Construction method for installing backing ring and furnace shell of converter

A converter support ring and construction method technology, applied in the manufacture of converters, etc., can solve the problems of unusable cranes and cranes, and achieve the effects of low construction cost, good positioning stability, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] 1) Measure the bottom elevation and center line of the equipment base of the civil bearing seat foundation of the drive end of the support ring and the non-drive end bearing seat. Install the drive end bearing seat of the support ring shaft and the lower half of the non-drive end bearing seat first.

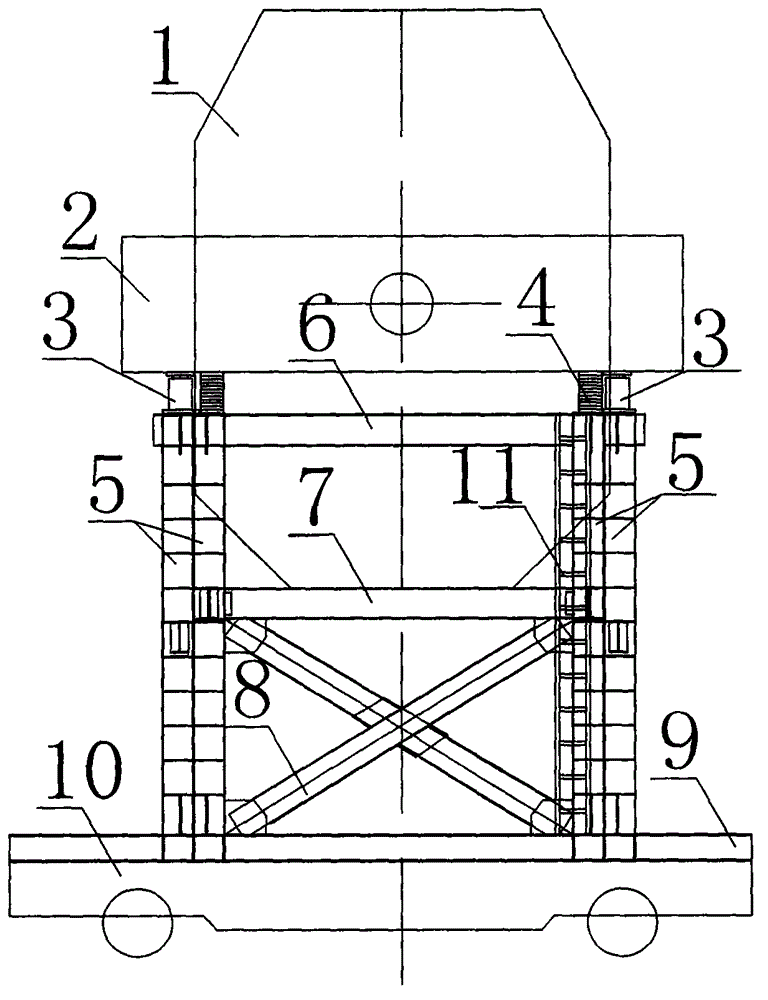

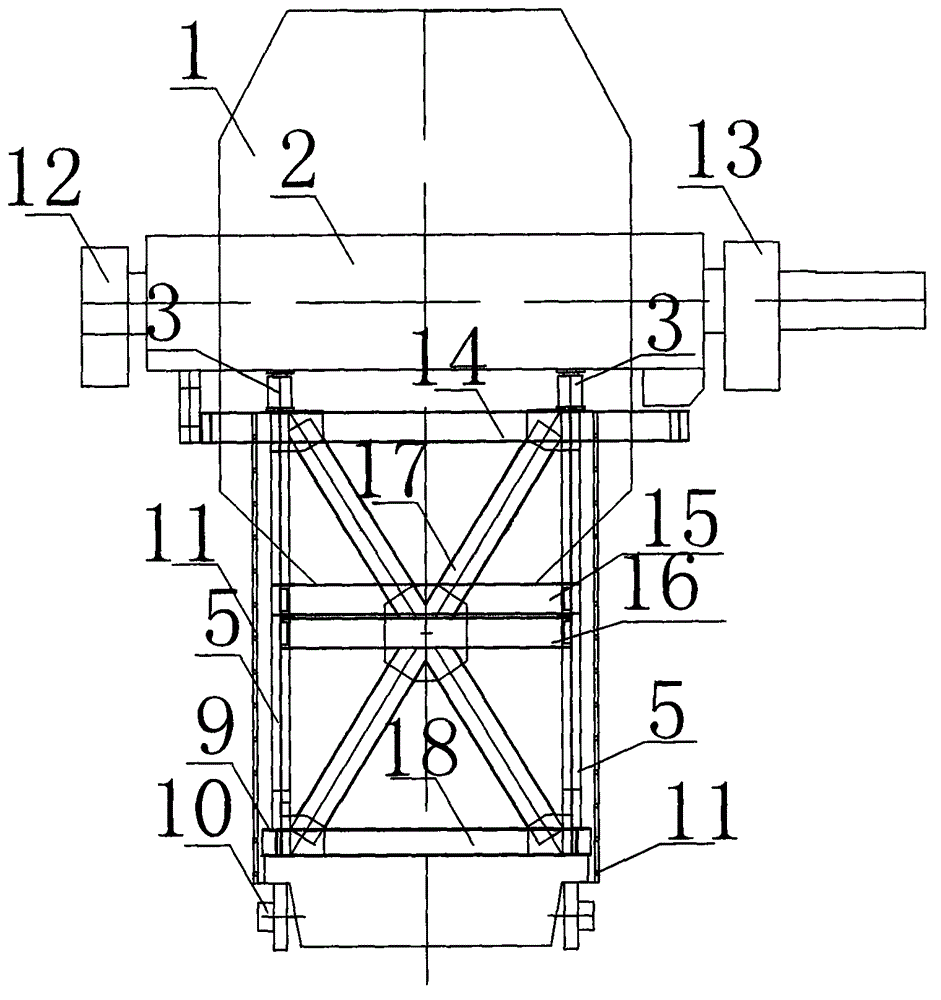

