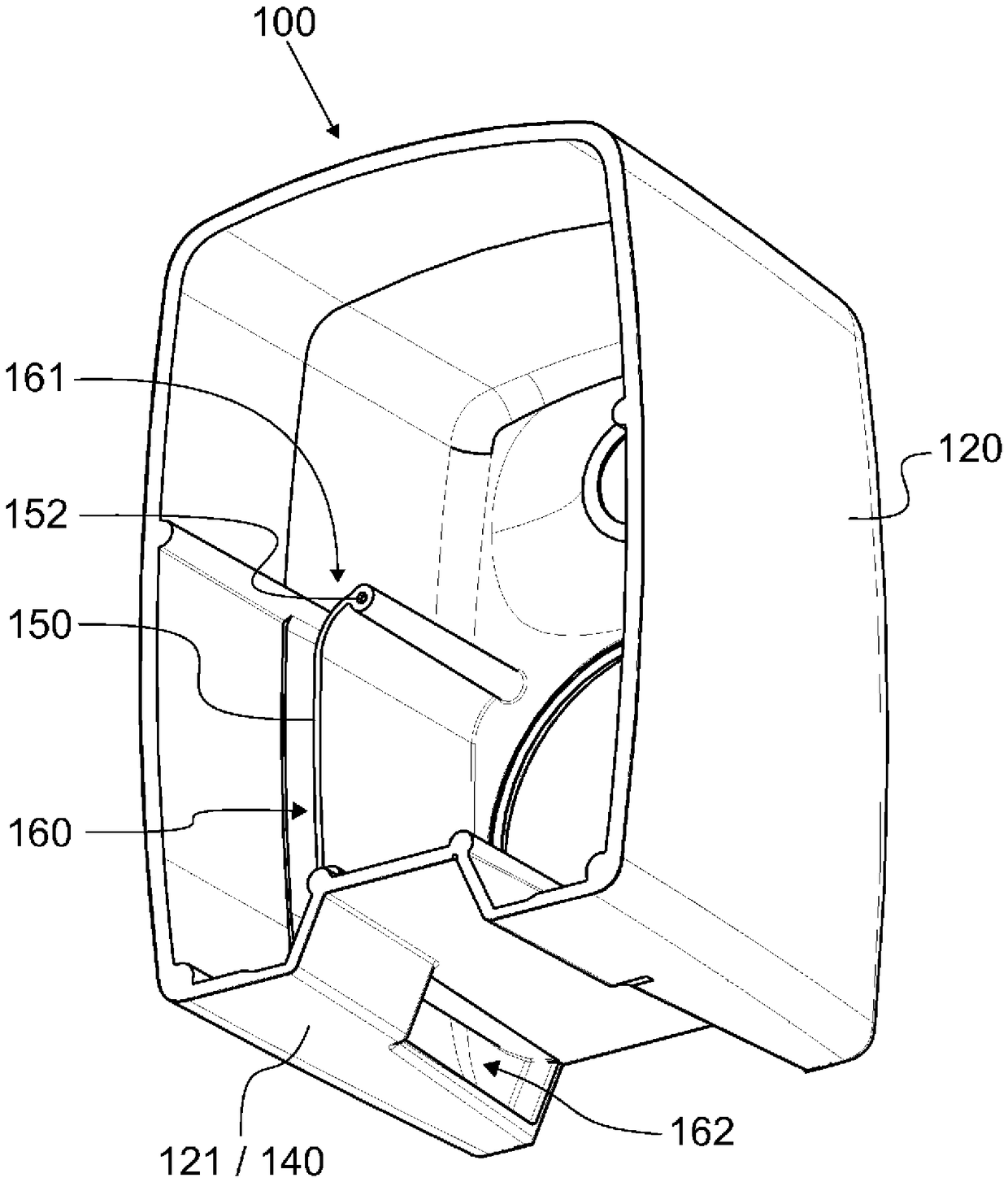

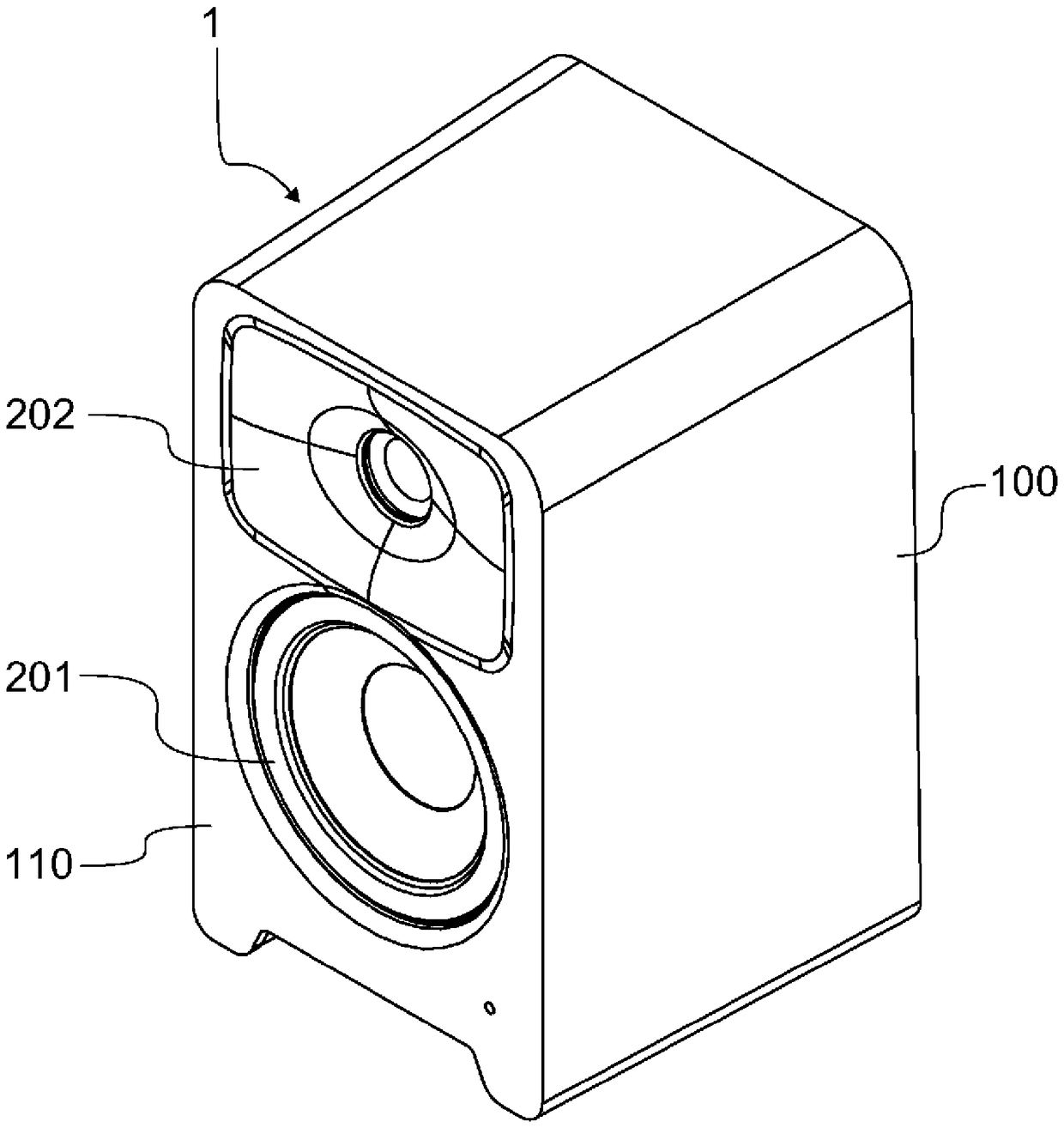

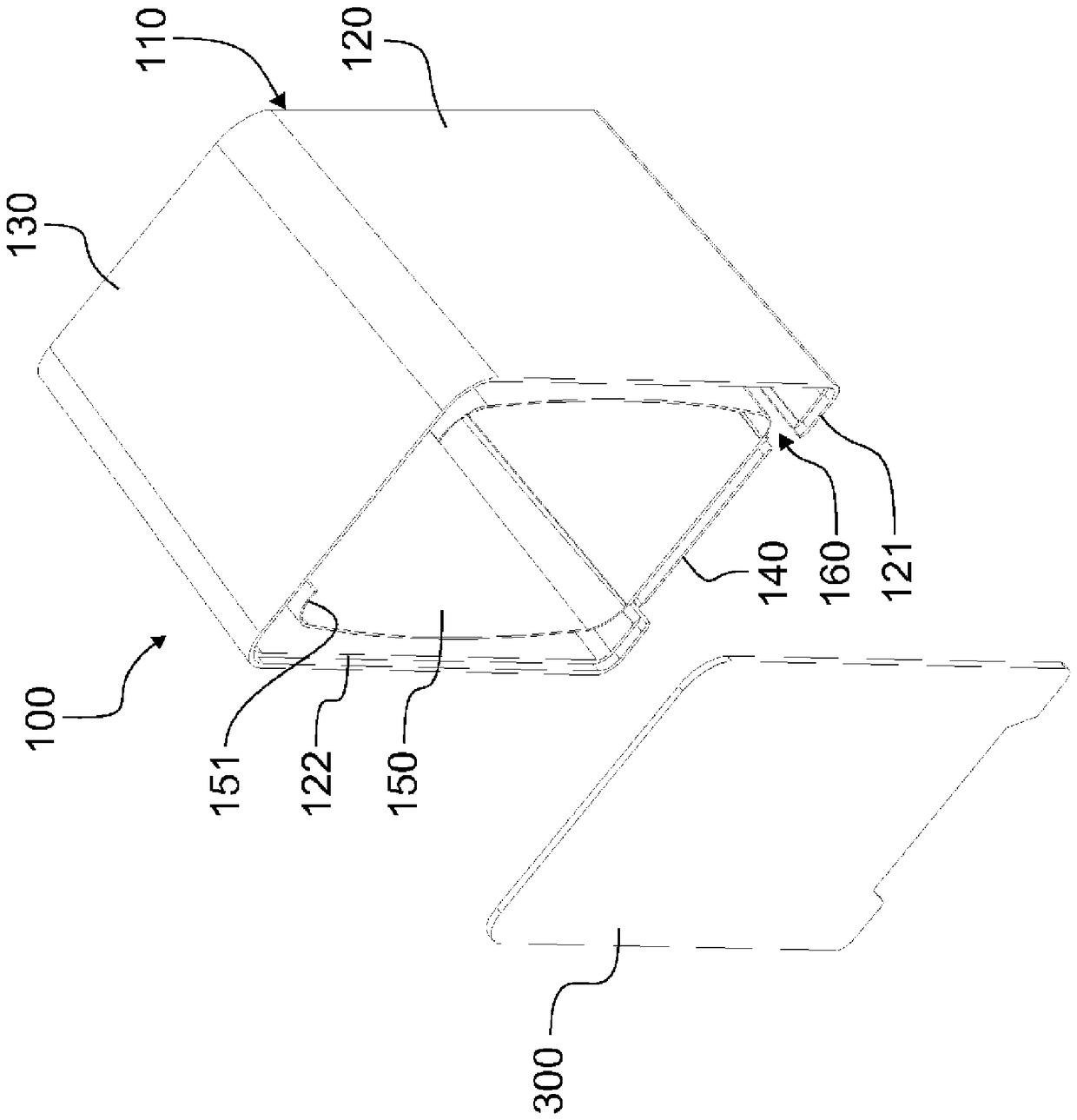

[0025] The baffle portion 100 according to an embodiment of the invention extends rearwardly such that it forms at least a part, preferably at least 50%, of the total internal volume of the loudspeaker 1 . In the embodiment presented in the figures, the bulkhead part 100 encloses the entire inner volume of the loudspeaker 1 , whereby the loudspeaker 1 is closed by a flat closing section 300 . A border ridge 122 has been provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com