Filter locking bolt

A technology for locking bolts and filters, applied in filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problem that the security filter cannot be replaced quickly, save manpower and time costs, fasten and open easily Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

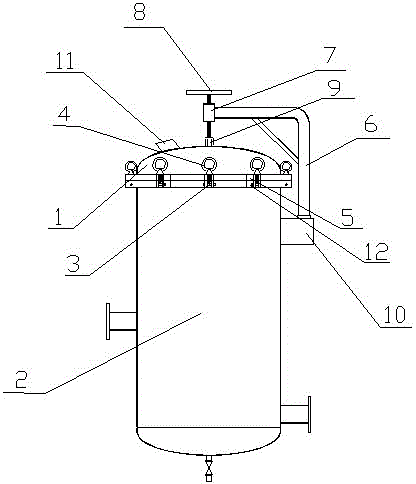

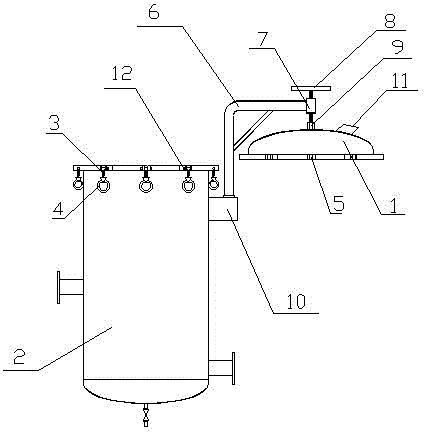

[0015] Such as figure 1 and figure 2 As shown, the filter locking bolt provided by the present invention includes an upper cover 1, a tank body 2, a T-bolt 3 and a nut 4, and the nut 4 is also provided with a ring handle, and the edge of the upper cover 1 is uniformly provided with an upper bolt groove 5 The edge of the filling mouth of the tank body 2 is evenly provided with a lower bolt groove 12 corresponding to the upper bolt groove 5, and both the upper bolt groove 5 and the lower bolt groove 12 are groove-shaped. The two ends of the crossbar part of the T-shaped bolt 3 are rotatably arranged in the two side walls of the lower bolt groove 12, and the T-shaped bolt 3 and the nut 4 are screwed together. When the security filter nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com