Liquid crystal panel and manufacturing method thereof and liquid crystal display device

一种液晶面板、制造方法的技术,应用在非线性光学、仪器、光学等方向,能够解决显示区多边色差、阵列基板和彩膜基板缝隙变大、胶框支撑的基板变形等问题,达到减小周边色差、提高显示画质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

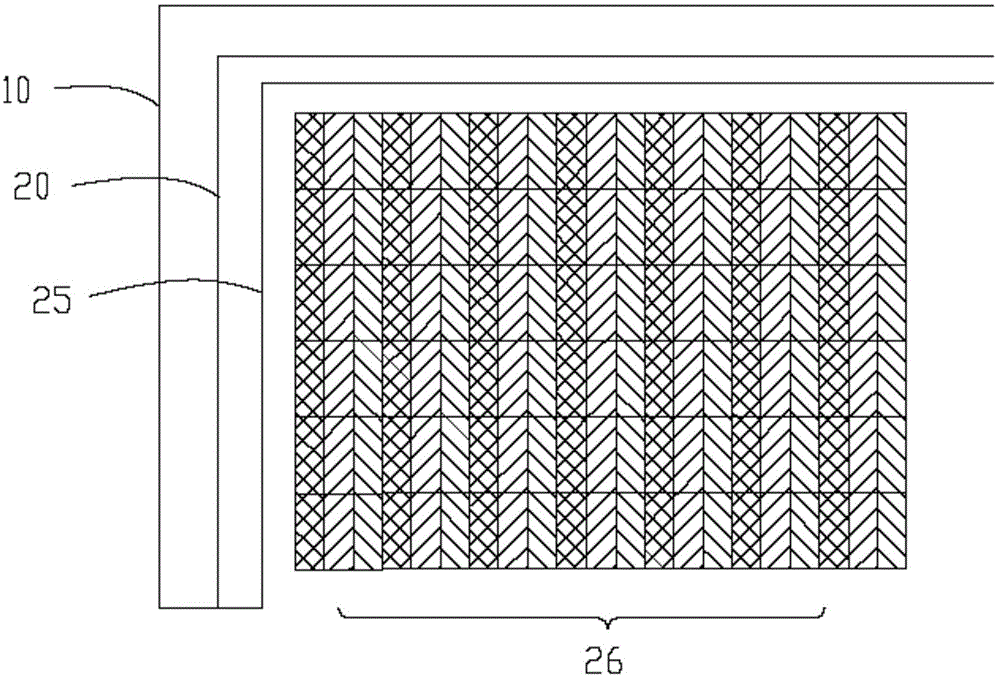

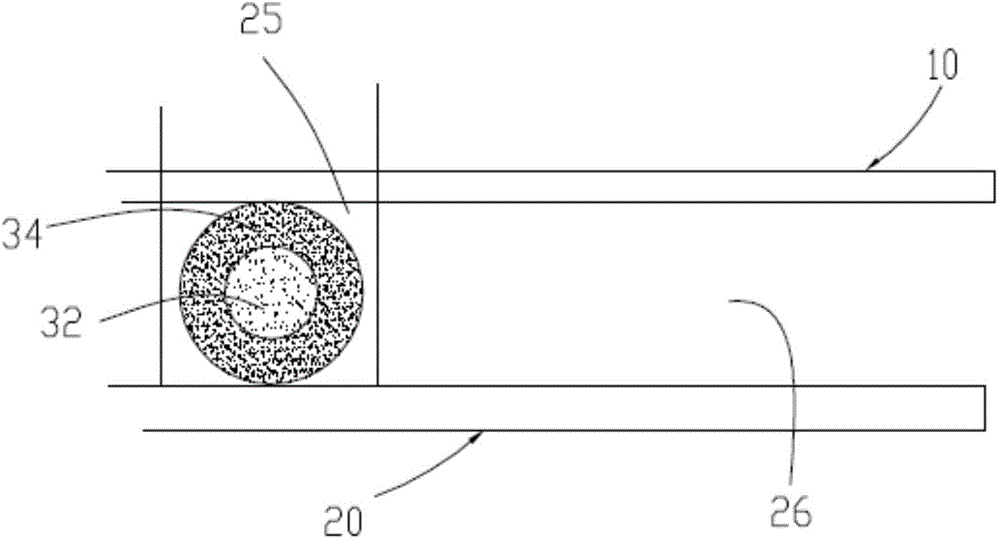

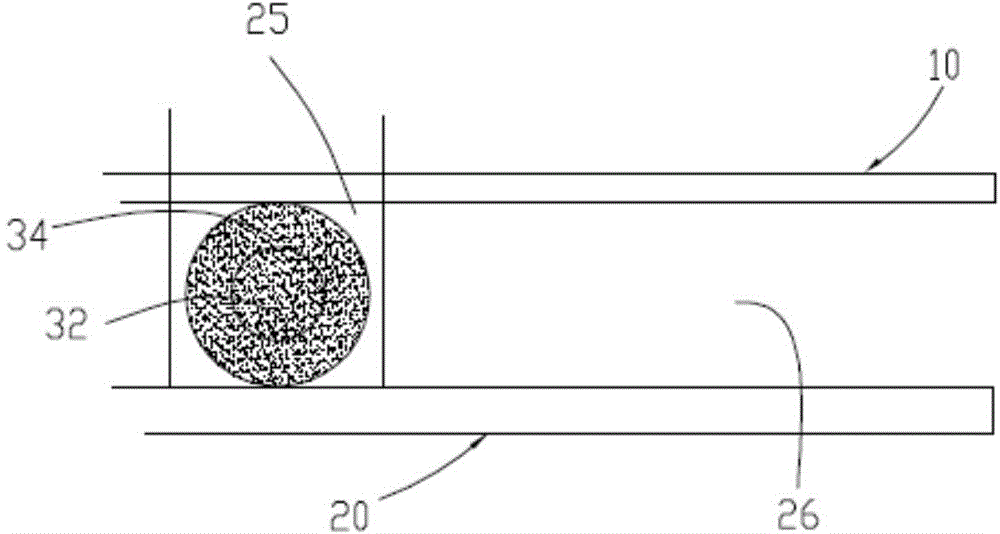

[0024] see figure 1 and figure 2 , a liquid crystal panel, comprising a first substrate 10 and a second substrate 20 opposite to the first substrate 10, a liquid crystal layer sandwiched between the first substrate 10 and the second substrate 20 and a liquid crystal layer located in the first The sealant frame 25 between the substrate 10 and the second substrate 20 seals the liquid crystal layer, and the position of the liquid crystal layer surrounded by the seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com