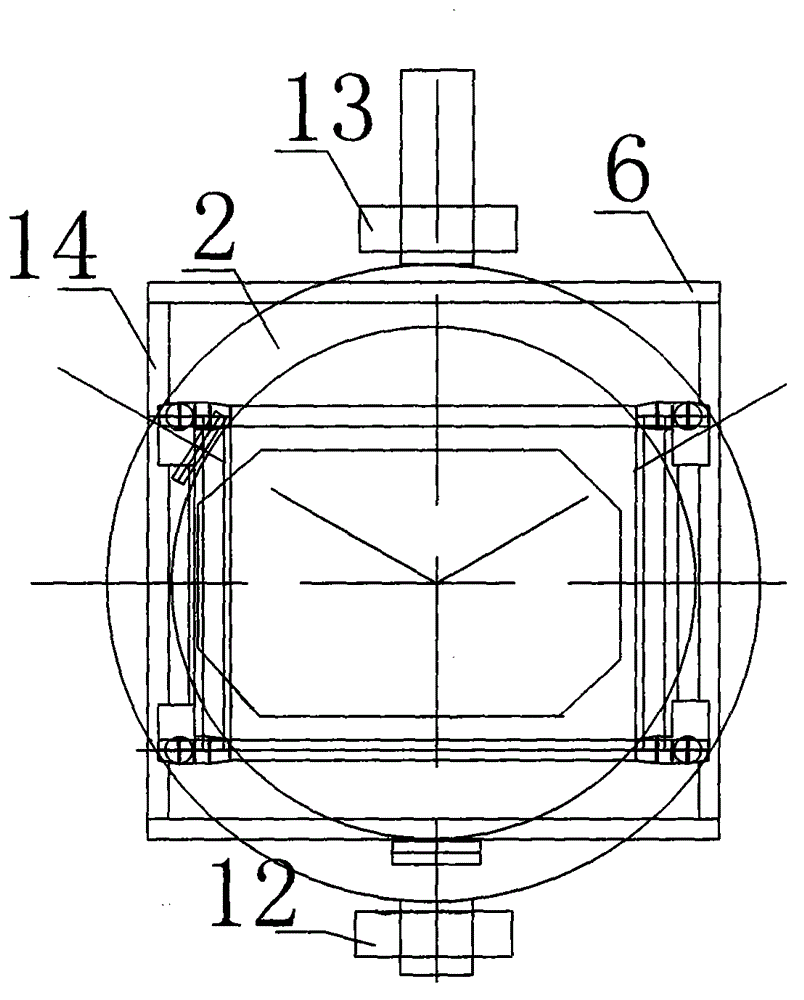

[0019] 2) Make a transport support bracket with a square mouth formed by four sets of columns 5 and a coaming plate, each set of columns is composed of two overlapping columns (for reinforcement), and the upper transverse side beams are used between the four sets of columns 6. The upper longitudinal beam 14, the middle transverse side beam 7, the first longitudinal beam 15 in the middle, the second longitudinal beam 16 in the middle, the lower transverse bottom beam 9, the lower longitudinal bottom beam 18, and the transverse side beam stay beam 8, the longitudinal side 17 groups of cable-stayed beams are welded and connected to form a rigid transport support bracket. Ladd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com