Hot air defrosting system for refrigerator and control method of hot air defrosting system

A technology for hot gas defrosting and refrigerators, applied in defrosting, refrigerators, refrigeration components, etc., can solve the problems of electric heater leakage, fire, low defrosting efficiency of electric heating, and temperature rise in freezer compartments, and reduce defrosting. Energy consumption, food quality assurance, and high defrosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

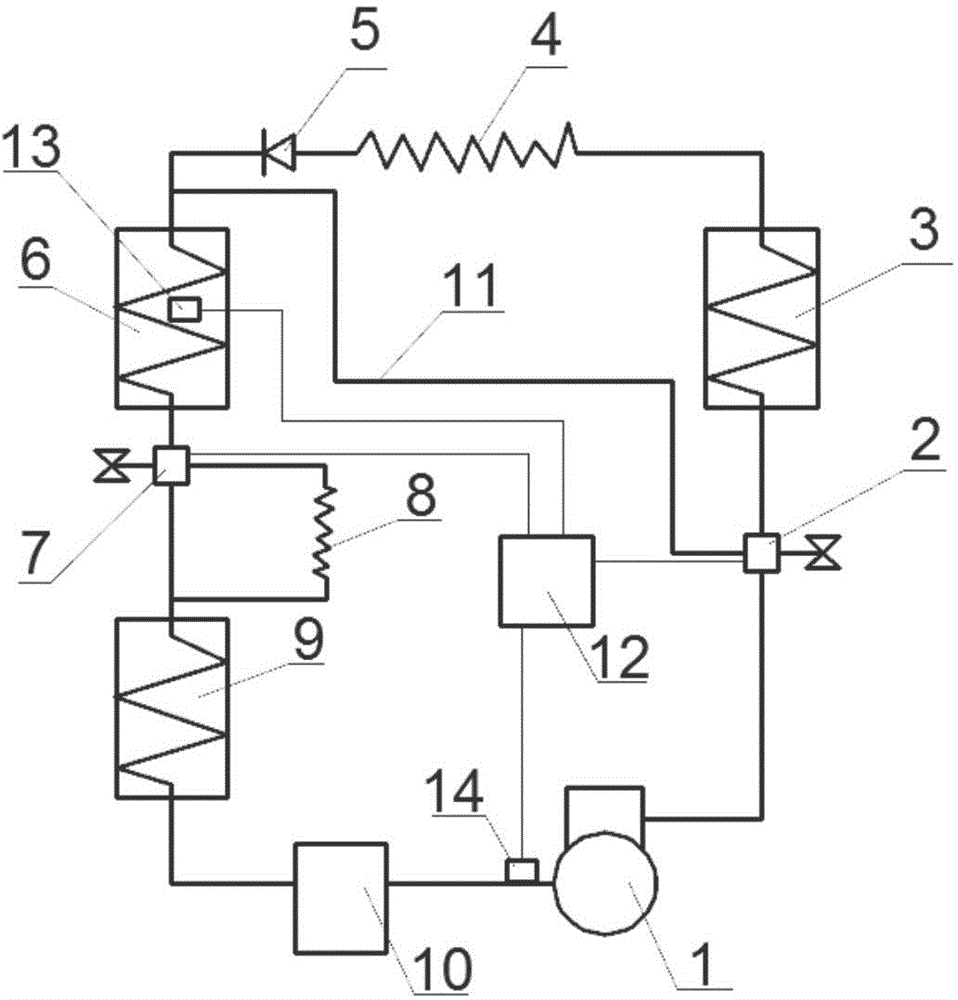

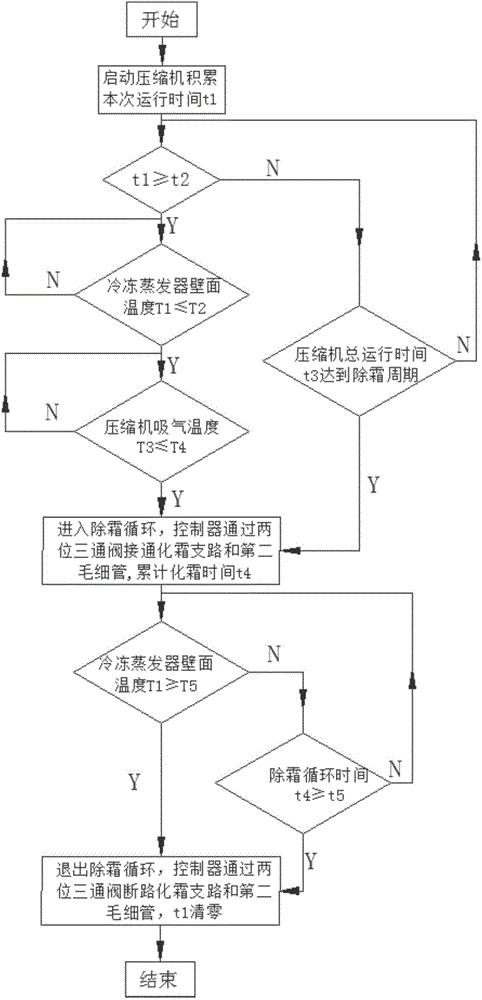

[0027] Such as figure 1 As shown, the hot gas defrosting system of a refrigerator in this embodiment is used for direct cooling refrigerators and air direct cooling refrigerators, including a compressor 1, a condenser 3, a first capillary tube 4, a one-way valve 5, and a freezing evaporator 6 connected in sequence , refrigerating evaporator 9 and accumulator 10, and accumulator 10 is also connected with compressor 1; the hot gas defrosting system includes defrosting branch 11, and described defrosting branch 11 is connected in parallel at the outlet of compressor 1 and freezing evaporator 6 between the inlets, the upstream end of the defrosting branch 11 is connected to the outlet of the compressor 1 through the first two-position three-way