Undercarriage wheel brake kinetic moment measuring method

A measurement method and landing gear technology, applied in force/torque/power measuring instruments, measuring devices, instruments, etc., can solve problems such as measuring the braking torque of wheels and wheels that cannot be equipped with landing gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] This embodiment is the measurement of the braking torque of a certain type of aircraft performing a braking test after taxiing on the runway.

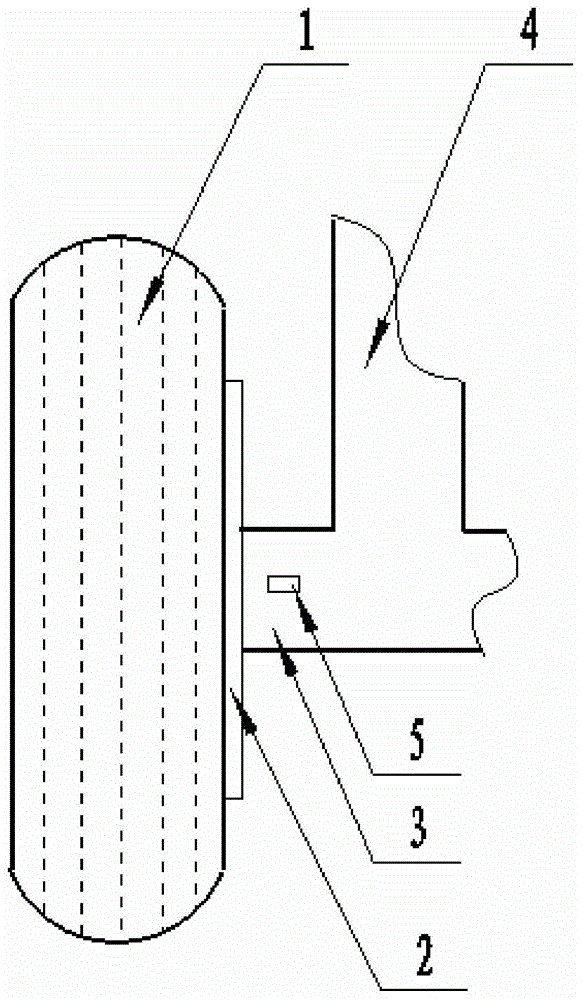

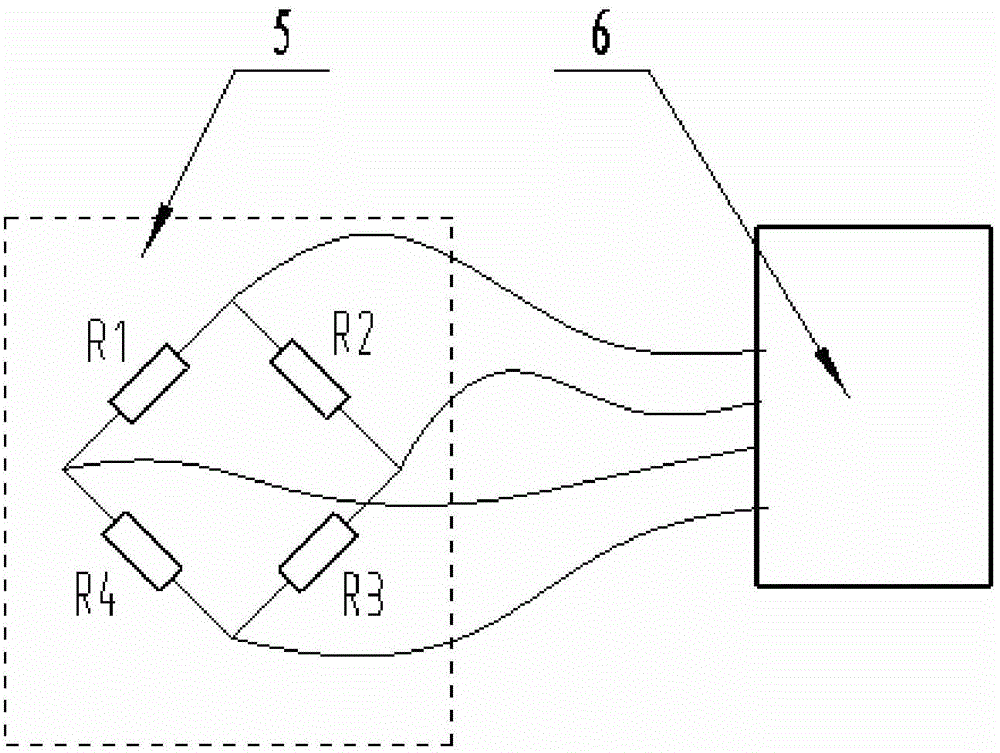

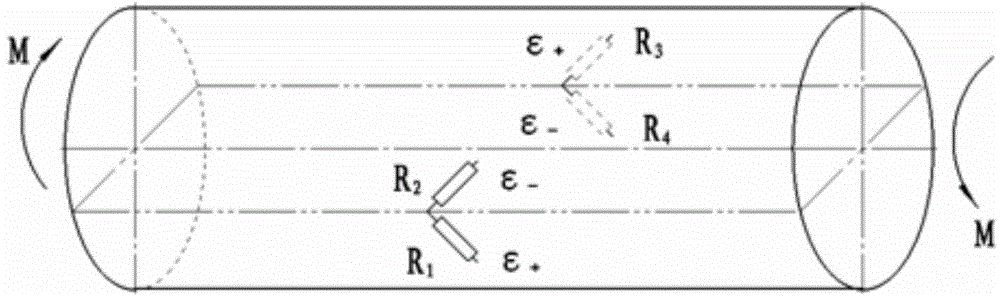

[0055] The strain gauge 5 has 4 pieces, which are respectively the first strain gauge R 1 , the second strain gauge R 2 , the third strain gauge R 3 and the fourth strain gauge R 4 . The data acquisition system 6 is a conventional strain acquisition system. Among them, the four strain gauges are divided into two groups, the first strain gauge R 1 with the second strain gauge R 2 One set, the third strain gauge R 3 with the fourth strain gauge R 4 One group; paste two groups of strain gauges symmetrically on the surface of the wheel shaft between the hub and the landing gear strut 4, and be on the horizontal plane where the axis of the wheel shaft is located. The angle between the centerlines of the two strain gauges in the length direction of each group is 90 degrees, and the angles between the centerlines of the two str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com