Handcart Mine Flameproof High Voltage Vacuum Switchgear

A vacuum switch and explosion-proof technology, which is applied in the direction of pull-out switchgear, switchgear, switchgear components, etc., can solve problems such as unusable, achieve strong adaptability, and improve the effect of flameproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

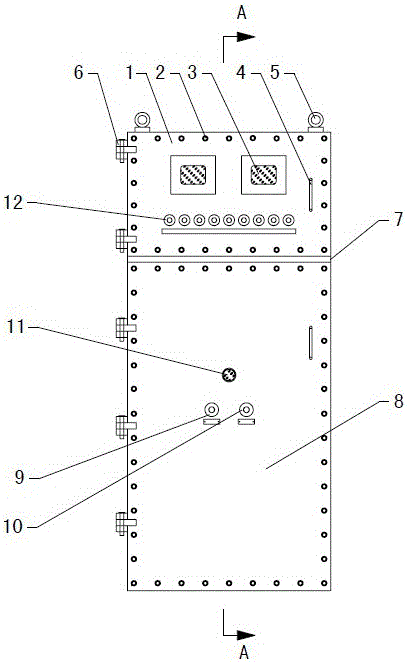

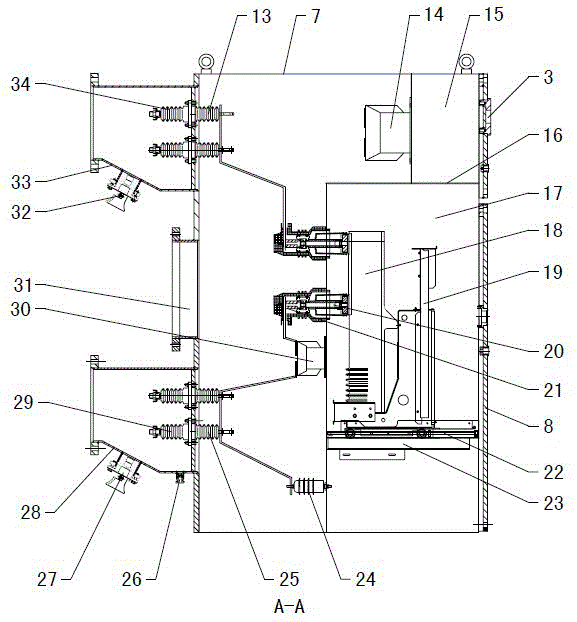

[0033] refer to figure 1 In this embodiment, the width of the cabinet body 7 is 820mm, the height is 1850mm, and the thickness is 1150mm. By increasing the width of the cabinet body 7, the distance between phases is changed from 190mm to 210mm, so that large-capacity circuit breakers such as VTK-1250A commonly used in ground high-voltage switch cabinets The device can be installed in the cabinet body 7. All performance indicators of the switchgear can meet the relevant national standards. In this way, the growing demand for large-capacity underground high-voltage switchgear in coal mines can be met. This provides convenience for maintenance, reduces potential safety hazards, and provides greater flexibility for the design of the width of the coal mine electromechanical chamber.

[0034] The handcart room 17 is moved up about 200mm as a whole to ensure that there is no obstacle for the handcart 19 to pass in and out. Preferably, a horizontal lead screw 22 is rotated in the h...

Embodiment 2

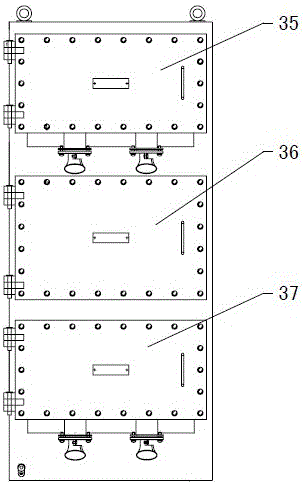

[0046] refer to Figure 6~7 , the handcart guide rail 23 is a square frame structure connected with the cabinet body. The frame guide rail does not require any support from the ground to prevent the handcart 19 from being subjected to large vibrations during the movement. The unevenness of the ground in the electromechanical chamber has nothing to do with the push and pull of the handcart, and there is no need to adjust the level of the door body during maintenance, which reduces the workload. Preferably, a rotating track 41 is provided on the rear side of the handcart guide rail 23, and the lower end of the rotating track 41 is connected to the cabinet body 7 through a slideway 42. 90 degrees, from the vertical position to the horizontal position, so as to be in the same horizontal plane as the handcart guide rail 23, which is convenient for the handcart 19 to move in and out. The handcart 19 is also provided with a grounding socket 43 . Other structures are with embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com