valve 2, and the downstream end is connected between the one-way valve 5 and the refrigeration evaporator 6; it also includes a controller 12, the freezer wall temperature sensor 13 arranged on the surface of the freezer evaporator 6 connec...

Embodiment 2

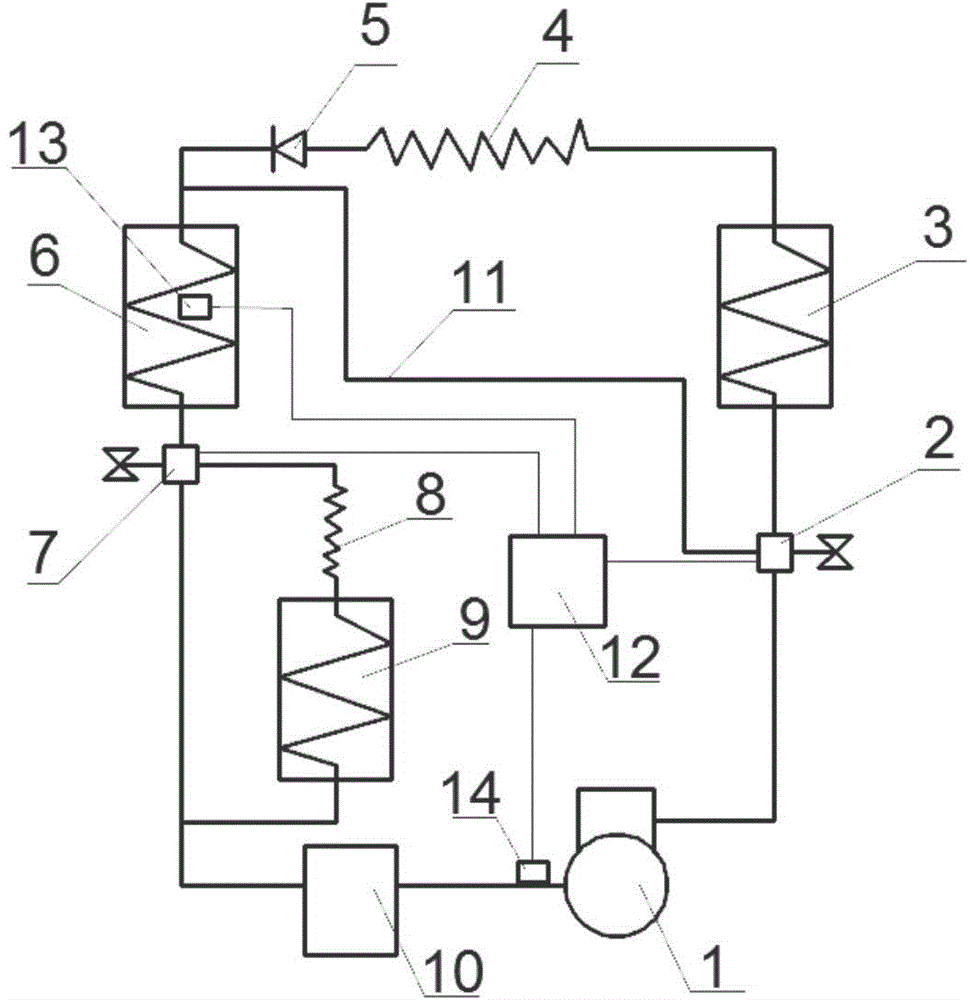

[0035] Such as figure 2As shown, the hot gas defrosting system of a refrigerator in this embodiment is used in an air-cooled refrigerator, including a compressor 1, a condenser 3, a first capillary tube 4, a one-way valve 5, a freezing evaporator 6 and a liquid accumulator connected in sequence 10. The accumulator 10 is also connected to the compressor 1; the hot gas defrosting system includes a defrosting branch 11, which is connected in parallel between the outlet of the compressor 1 and the inlet of the refrigerating evaporator 6, and the defrosting branch The upstream end of 11 is connected to the outlet of compressor 1 through the first two-position three-way valve 2, and the downstream end is connected between the one-way valve 5 and the refrigeration evaporator 6; it also includes a controller 12, the arrangement connected with the controller 12 The freezer wall temperature sensor 13 on the surface of the freezer evaporator 6, the compressor suction temperature sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com